Standard punching sample plate

A punching plate and template technology, applied in the direction of perforating tools, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the drilling quality, low production efficiency, time-consuming and labor-intensive, etc., so as to improve the operation effect, increase the cost rate, reduce the The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

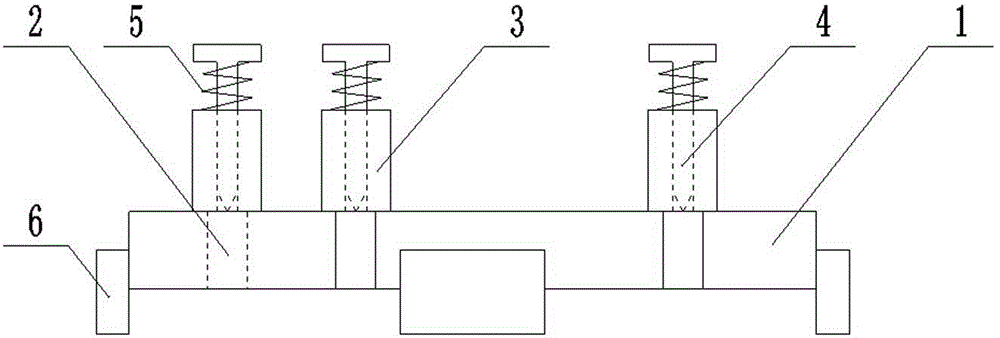

[0010] The standard punching template includes a template body 1 with the same horizontal section as the punching plate. The template body 1 is provided with through holes 2 corresponding to the drawing positions on the punching plate, and the upper surface of the template body 1 is provided with through holes 2 The guide sleeve 3 corresponding to the position, the guide sleeve 3 is pierced with a punching steel nail 4 which is closely matched with it, and between the tail end of the punching steel nail 4 and the upper end surface of the guide sleeve 3, a sleeve on the punching steel nail 4 is arranged. Return spring 5.

[0011] In the specific implementation process, several limit plates 6 are fixed on the surrounding side walls of the template body 1, so that the overlapping placement between the template body 1 and the impact plate can be realized more quickly and conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com