Drainage tubes

A technology of drainage tube and round tube, applied in the field of diameter drainage tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

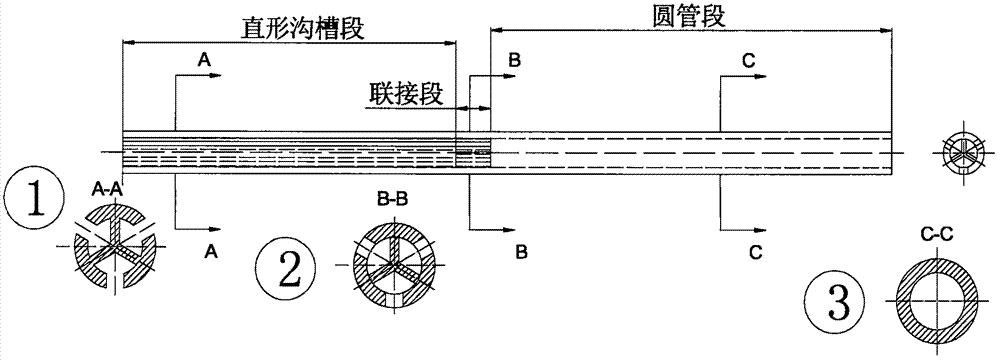

specific Embodiment 2

[0018] Specific embodiment two, equal diameter drainage tube with three straight channels

[0019] See figure 2 , The invention relates to a three-channel straight drainage tube with equal diameter. The three-channel straight equal-diameter drainage tube is divided into three sections, which are respectively a straight channel groove section, a connecting section and a round pipe section. The connection method of the groove section, the connection section and the round pipe is the same as that in the first embodiment.

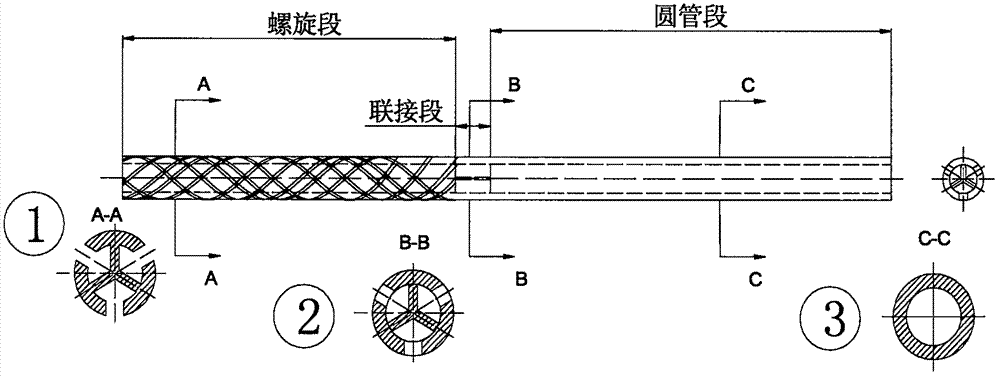

specific Embodiment 3

[0020] Specific embodiment three, equally divided three-channel helical equal-diameter drainage tube

[0021] See image 3 , The invention relates to a three-channel helical drainage tube of equal diameter. Divide the equally divided three-channel helical equal-diameter drainage tube into three sections, which are the grooved section of the spiral channel, the connecting section and the round pipe section. The connection method of the groove section, the connection section and the round pipe is the same as that in the first embodiment.

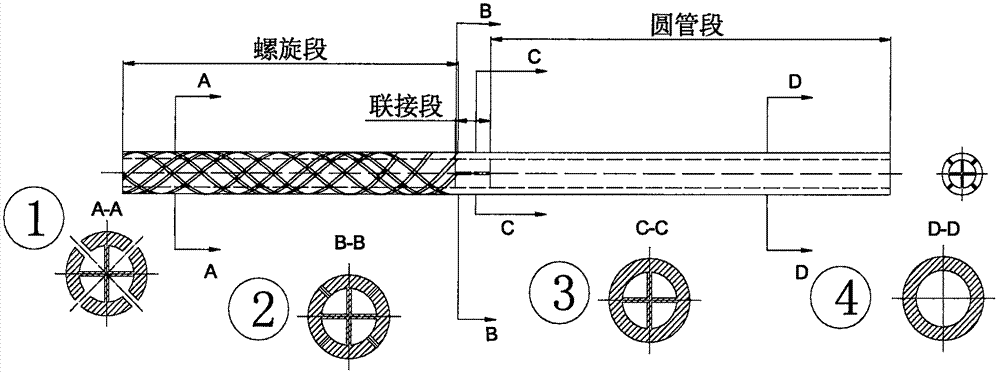

specific Embodiment 4

[0022] Specific embodiment four, equal diameter drainage tube with three straight channels with holes

[0023] See Figure 4 , The invention relates to a three-channel straight drainage tube with holes and equal diameters. The wall of the hole is a sealed hole, the opening of the hole is at the insertion end, and the hole ends at 100mm from the end of the round hole. The three-channel straight drainage tube with holes and equal diameters is divided into three sections, which are respectively a straight channel groove section, a connecting section and a round pipe section. The connection method of the groove section, the connection section and the round pipe is the same as that in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com