Intelligent PCB separating machine

A PCB board and board splitting machine technology, applied in the direction of conveyors, conveyor objects, metal processing, etc., can solve the problems of increasing labor intensity of operators, time-consuming and laborious, and affecting operation efficiency, etc., to achieve low cost of board splitting, Improve the quality of sub-boards and ensure the effect of physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

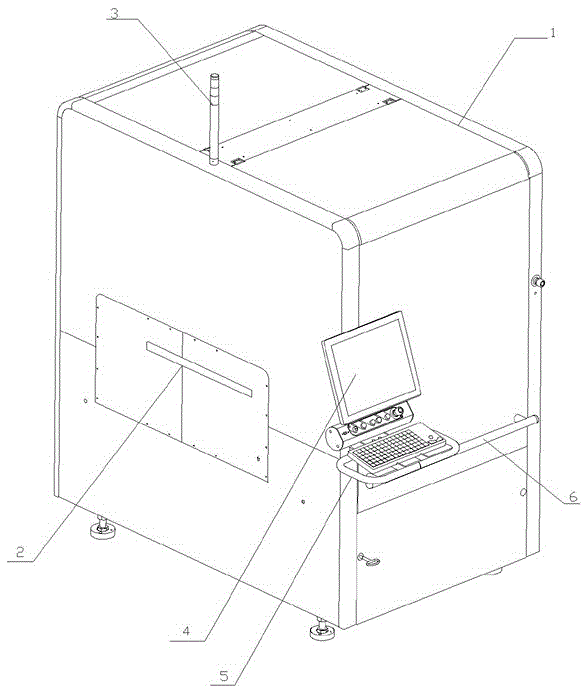

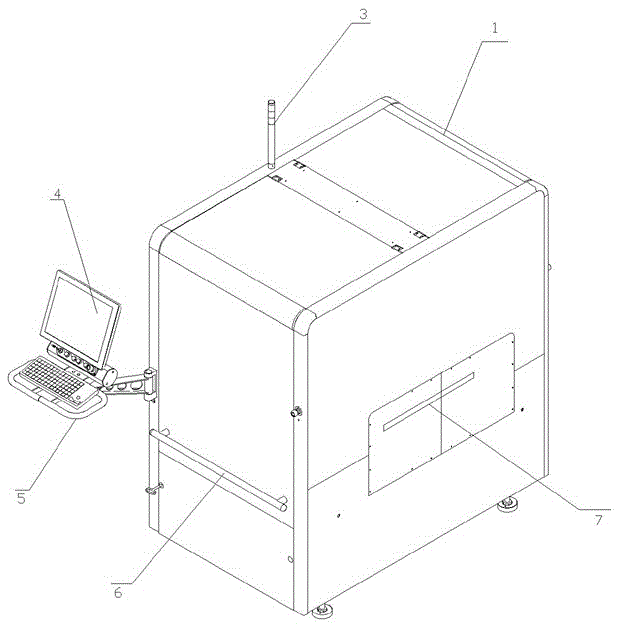

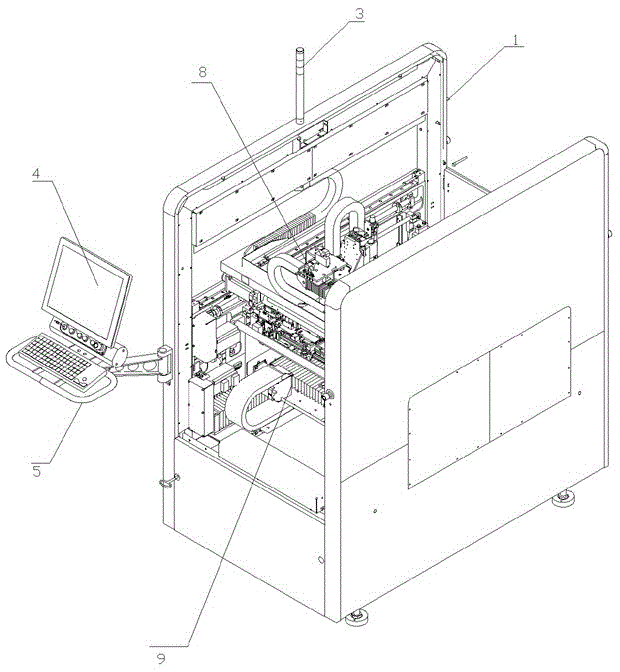

[0024] Such as Figure 1 to Figure 5 As shown, the intelligent PCB splitter of the present invention is provided with a frame 1, a conveying device disposed in the frame 1 and used for conveying PCB boards, a manipulator 8 disposed above the conveying device and used for grabbing PCB boards, A cutter 9 arranged under the conveying device and used for cutting PCB boards, a dust collection device arranged in the frame 1 and used for collecting PCB board scraps, a waste collection device and a control system for collecting PCB board scraps; The frame 1 is provided with a material inlet 2 and a material outlet 7, one end of the conveying device is located at the material inlet 2, and the control system is electrically connected to the conveying device, the manipulator 8, the cutter 9 and the suction device. dust device.

[0025] Further, the manipulator 8 is provided with an upper end moving device and a grabbing device 11, and the upper end moving device is provided with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com