Stope face parallel dual-U-type roadway

A technology for mining working face and roadway, which is applied in tunnels, mining equipment, earthwork drilling, etc., can solve the problems of incomplete governance, low recovery rate of multi-lane layout, and difficulty in gas control at upper corners, and achieves reasonable structural design. Reliable, improve the extraction effect, increase the effect of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

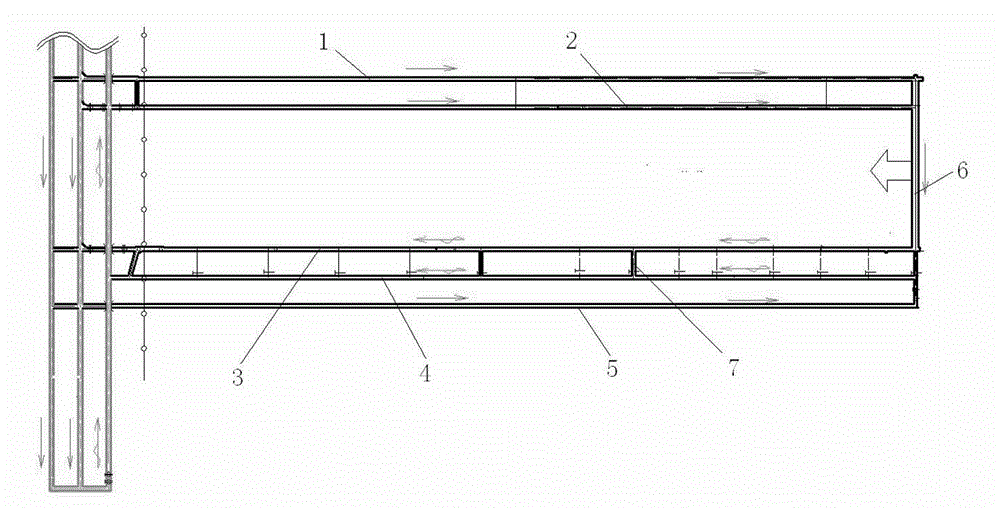

[0009] Double U-shaped roadways are paralleled in the recovery working face, including track lane 1, equipment lane 2, return air lane 3, auxiliary return air lane 4, and auxiliary air inlet lane 5, which are arranged in sequence from top to bottom; track lane 1 and equipment lane 2 are located at Above the mining face, return air lane 3, auxiliary air return lane 4 and auxiliary air inlet lane 5 are located below the mining face, and the right end of track lane 1, equipment lane 2 and return air lane 3 is provided with a The cut-out lane 6, the right end of the auxiliary air return lane 4 and the auxiliary air inlet lane 5 are connected, and a number of ventilation connection lanes 7 are arranged at intervals between the auxiliary air return lane 4 and the auxiliary air inlet lane 5, and the auxiliary air return lane 4 is provided with There is a gas drainage pipe connected with the goaf.

[0010] In the specific implementation process, the first U-shaped roadway is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com