Cutting mechanism for battery case production

A technology of battery shells and incisions, which is applied to battery pack parts, battery boxes/coats, small-sized batteries/battery packs, etc., which can solve the problems of high labor intensity, low production efficiency, and high labor cost, and reduce labor intensity , high cost rate, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

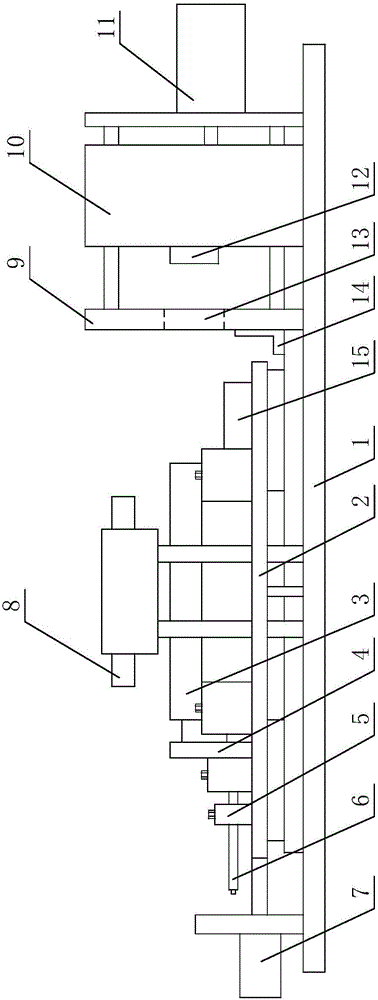

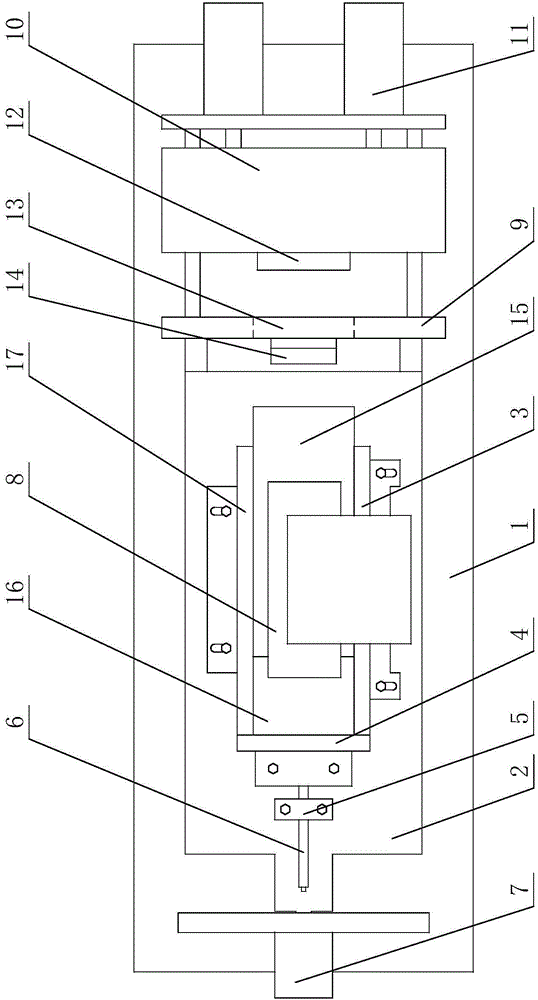

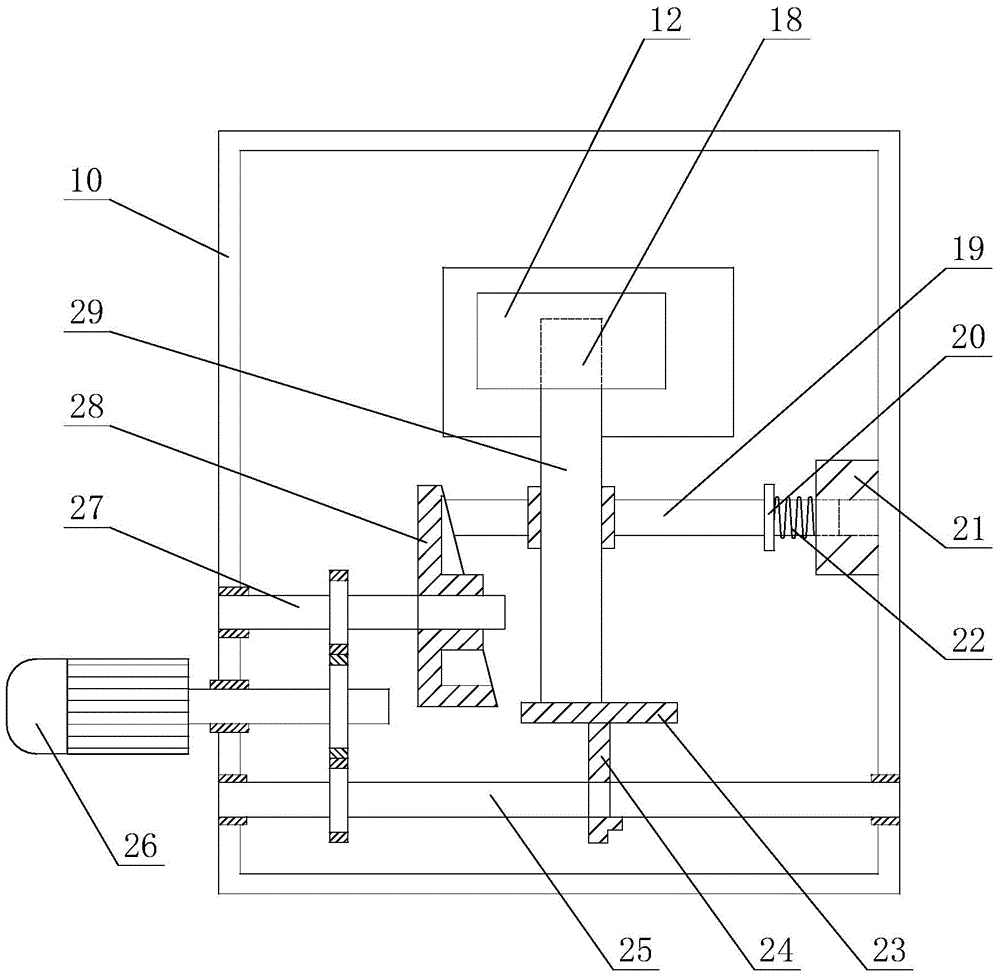

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0016] Please refer to figure 1 and figure 2 As shown, in this embodiment, a cutting mechanism for battery case production includes a bottom plate 1, a positioning mechanism is provided at the left end of the bottom plate 1, an outer cutter mechanism is arranged at the middle, and an inner cutting mechanism is arranged at the right end. Knife mechanism, the positioning mechanism includes a sliding seat 2 driven by the first cylinder 7 and slidably arranged on the bottom plate 1, the sliding seat 2 is provided with a notch for positioning the battery case, and the notch is controlled by the front stopper 17. The rear stopper 3 and the left stopper 4 are surrounded by a support block 15 arranged in the notch. The limit block 16 is arranged on the left end of the notch on the support block 15. The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com