Patents

Literature

53 results about "Depaneling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Depaneling is a process step in high-volume electronics assembly production. In order to increase the throughput of printed circuit board (PCB) manufacturing and surface mount (SMT) lines, PCBs are often designed so that they consist of many smaller individual PCBs that will be used in the final product. This PCB cluster is called a panel or multiblock. The large panel is broken up or "depaneled" as a certain step in the process - depending on the product, it may happen right after SMT process, after in-circuit test (ICT), after soldering of through-hole elements, or even right before the final case-up of the assembly.

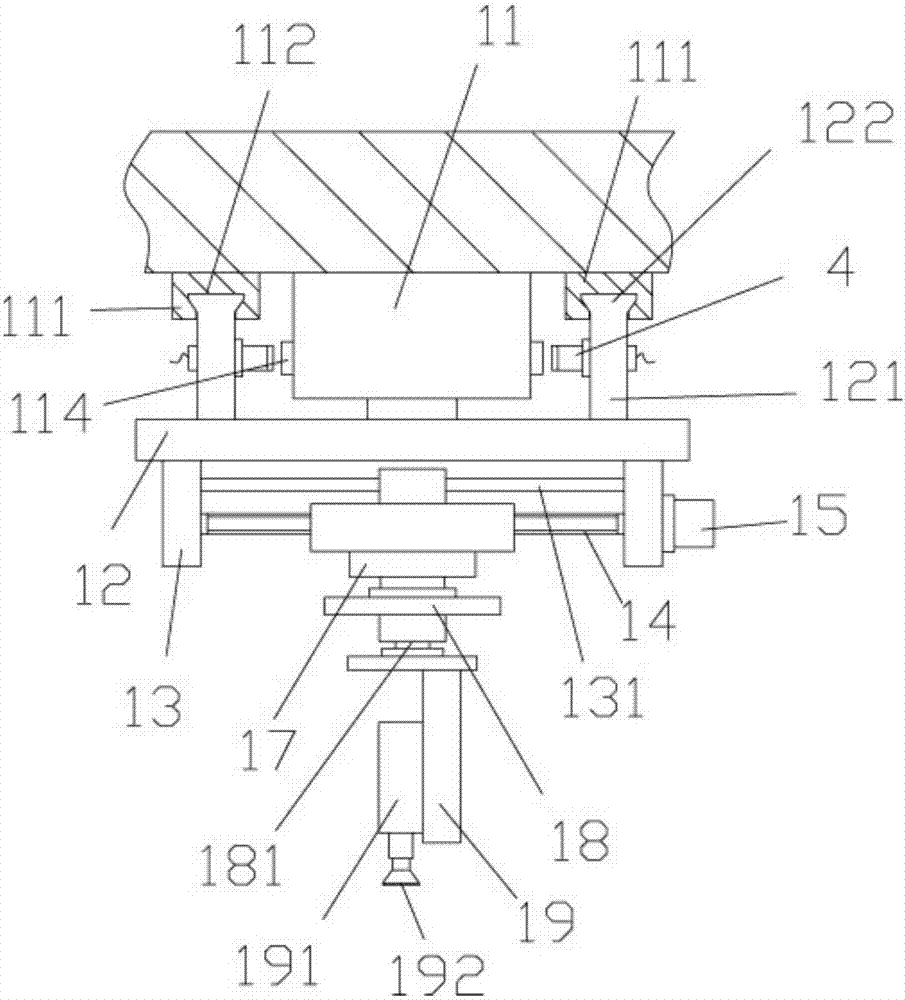

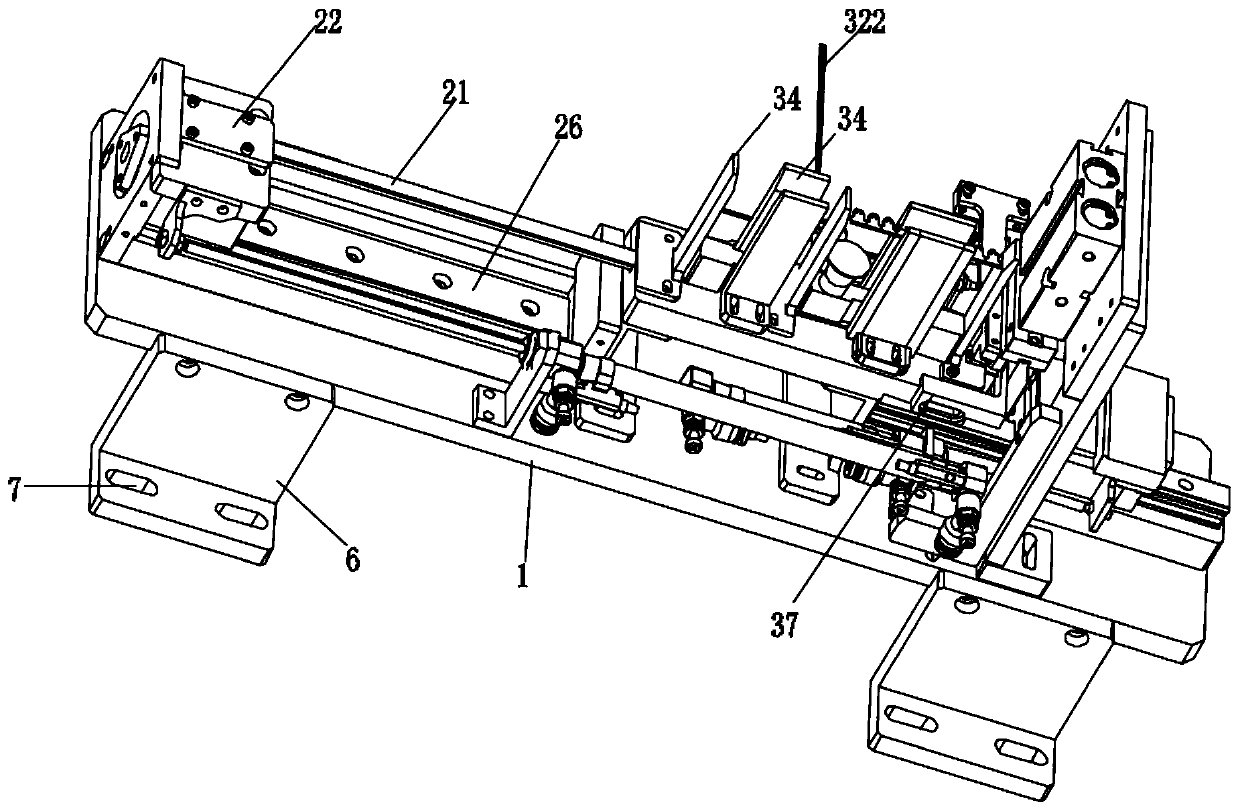

Board grabbing and putting mechanism for PCB board splitting machine

ActiveCN106966160AEasy to processHigh degree of automationConveyorsInsulating layers/substrates workingDepanelingThreaded rod

The invention discloses a board grabbing and putting mechanism for a PCB board splitting machine. The board grabbing and putting mechanism comprises a grabbing rack, a placement frame, a board frame and a board pressing frame. The board frame is located on the left side of the board pressing frame, the placement frame is arranged on the right side of the board pressing frame, and the placement frame, the board frame and the board pressing frame are located below an upper top board of the grabbing rack. A middle partition board is fixed to the middle portion of the board frame. A lifting motor is fixed to the middle portion of the bottom face of the middle partition board. An output shaft of the lifting motor penetrates the middle partition board, an adjusting screw hole is formed in the middle portion of the top face of the output shaft of the lifting motor, a lifting threaded rod is screwed into the adjusting screw hole, a lifting board is fixed to the top end of the lifting threaded rod, and the lifting board is arranged in a feeding cavity in the upper portion of the board frame. The board grabbing and putting mechanism can automatically grab a board and a pressing board body, carry out feeding and install the board and the board pressing body on a lower template of the placement frame, following machining is facilitated, and the board grabbing and putting mechanism is high in automation degree and efficiency and good in effect.

Owner:道县东圣电子科技有限公司

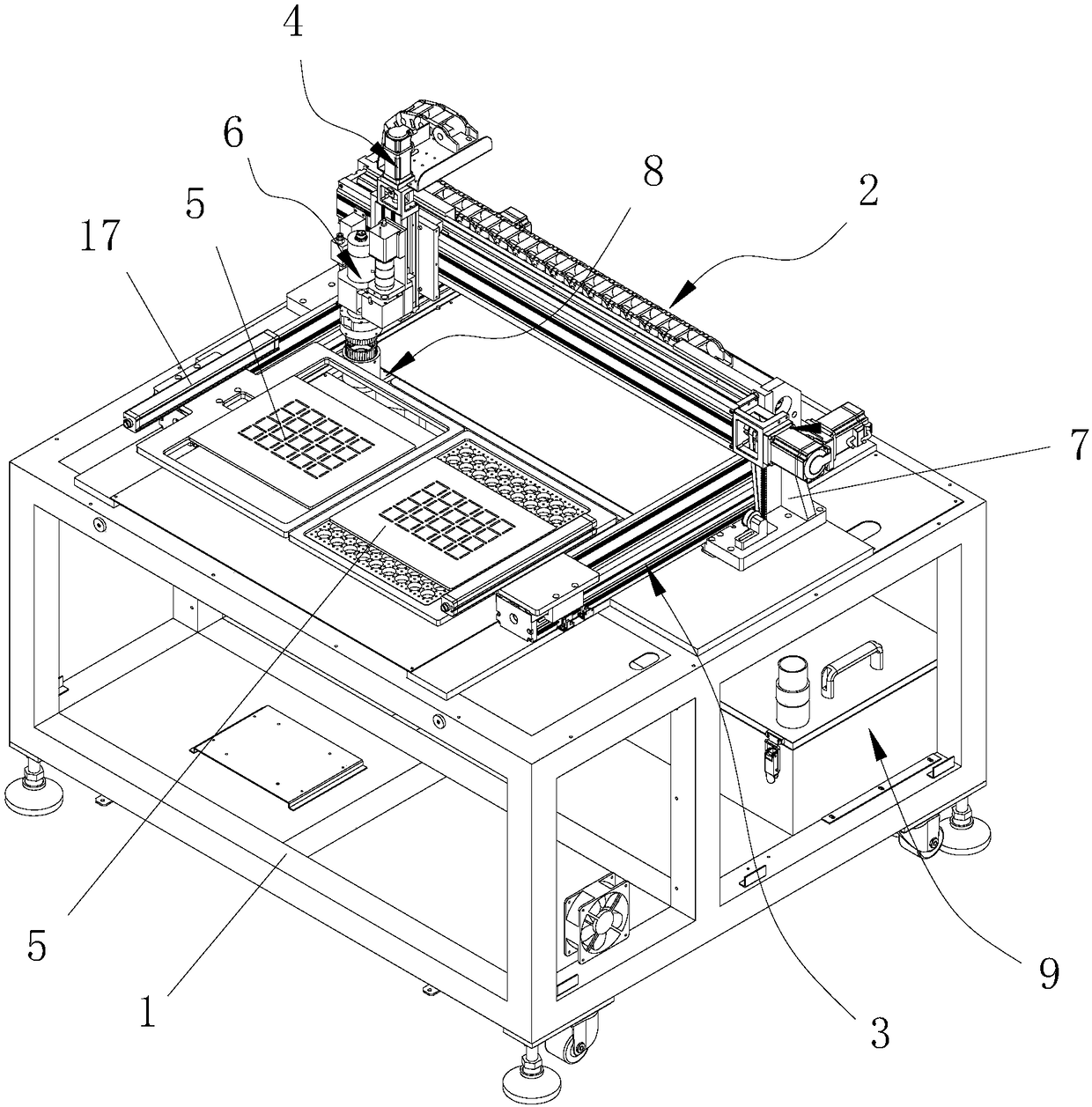

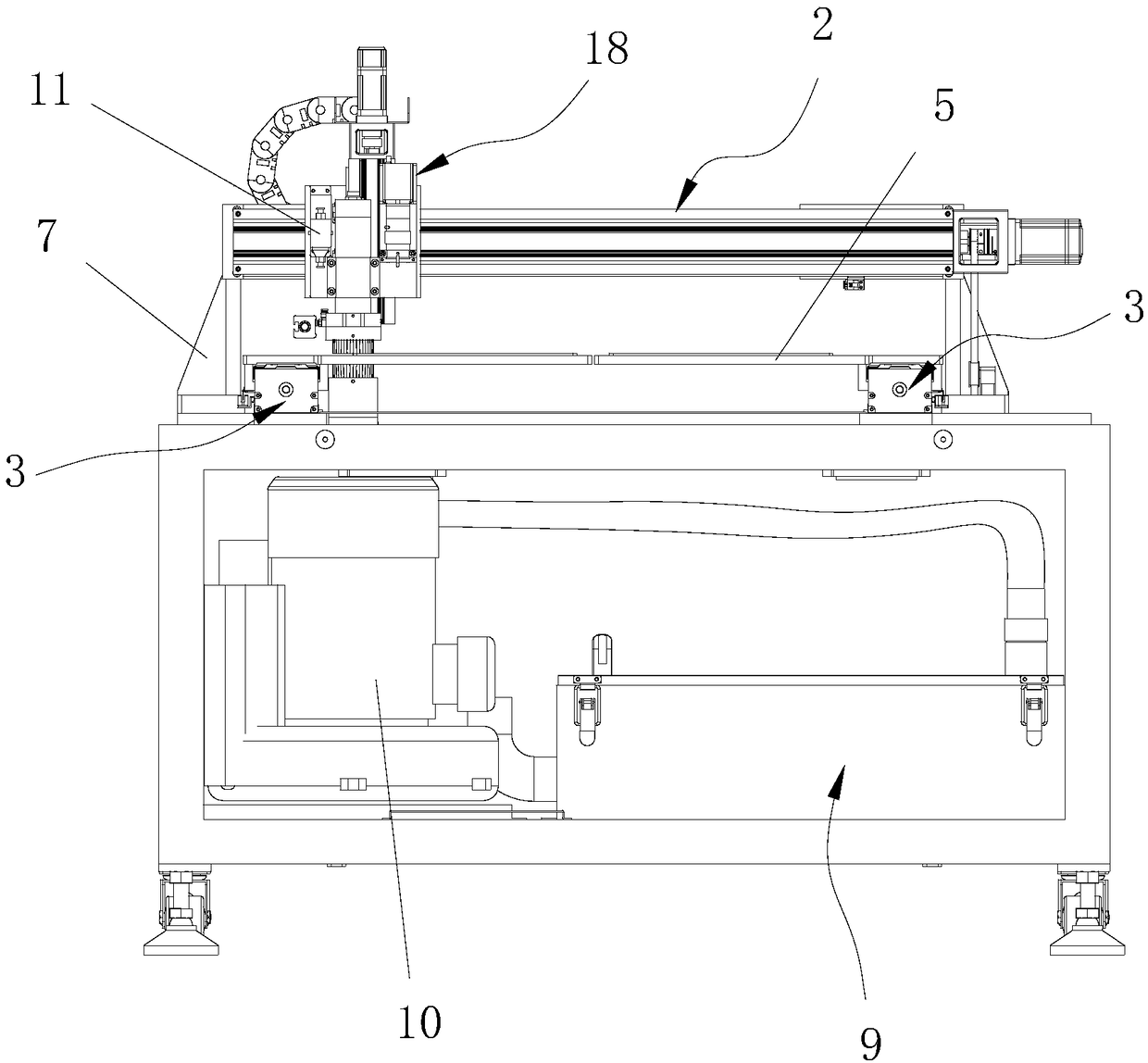

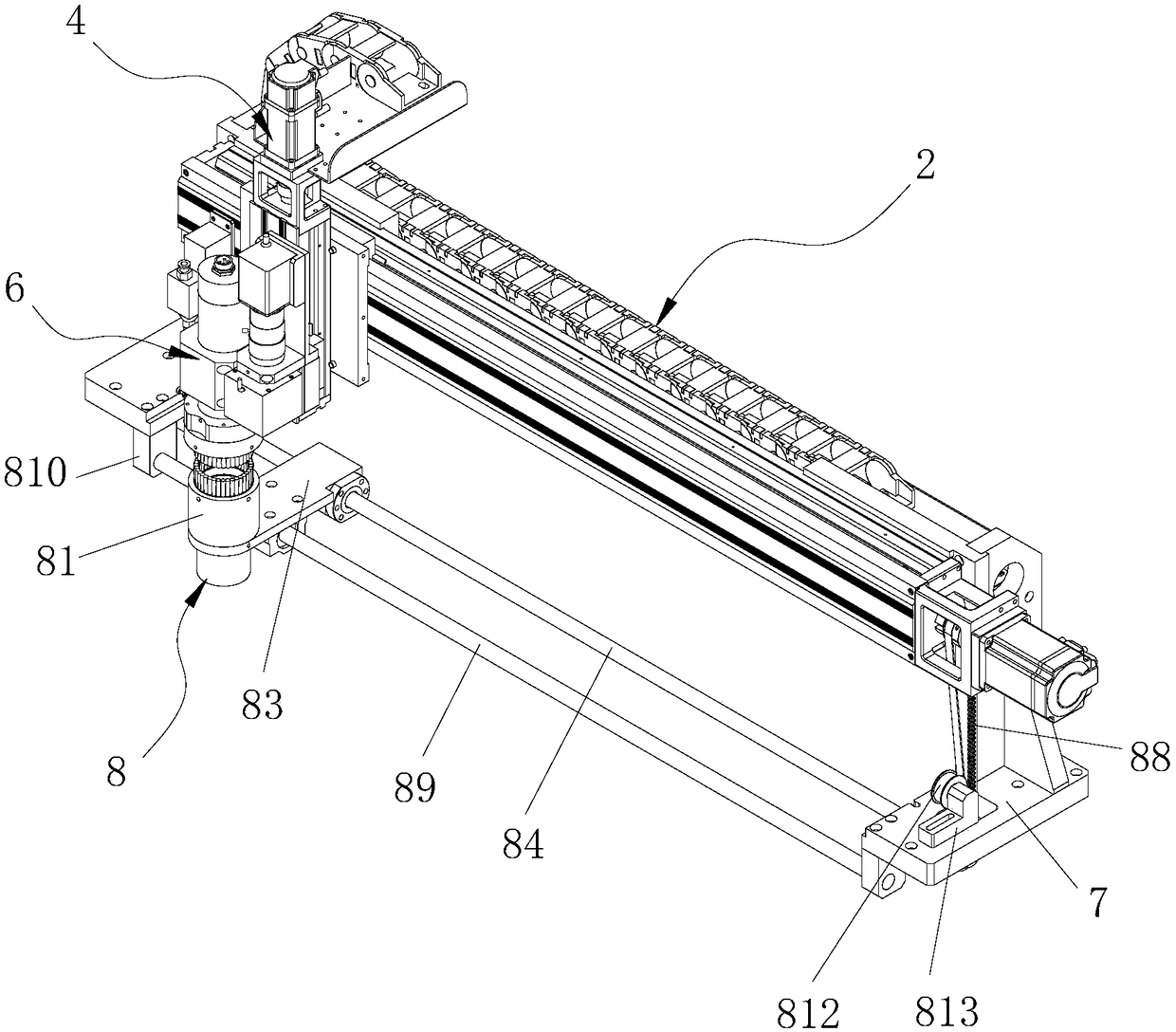

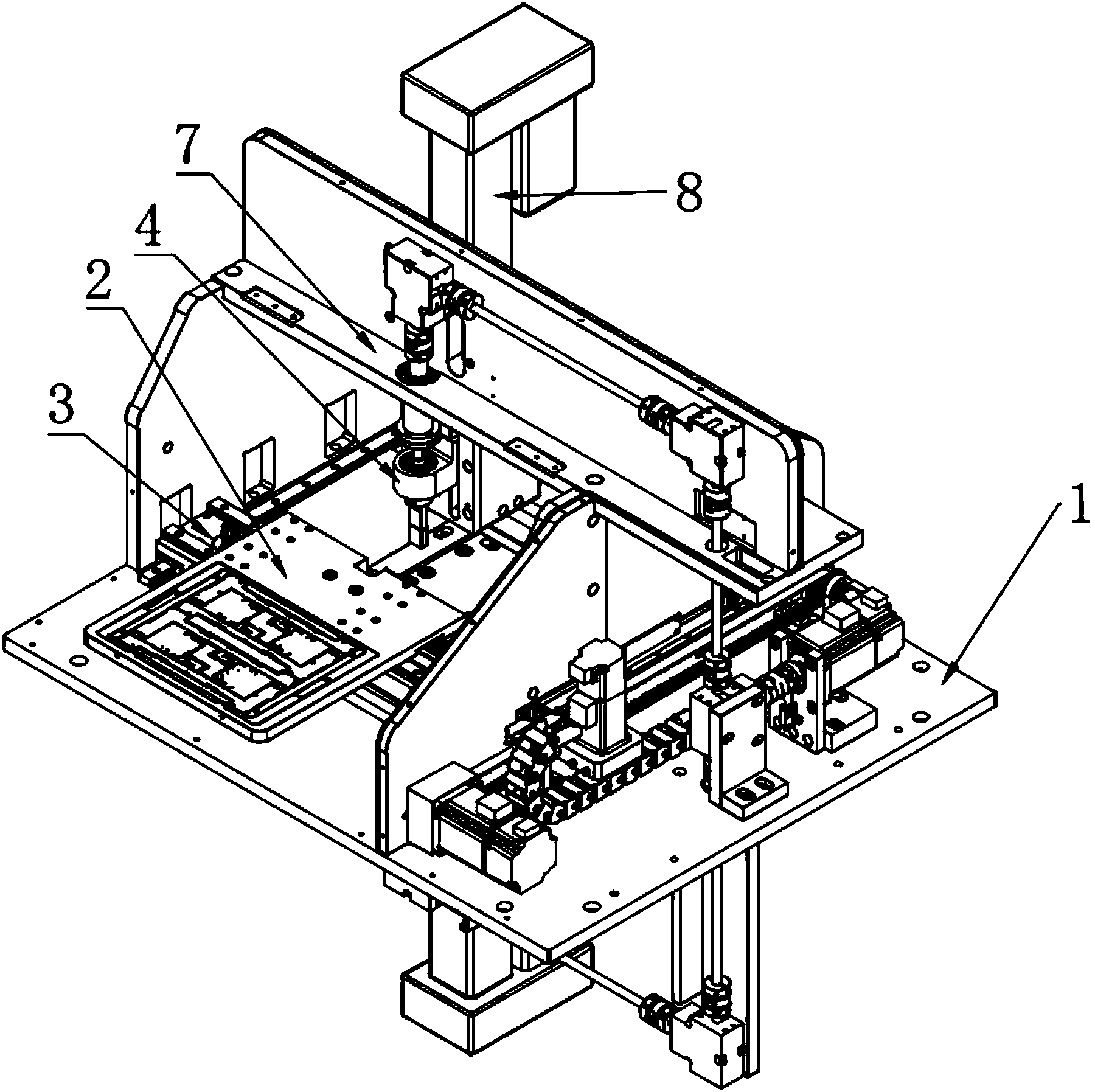

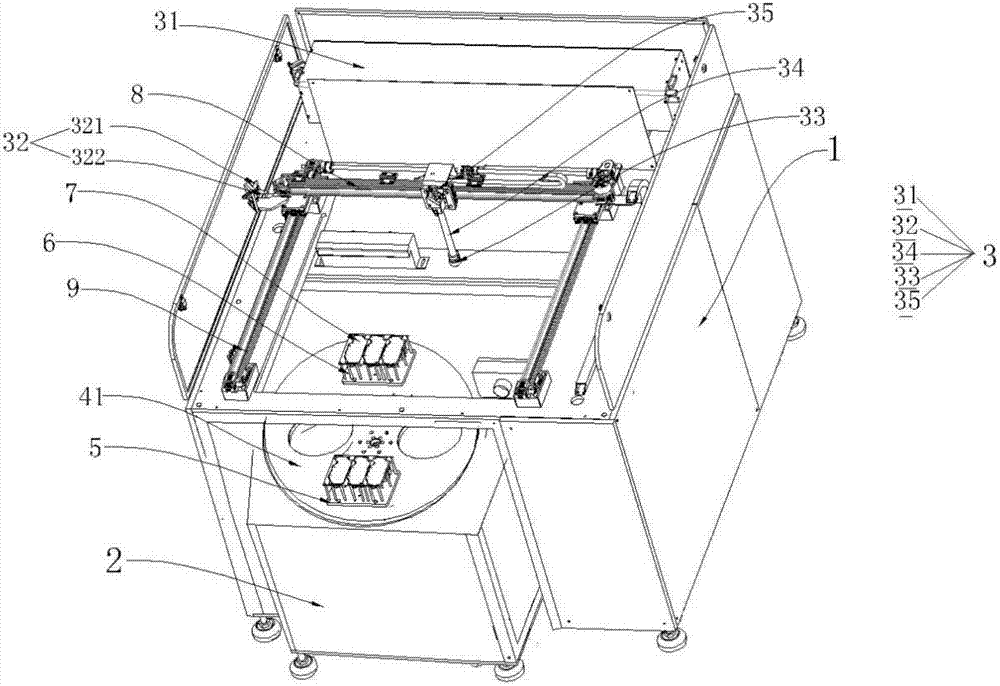

Novel PCB separator

InactiveCN108262779AClean up thoroughlyReduce manufacturing costDispersed particle filtrationTransportation and packagingDepanelingFilter effect

The invention discloses a novel PCB separator. The novel PCB separator comprises a frame, an X-axle moving mechanism, a Y-axle moving mechanism, a Z-axle moving mechanism, a tool tray, a main shaft cutting mechanism, a linked dust sucking mechanism and a dust collection and filter mechanism; the linked dust sucking mechanism is in transmission connection with the X-axle moving mechanism, and can synchronously move along with the main shaft cutting mechanism on the X-axle moving mechanism to suck dust on PCBs on the tool tray; a dust sucking part of the linked dust sucking mechanism is connected with an inlet of the dust collection and filter mechanism through a pipe; and an outlet of the dust collection and filter mechanism is connected with an air sucker through another pipe. The novel PCB separator is reasonable in structural design, stable and reliable in operation, convenient to operate, high in machining precision, excellent in dust sucking effect and high in efficiency, can thoroughly remove the dust, and can realize linear and curve trajectory cutting. In addition, the dust collection and filter mechanism needs no disposable dust collection bag, can achieve recycling after cleaning to prevent the resource waste, and is low in cost and excellent in dust collection and filter effect.

