High-strength aluminum alloy material and preparation method thereof

An aluminum alloy material, high-strength technology, applied in the field of aluminum alloy materials, can solve problems such as fracture and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned high-strength aluminum alloy material, comprising the following steps:

[0036] a) Prepare the raw materials according to the weight percentage of each component of the alloy, and put them into a constant temperature preheating drying oven for drying;

[0037] b) Prepare a slag-removing agent according to 0.7-1.1% of the total amount of each raw material in step a), and put the slag-removing agent into a constant temperature preheating drying oven for drying;

[0038] c) Put the aluminum obtained in step a) into the melting furnace, ignite it, and control the temperature of the furnace to 700-750°C. After the aluminum is completely melted, add other raw materials obtained in step a), and continue to heat up to 800-900°C and keep it warm for 15-50°C. 20min; cool down to 750-850°C, spray the slag-cleaning agent obtained in step b), and keep warm for 10-15min to obtain an aluminum alloy solution...

Embodiment 1

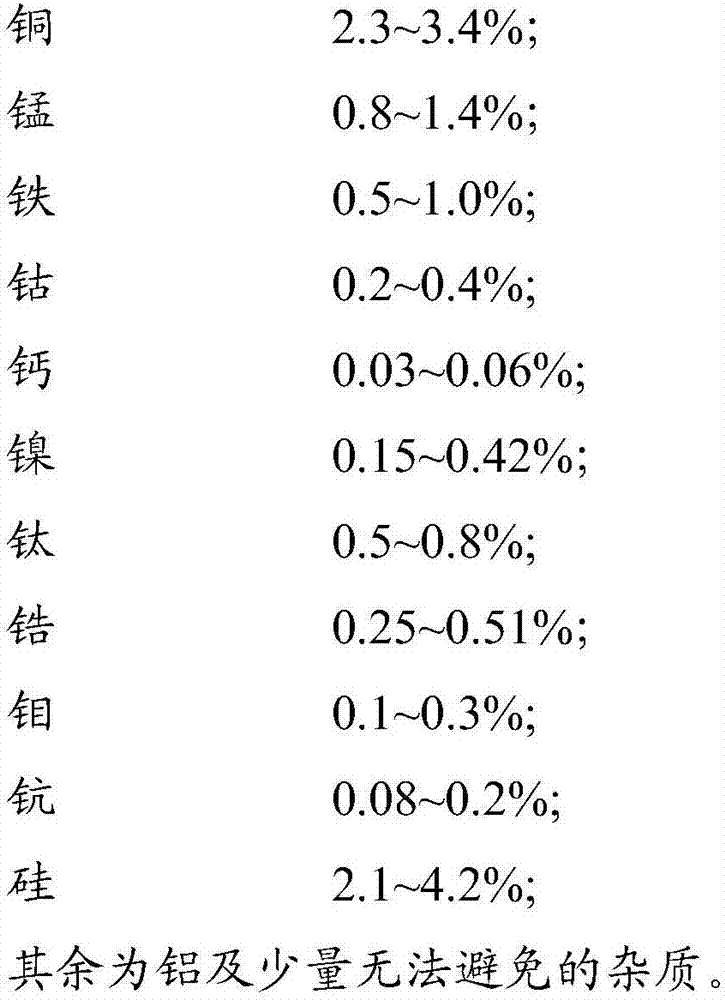

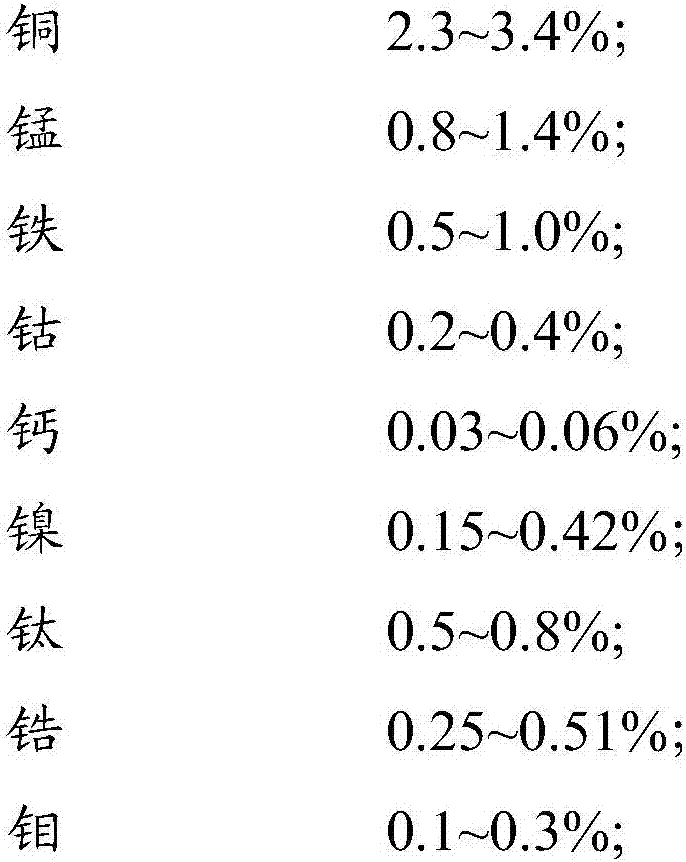

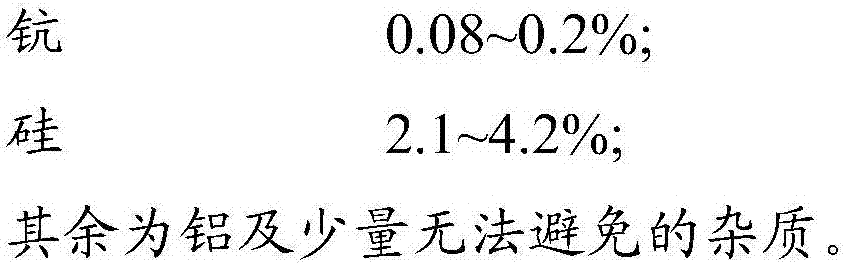

[0045] The high-strength aluminum alloy material consists of the following components by weight percentage:

[0046] 2.6% copper, 0.8% manganese, 0.9% iron, 0.27% cobalt, 0.04% calcium, 0.26% nickel, 0.6% titanium, 0.34% zirconium, 0.18% molybdenum, 0.13% scandium, 4.2% silicon, the rest is aluminum and a small amount of Impurities to avoid;

