Forming die for half-housing body of axle housing and machining technology

A technology for forming molds and molds, which is applied in the directions of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy formation of built-up edge, uneven disk surface, easy pulling, etc., and achieves easy surface quality, slow lifting, and difficult to lift. wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

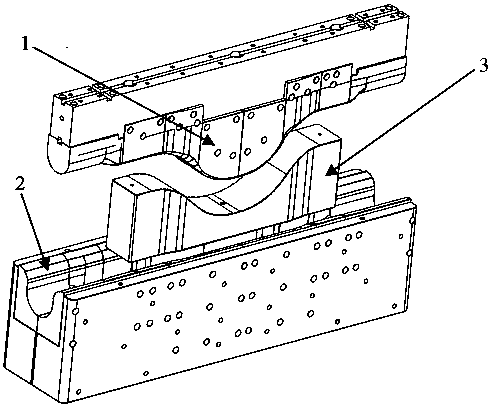

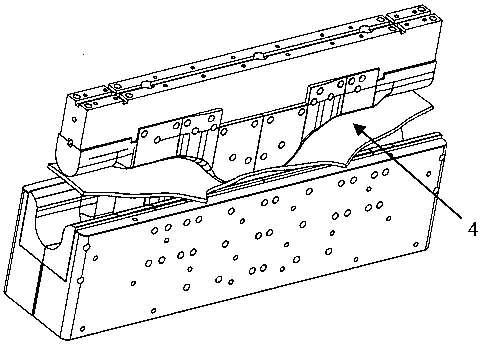

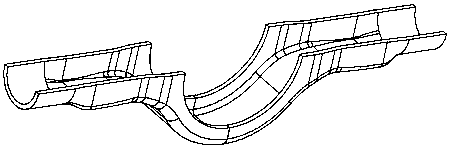

[0019] like image 3 When stamping the half-shell of the axle housing shown in the figure, first the mold punch 1 goes down, and the bottom of the mold punch 1 first makes partial line contact with the upper surface of the sheet material 4, and then the sheet material 4 is under the joint action of the mold punch 1 and the mold die 2 At the beginning, compression-like flanging occurs locally, the curvature of the flanging is small, and no wrinkles are generated during the flanging process; the contact area between the die punch 1 and the sheet 4 gradually expands, and the flanging length gradually expands from the middle to both sides, and the sheet 4 is two The end is gradually upturned, and the upturning speed is slow; as the mold punch 1 descends, the flanging process further expands to both ends, and the bottom sides of the sheet 4 contact the shoulders of the ejector 3, and reverse bending begins At the same time, the middle area of the sheet 4 has completed the flangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com