Owner:东莞市手拉手电子科技有限公司

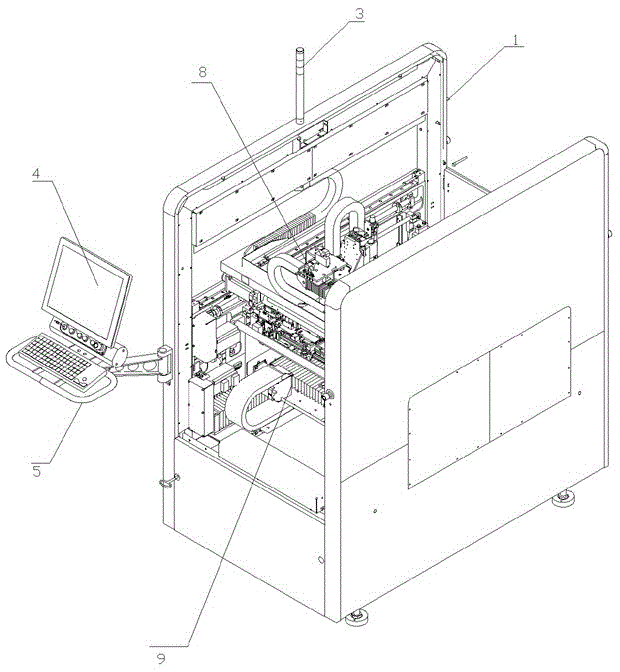

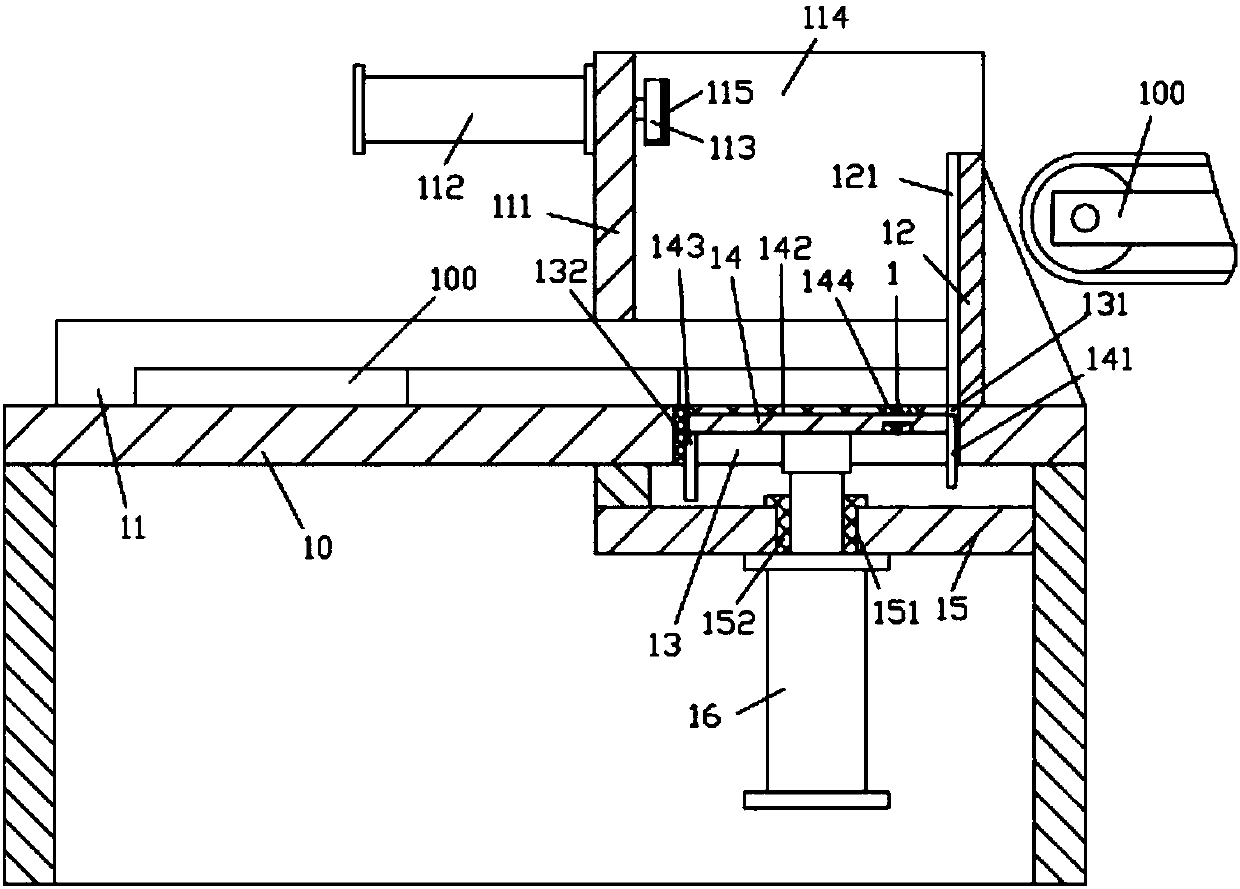

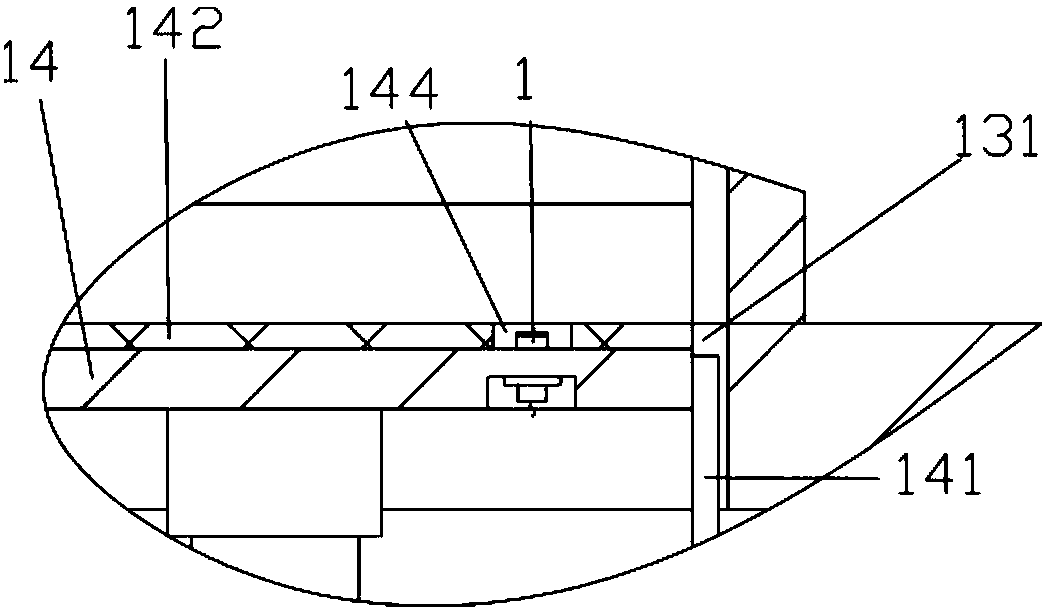

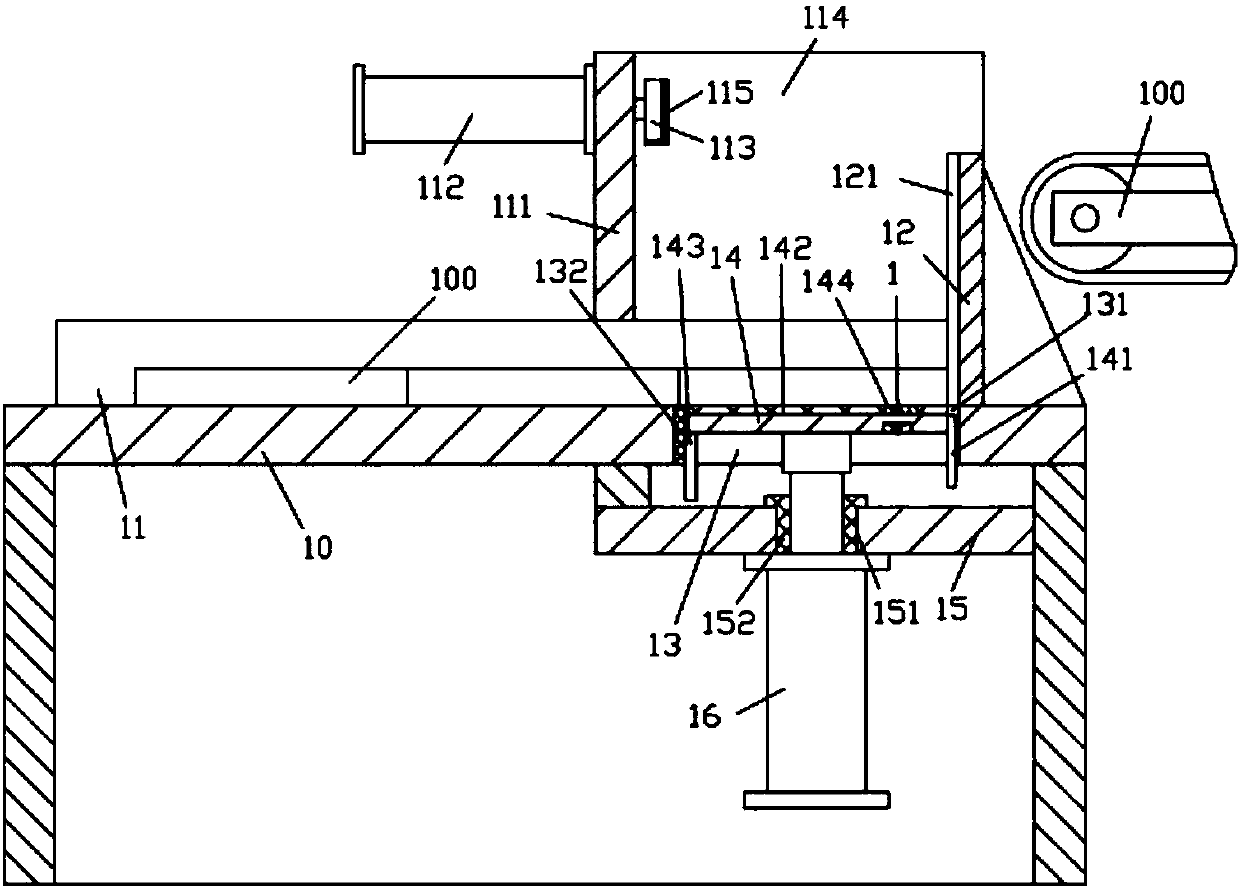

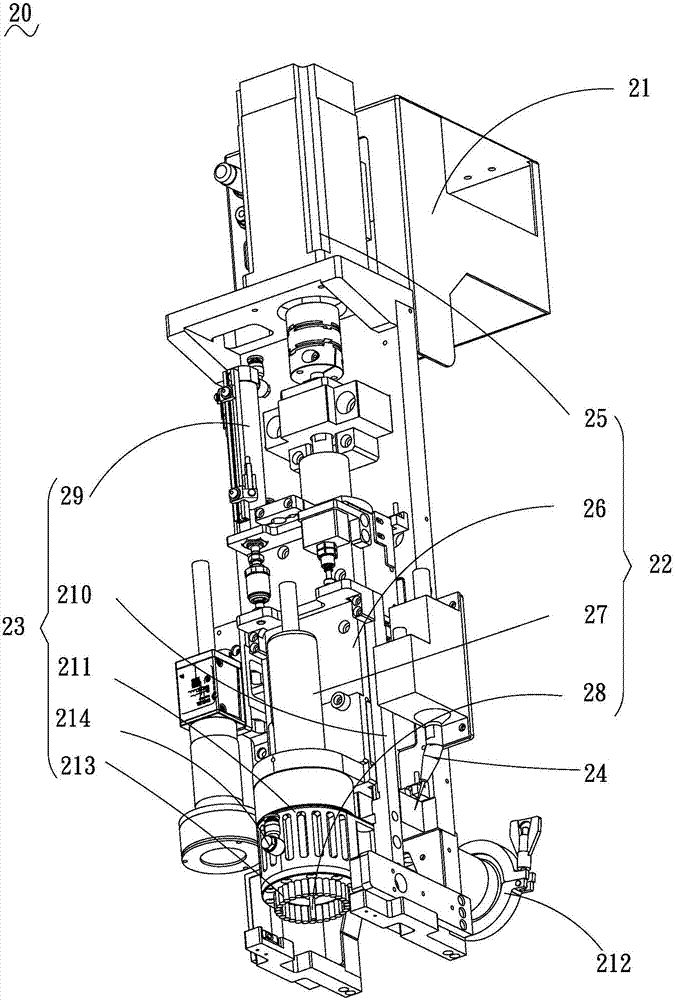

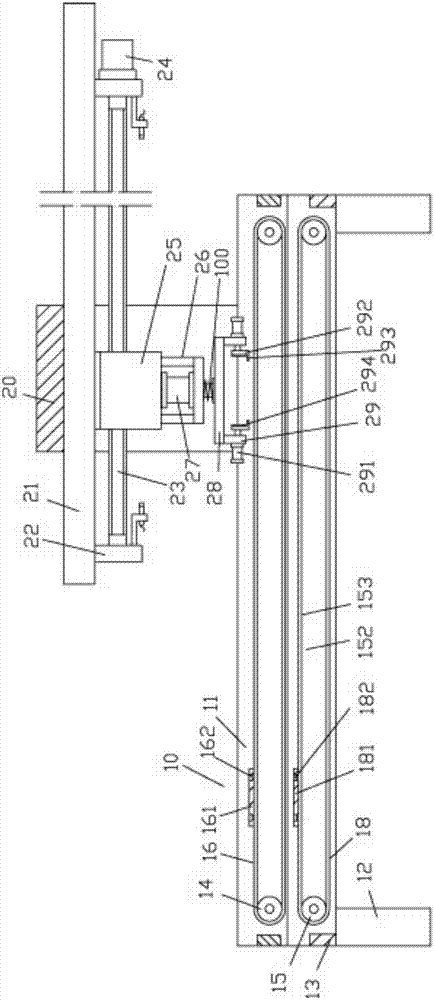

Intelligent PCB separating machine

The invention discloses an intelligent PCB separating machine which is provided with a rack, a conveying device arranged in the rack and used for conveying a PCB, a mechanical arm arranged above the conveying device and used for grabbing the PCB, a cutter arranged below the conveying device and used for cutting the PCB, a dust collecting device arranged in the rack and used for collecting PCB sweeps, a waste collecting device used for collecting the PCB sweeps and a control system. The rack is provided with a feeding port and a discharging port. One end of the conveying device is arranged at the position of the feeding port. The control system is electrically connected to the conveying device, the mechanical arm, the cutter and the dust collecting device. The whole PCB can be automatically separated into a plurality of small modules, the board separating efficiency is high, the board separating cost is low, the pollution of board separation to the environment is reduced, the factor that the health of a worker on site is threatened by cutting is lowered, different styles of PCBs can be automatically recognized, the cutting position can be adjusted, the board separating quality is good, and meanwhile the beneficial effect of the stable performance is achieved.

Owner:珠海市申科谱工业科技有限公司

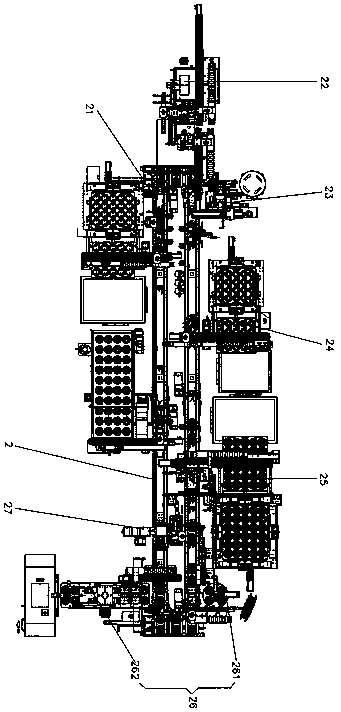

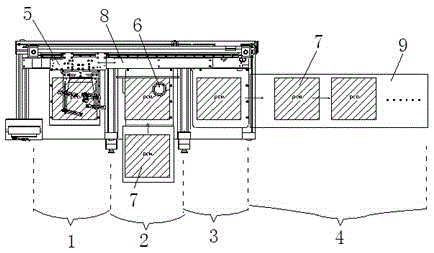

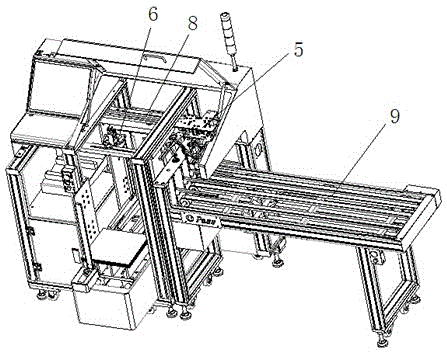

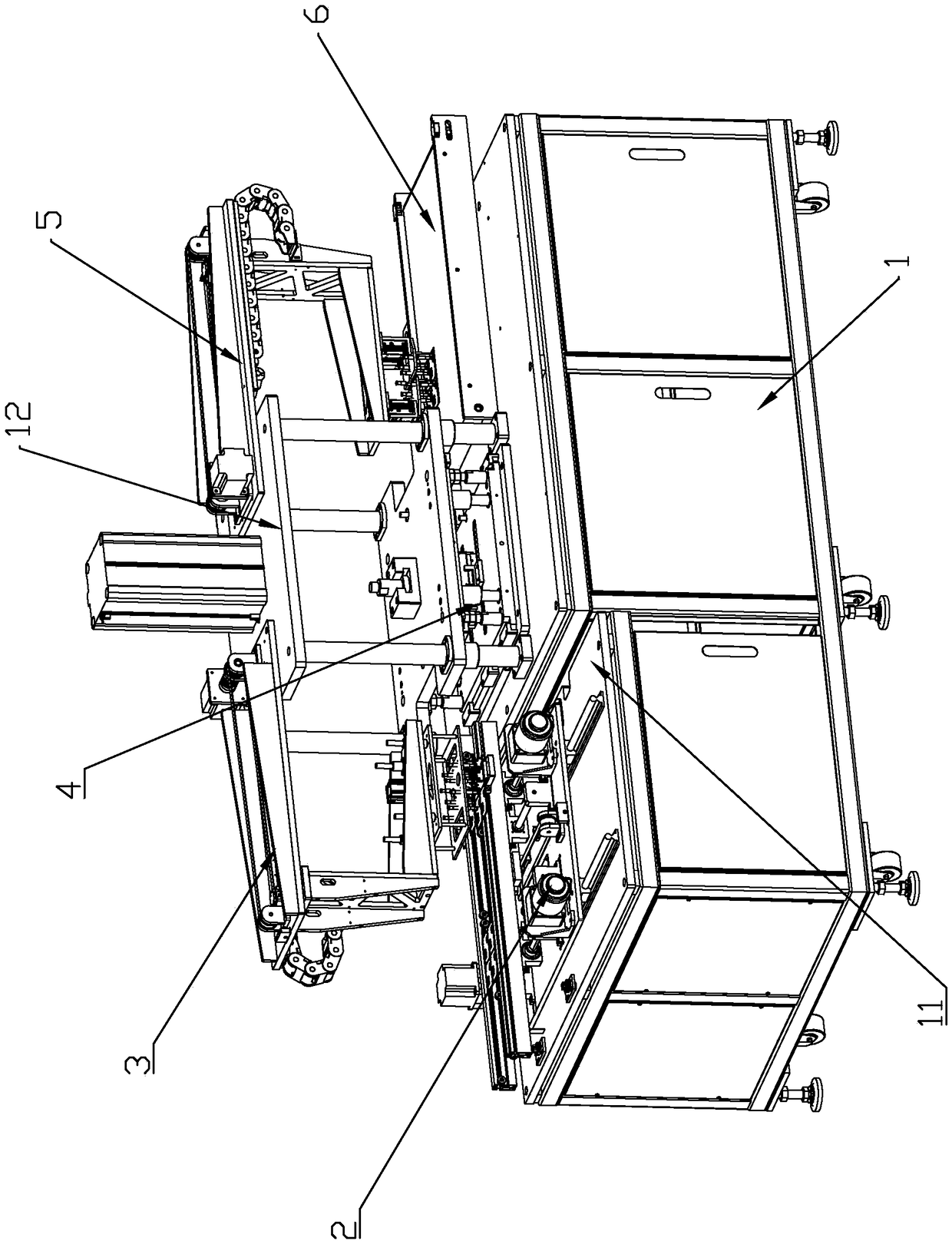

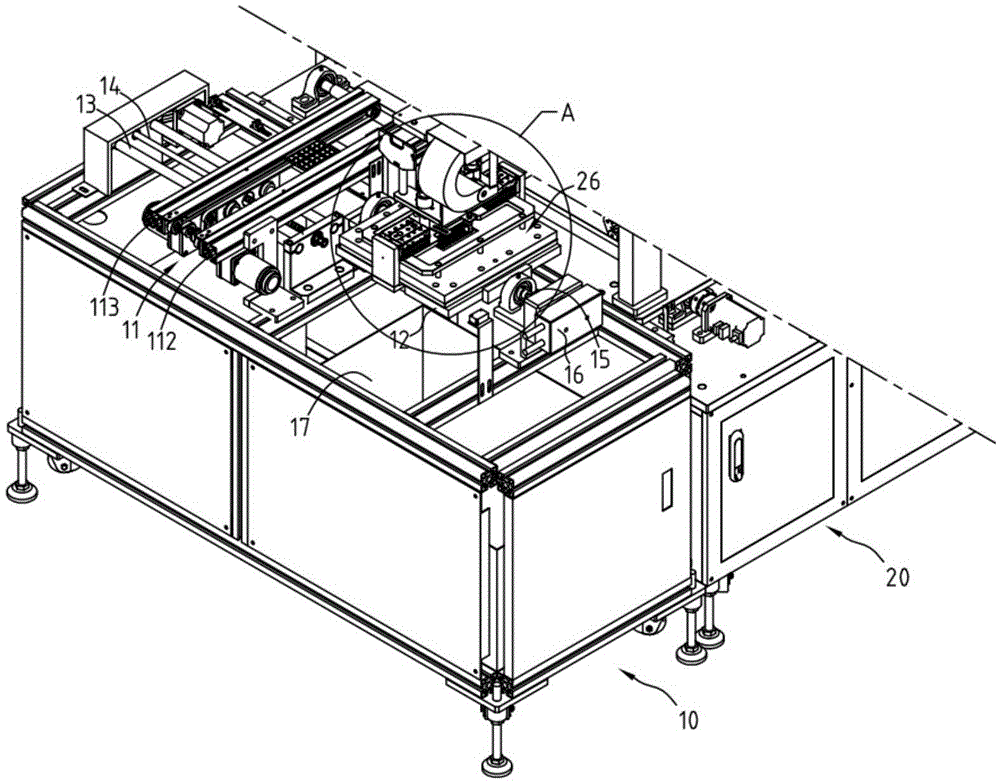

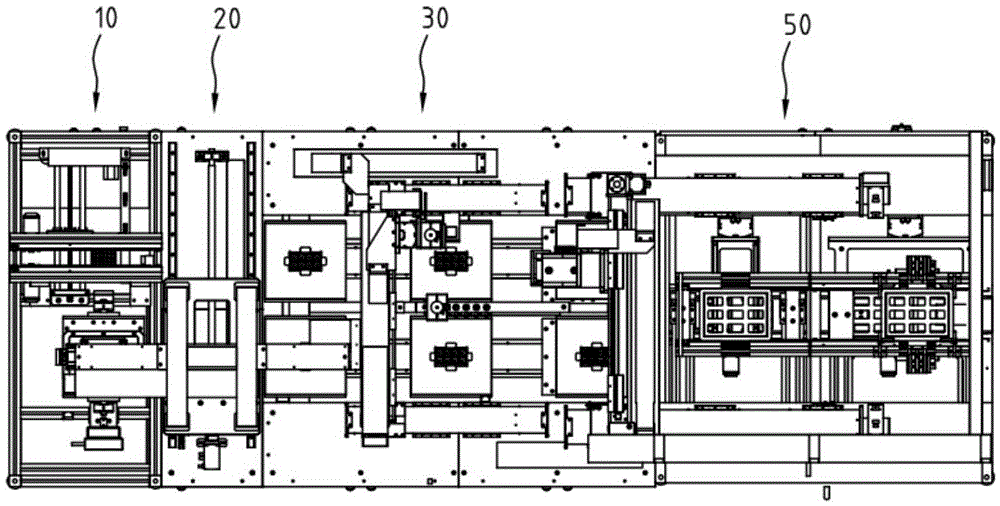

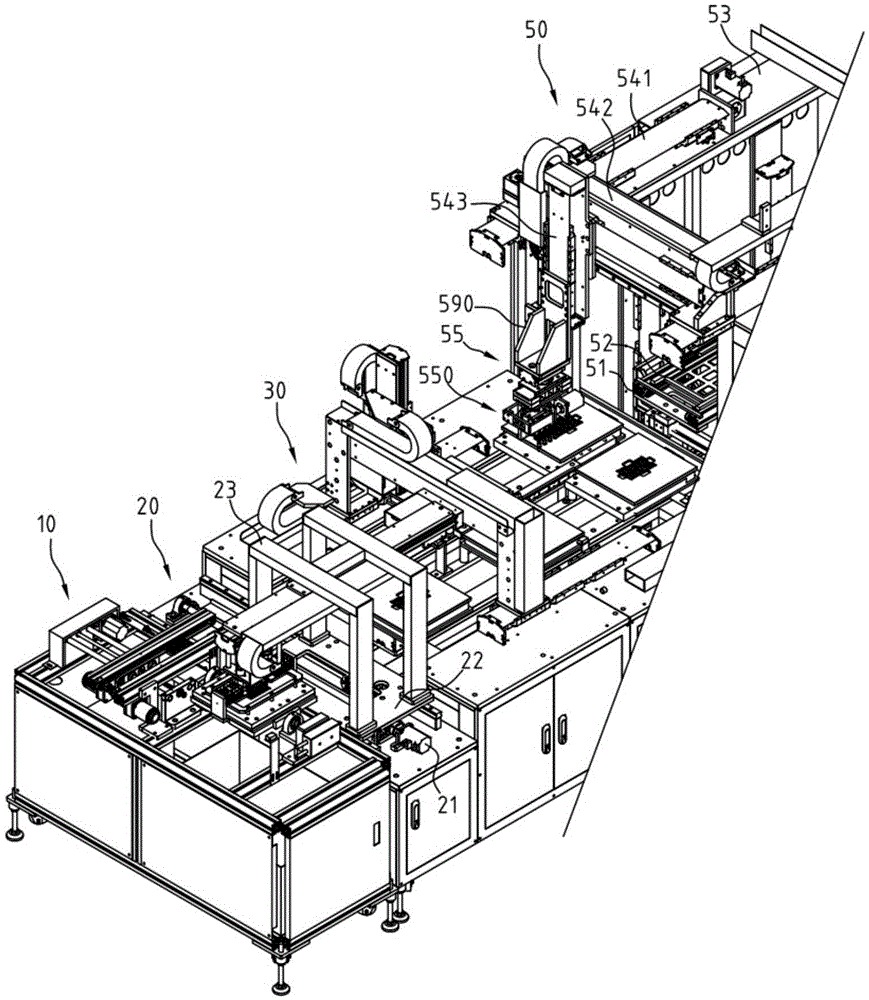

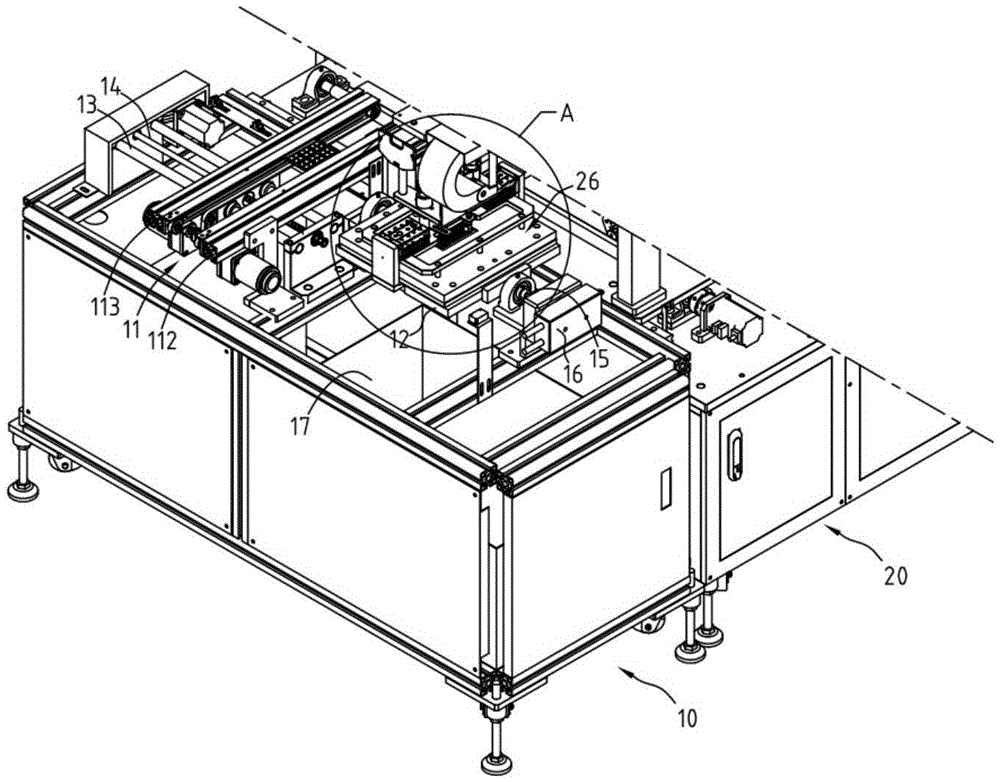

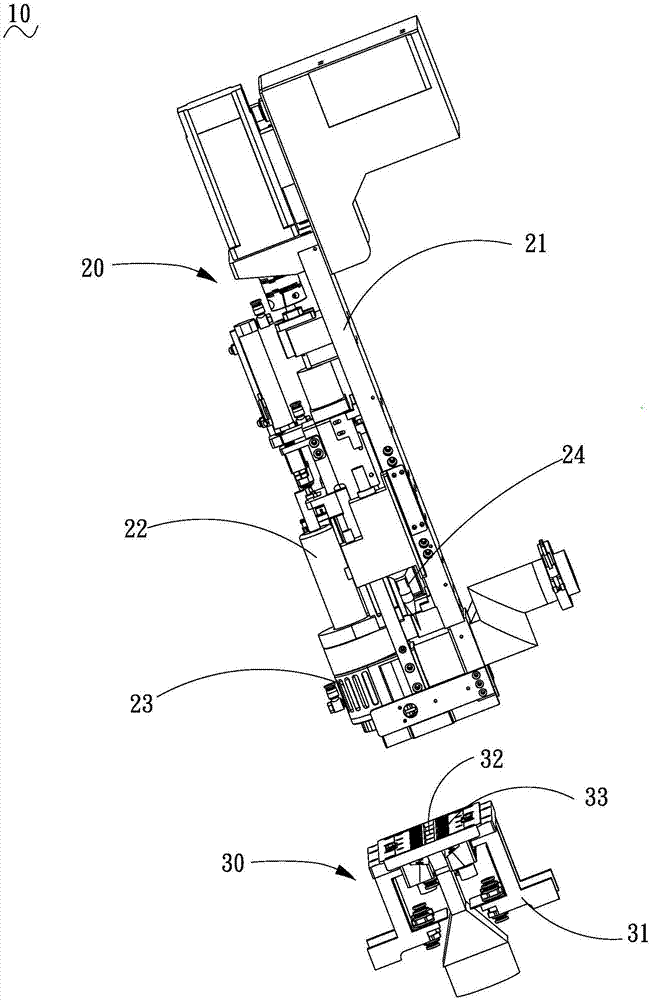

Automatic board feeding machine and automatic board feeding system

PendingCN108262798AAutomate the processImprove work efficiencyMetal working apparatusDepanelingEngineering

