Combined water jacket and manufacturing method

A manufacturing method and water jacket technology, applied in heating methods, stoves/stoves with hot water devices, household heating, etc., can solve the problems of complex core manufacturing process, no reduction in product weight, and high production costs, and achieve The effect of reducing the weight of the water jacket, increasing the product cost rate, and simplifying the molding casting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

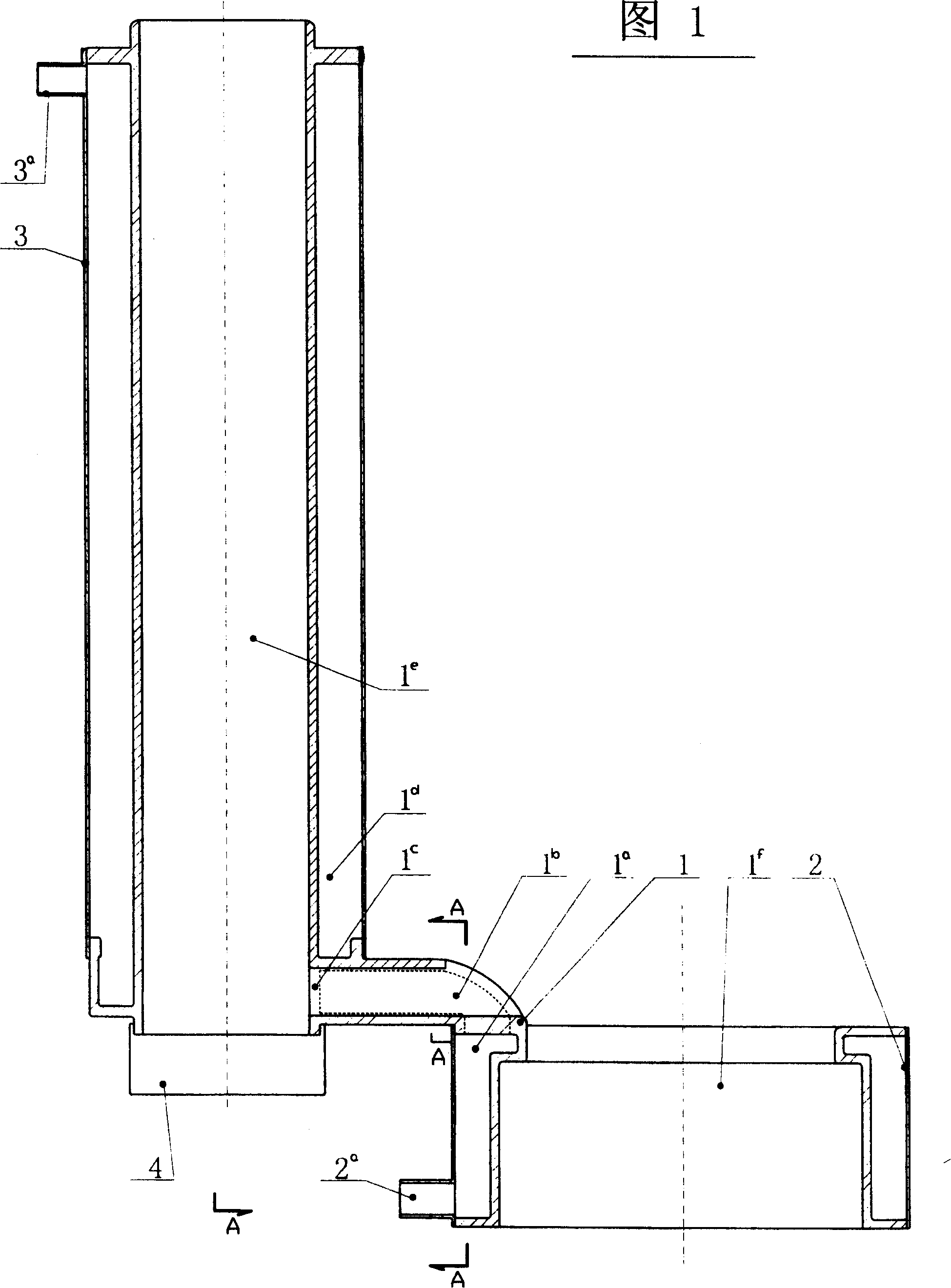

