Numerical control corner cutting and edge folding machine equipment

A technology of edge folding machine and corner cutting, applied in metal processing equipment, feeding device, positioning device, etc., can solve the problems of many turnover links, large size deviation, strain, etc., save manpower and material resources, simple and convenient operation, The effect of saving mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

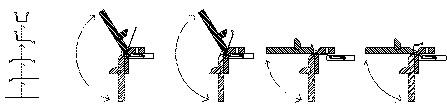

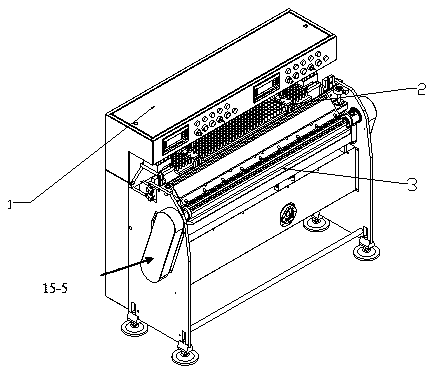

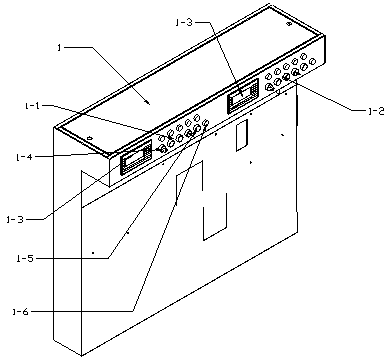

[0022] Such as Figure 1 to Figure 4 As shown, a numerically controlled corner cutting and folding machine equipment is characterized in that it includes a numerical control system electrical cabinet 1, a numerically controlled cylinder corner cutting device 2, and a numerically controlled corner folding machine device 3. The scratched brush table top 4 is also provided with a numerical control cylinder corner cutting device 5 on both sides of the brush table top 4, and a first linear screw module 6 is installed next to the numerical control cylinder corner cutting device 5, and the first linear screw The module 6 is equipped with a cylinder induction clamping slide table 7, and the CNC folding machine equipment 3 includes a main frame 8 of the folding machine, and the rear side of the main frame 8 of the folding machine is provided with a gear position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com