The invention belongs to the technical field of PCB machining process automation, and is especially suitable for automatic equipment for PCB automatic tray loading arrangement and storage. An automatic board feeding machine comprises a rack, a board feeding mechanism, a tray conveying mechanism and a discharging mechanism, and the board feeding mechanism, the tray conveying mechanism and the discharging mechanism are arranged on the rack. A material moving mechanism is arranged at the rear end of a PCB dividing machine, and the tray conveying mechanism comprises a PCB feeding mechanism, a traygrabbing mechanism, a PCB placing mechanism, a tray shifting mechanism, a tray turnover car loading mechanism and the like. Compared with the prior art, due to the fact that the automatic board feeding machine comprises a plurality of sets of transferring module mechanisms, a plurality of divided PCBs can be subjected to a series of automatic work of placing in trays in sequence, loading in a turnover car to be stored and the like at the same time; and production efficiency is greatly improved, labor cost is reduced, and the automatic process of the manufacturing process can be achieved. Therefore, the automatic board feeding machine is high in automation degree and suitable for volume production.

Owner:DONGGUAN AOSHANGTE ELECTRONICS TECH

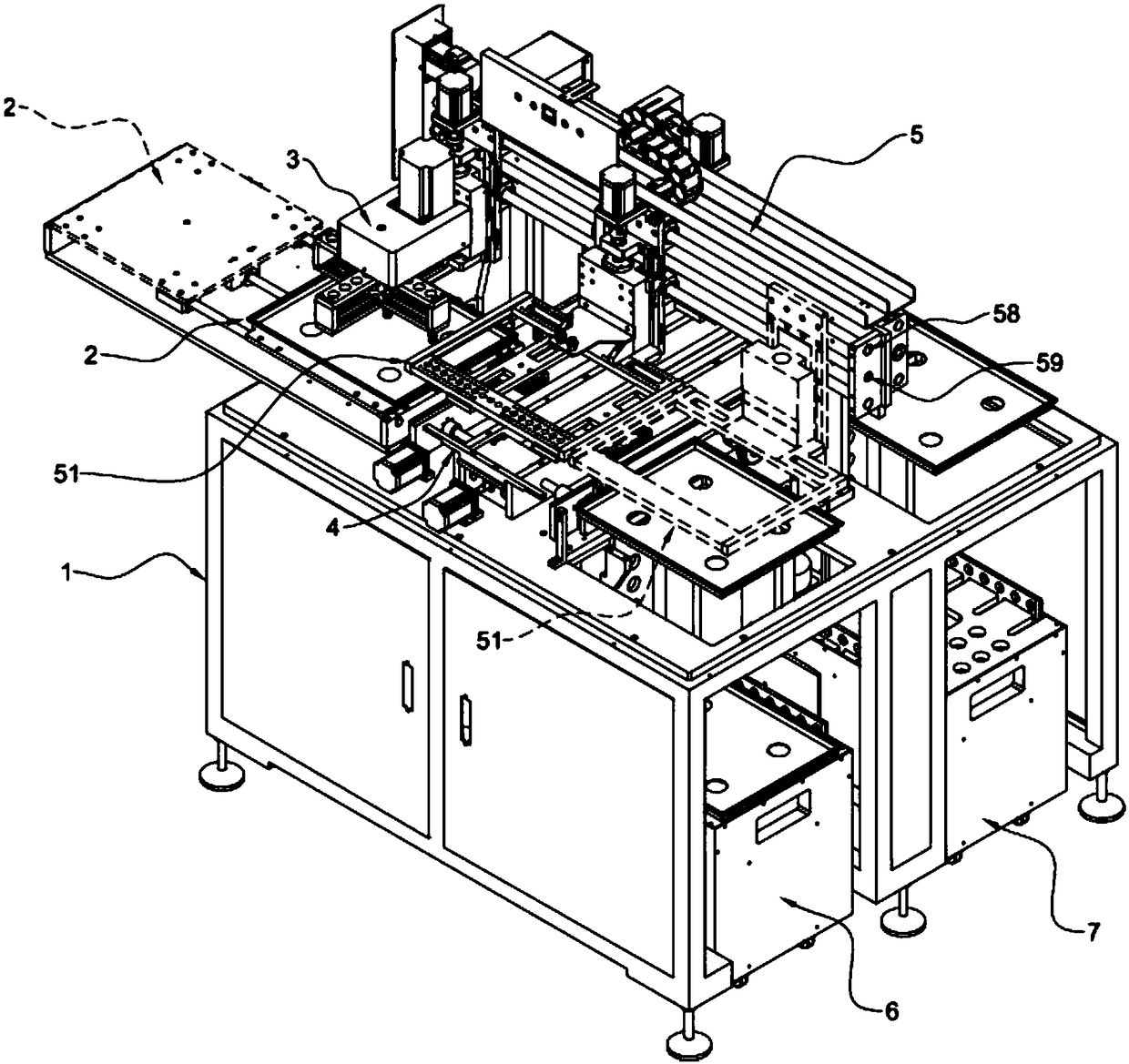

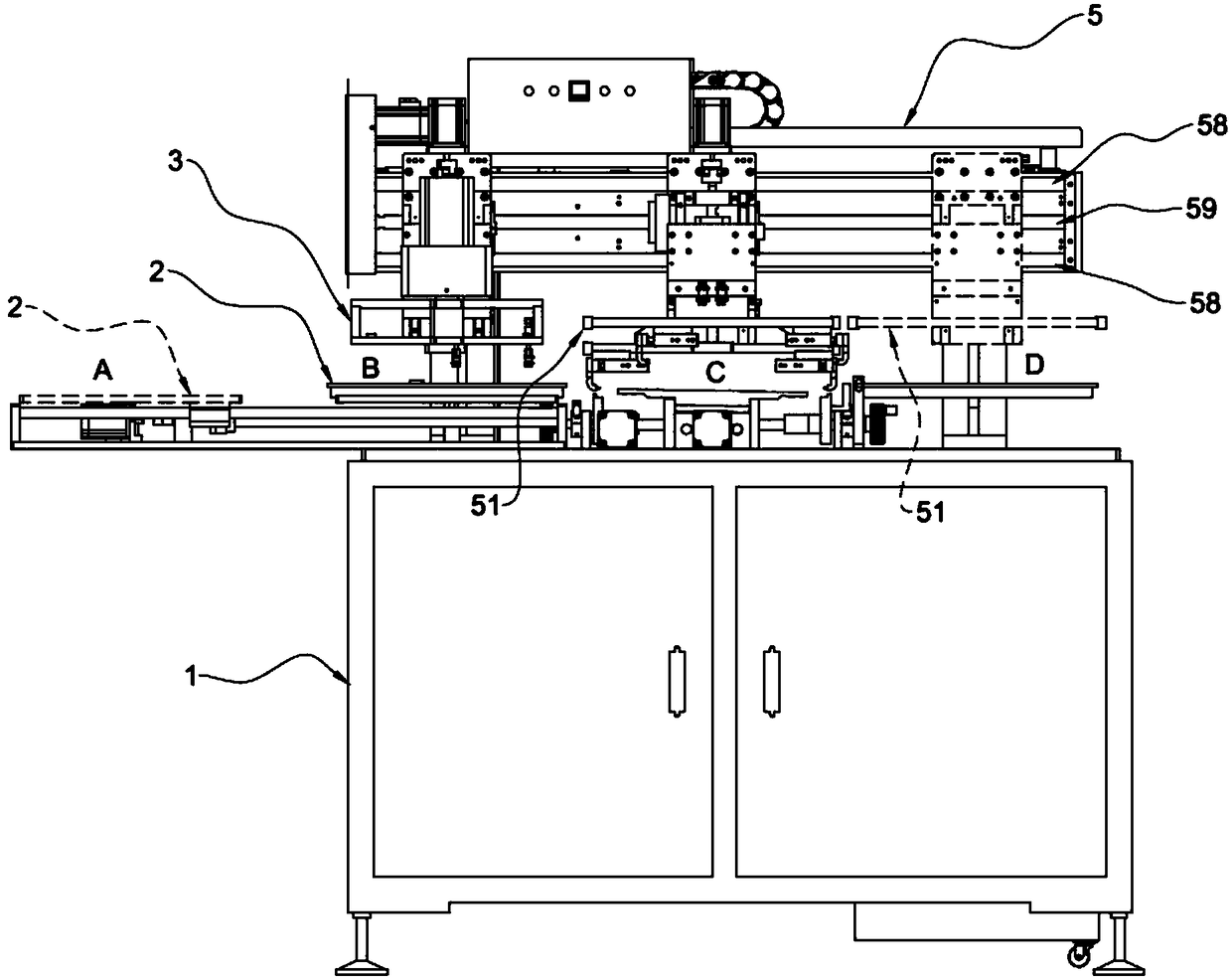

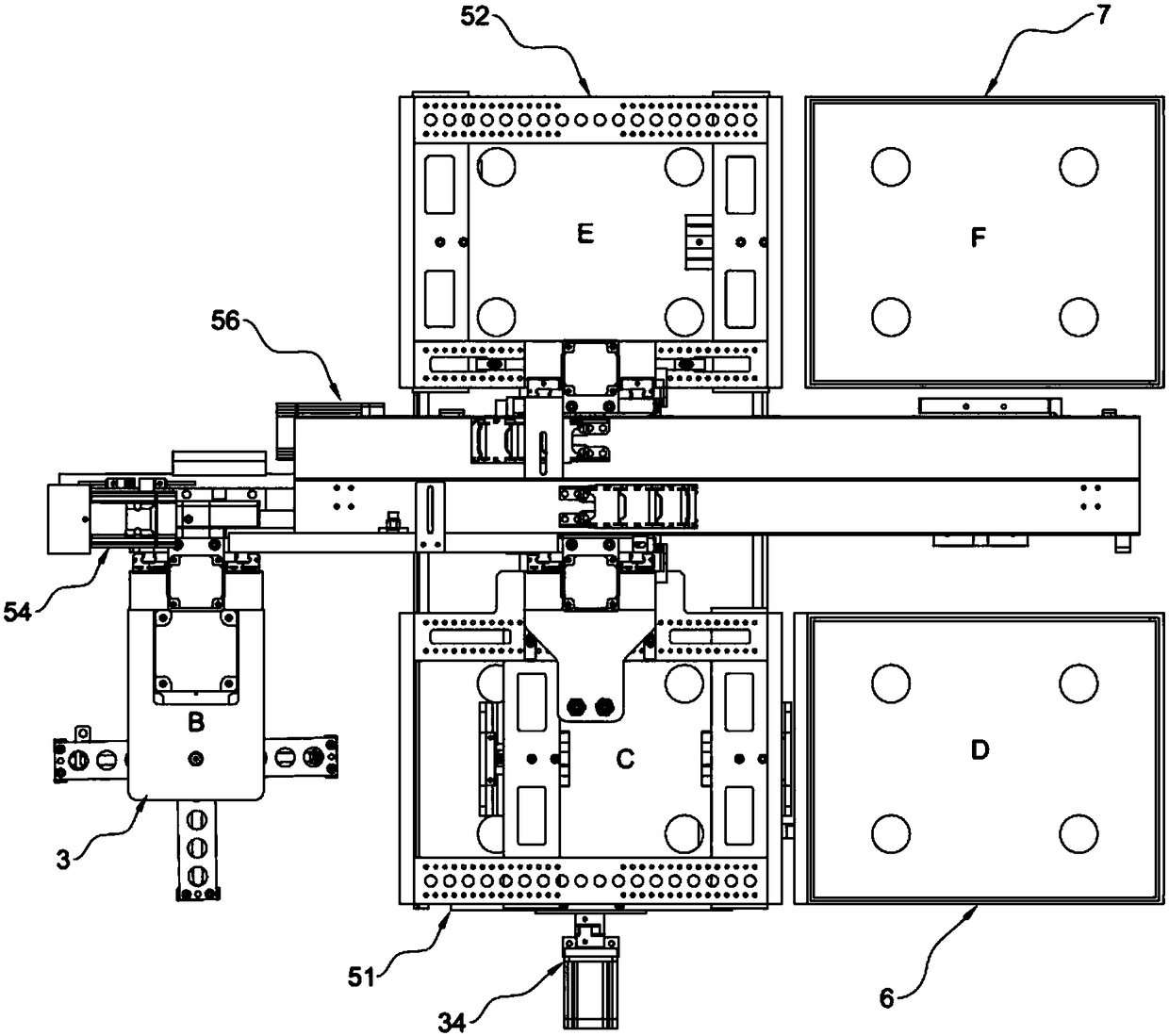

PCB splitting machine provided with stacking table

The invention discloses a PCB splitting machine provided with a stacking table. The PCB splitting machine comprises a feeding station, a transfer station, a board splitting station and a discharging station, which are arranged in sequence. The feeding station comprises an output track, second jigs placed on the output track, a suction claw device used for sucking PCBs, and the stacking table. The stacking table comprises a pair of lifting cylinders, a pair of telescopic cylinders and a pair of L-shaped supporting blocks. The lifting cylinders are mounted on two sides of the output track. The telescopic cylinders are mounted on the lifting cylinders. The supporting blocks are mounted on the telescopic cylinders. When the PCB connecting plate cutting efficiency of the board splitting station is not matched with the PCB storing efficiency of a storage device, the pair of telescopic cylinders and the pair of lifting cylinders expand, and the second jigs are supported by the pair of L-shaped supporting block by the thickness of at least one second jig, so as to transport a next second jig to the storage device through the output track. The stacking table can be used for effectively stacking the second jigs left on the output track between the board splitting station and the storage device.

Owner:SUZHOU HEROIC AUTOMATION TECH

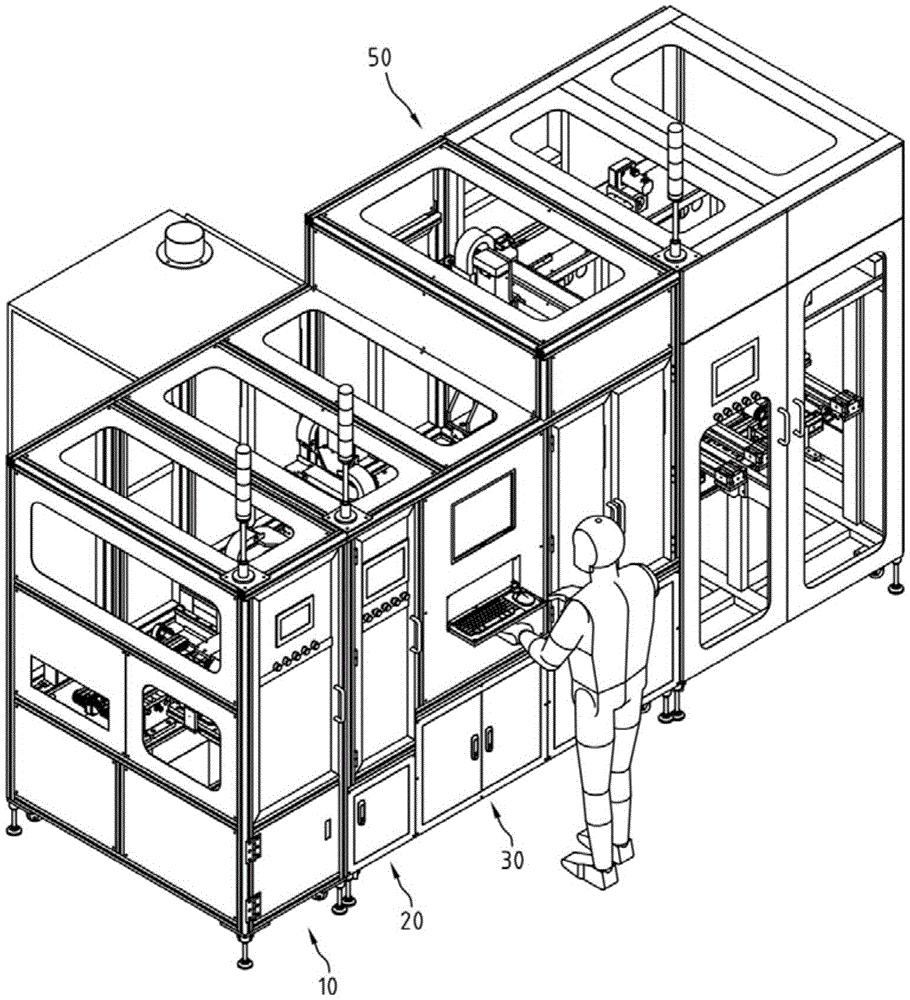

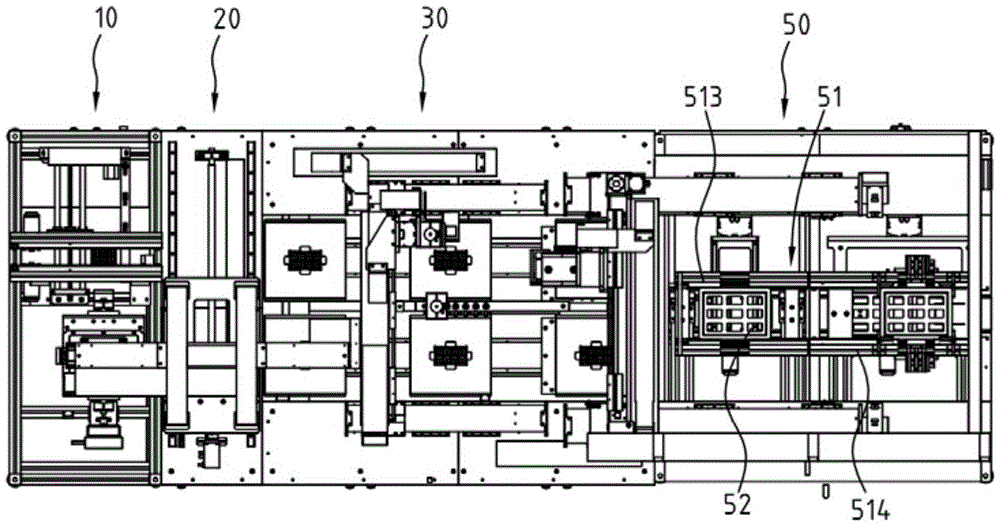

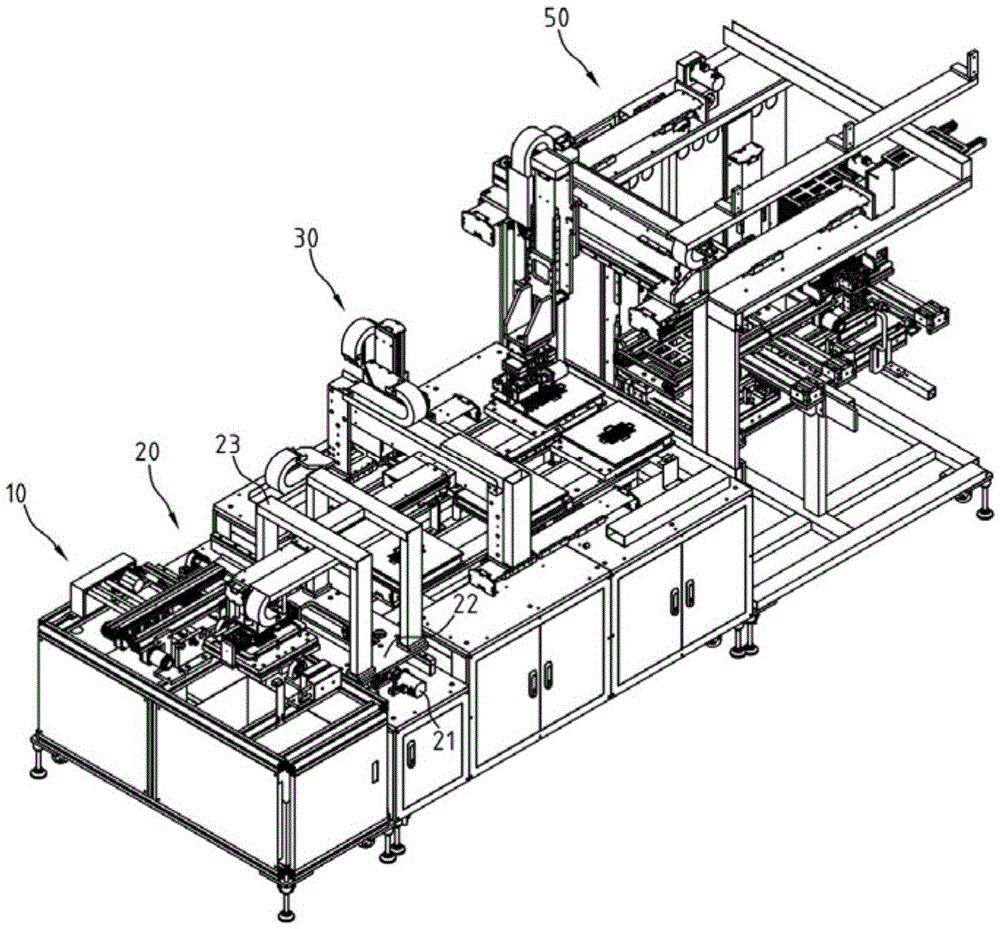

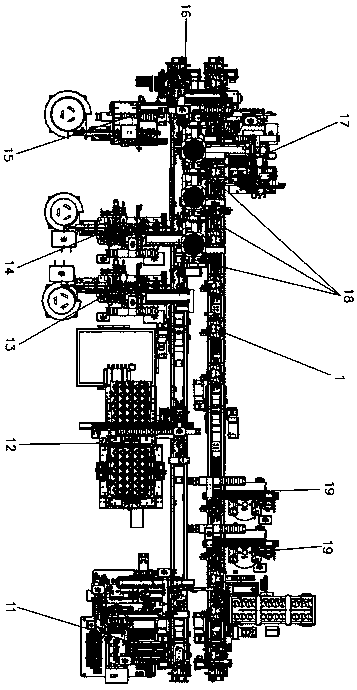

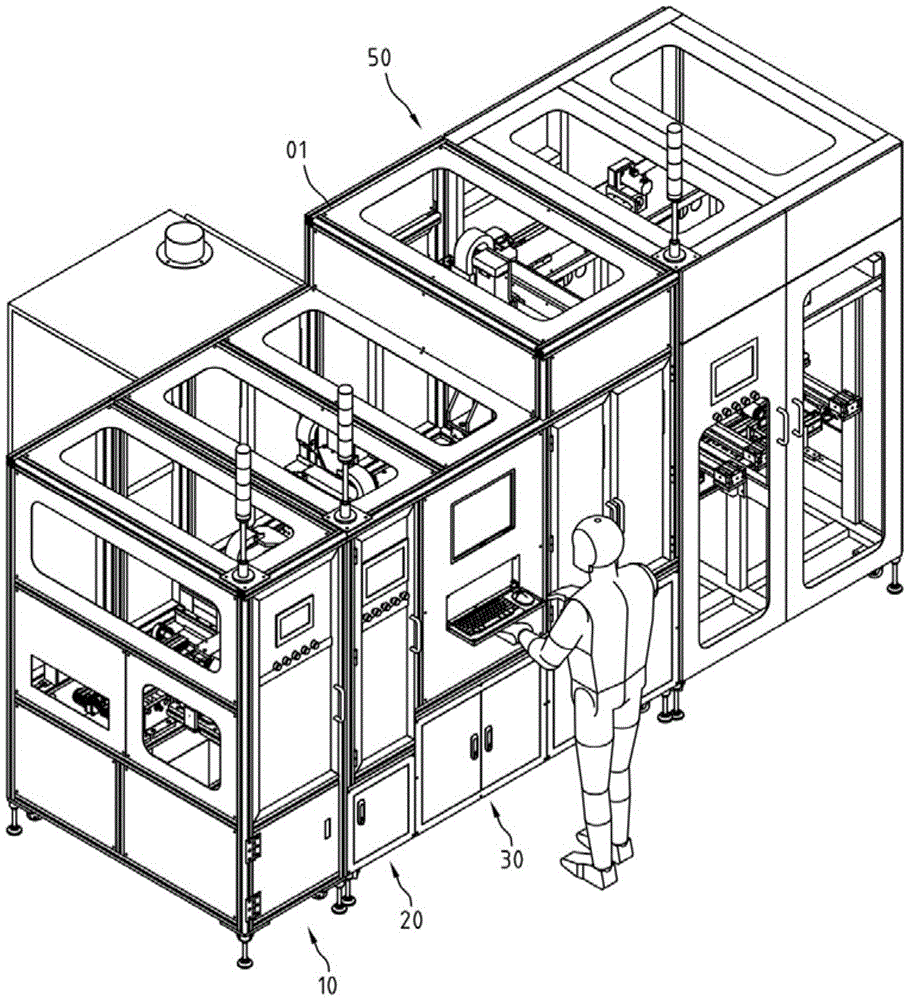

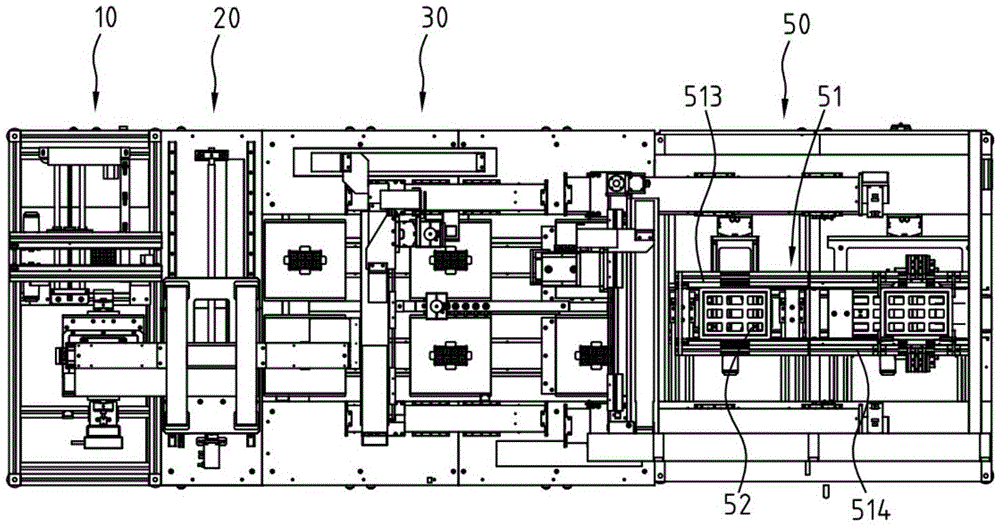

Smoke alarm automatic assembling production line

PendingCN108323151ARealize integrated operationAvoid inconsistent wax dipping volumesPrinted circuit assemblingAssembly machinesProduction lineCapacitance

