Packaging method of integrated optical isolator and integrated optical isolator

An optical isolator and packaging method technology, applied in the field of optical fiber communication, can solve the problems of high processing cost and complicated processing technology, and achieve the effects of low processing cost, simple process and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in connection with the examples, but the present invention is not limited to these examples.

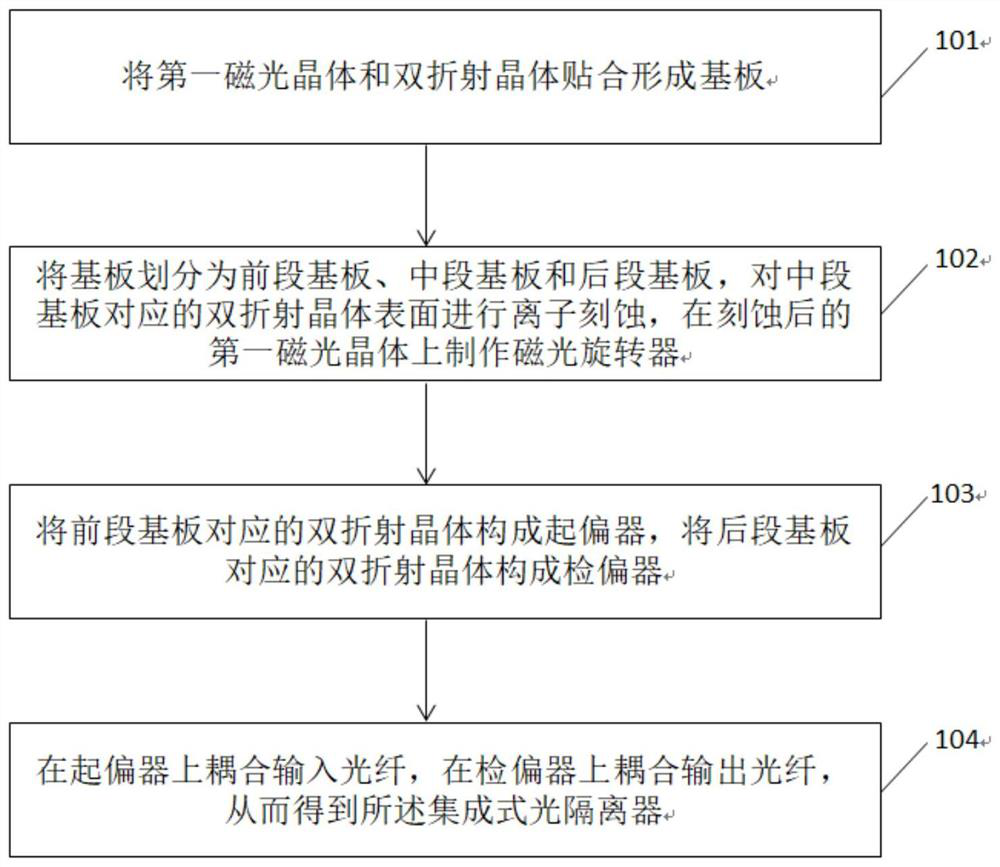

[0041] The embodiment of the present invention provides a package method of an integrated optical isolator, such as figure 1 As shown, the method includes:

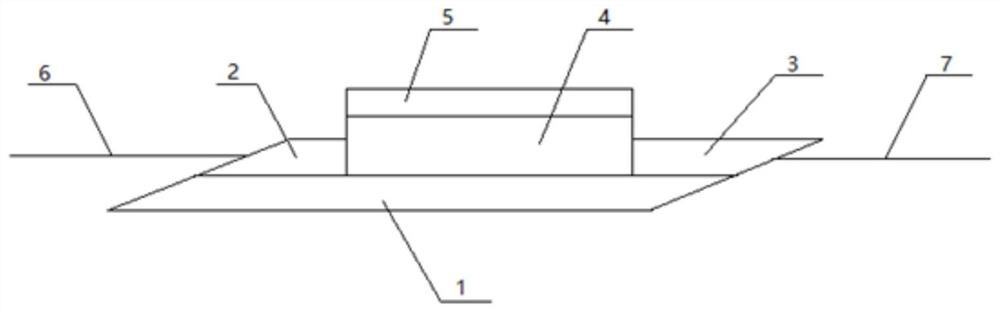

[0042] Step 101, a first magneto-optical crystal 1 and a birefringent crystal form a substrate.

[0043] Wherein, the first magnetine crystal 1 and the birefringent crystal may be provided to a length or square body shape, and the birefringent crystal is covered with the first magneto-optical crystal 1.

[0044] The first magnetine crystal 1 can be any of the existing magneto-optical crystals, such as yig, doped YIG system; gallate garnet system GGG, TGG; rare earth aluminate garnet system System TAG, TAG-TGG, etc., the embodiment of the present invention is not limited.

[0045] The birefringent crystal may be any of the conventional birefringent crystals, such as: square almene, lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com