[0047] A method for preparing a high-strength aluminum alloy material, comprising the following steps:

[0048] Prepare the raw materials according to the weight percentage of each component of the alloy, and put them in a constant temperature preheating drying oven for drying;

[0049] Calcium silicate is prepared according to 0.9% of the total amount of each raw material, and the slag cleaning agent is placed in a constant temperature preheating drying oven for drying;

[0050] Put the aluminum in the melting furnace, ignite it, and control the furnace temperature to 700°C. After the aluminum is completely melted, add other raw mater...

Embodiment 2

[0053] The high-strength aluminum alloy material consists of the following components by weight percentage:

[0054] 3.2% copper, 1% manganese, 0.5% iron, 0.208% cobalt, 0.035% calcium, 0.21% nickel, 0.55% titanium, 0.51% zirconium, 0.26% molybdenum, 0.08% scandium, 3.8% silicon, the rest is aluminum and a small amount cannot Impurities to avoid;

[0055] A method for preparing a high-strength aluminum alloy material, comprising the following steps:

[0056] Prepare the raw materials according to the weight percentage of each component of the alloy, and put them in a constant temperature preheating drying oven for drying;

[0057] Prepare magnesium silicate according to 1.1% of the total amount of each raw material, and put the slag cleaning agent in a constant temperature preheating drying oven for drying;

[0058] Put the aluminum in the melting furnace, ignite it, and control the temperature of the furnace to 750°C. After the aluminum is completely melted, add other raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com