The invention discloses a smoke alarm automatic assembling production line. The production line comprises a semi-finished product assembling line and a finished product assembling line. The semi-finished product assembling line is successively provided with PCB sub-board material loading equipment, labyrinth material loading equipment, transmitting tube material loading assembling equipment, receiving tube material loading assembling equipment, shield cover material loading assembling equipment, overturn equipment, capacitor material loading assembling equipment, welding equipment and semi-finished product detection equipment. The finished product assembling line is successively provided with middle buckle material loading assembling equipment, wax dipping equipment, light guide column material loading assembling equipment, labyrinth cover material loading assembling equipment, upper cover material loading assembling equipment, finished product detection equipment and coding equipment.The production line is used for automatically completing the assembling of a smoke alarm.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

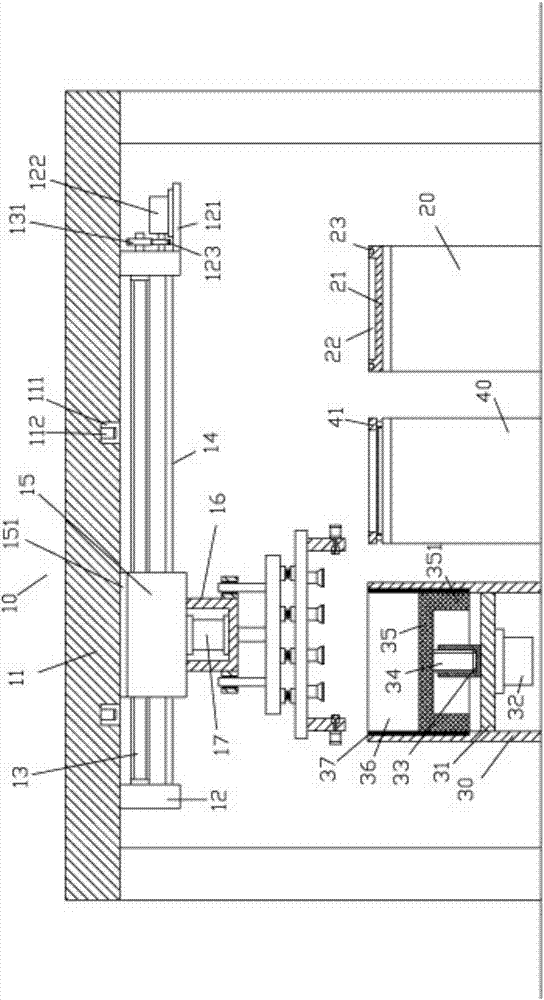

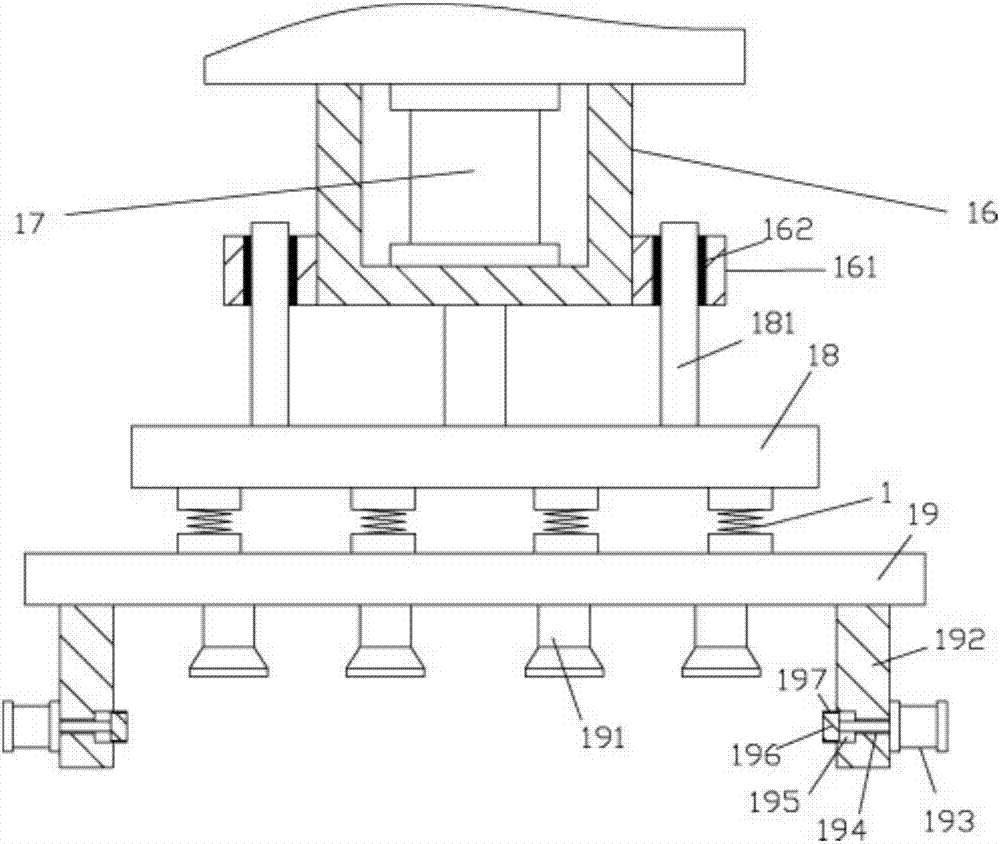

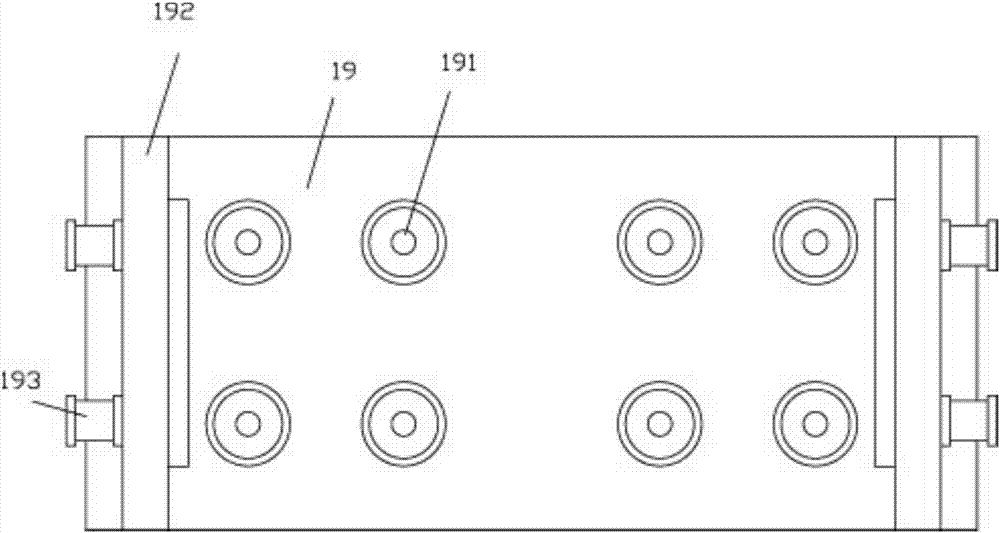

Cut-off PCB (printed circuit board) separator

The invention discloses a cut-off PCB (printed circuit board) separator comprising a workbench. A mounting fixture used for fixing a PCB and an X-Y motion platform mechanism driving the mounting fixture to transversely and longitudinally move on a horizontal operating plane are arranged on the workbench. The mounting fixture is mounted on the X-Y motion platform mechanism. An upper cutter feeding mechanism and a lower cutting feeding mechanism for cutting upper and lower surfaces of the PCB respectively at the same time are arranged above and below the mounting fixture. The cut-off PCB separator has the advantages that the upper and lower surfaces of the PCB on the mounting fixture are cut at the same time by the upper cutter feeding mechanism and the lower cutting feeding mechanism, the application of cutting processing prevents quality problems, such as welding spot cracks, caused by stress during separating and also avoids dust, and the air pollution problem caused by cutting processing by a milling cutter is solved, the PCB can flexibly move on the X-Y motion platform mechanism, the requirements for separating under nonlinearity, multi-angle and the like conditions are met, and the cut-off PCB separator is widely applicable.

Owner:FORYOU GENERAL ELECTRONICS

PCB separation counting machine

InactiveCN105035438AReduce work intensityAvoid Automation PointsConveyor partsPackaging machinesDepanelingEngineering

The invention discloses a PCB separation counting machine for circuit board production. The PCB separation counting machine comprises a feeding area where circuit boards to be detected are placed, an unqualified product area where detected unqualified products are placed, a qualified product area where detected qualified products are placed, and an automatic discharging area which is used for outputting the detected qualified products. The feeding area is provided with a camera used for detecting, recognizing and counting the circuit boards. The PCB separation counting machine further comprises a mechanical arm used for grasping and conveying the circuit boards into the unqualified product area or the qualified product area. Through camera recognition, human errors can be avoided as far as possible, various automatic counting and recognition functions can be achieved, and the working intensity of personnel can be relieved so as to reduce operating cost. The PCB separation counting machine is simple in structure, low in cost and easy to maintain.

Owner:SHENZHEN GALLON TECH

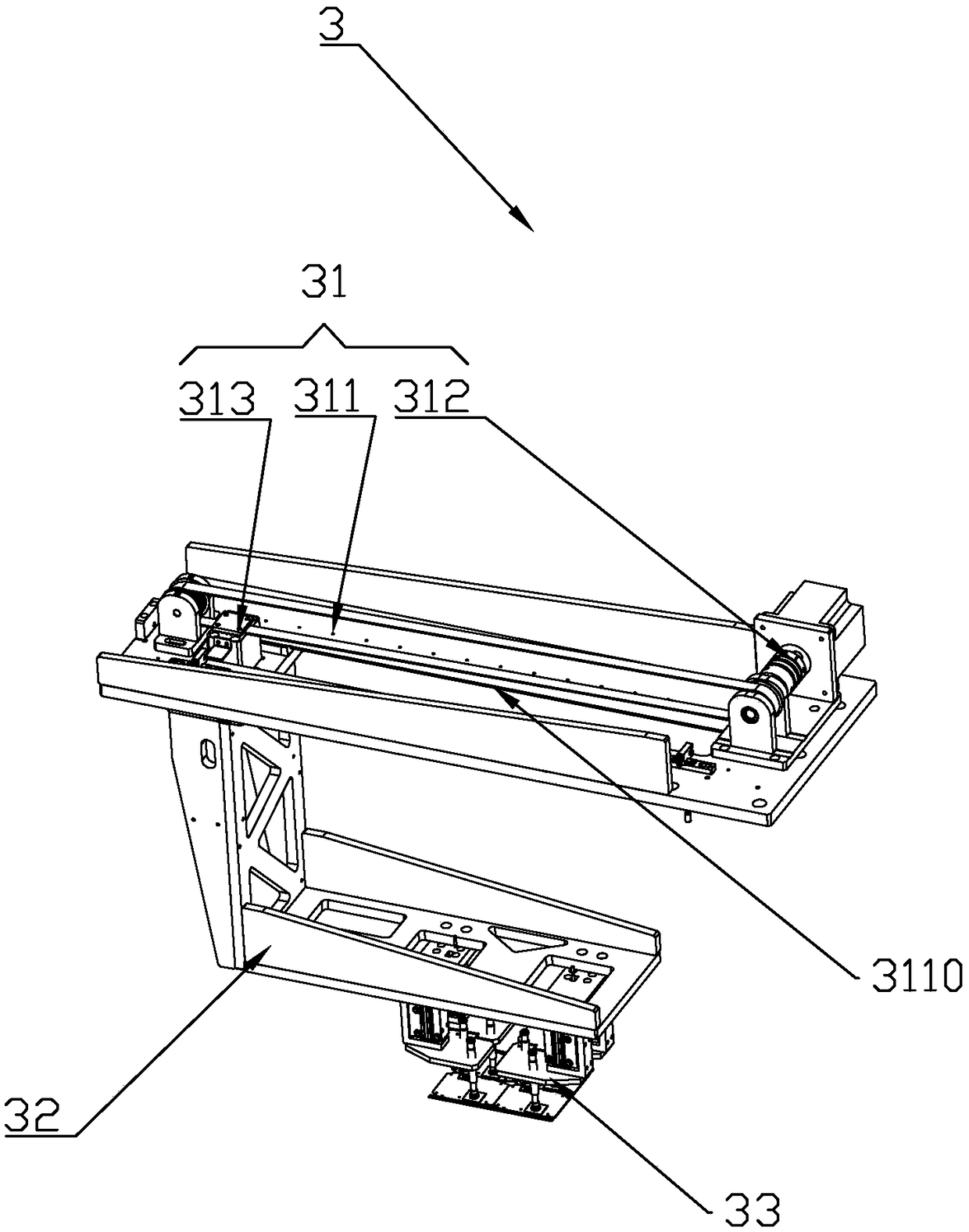

PCB split board moving and carrying mechanism

ActiveCN106971972ANo need for manual disassembly and handlingImprove efficiencySemiconductor/solid-state device manufacturingConveyor partsDepanelingDrive motor

Owner:王良仁

PCB splitting machine

InactiveCN103991095AReduce split plate stressAvoid emergency brakingMetal working apparatusDepanelingDrive motor

The invention discloses a PCB splitting machine. The technical problems of coarse cuts and welding spot crazing or part breakage caused by cutting stress of a circuit board in the prior art is solved. The PCB splitting machine comprises a cutting table, a tool rest and a horizontal guide rod, wherein a left protecting plate and a right protective plate are arranged on the cutting table, and an upper cover plate is arranged between the left protecting plate and the right protective plate. Threads are distributed on the horizontal guide rod, a nut sleeve is arranged on the tool rest, the tool rest is in threaded connection with the horizontal guide rod through the nut sleeve, a driving motor I is arranged at one end of the horizontal guide rod and supported on the cutting table. Two ends of the horizontal guide rod are supported on a liftable support through bearing seats, and the liftable support is fixed on the cutting table. A blade for cutting the circuit board is arranged on the tool rest. The PCB splitting machine performs cutting in a feeding type advance mode, the board splitting stress of the circuit board can be decreased, smooth cuts can be ensured, and welding spot crazing and part breakage can be prevented. The PCB splitting machine is provided with the liftable support, free lifting of the tool rest is achieved, and cutting of circuit boards different in thickness is achieved.

Owner:SUZHOU BECHENLAI ELECTRONICS

PCB (Printed Circuit Board) dividing machine provided with jig returning lifting platform

The invention discloses a PCB (Printed Circuit Board) dividing machine provided with a jig returning lifting platform. The PCB dividing machine comprises a material feeding workstation, a transit workstation, a board dividing workstation and a material discharging workstation which are sequentially arranged. The material feeding workstation is used for supplying PCB connection sheets; the transit workstation conveys the PCB connection sheets to the board dividing workstation; the board dividing workstation divides the PCB connection sheets by utilizing a milling cutter. The material discharging workstation comprises an output rail and jigs arranged on the output rail; the output rail is arranged on a transverse telescopic cylinder group, and a returning rail is arranged below the output rail; a lifting rack provided with a clamping jaw cylinder is arranged on one side of the returning rail; and the conveying direction of the returning rail and the conveying direction of the output rail are opposite. Unloaded jigs are conveyed by the returning rail and are lifted by the lifting rack, and the transverse telescopic cylinder group moves the output rail to make room for lifting of the jigs. By adopting the above technical scheme, the unloaded jigs can be supplied to the output rail from the returning rail continuously, so that divided PCBs can be placed on the unloaded jigs.

