Printed circuit board (PCB) body fixing die moving device for PCB cutting machine

A technology for moving PCB boards and molds, applied in metal processing, etc., can solve the problems of troublesome installation and disassembly, low degree of automation, easy damage to the board, etc., and achieve the effect of firm fixation and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

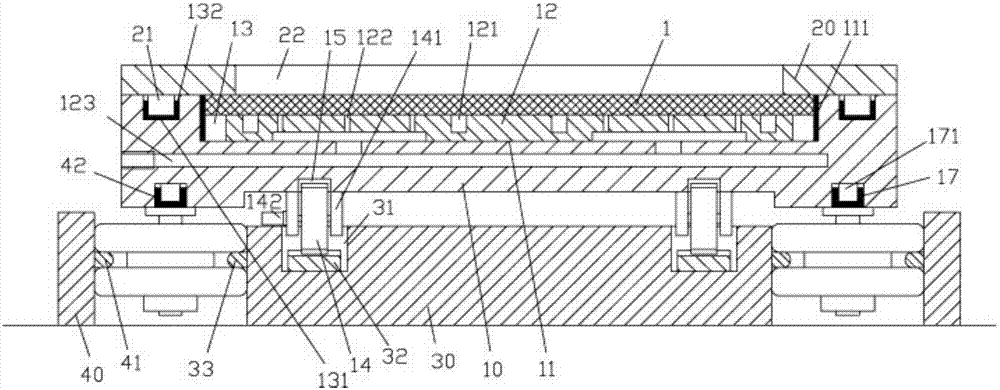

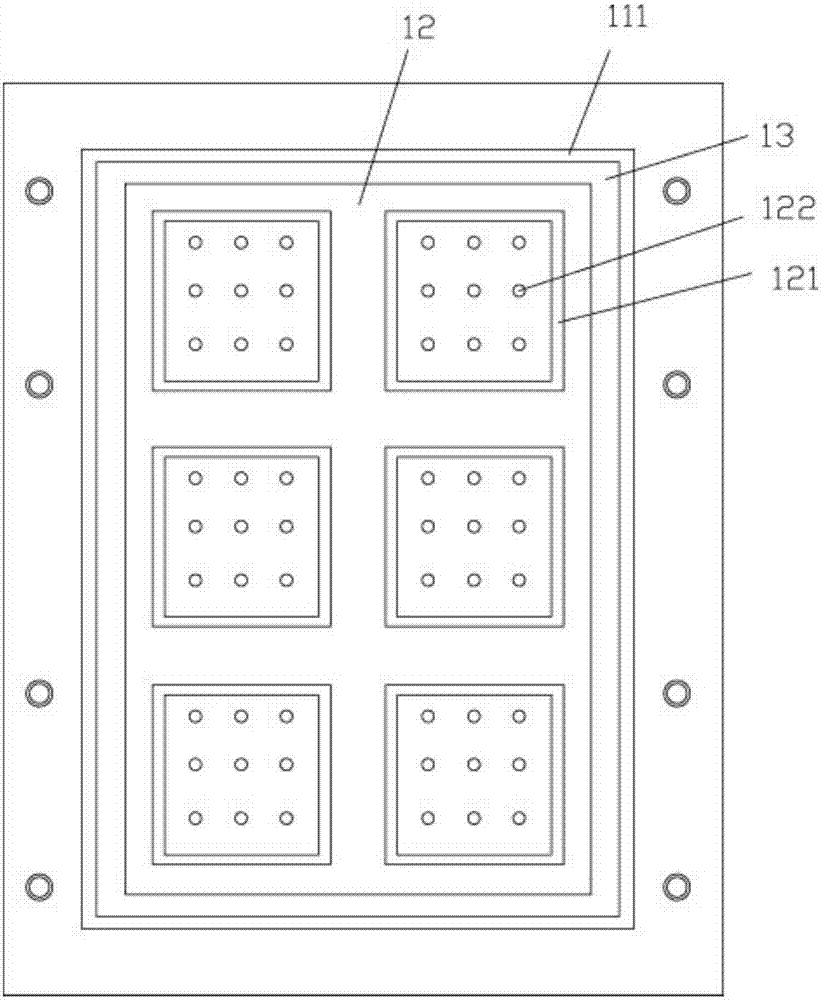

[0027] Examples, see e.g. Figure 1 to Figure 2 As shown, a PCB board body fixed mold moving device for a PCB splitter includes a lower mold 10 and a lower center rail bar 30, the lower center rail bar 30 is located below the lower mold 10, and the middle part of the top surface of the lower mold 10 There is a placement groove 11, the bottom surface of the placement groove 11 has a mounting raised plate 12, there is a hollow groove 13 between the mounting raised plate 12 and the inner side wall of the placing groove 11, and the middle part of the mounting raised plate 12 has a plurality of square Groove 121, the mounting raised plate 12 in the middle of the square groove 121 has a plurality of ventilation holes 122, the side wall of the lower mold 10 has a plurality of communication holes 123, and the ventilation holes 122 communicate with the communication holes 123;

[0028] The top surface edge of the lower mold 10 has a plurality of positioning concave holes 131, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com