Smoke alarm automatic assembling production line

A smoke alarm and automatic assembly technology, which is applied to alarms, fire alarms, assembly machines, etc., can solve the problems of increased labor costs, low efficiency, and high labor intensity, so as to avoid inconsistent wax dipping and liquid Reduced surface area and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

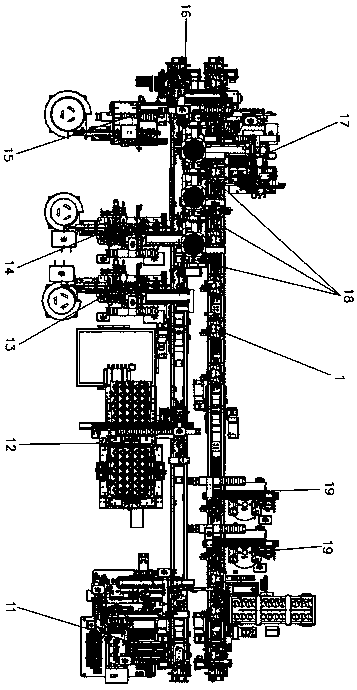

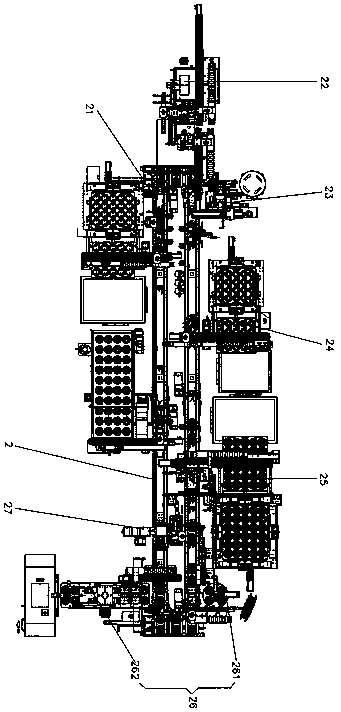

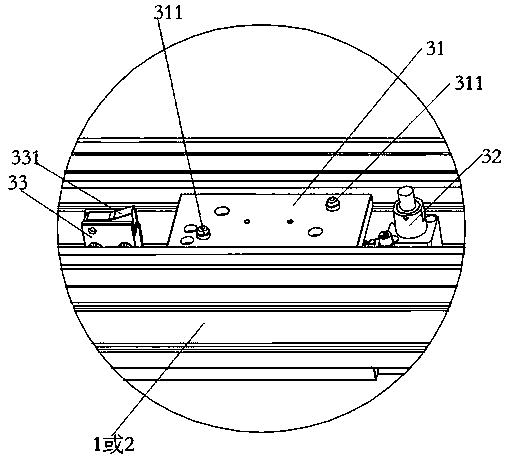

[0040] refer to Figure 1~Figure 2 , an automatic assembly line for smoke alarms, including a semi-finished product assembly line 1 and a finished product assembly line 2, the semi-finished product assembly line 1 is mainly used for welding and assembling PCB boards, transmitting tubes, receiving tubes, shielding covers, capacitors and other components , the finished product assembly line 2 mainly assembles the PCB assembled by the semi-finished product assembly line and the labyrinth cover, light guide column, upper cover and other materials. The described semi-finished product assembly line 1 is provided with PCB sub-board feeding and assembling equipment 11, maze feeding and assembling equipment 12, launching tube feeding and assembling equipment 13, receiving tube feeding and assembling equipment 14, shielding cover feeding and assembling equipment 15, Flipping equipment 16, capacitor feeding assembly equipment 17, welding equipment 18 and semi-finished product testing equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com