Owner:SUZHOU HEROIC AUTOMATION TECH

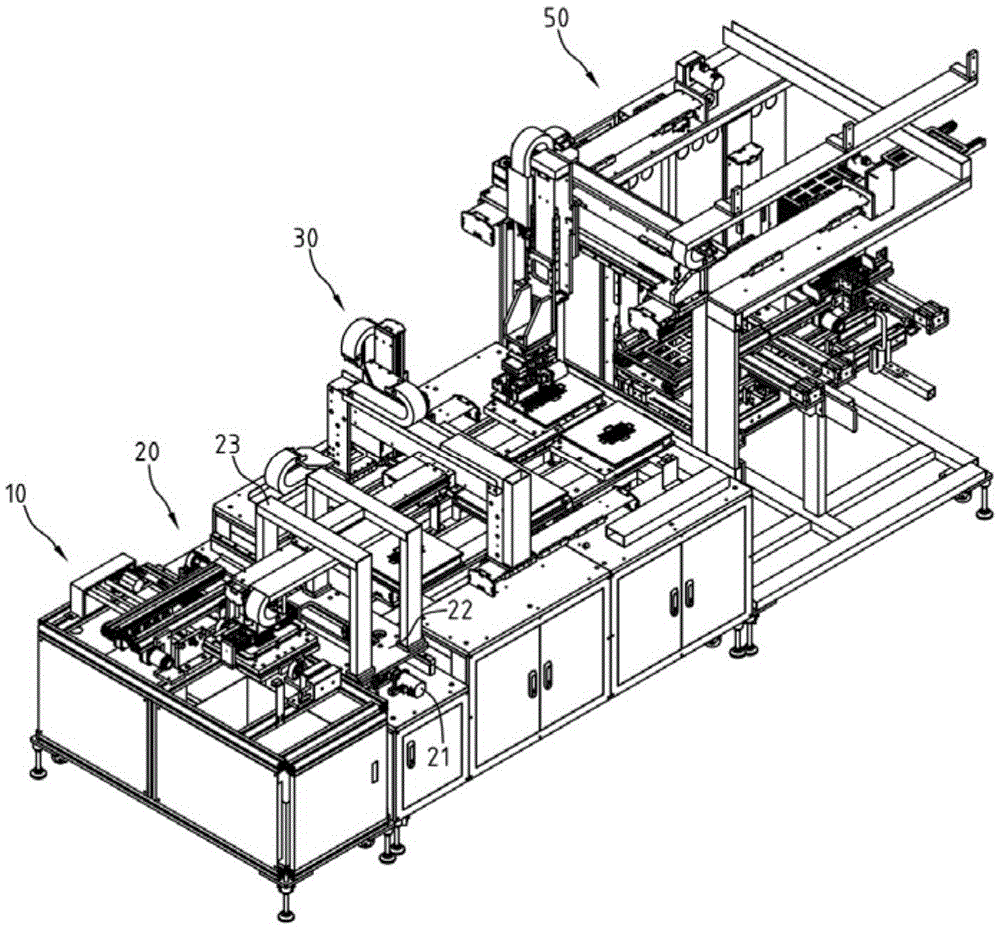

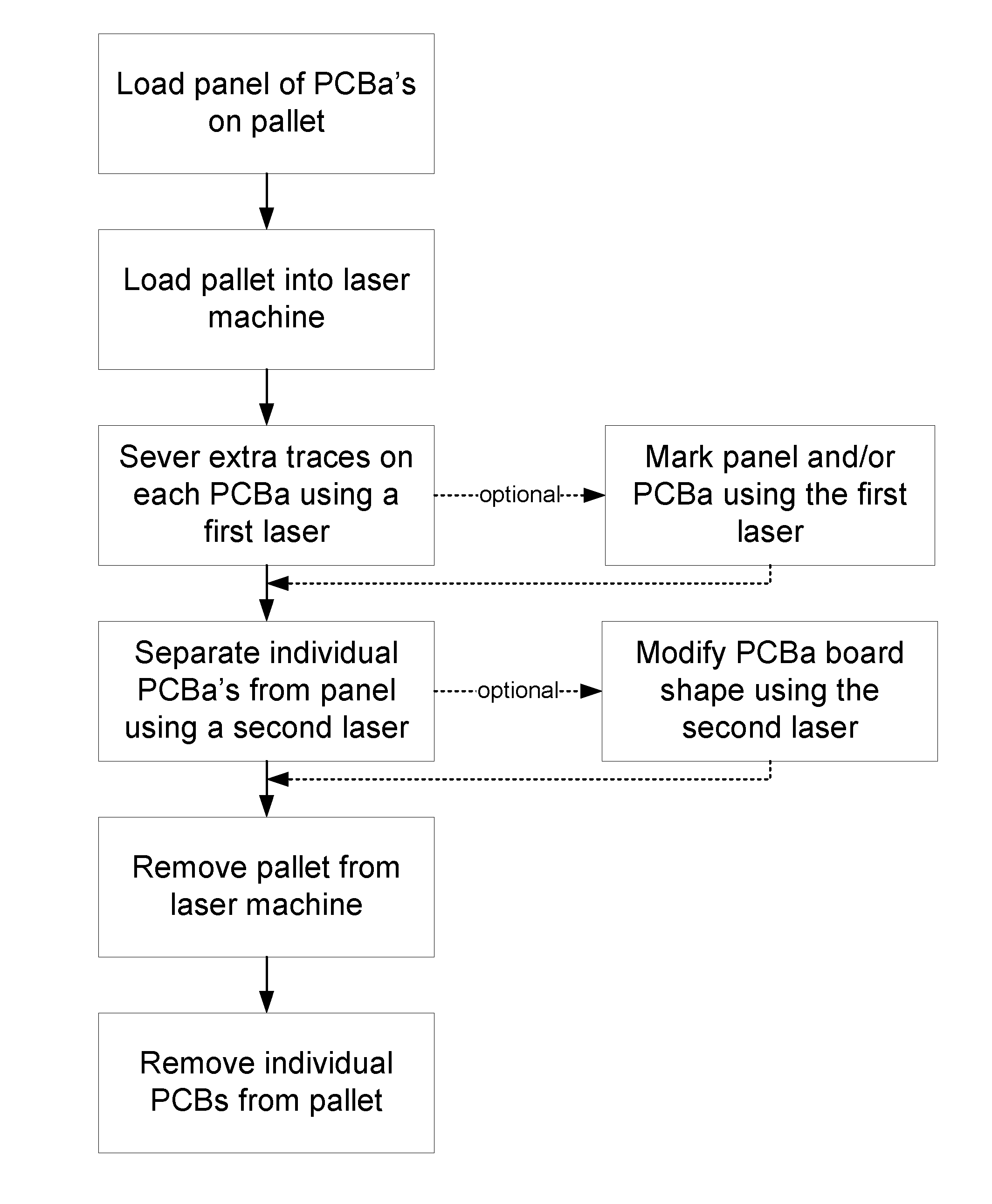

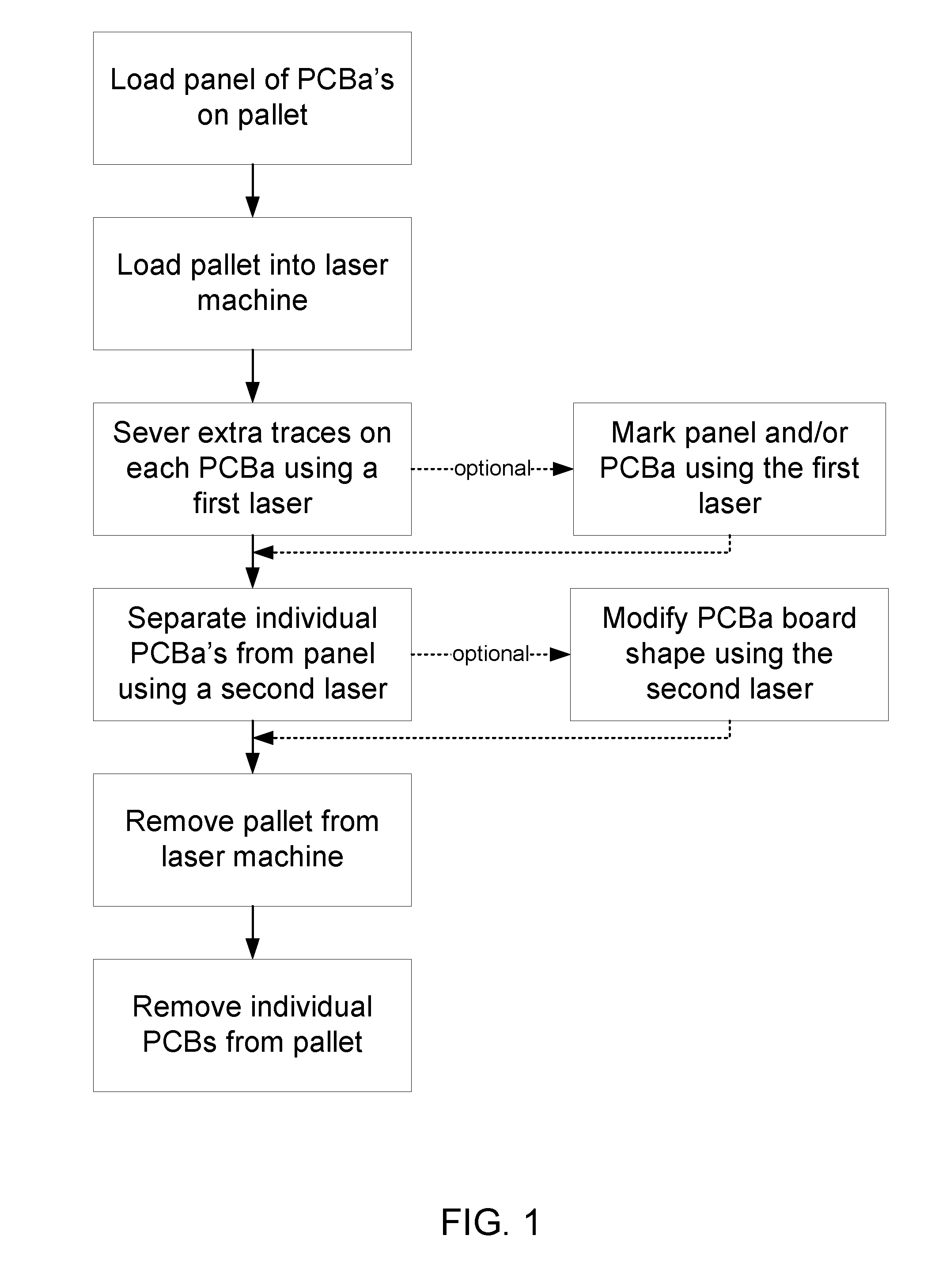

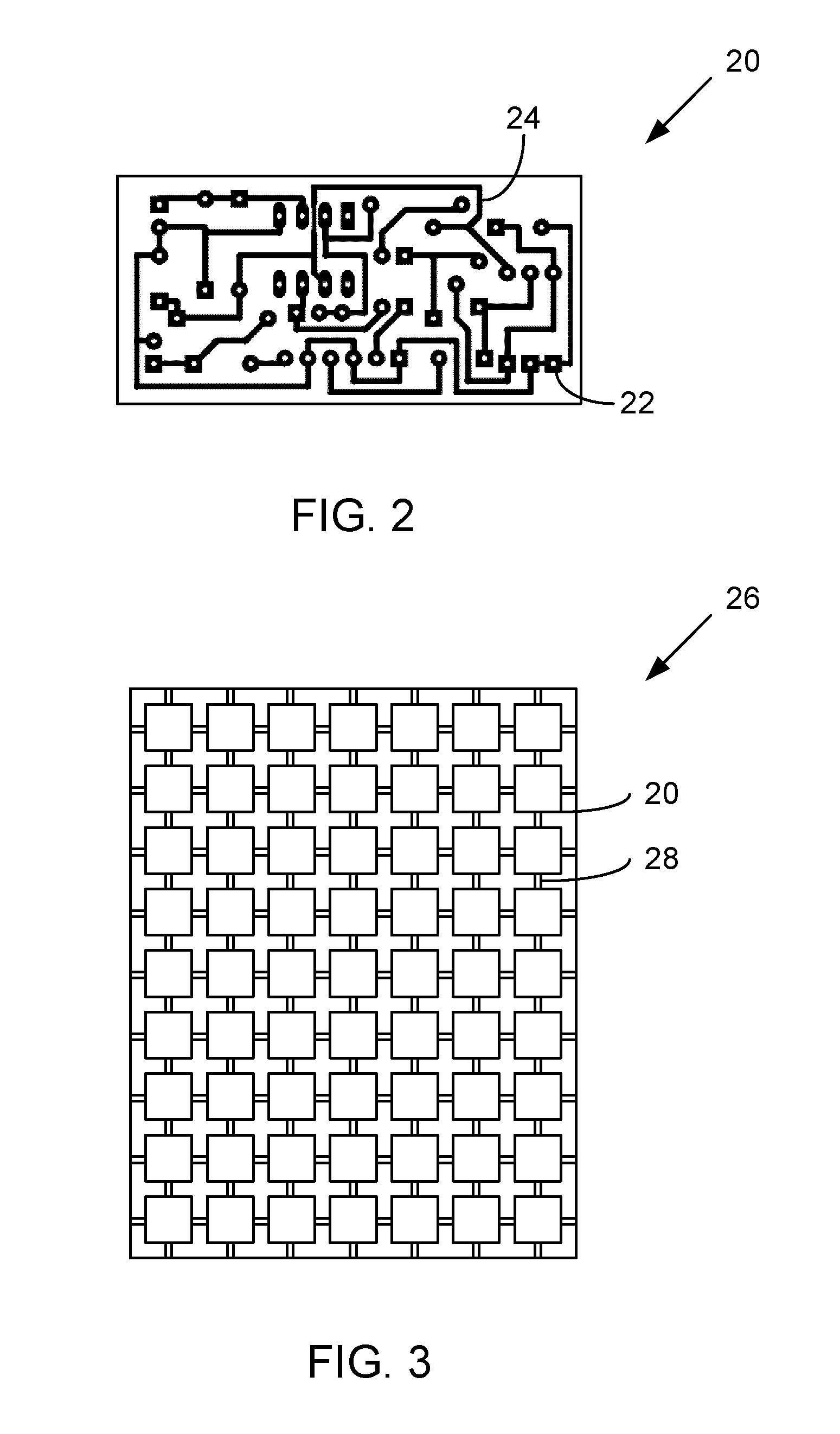

Methods of Laser Trace Post Processing and Depaneling of Assembled Printed Circuit

ActiveUS20160338204A1Printed circuit aspectsInsulating layers/substrates workingDepanelingEngineering

A method for processing a PCBa panel to individualize the PCBa's on the PCBa panel and depanel the PCBa panel in substantially one step is described. The PCBa panel initially comprises a number of PCBa's having components and traces common to a number of different product SKUs. During processing, the PCBa panel is loaded into a machine containing a first and second laser. The first laser severs extra traces on each PCBa to individualize the PCBa's for specific SKUs and the second laser cuts the links between each PCBa, thereby depaneling the PCBa panel.

Owner:SMART WAVE TECH

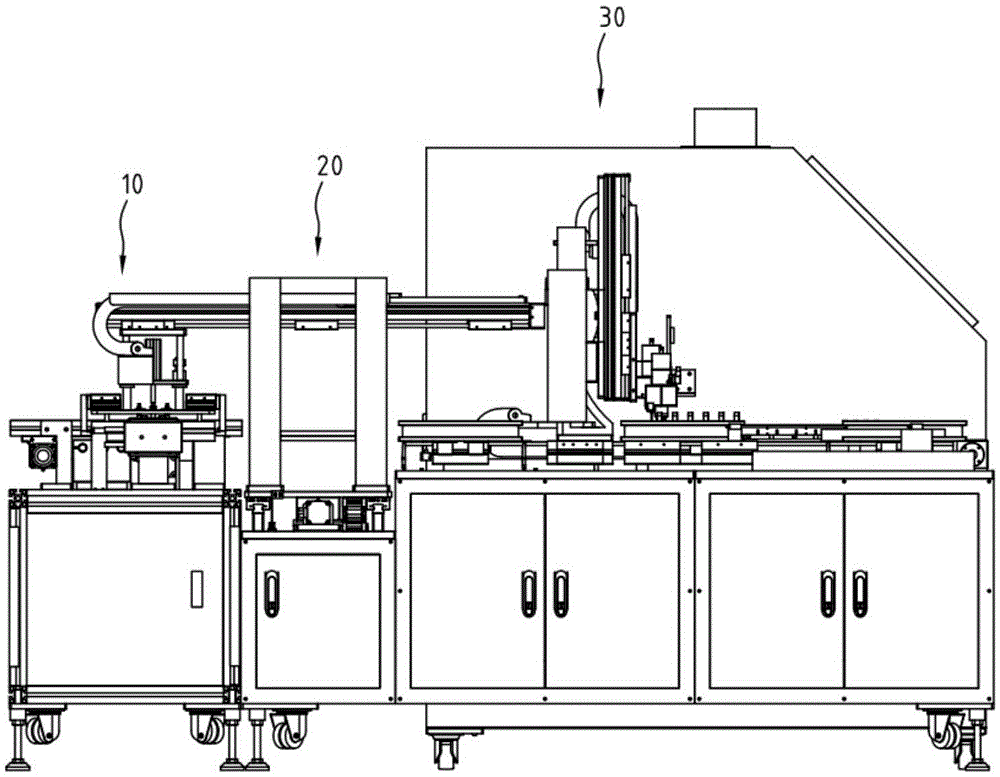

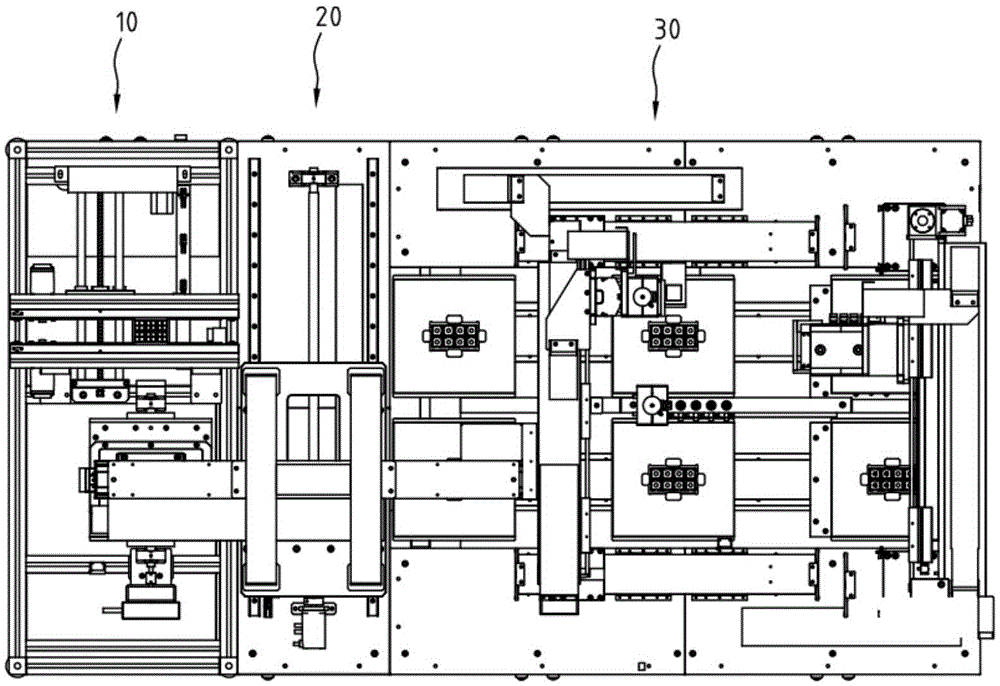

Full-automatic PCB board splitting machine

PendingCN108834316ARealize automatic flow operationImprove work efficiencyInsulating layers/substrates workingMetal working apparatusDepanelingEngineering

The invention discloses a full-automatic PCB board splitting machine, which relates to the technical field of PCB board splitting equipment. The full-automatic PCB board splitting machine adopts a feeding and conveying mechanism, a feeding mechanism, a board splitting mechanism, a discharging mechanism and a discharging and conveying mechanism which are arranged on a machine frame and operate cooperatively, wherein the feeding and conveying mechanism is used for inputting a PCB at a preorder station to a feeding station, the feeding mechanism is used for moving the PCB from the feeding stationto a board splitting station, the discharging mechanism is used for moving the PCB from the board splitting station to a discharging station, and the discharging and conveying mechanism is used for outputting the processed PCB. The full-automatic PCB board splitting machine realize the fully automatic assembly line operation of the PCB in the process from aligned transmission to feeding, board splitting, discharging and output, and has the advantages of high working efficiency, good board splitting quality, high yield, high automation degree and low labor cost.

Owner:江门市蓬江区科技中心

Sheet metal lifting device, provided with automatic locating device, for PCB splitting machine

ActiveCN107082270AEasy accessEasy to grabConveyorsControl devices for conveyorsDepanelingManipulator

The invention discloses a sheet metal lifting device, provided with an automatic locating device, for a PCB splitting machine. The sheet metal lifting device comprises a feeding rack. A discharging through hole is formed in the middle of a top plate of the feeding rack. A supporting plate is fixed in the middle of the feeding rack. A pushing opening is formed in the left side of a part between the supporting plate and the top plate of the feeding rack. A lifting through hole is formed in the middle of the supporting plate. A pushing column is inserted into and sleeved by the lifting through hole. The bottom end of the pushing column is arranged below the supporting plate. A lifting connecting plate is fixed at the bottom end of the pushing column. A feed box is arranged on the top surface of the supporting plate. A rotating stud is screwed in a side plate above the right side of the supporting plate. A spacing block is hinged to the inner end of the rotating stud, and is presses on and leans against the right side wall surface of the feed box. The front wall surface and the rear wall surface of the feed box are close to a front wall plate and a rear wall plate of the feeding rack. The feed box can be placed on the supporting plate, locating is realized through an expansion plate and the spacing block, a feed plate is automatically lifted by the pushing column, taking or grabbing by a hand or a manipulator is facilitated, the efficiency is high, and the effect is good.

Owner:江西威尔高电子股份有限公司

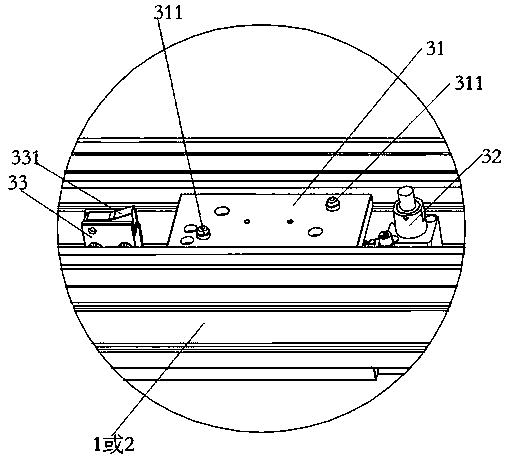

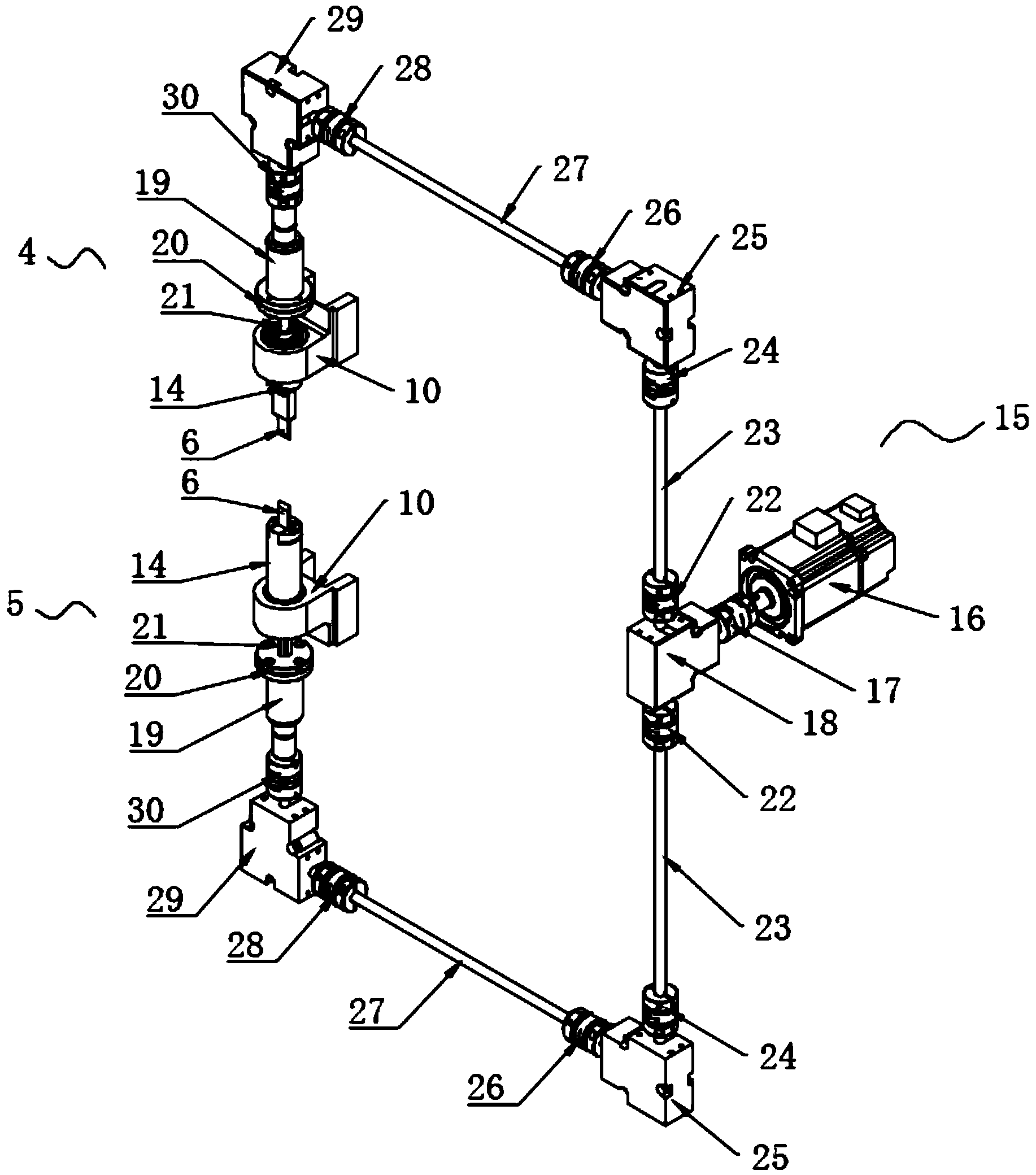

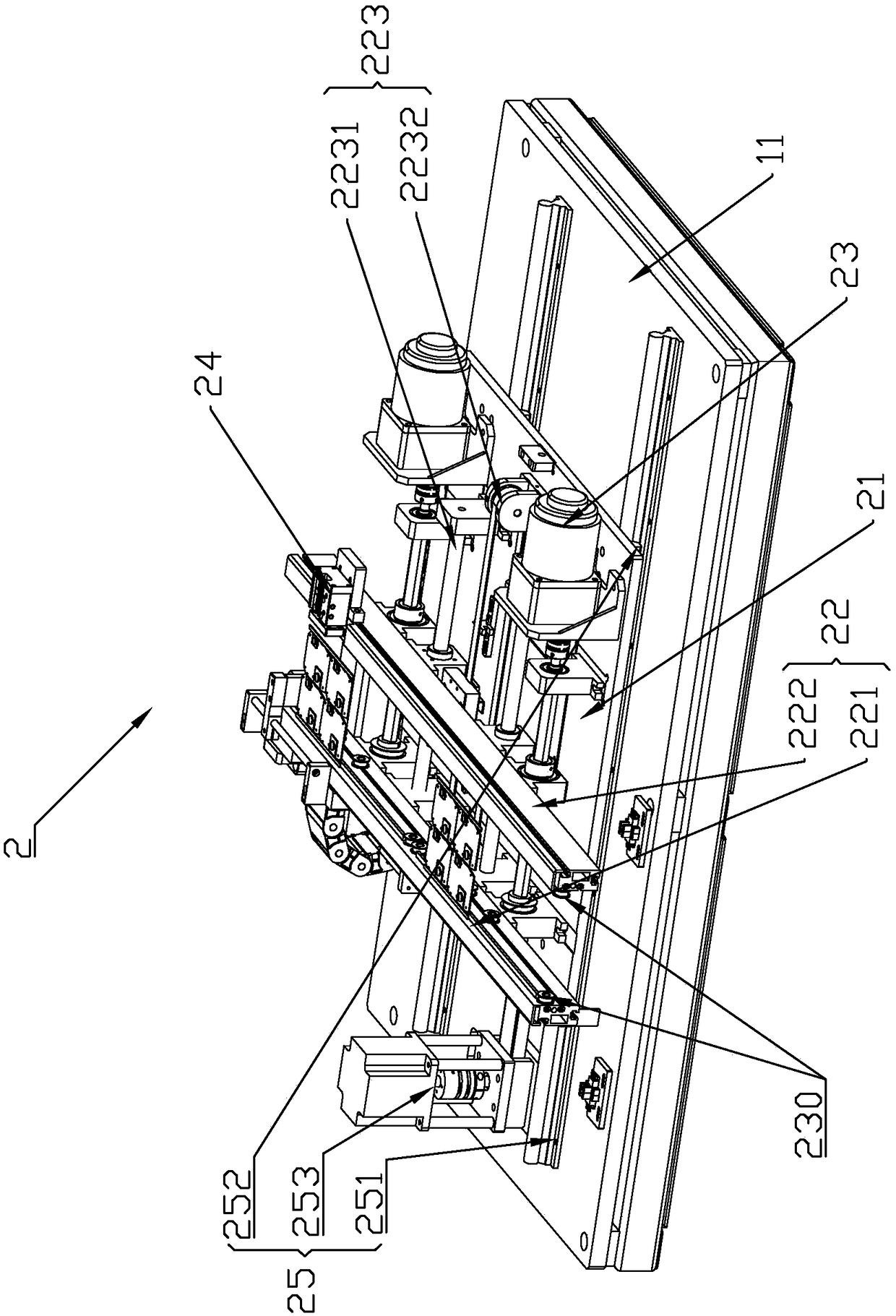

PCB splitter with cover plate

The invention discloses a PCB splitter with a cover plate. The PCB splitter comprises a feeding working station, a transfer working station and a board-splitting working station, the three of which are orderly arranged in a longitudinal direction. The feeding working station comprises a feeding track and a jig placement platform located beside the feeding track. The transfer working station is provided with a manipulator that comprises a suction nozzle for sucking PCB continuous sheets and a clamp for grabbing a jig; a support on which the cover plate is placed is arranged below the manipulator. The board-splitting working station comprises a longitudinal conveying track, X-direction, Y-direction and Z-direction driving mechanisms, and a milling cutter device mounted on the Z-direction driving mechanism. In actual operations, the manipulator conveys PCB continuous sheets on the feeding working station together with the jig to the longitudinal conveying track, and then the cover plate is pressed on the PCB continuous sheet. In such a manner, in a process when the PCB continuous sheets are partitioned by using a milling cutter, the PCB continuous sheets may not be warped, and therefore, a segmentation effect of the PCB continuous sheets is enhanced.

Owner:SUZHOU HEROIC AUTOMATION TECH

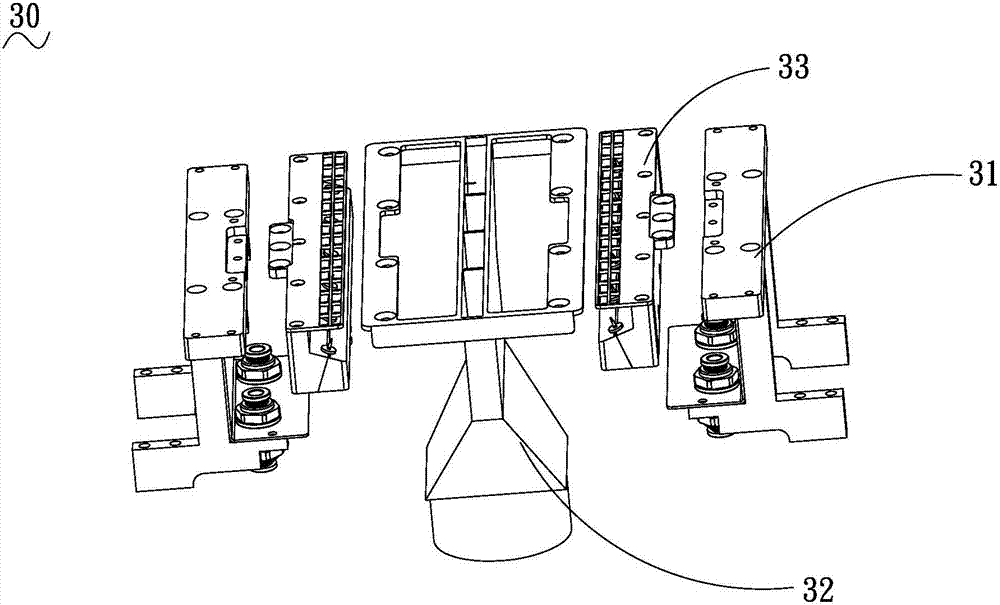

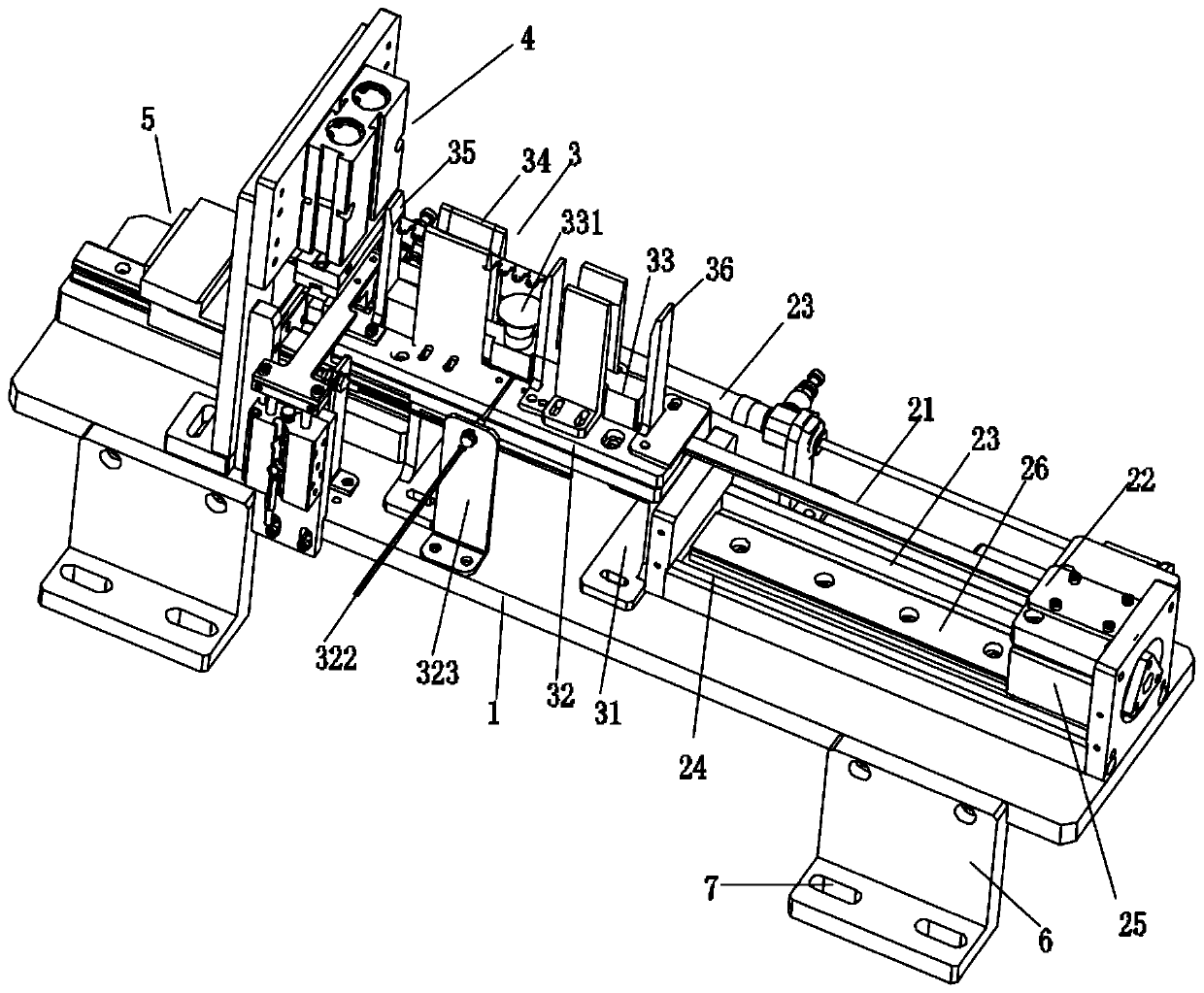

PCB splitting machine provided with device capable of adjusting distance between every two adjacent suction nozzles among plurality of suction nozzles

The invention discloses a PCB splitting machine provided with a device capable of adjusting the distance between every two adjacent suction nozzles among a plurality of suction nozzles. The PCB splitting machine comprises a feeding station, a transfer station, a board splitting station and a discharging station, which are longitudinally arranged in sequence. The feeding station comprises a feeding track and a jig placing platform positioned beside the feeding track. The transfer station is provided with a manipulator. The manipulator comprises a suction nozzle and a fixture. The suction nozzle is used for sucking PCB connecting plates. The fixture is used for grabbing a jig. The board splitting station comprises a longitudinal conveying track, an X-direction driving mechanism, a Y-direction driving mechanism, a Z-direction driving mechanism, and a milling cutter device mounted on the Z-direction driving mechanism. The discharging station is provided with a suction claw device for sucking cut PCBs; and the distance between two adjacent suction nozzles in the suction claw device can be adjusted. Through the technical scheme, the distance between two adjacent suction nozzles in a group of suction nozzles for sucking a plurality of PCBs from the jig synchronously can be adjusted, so as to facilitate cutting PCBs of various sizes by a processing device.

