PCB splitter with cover plate

A technology of PCB board and board splitting machine, which is applied in metal processing and other directions, and can solve problems such as warping of PCB boards, affecting the quality of PCB boards, and damage to electrical circuits of PCB boards and tin channels of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

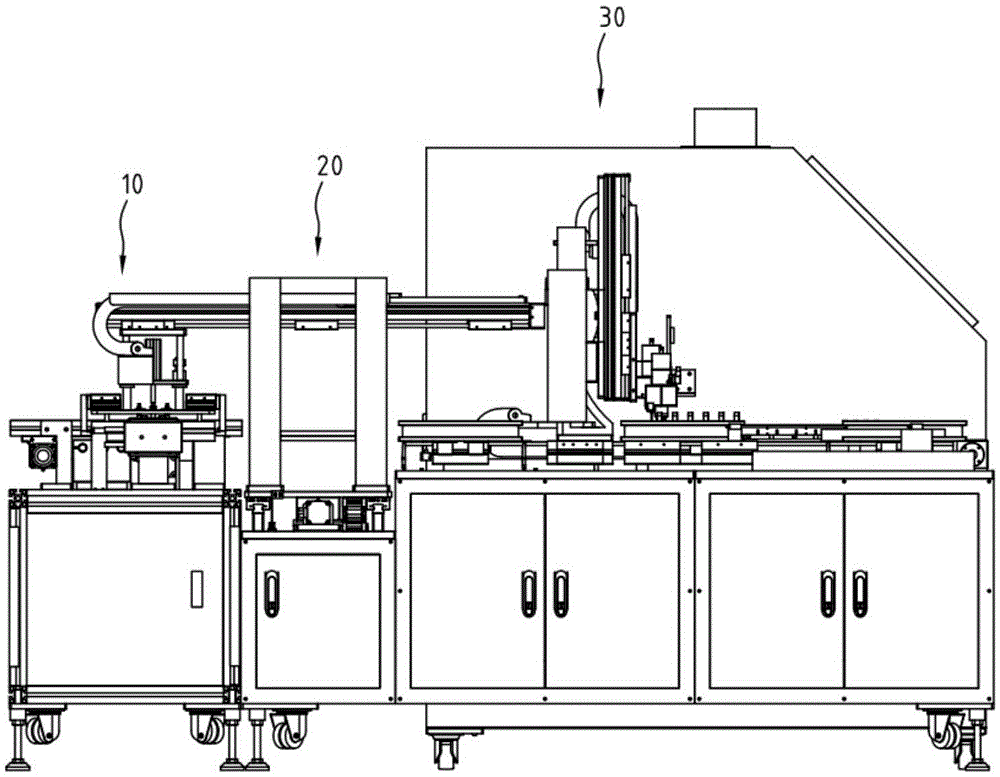

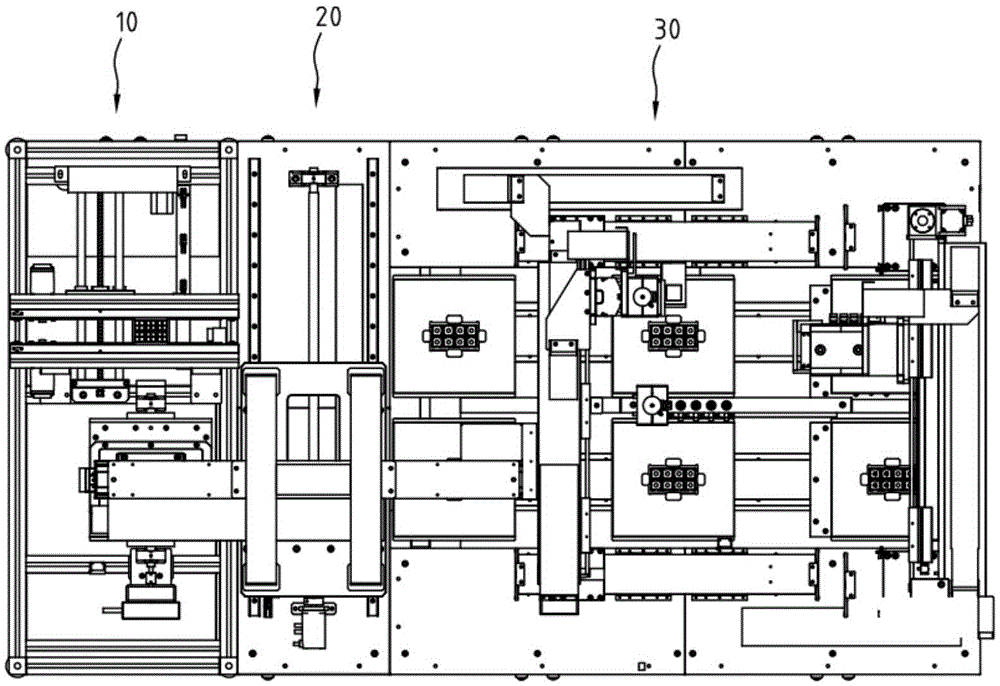

[0041] combine figure 1 , figure 2 , a PCB splitting machine provided with a cover plate, including a feeding station 10, a transfer station 20, and a splitting station 30 arranged longitudinally in sequence.

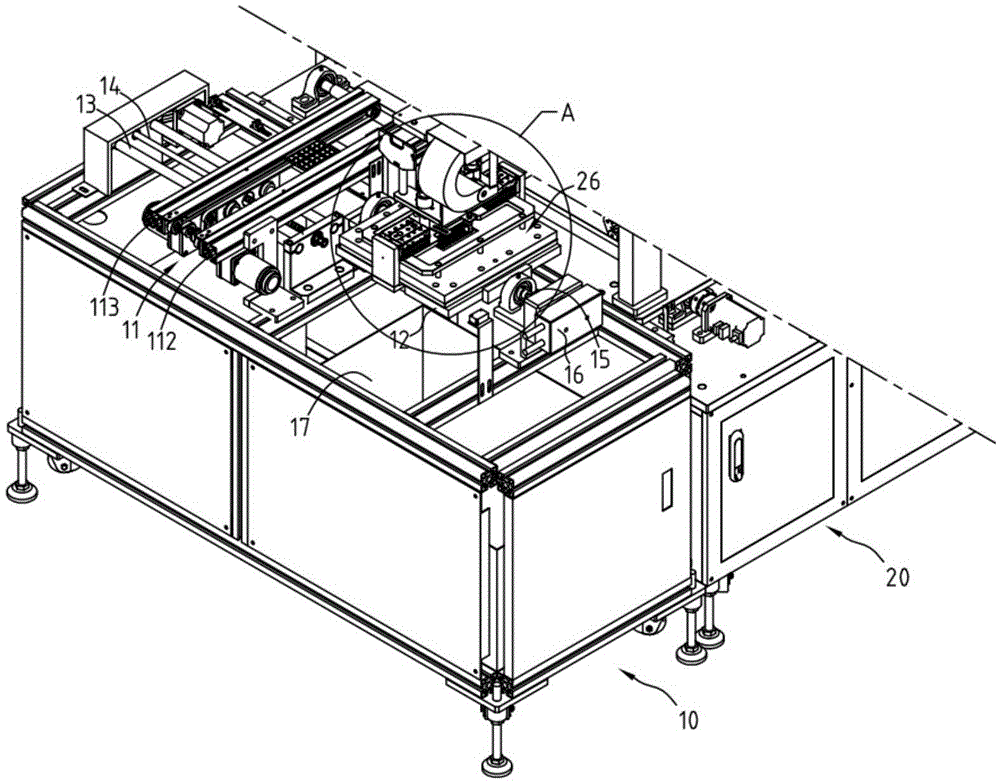

[0042] combine image 3 , Figure 4 , the feeding station includes a feeding track 11, a fixture placement platform 12 positioned at the side of the feeding track, and a fixture 40 for positioning the PCB board connecting piece 400 is placed on the fixture placement platform; the central part of the fixture Set up a positioning slot for positioning the PCB board connection.

[0043] In the feeding station 10, the feeding track 11 includes a first feeding sub-track 112 and a second sub-track 113 arranged side by side; the first feeding sub-track includes a first conveyor belt for conveying PCB boards. 1. The first feed motor for driving the first conveyor belt, the second feed sub-track includes a second conveyor belt for conveying PCB boards, and a second feed moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com