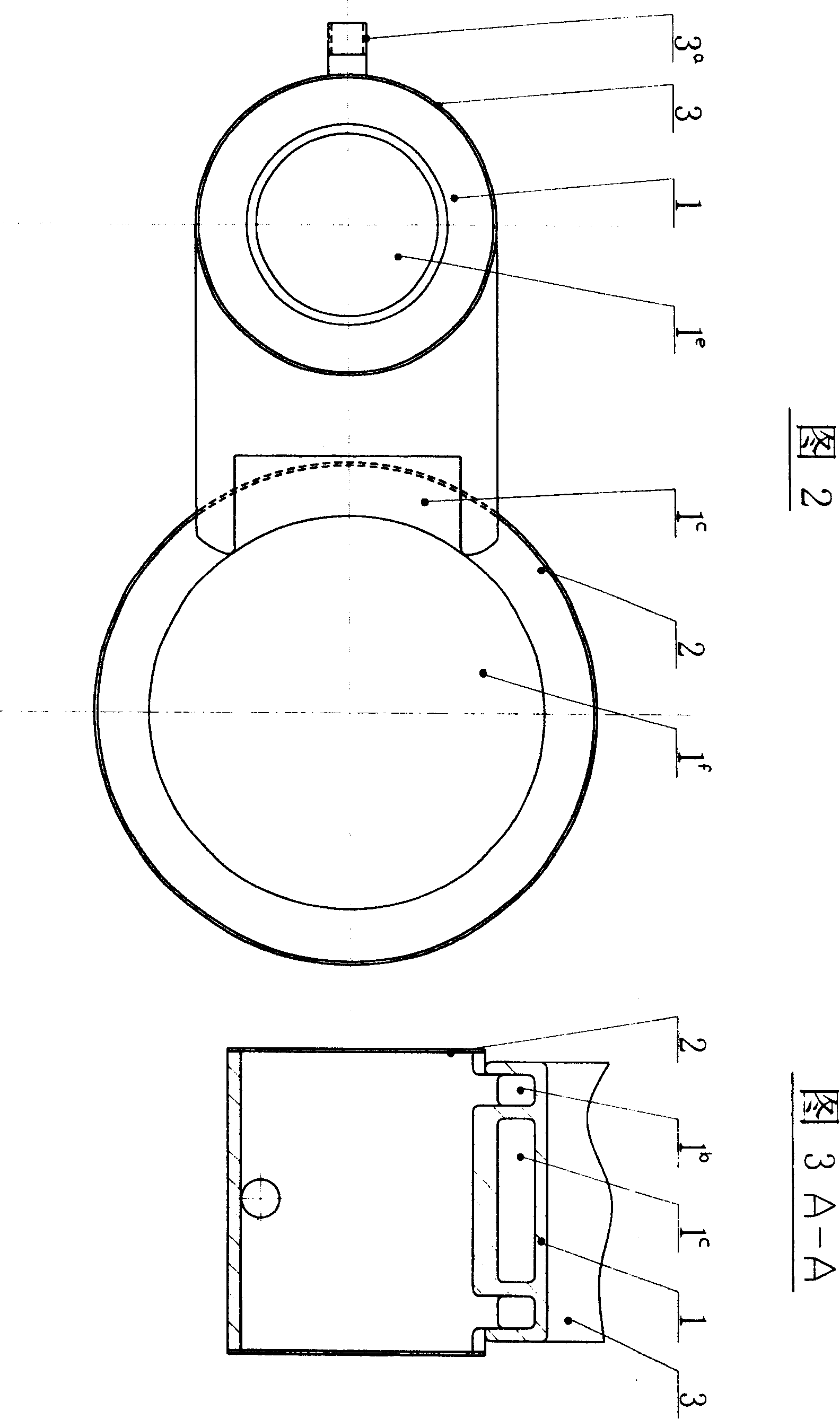

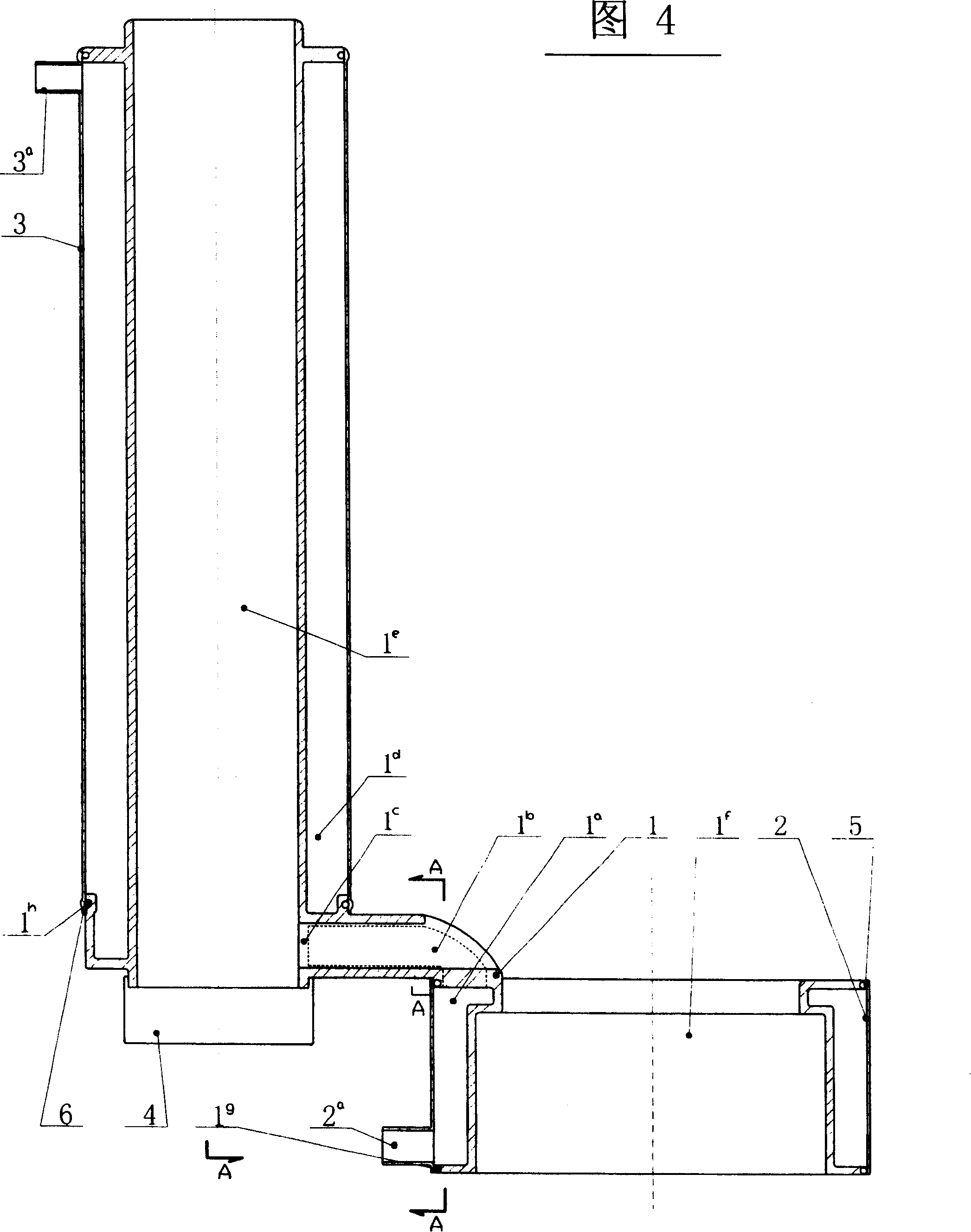

[0007] In the embodiment of the present invention, after the outer diameter of the cast inner water jacket (1) is processed, its corresponding outer diameter is larger than the inner diameter of the thin-walled outer water jacket (2) of the furnace and the thin-walled outer water jacket (3) of the chimney by about 0.08 mm. , Weld the thin-walled outer water jacket (2) of the furnace to the water inlet (2) a ) and the thin-walled outer water jacket (3) of the chimney are welded on the water outlet (3) a ) and then heat it to about 300°C and put it into the corresponding part of the inner water jacket (1) while it is still hot. After the outer diameter of the cast inner water jacket (1) is processed, its corresponding outer diameter is smaller than that of the furnace thin-walled outer water jacket (2) and the chimney thin-walled outer water jacket (3) with an inner diameter of about 0.08mm. Machined with large rubber gasket grooves (1 g ) and a small rubber pad slot (1 h ) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com