Owner:SUZHOU HEROIC AUTOMATION TECH

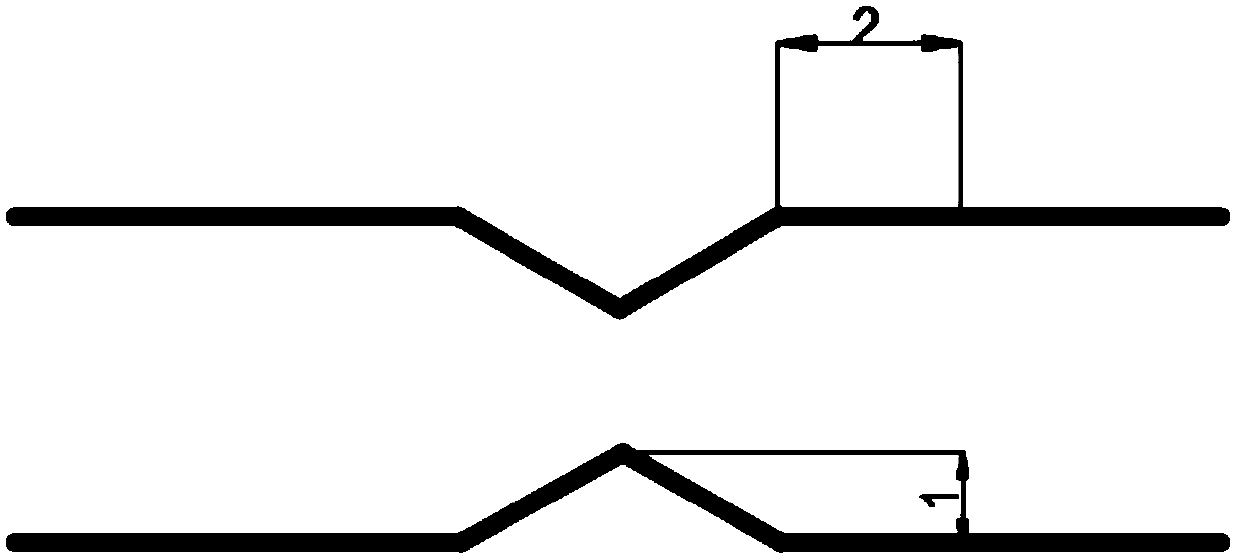

Array-type multi-makeup PCB splitting method

InactiveCN110324970AAdd V-CUT processSimple processInsulating layers/substrates workingDepanelingEngineering

The invention relates to the technical field of PCB splitting methods, and particularly discloses an array-type multi-makeup PCB splitting method. The method comprises the following steps: (1) removing stamp holes and connecting blocks, and reducing the distance between PCBs to 0.4 mm; (2) executing a pre-process; (3) performing CNC; (4) forming V-shaped grooves in the two faces of a designed PCBsub-board through a V-CUT knife, wherein the depth of the V-shaped grooves is 1 / 3 of the thickness of the whole PCB, and the angle of the V-CUT knife is 30 degrees; (5) performing a subsequent process, and then reserving safety belts (0.1 mm) at two sides of the V-shaped grooves to prevent the circuit from being damaged during board splitting. Compared with the prior art, the method has the advantages that residual boards after board splitting are reduced, other circuit boards are prevented from being scratched, the assembly efficiency is improved, the distance is reduced, and the board utilization rate is also improved, so that the method can reduce the PCB material cost while guaranteeing the customer quality requirements and reducing the customer cost.

Owner:GUANGDONG KINGSHINE ELECTRONICS TECH CO LTD

Board grabbing mechanism used for PCB board separating machine

ActiveCN106879176AHigh degree of automationImprove efficiencyInsulating layers/substrates workingDepanelingEngineering

The invention discloses a board grabbing mechanism used for a PCB board separating machine. The board grabbing mechanism comprises a grabbing rack, wherein vertical supporting plates are fixed on two sides of the bottom surface of the upper top plate of the grabbing rack; two ends of a drive screw are articulated onto the two vertical supporting plates; two ends of a guide rod are articulated onto the two vertical supporting plates; a grabbing connecting block is in screw joint into the drive screw; the guide rod sleeves the grabbing connecting block; a grabbing cylinder rack is fixed at the middle part of the bottom surface of the grabbing connecting block; a grabbing cylinder is fixed on the grabbing cylinder rack; a push rod of the grabbing cylinder passes through a base plate of the grabbing cylinder rack, and an upper connecting plate is fixed on the push rod of the grabbing cylinder; a plurality of vertical guide rods are fixed on the top surface side of the upper connecting plate; and the vertical guide rods sleeve guide blocks fixed on two sides of the base plate of the grabbing cylinder rack. According to the board grabbing mechanism, material boards can be grabbed automatically, and upper pressing boards can be loaded and installed, so that the mechanism is high in degree of automation, high in efficiency and good in effect.

Owner:惠州市雅信达电路科技有限公司

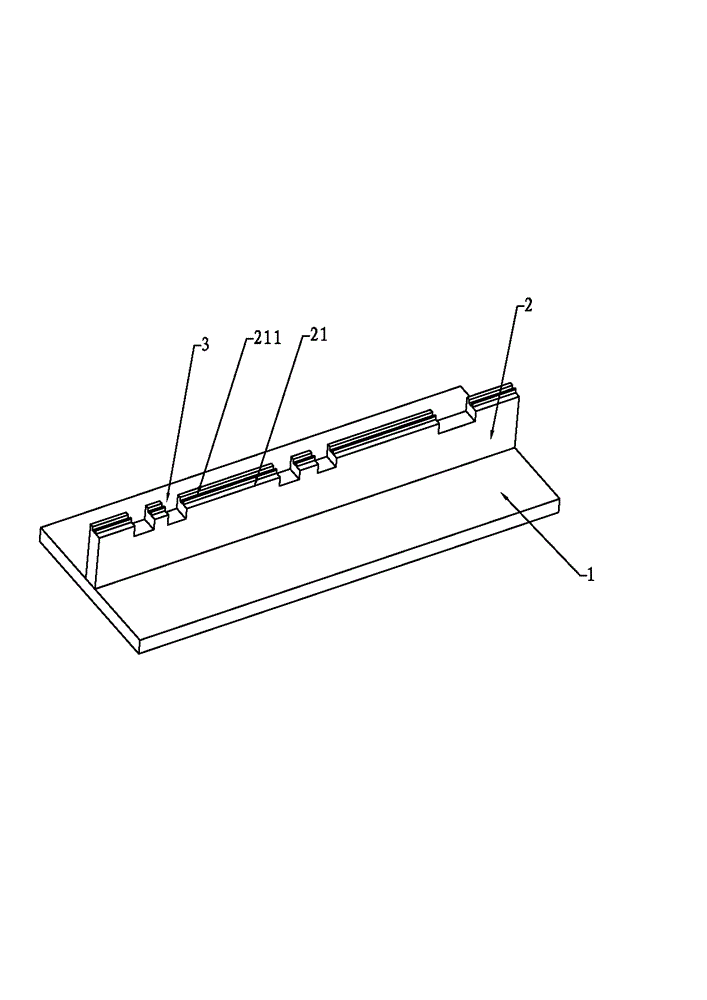

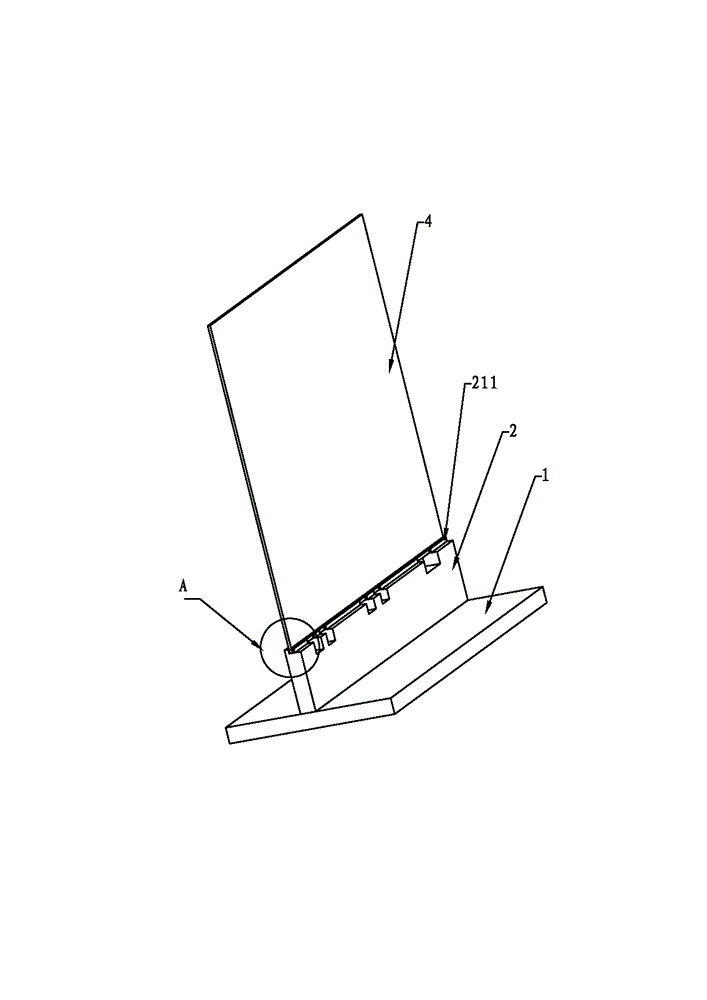

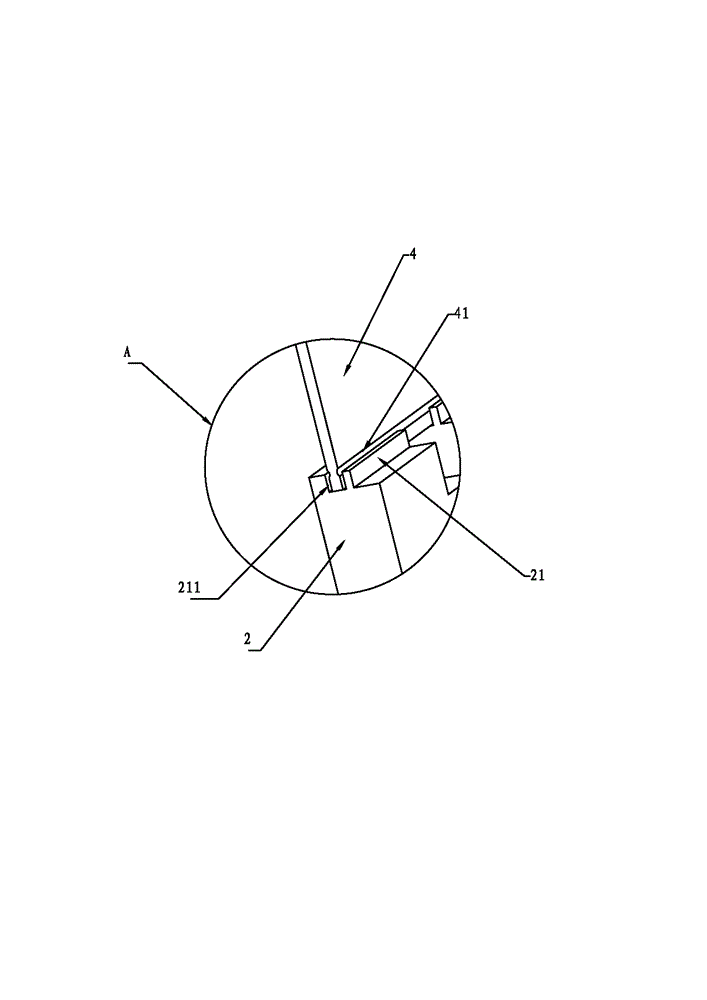

PCB (printed circuit board) divider

The invention relates to the technical field of cutting of a PCB(printed circuit board), and in particular relates to a PCB divider, wherein the PCB divider structurally comprises a base and a cutting board vertically arranged on the base; at least two convex blocks are arranged on the top part of the cutting board by extending upwards; grooves are formed among the adjacent convex blocks; cutting grooves for containing the PCB are formed in the convex blocks; each cutting groove is arranged along the same line, and the width of the opening part of each cutting groove is matched with the thickness of the PCB. Compared with the prior art, the PCB divider is simple in structure, is convenient to operate, improves the production efficiency obviously, and also prevents the damage to circuits and electronic elements on the PCB, which is caused by machine cutting.

Owner:DONGGUAN LONGJOIN ELECTRONICS

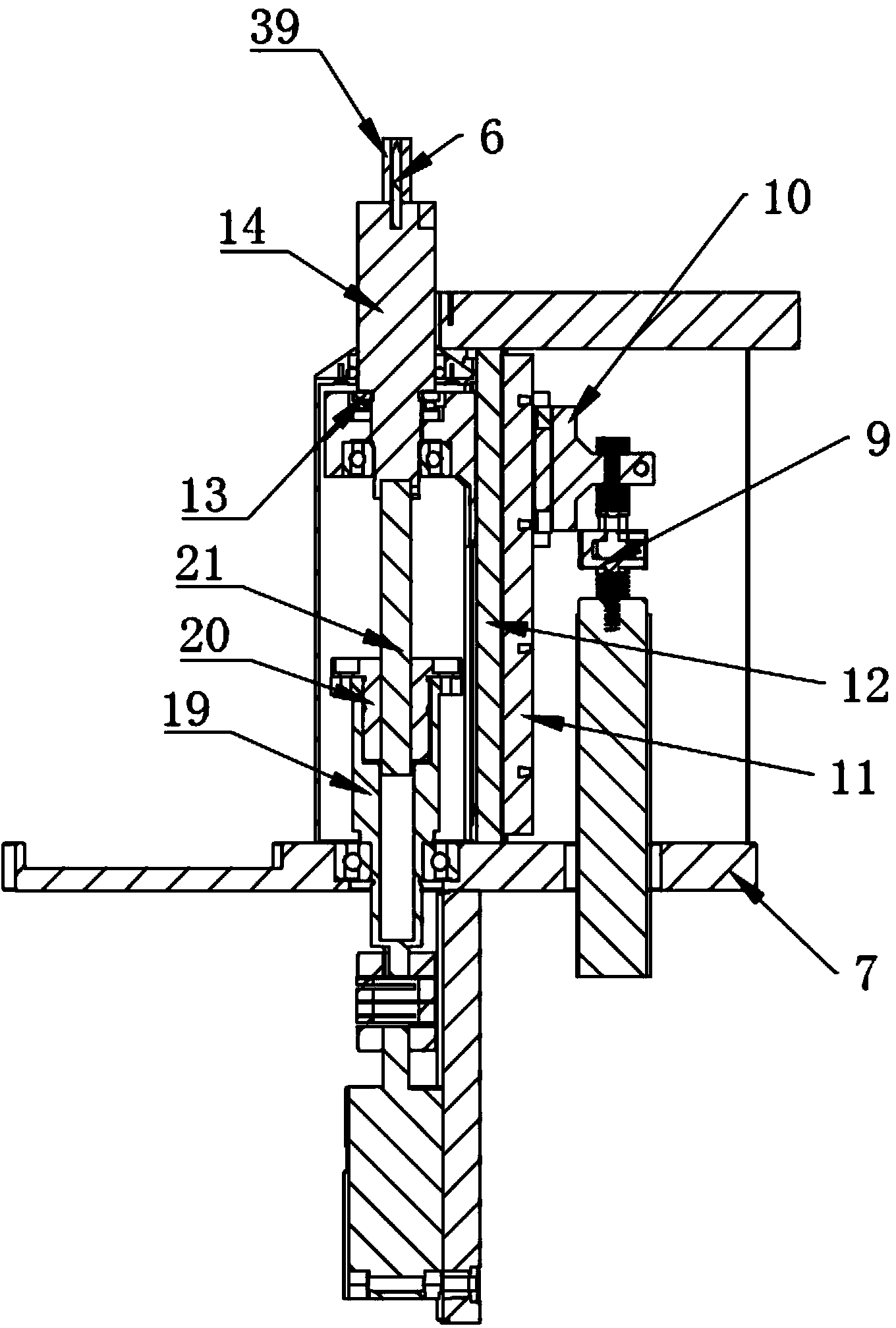

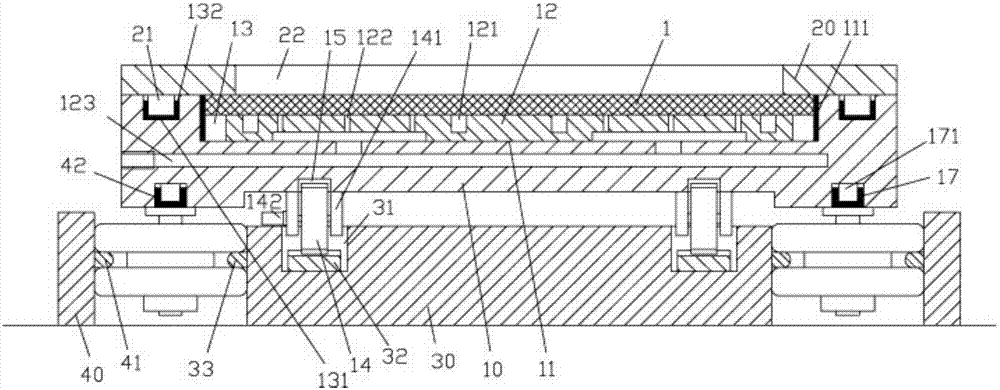

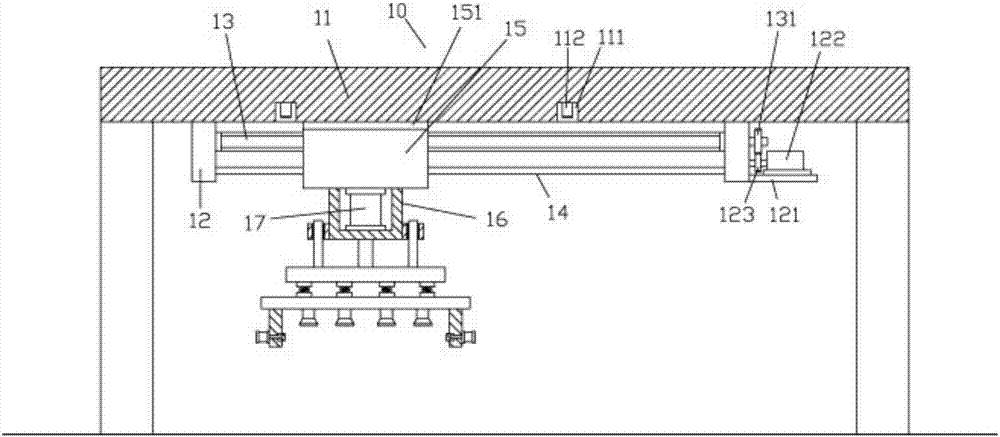

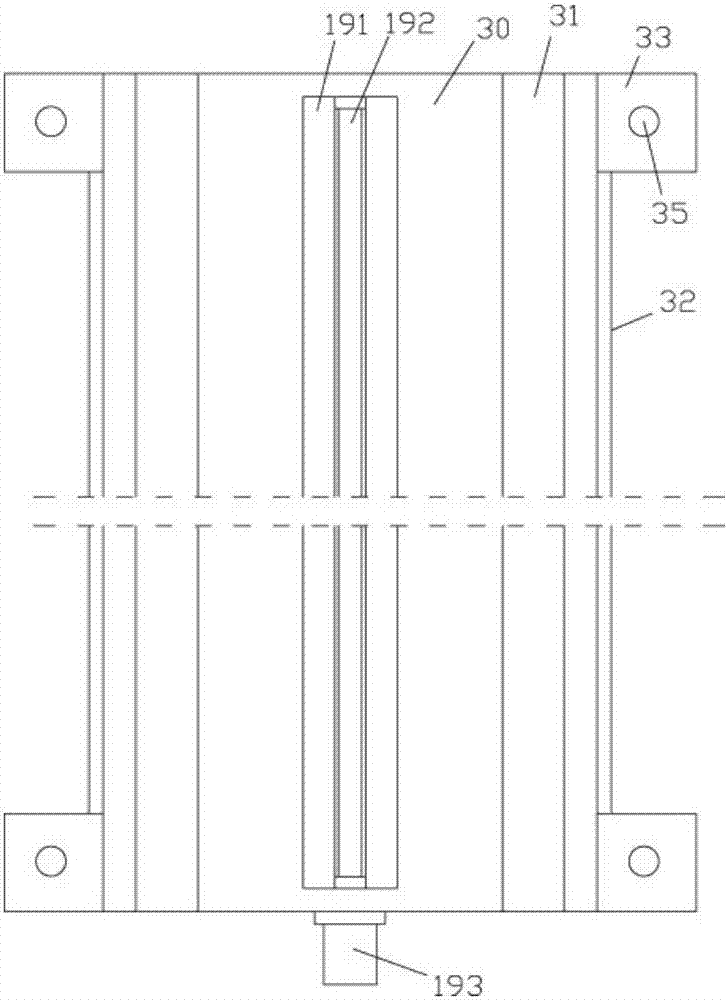

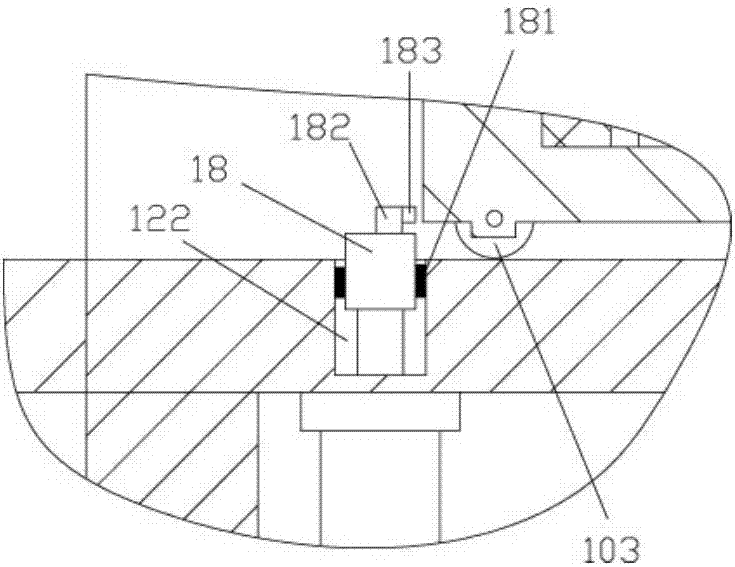

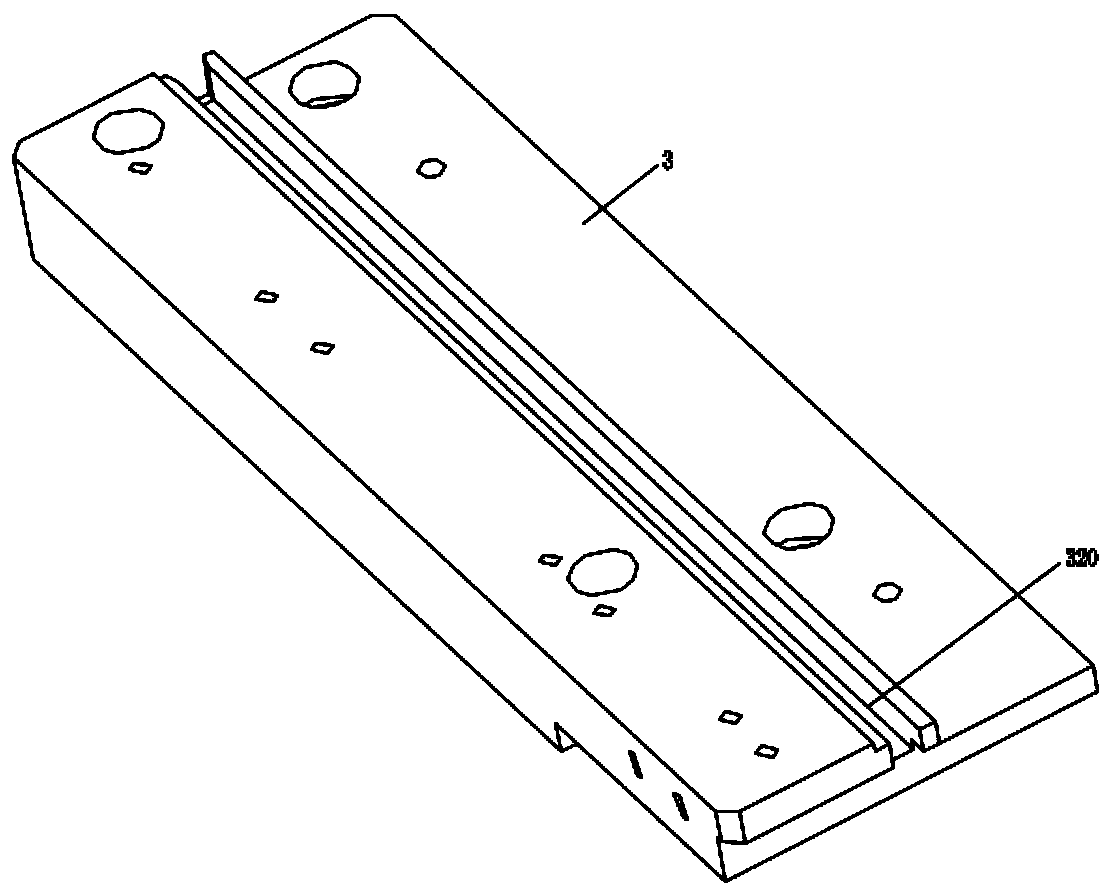

PCB body automatic fixing and moving mechanism for PCB depaneling machine

ActiveCN106973504ARealize automatic handlingEasy to fixInsulating layers/substrates workingDepanelingDrive motor

The invention discloses a PCB body automatic fixing and moving mechanism for a PCB depaneling machine. The PCB body automatic fixing and moving mechanism comprises a lower mold and a lower main guiding block, two sides of the top face of the lower main guiding block are provided with bar-shaped guiding grooves, wear-resisting blocks are fixed on the bottom face and two sides of the guiding block, the wear-resisting blocks press against corresponding inner sidewalls or bottom faces of the bar-shaped guiding grooves a movement guiding block is fixed on the central part of the bottom face of the lower mold, the movement guiding block is inserted into a movement guiding groove in the central part of the top face of the lower main guiding block, an adjusting screw is inserted into the movement guiding groove, two ends of the adjusting screw are hinged to the wall surfaces of the front and rear ends of the movement guiding groove, and a driving motor is fixed on the front end face of the lower main guiding block. The PCB body automatic fixing and moving mechanism can automatically fix and move the PCB body, automatic carrying is achieved, the PCB body automatic fixing and moving mechanism is firm in fixation and convenient to assemble and disassemble, manual assembly and disassembly of the mold are not needed, and the labor quantity is greatly reduced.

