PCB separation counting machine

A technology of counting and sub-board, applied in the field of PCB sub-board counting machine, which can solve problems such as cost increase, customer return or deduction, and increase of manual inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

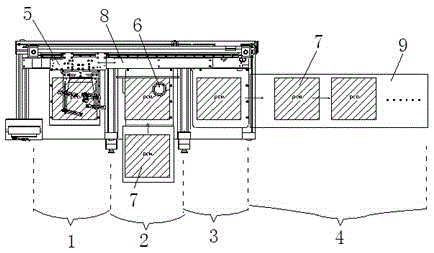

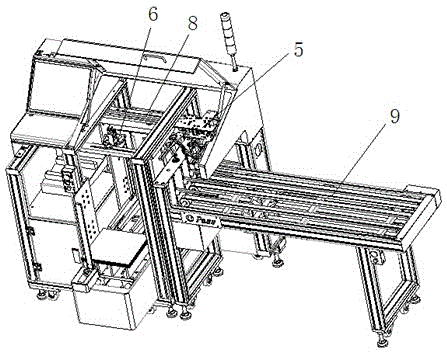

[0017] Please refer to figure 1 , figure 2 The shown embodiment, a kind of PCB board counting machine, comprises the feeding area 2 that is used to put into the circuit board 7 to be tested, is used to place the unqualified area 1 that detects unqualified products, is used to place and detect qualified Qualified area 3 of the product and an automatic discharge area 4 for outputting the qualified product. The feeding area 2 is provided with a camera 6 for detecting, identifying and counting the circuit board 7, and is also provided with a camera 6 for detecting and counting the circuit board 7. Manipulator 5 that grabs and sends to unqualified area 1 or qualified area 3.

[0018] Such as figure 2 As shown, the camera 6 is located above the feeding area 2 and below the manipulator 5 .

[0019] Such as figure 1 In the implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com