Filter plate comprising a temperature control body and filter cartridge comprising such a filter plate

A technology of filter group and temperature regulating plate, which is applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problem of expensive filter plate and achieve the effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

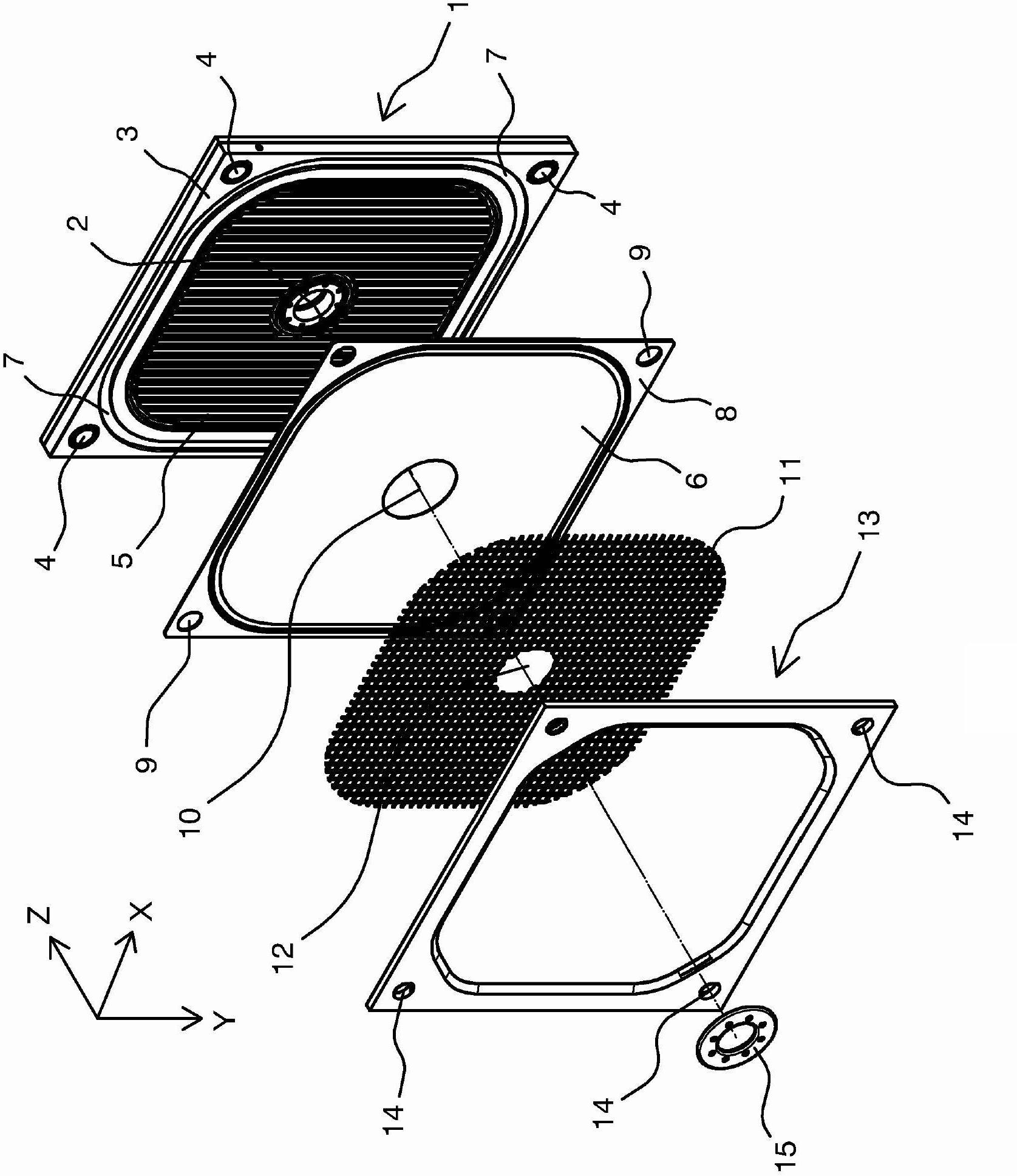

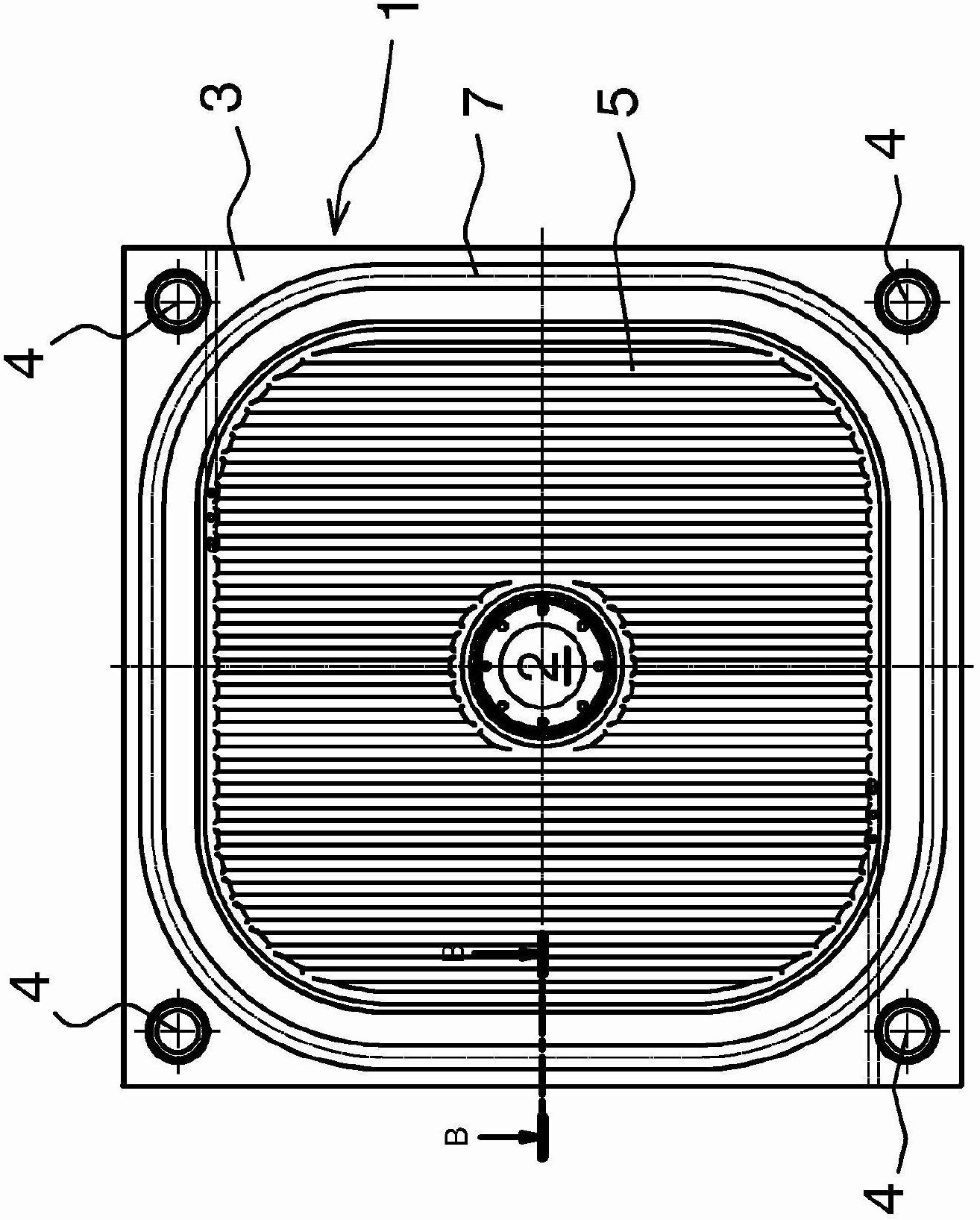

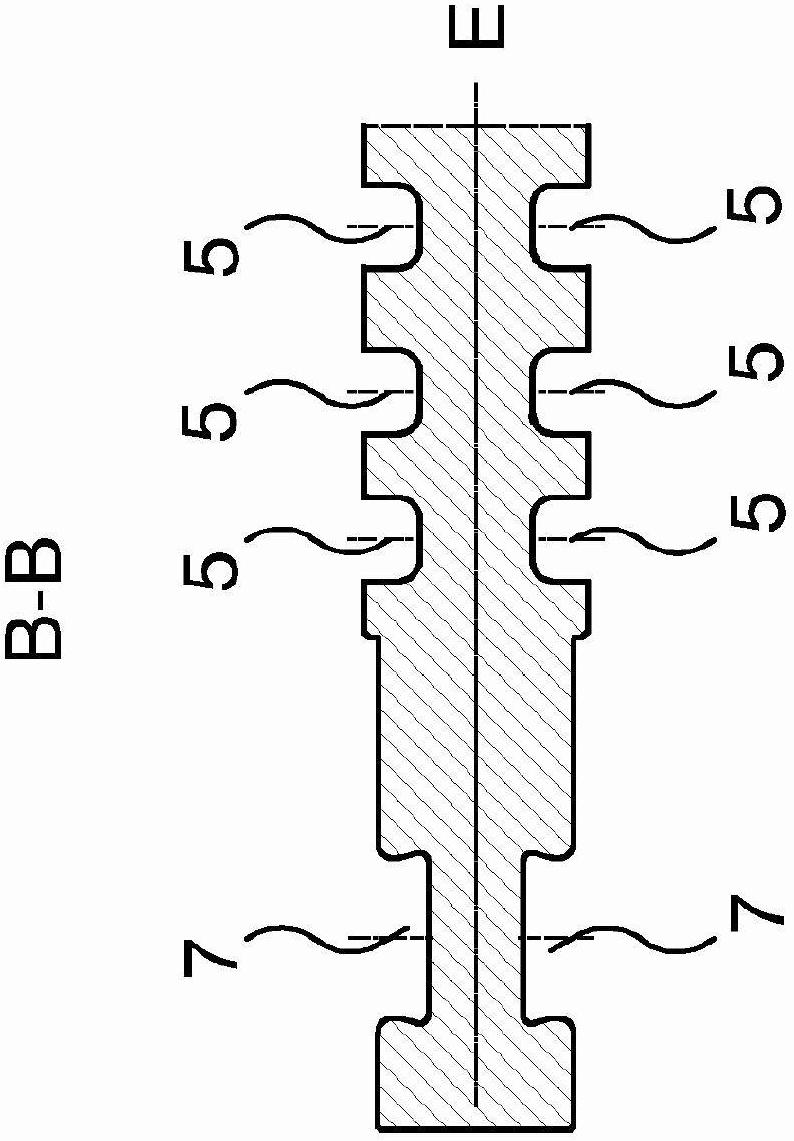

[0042] figure 1 The basic structure of a multi-component filter plate is shown. The filter plate includes a base body 1 . The base body 1 has a central filtrate inlet opening 2 and corner openings 4 in the edge region 3 through which the filtrate is discharged. Furthermore, an annular circumferential fastening groove 7 is formed in the edge region 3 . Furthermore, distribution channels 5 are formed on the surface of the base body 1 facing the temperature control plate 6 , through which a temperature control medium can flow. as figure 1 and 2 As an alternative to the channels 5 or grooves shown in , the base body 1 can also have a textured / grained surface, so that the temperature-regulating medium can be distributed rapidly in all directions.

[0043] The unit formed by the elastic element 8 and the tempering plate 6 is connected to the base body 1 . For example, the elastic element 8 consists of an elastomer. The elastic element 8 in particular forms a ring and, as will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com