Owner:安徽邮谷快递智能科技有限公司

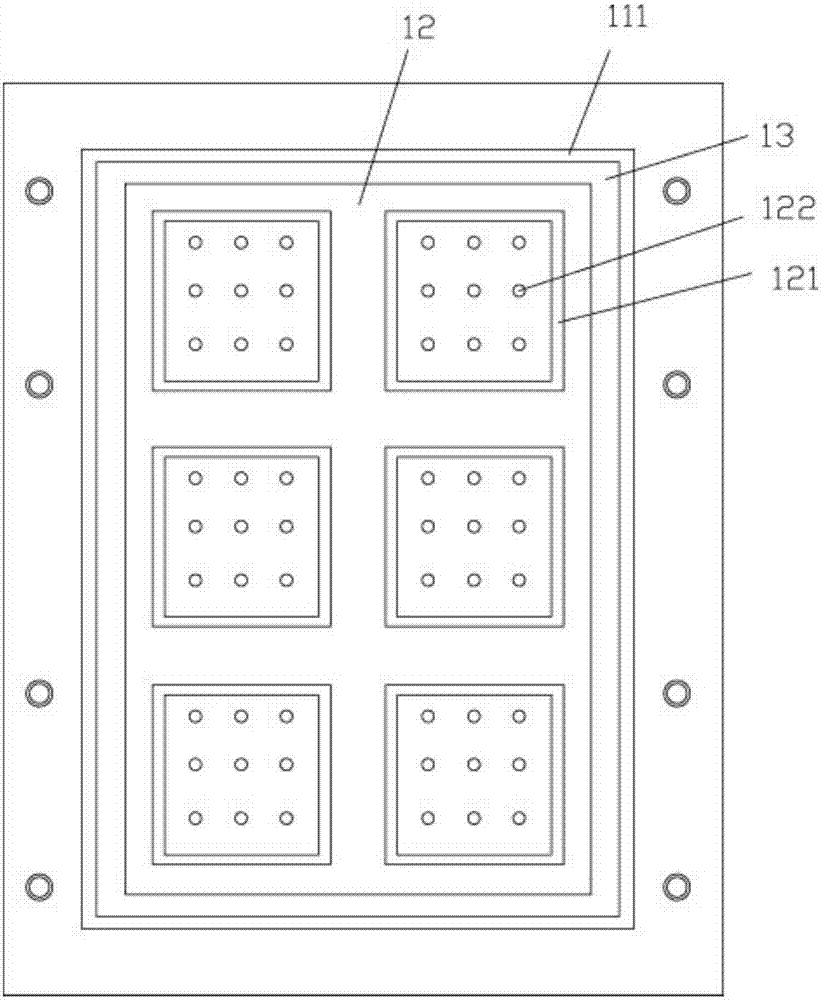

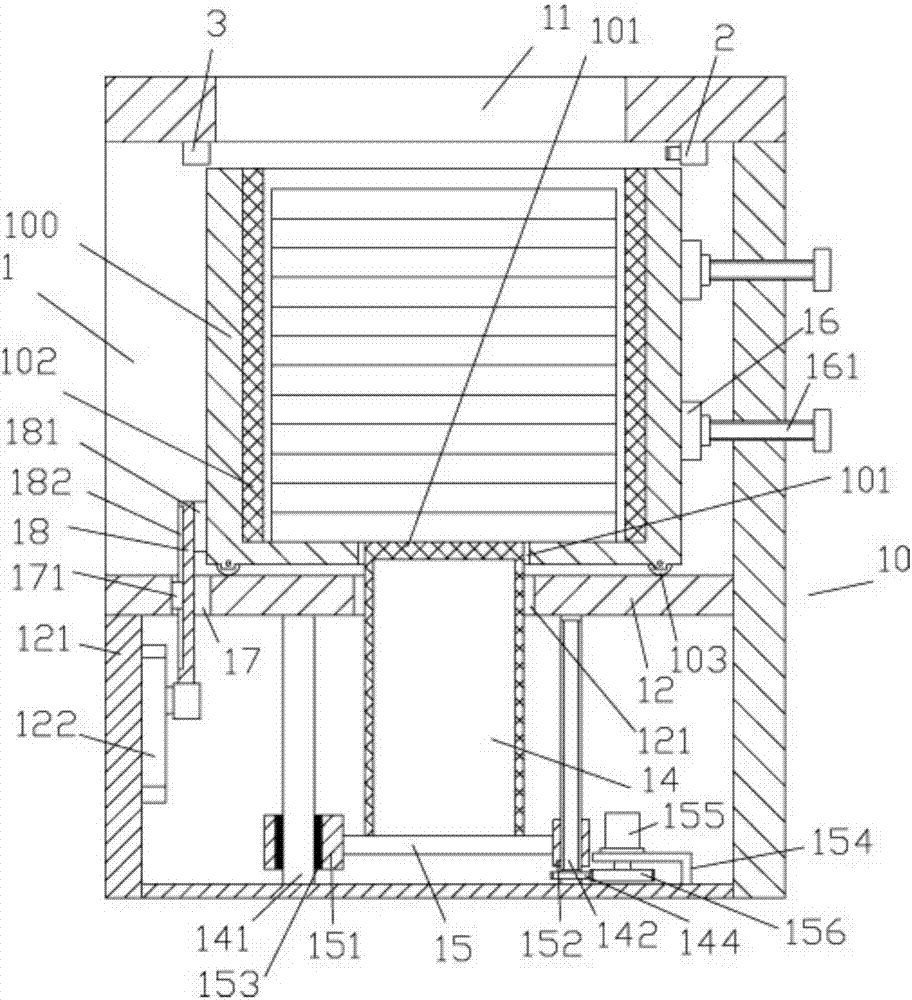

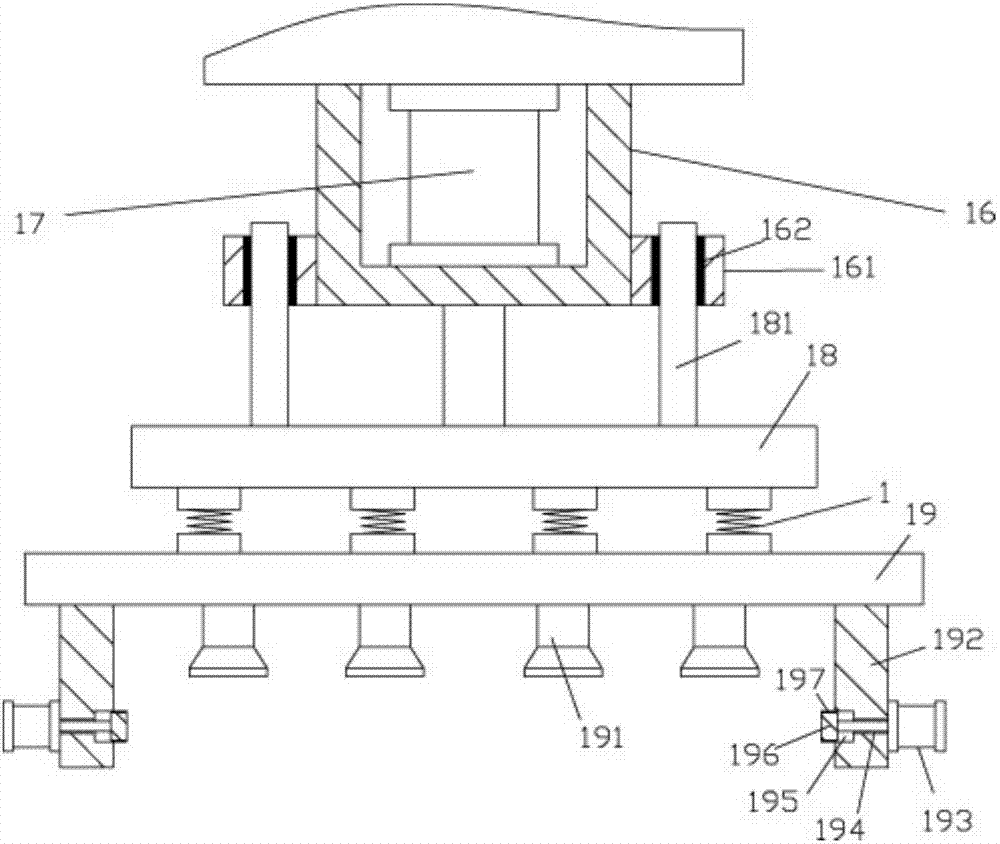

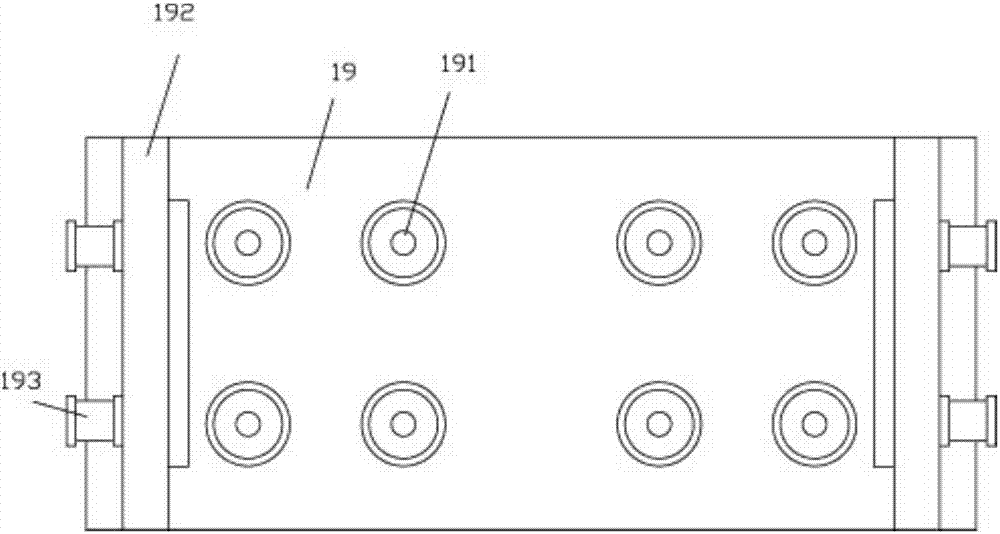

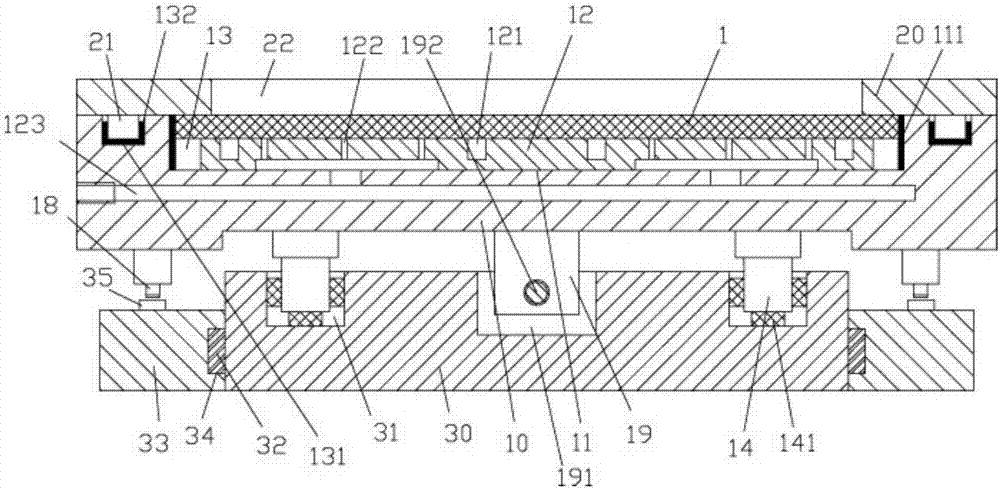

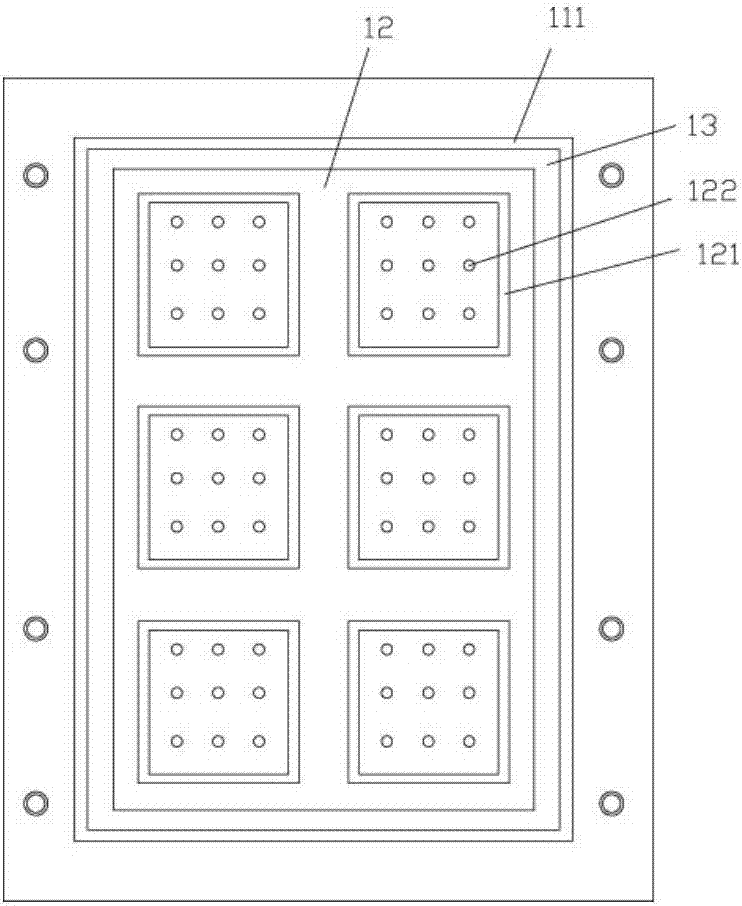

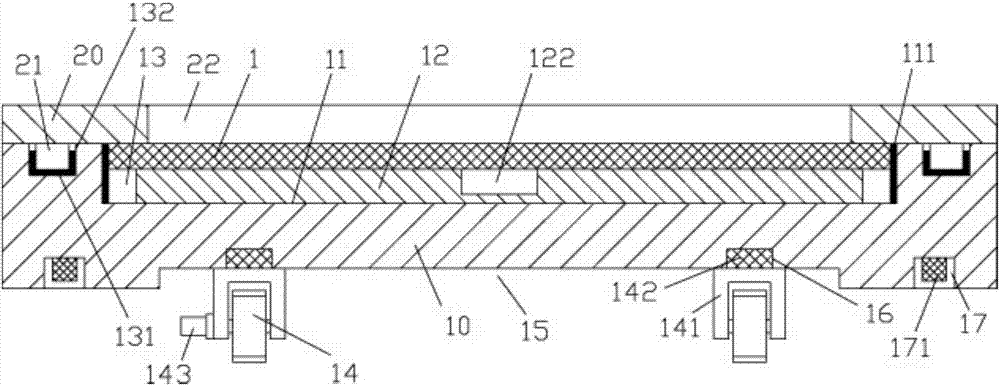

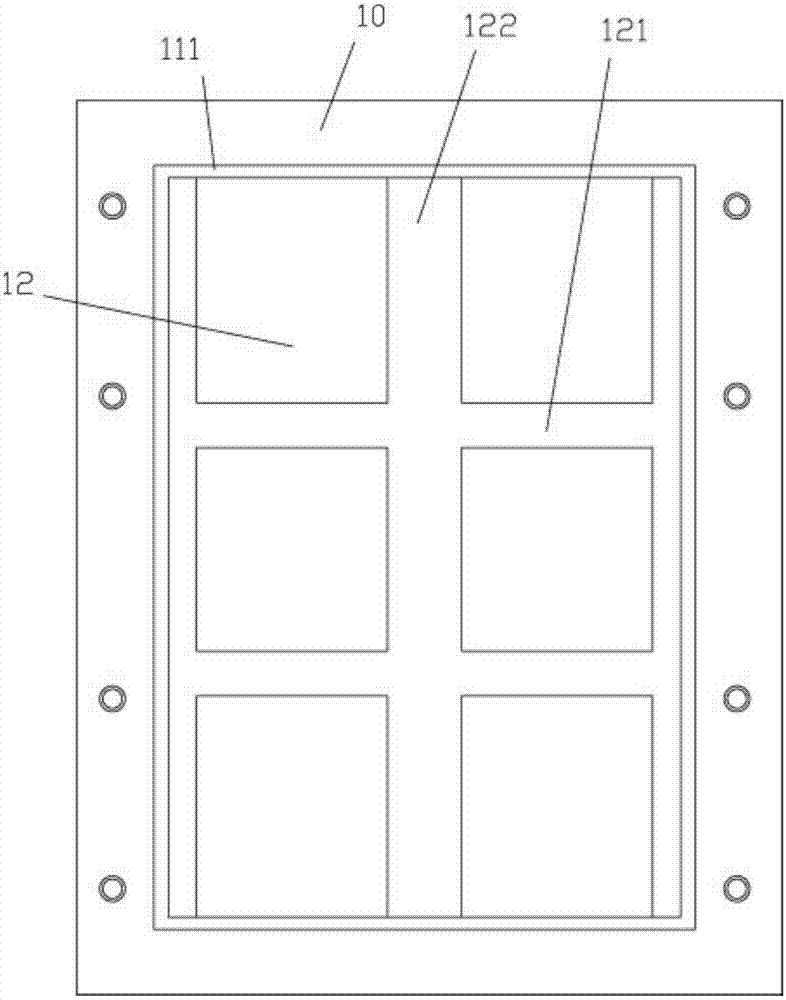

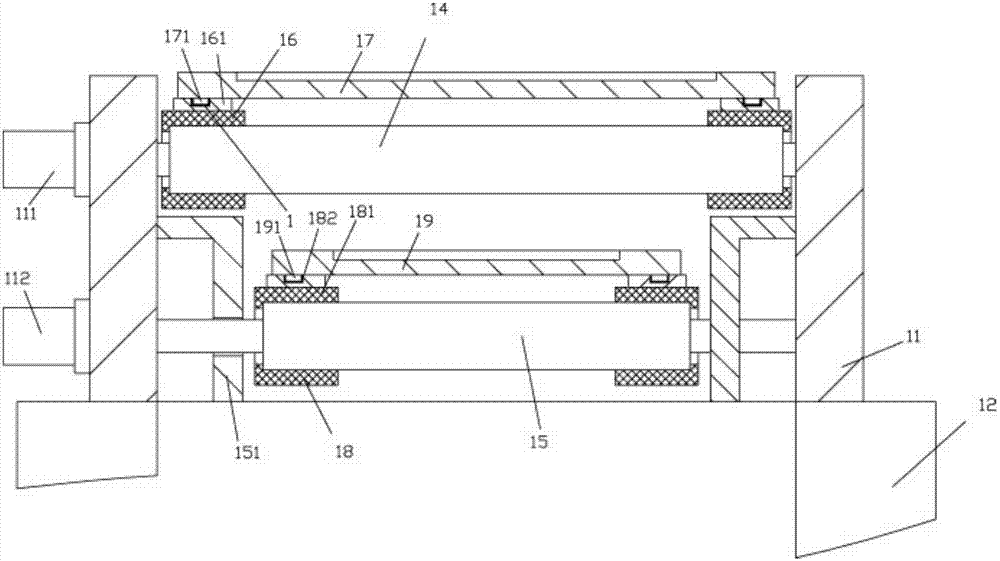

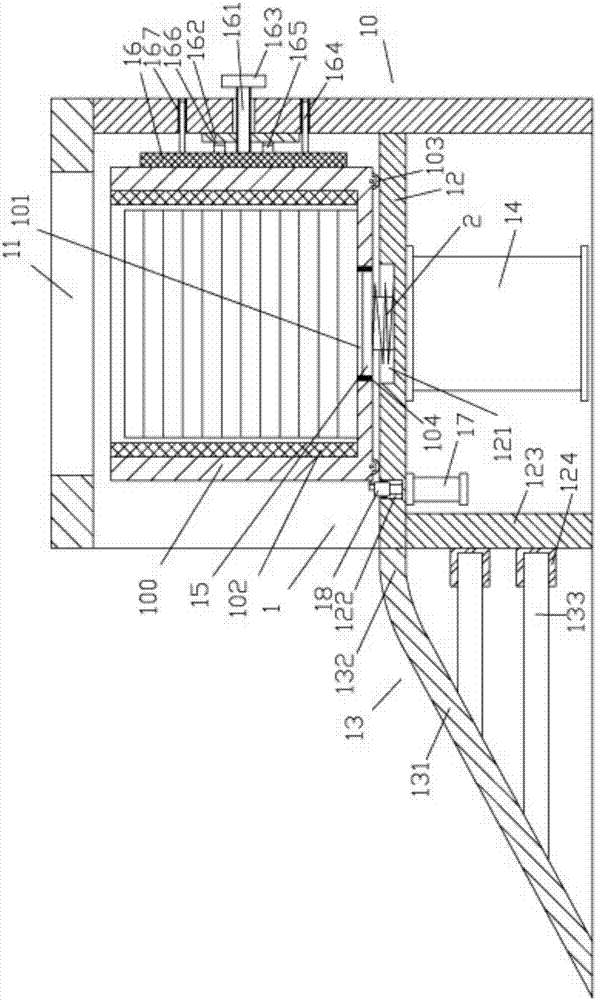

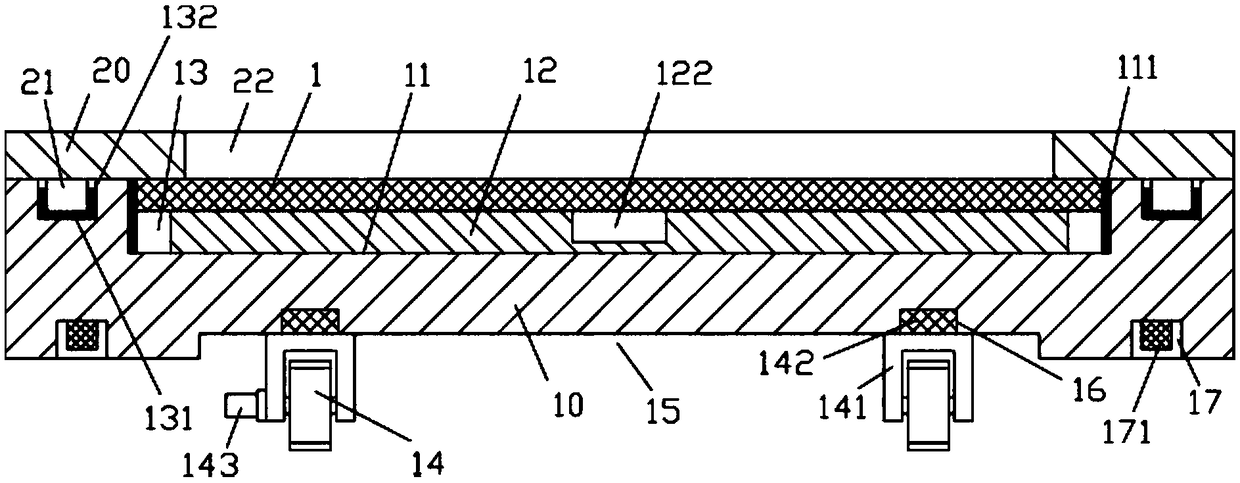

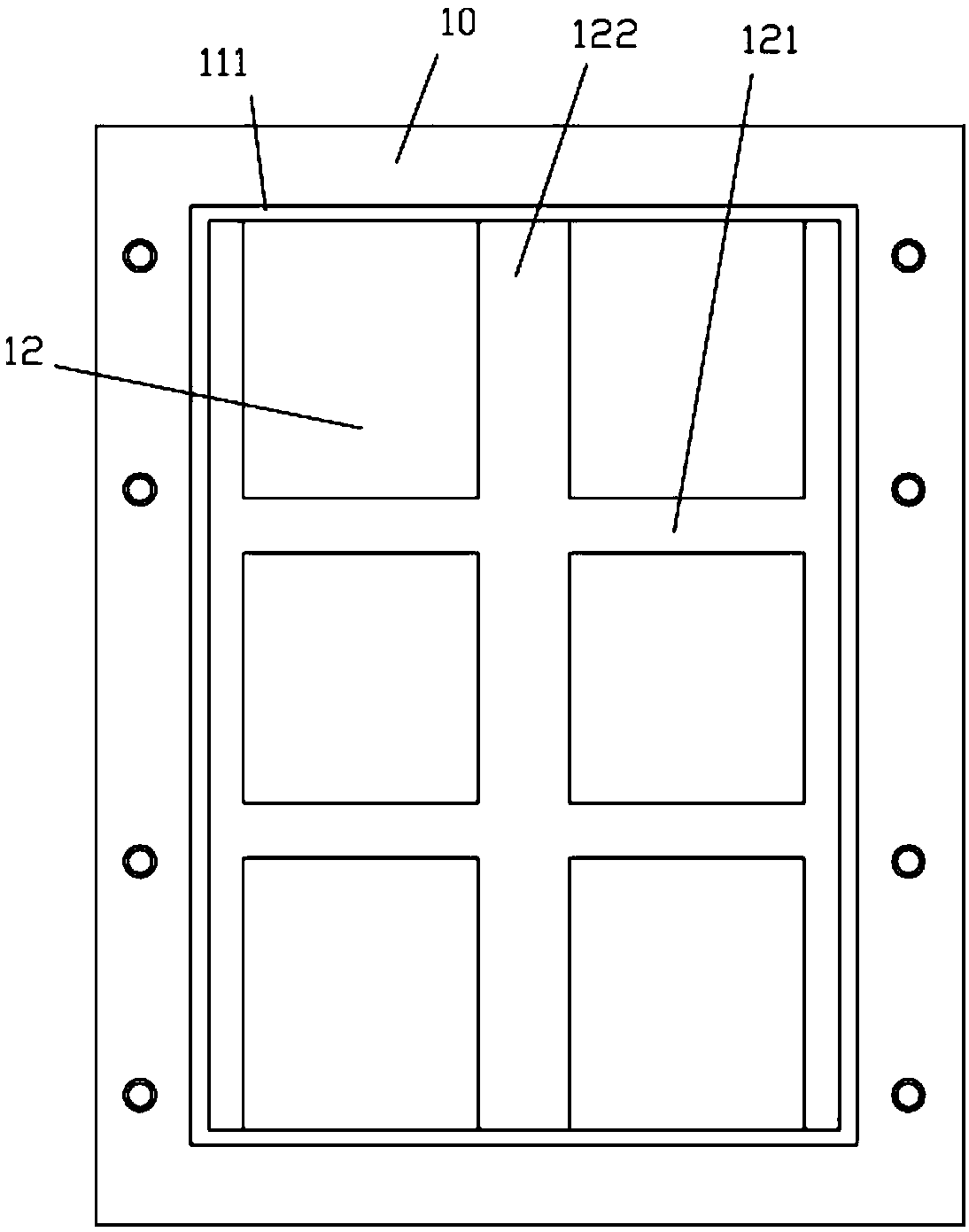

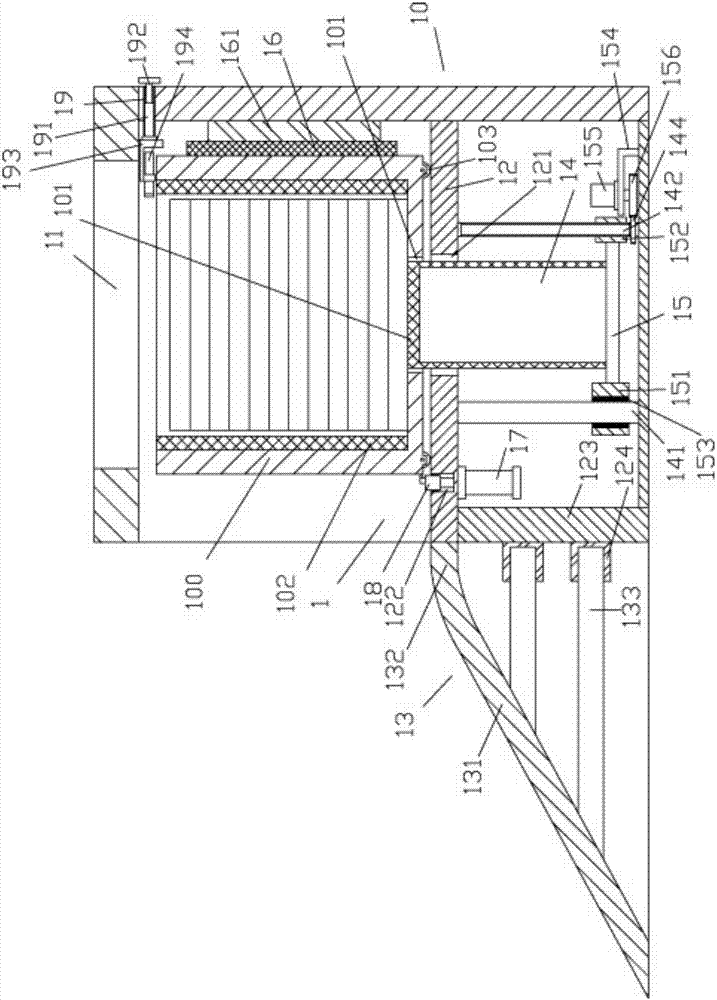

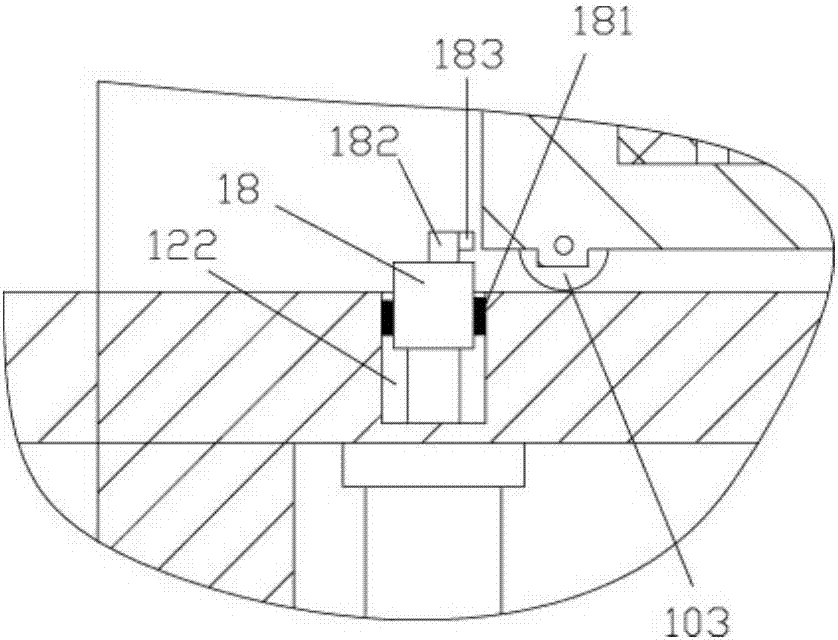

PCB body fixing mold device for PCB depaneling machine

ActiveCN106973503AEasy to fixEasy to install and disassembleInsulating layers/substrates workingDepanelingTransverse groove

The invention discloses a PCB body fixing mold device for a PCB depaneling machine. The PCB body fixing mold device comprises a lower mold, a placing groove is arranged in the central part of the top face of the lower mold, the bottom face of the placing groove is provided with a mounting convex plate, an empty slot is arranged between the mounting convex plate and the inner sidewall of the placing groove, the central part of the mounting convex plate is provided with a plurality of transverse grooves which are parallel to one another and a vertical groove, and the transverse grooves and the vertical groove uniformly divide the mounting convex plate into a plurality of convex parts; the top side of the lower mold is provided with a plurality of positioning concave holes, an upper pressing plate presses against the top face of the lower mold, the bottom side of the upper pressing plate is provided with convex columns, the convex columns are inserted into corresponding positioning concave holes, the central part of the upper pressing plate is provided with a main through groove, and the PCB body is inserted into the placing groove and is clamped between the upper pressing plate and the mounting convex plate. The PCB body fixing mold device can automatically fix the PCB body, and is firm in fixation and convenient to install and dismount.

Owner:苏州淏源精密科技有限公司

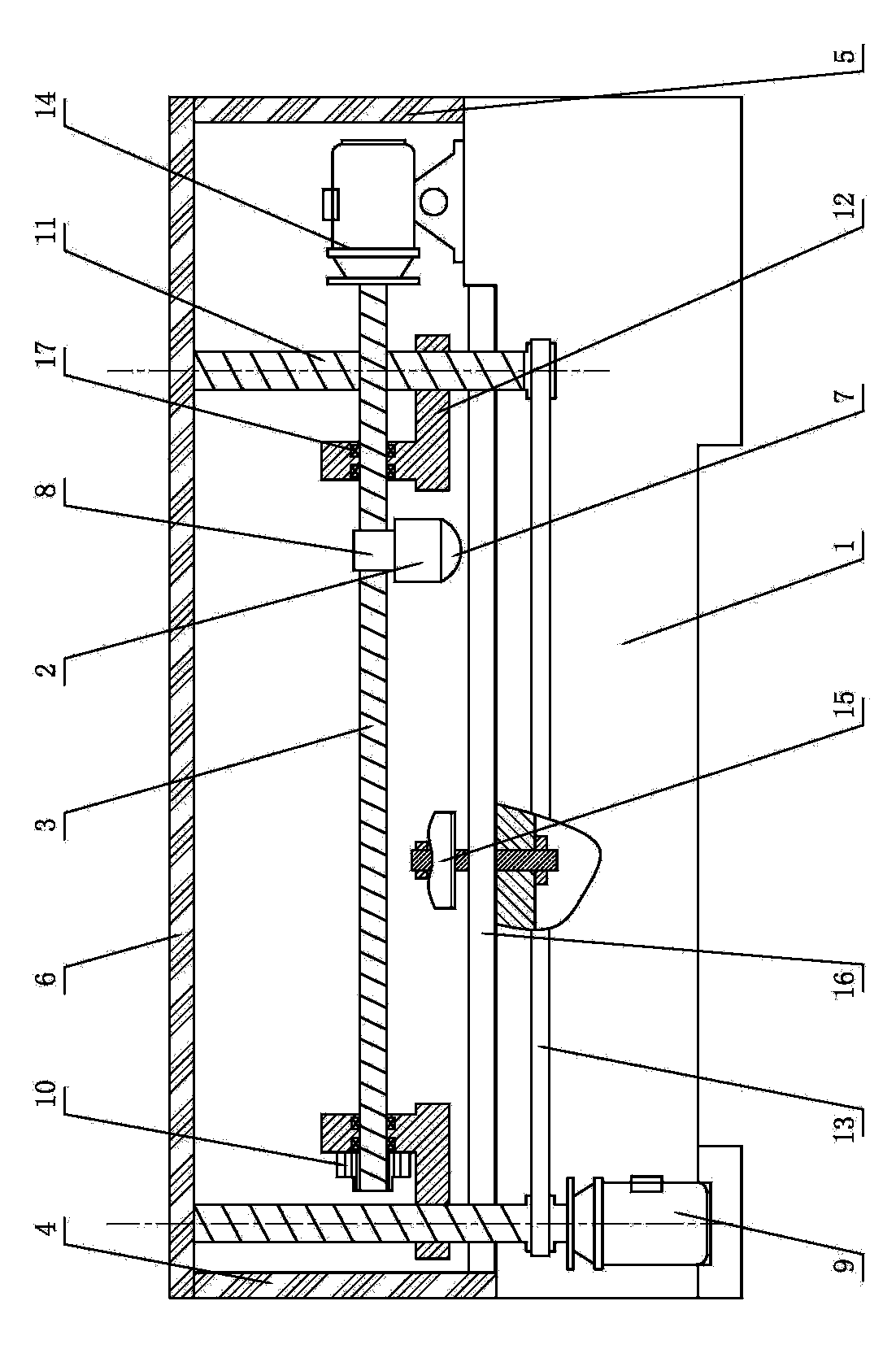

Automatic lifting and conveying mechanism for PCB distribution conveying box

ActiveCN106865189ANo need for manual handlingImprove efficiencyConveyorsConveyor partsDepanelingEngineering

The invention discloses an automatic lifting and conveying mechanism for a PCB distribution conveying box. The automatic lifting and conveying mechanism comprises a lifting machine frame. Running guide plates are fixed to the front side and the rear side of a top plate of the lifting machine frame, a vertical support plate is fixed to the top surface of the right end of the top plate of the lifting machine frame, and a vertical guide groove is formed in the left wall of the vertical support plate. A vertical lifting through groove is formed in the portion, located on the left side of the vertical support plate, of the top plate of the lifting machine frame, and a lifting plate is inserted in the vertical lifting through groove in a sleeved mode. A lower support plate is arranged below the top plate of the lifting machine frame, a lifting cylinder is fixed to the bottom surface of the lower support plate, and a push rod of the lifting cylinder penetrates through a guide through hole formed in the lower support plate and is fixed to the middle portion of the bottom surface of the lifting plate. Main support plates are fixed to the top surfaces of the two running guide plates on the left of the vertical lifting through groove, and push cylinders are fixed to the left walls of the upper portions of the main support plates. The automatic lifting and conveying mechanism for the PCB distribution conveying box is capable of lifting the conveying box of a PCB distribution device automatically and pushing out the conveying box without manual transferring, high in efficiency and high in automation degree.

Owner:龙南骏亚精密电路有限公司

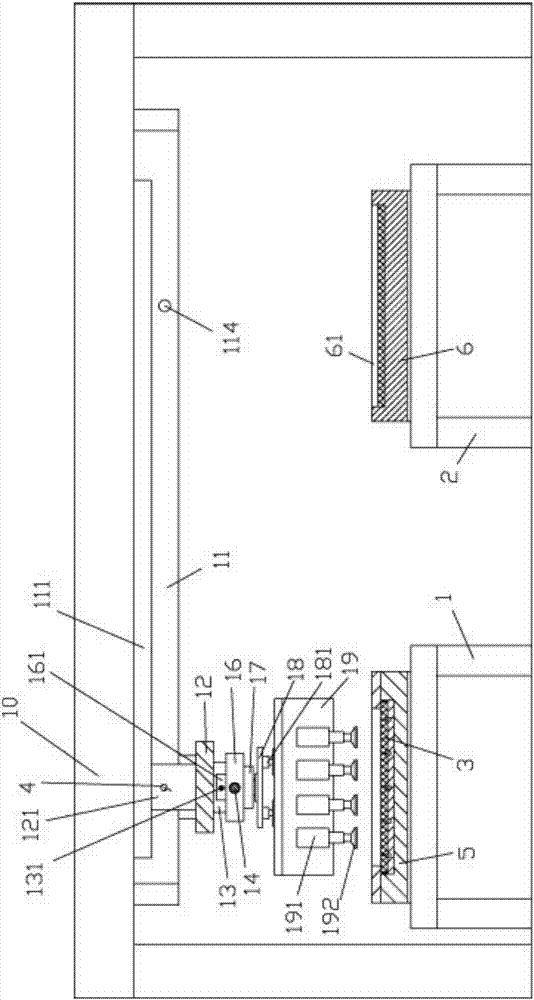

Up-down dust suction device of PCB distributor

The invention relates to an up-down dust suction device of a PCB distributor. The up-down dust suction device of the PCB distributor comprises an upper dust suction assembly and a lower dust suction assembly. The upper dust suction assembly comprises a base, a machining unit and an upper dust suction unit, wherein the machining unit and the upper dust suction unit are connected to the base; the machining unit comprises a driver connected to the base, a sliding base slidably connected to the base and connected with the driver, a spindle installed on the sliding base, and a milling cutter installed on the spindle; the upper dust suction unit comprises a driving piece connected to the base, a sliding plate slidably connected to the base and connected with the driving piece, and an upper dust suction cylinder installed on the sliding plate; and the upper dust suction cylinder is arranged on the spindle in a sleeving mode, and the center axis of the upper dust suction cylinder coincides with the center axis of the milling cutter. The lower dust suction assembly comprises a mounting plate and a dust suction trough connected to the mounting plate. The dust suction trough is arranged towards the upper dust suction cylinder. The up-down dust suction device of the PCB distributor achieves wrapping type dust suction operation and direct drawing type dust suction operation during distribution of PCBs, the dust removal rate is improved, and dust is prevented from being leaked out.

Owner:SHENZHEN ZOWEE TECH

PCB separating and conveying frame grabbing mechanism

InactiveCN106927249AFacilitate subsequent processingNo need for manual handlingConveyorsConveyor partsDepanelingEngineering

The invention discloses a PCB separating and conveying frame grabbing mechanism which comprises a frame body. The frame body comprises two side boards. Supporting legs are fixed to the bottoms of the side boards. Multiple transverse beams are located at the two ends of the two side boards. The two ends of each transverse beam are fixed to the inner side walls of the two side boards. Two upper conveying belts are arranged on the upper portion of the position between the two side boards, and two lower conveying belts are arranged on the lower portion of the position between the two side boards. An upper placement board is located on the two upper conveying belts, and a lower placement board is located on the two lower conveying belts. An upper grabbing connecting frame is fixed to the upper portions of the right ends of the two side boards, a conveying board is fixed to the bottom face of a top board of the upper grabbing connecting frame, and conveying supporting boards are fixed to the bottom faces of the two ends of the conveying board. The PCB separating and conveying frame grabbing mechanism is provided with the upper placement board and the lower placement board, and therefore separated PCBs of different specifications can be contained, then automatically conveyed and grabbed and carried to subsequent machining stations; subsequent machining is facilitated; manual carrying is not needed; machining continuity is improved; and the automation degree is high.

Owner:徐州对河建材有限公司

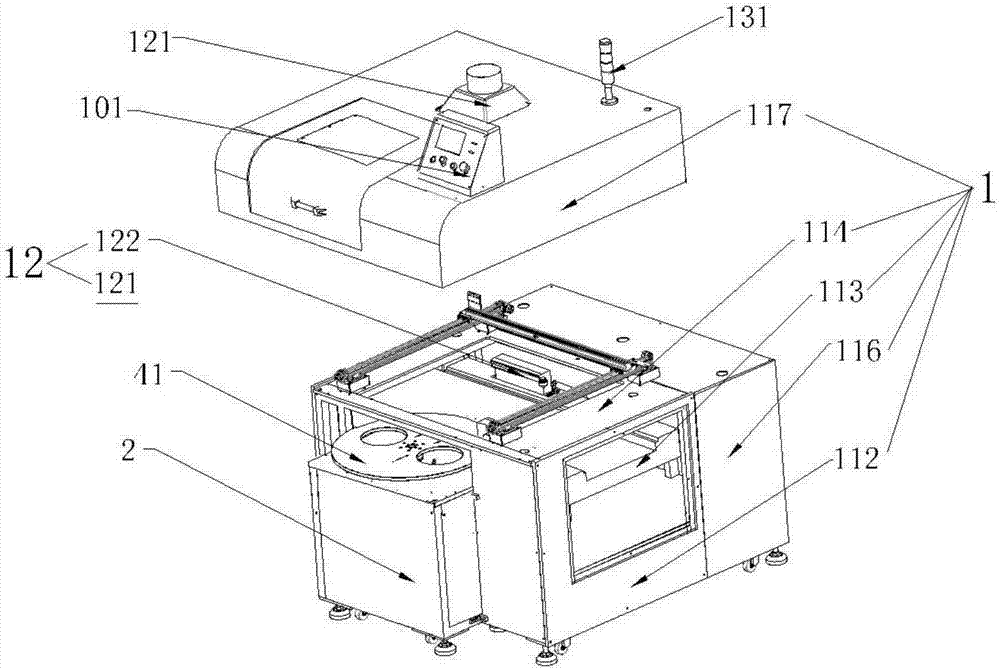

Automatic board material lifting mechanism for PCB distributor

ActiveCN106865221AEasy accessEasy to grabPrinted circuit manufactureConveyor partsDepanelingEngineering

The invention discloses an automatic board material lifting mechanism for a PCB distributor. The automatic board material lifting mechanism comprises a feeding rack; a discharging through hole is formed in the middle of a top plate of the feeding rack; a supporting plate is fixedly arranged in the middle of the feeding rack; an inclined feeding box conveying rack is arranged at the left side of the supporting plate; a pushing hole is formed in the left side between the supporting plate and the top plate of the feeding rack; a lifting cylinder is fixedly arranged in the middle of the bottom surface of the supporting plate; a push rod of the lifting cylinder penetrates through the supporting plate and is fixedly provided with a pushing plate; a feeding box is located on the top surface of the supporting plate; the pushing plate is inserted and sleeved in a pushing through hole formed in the middle of the bottom surface of the feeding box; a side plate located above the right side of the supporting plate is provided with a limiting plate pressing and leaning against the wall surface at the right side of the feeding box; and the front or rear wall surface of the feeding box is close to a front or rear wall plate of the feeding rack. The feeding box can be placed on the supporting plate, and material boards can be automatically lifted by an air cylinder so as to be conveniently manually or mechanically taken or grabbed; and the automatic board material lifting mechanism is high in efficiency and good in effect.

Owner:江门市勤智电路有限公司

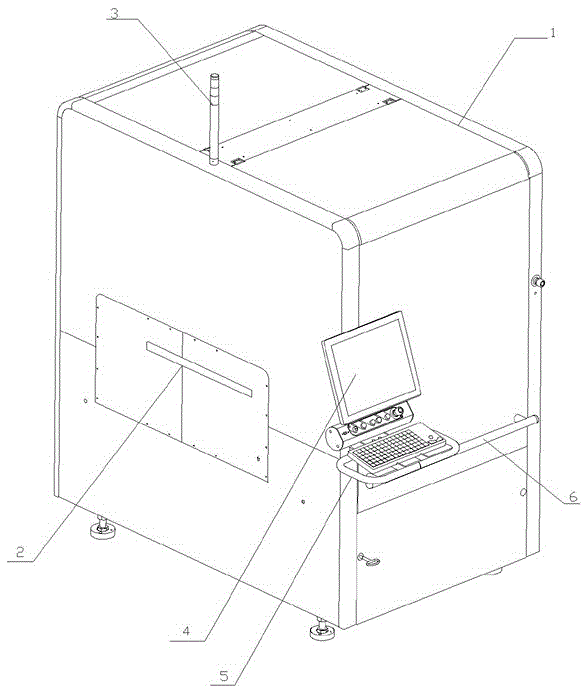

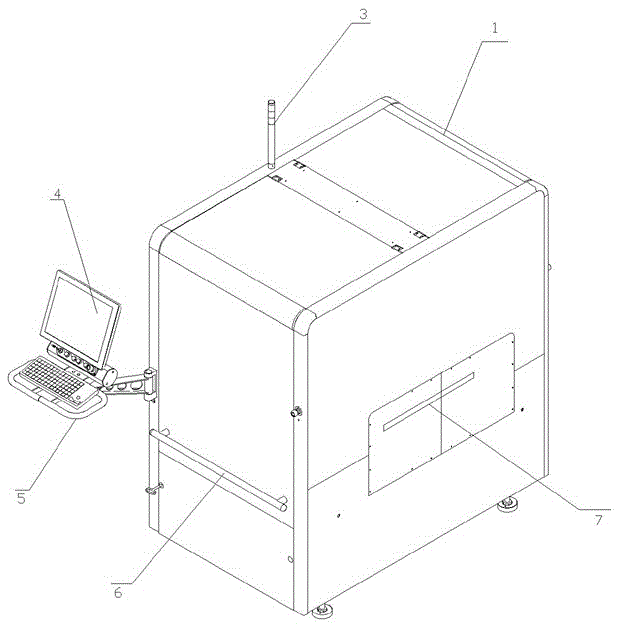

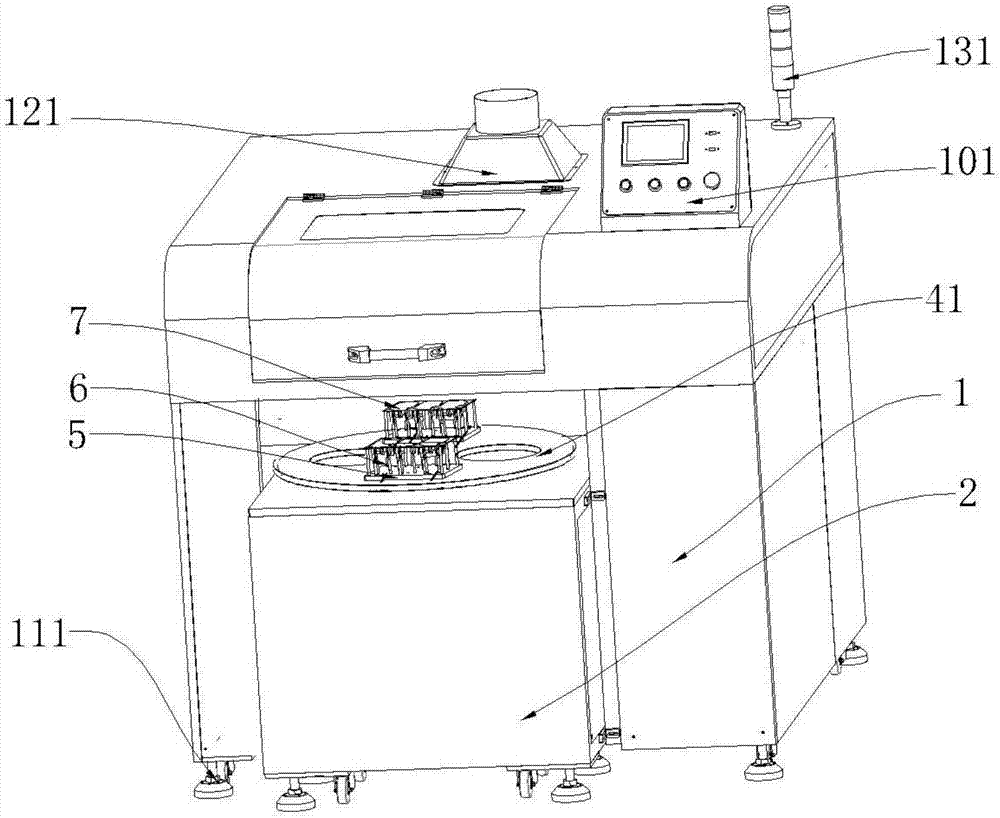

Turntable laser pcb separating machine and method

PendingCN107999973AQuality is not affected in any wayEasy to fixInsulating layers/substrates workingLaser beam welding apparatusDepanelingEngineering

The invention provides a turntable laser pcb separating machine and method. The turntable laser pcb separating machine is provided with a cabinet body. The cabinet body comprises a pcb separating machine cabinet and a material conveying cabinet. An electric control assembly, a cooling assembly and a laser assembly are arranged inside the pcb separating machine cabinet. The material conveying cabinet is provided with a conveying assembly. The electric control assembly controls the cooling assembly, the laser assembly and the conveying assembly. The conveying assembly comprises a turntable arranged above the material conveying cabinet and an induction motor arranged inside the material conveying cabinet. The turntable and the induction motor are connected through a rotating pillar. The induction motor drives the turntable so as to drive a jig to rotate to the position below the laser assembly, and the laser assembly is used for cutting pcbs. The jig is provided with positioning pillars used for placing the pcbs. The induction motor drives the turntable so as to drive the jig to rotate by 180 degrees after cutting is completed, and the cut pcbs are output. According to the turntable laser pcb separating machine and method, the turntable is used for conveying the pcbs, the structure is simple and stable, and contactless pcb separating in laser separating is realized. Moreover, theautomatic pcb separating process is achieved, the labor intensity is relieved and production efficiency is improved.

Owner:SHENZHEN BEYOND LASER TECH CO LTD

A pcb plate body fixing mold device for pcb board splitting machine

ActiveCN106973503BEasy to fixEasy to install and disassembleInsulating layers/substrates workingTransverse grooveDepaneling

The invention discloses a PCB body fixing mold device for a PCB depaneling machine. The PCB body fixing mold device comprises a lower mold, a placing groove is arranged in the central part of the top face of the lower mold, the bottom face of the placing groove is provided with a mounting convex plate, an empty slot is arranged between the mounting convex plate and the inner sidewall of the placing groove, the central part of the mounting convex plate is provided with a plurality of transverse grooves which are parallel to one another and a vertical groove, and the transverse grooves and the vertical groove uniformly divide the mounting convex plate into a plurality of convex parts; the top side of the lower mold is provided with a plurality of positioning concave holes, an upper pressing plate presses against the top face of the lower mold, the bottom side of the upper pressing plate is provided with convex columns, the convex columns are inserted into corresponding positioning concave holes, the central part of the upper pressing plate is provided with a main through groove, and the PCB body is inserted into the placing groove and is clamped between the upper pressing plate and the mounting convex plate. The PCB body fixing mold device can automatically fix the PCB body, and is firm in fixation and convenient to install and dismount.

Owner:苏州淏源精密科技有限公司

High-precision PCB plate separating device

PendingCN110370329AImprove work efficiencyReasonable structural designInsulating layers/substrates workingMetal working apparatusEngineeringDepaneling

The invention provides a high-precision PCB plate separating device. The device comprises a main machine frame, wherein the main machine frame is sequentially provided with a pushing structure, a material pressing structure, a material cutting structure and a material loading structure, the material pushing structure and the material pressing structure are connected, and the material pressing structure is connected with the material cutting structure. One side of the material cutting structure is provided with the material loading structure, the material pressing structure is used for fixing PCB materials, the material pushing structure is used for pushing the PCB materials of the material pressing structure to the material cutting structure, and the material loading structure used for collecting cut materials. The main machine frame is provided with a support block, wherein the support block is provided with fixing adjusting through holes. The high-precision PCB plate separating device has the advantages of being reasonable in structural design, high in working efficiency, easy to maintain and convenient to use.

Owner:广东中孚智能装备有限公司

Screw lifting type high-precision board automatic lifting mechanism for PCB separation machine

The invention discloses a screw lifting type high-precision board automatic lifting mechanism for a PCB separation machine. The screw lifting type high-precision board automatic lifting mechanism comprises a feeding rack. A discharging through hole is formed in the middle portion of a top board of the feeding rack. A supporting board is fixed to the middle portion of the feeding rack. A material box conveying slant frame is arranged on the left side of the supporting board. A material pushing opening is formed in the left side of the position between the supporting board and the top board of the feeding rack. A lifting through hole is formed in the middle portion of the supporting board. A pushing column is inserted into the lifting through hole in a sleeved manner. The bottom end of the pushing column is located below the supporting board and is fixedly provided with a lifting connecting board. A guide block is fixed to the left end of the lifting connecting board. A screw joint block is fixed to the right end of the lifting connecting board. The bottom end of a vertical guide rod is hinged to the left end of a bottom board of the feeding rack. The top end of the vertical guide rod is hinged to the supporting board. The bottom end of an adjusting screw is hinged to the right end of the bottom board of the feeding rack. According to the screw lifting type high-precision board automatic lifting mechanism, a material box can be placed on the supporting board, a material board is automatically lifted through the pushing column, manual or mechanical arm taking or grabbing is facilitated, and the screw lifting type high-precision board automatic lifting mechanism is high in efficiency and good in effect.

Owner:浙江蓝天知识产权运营管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com