PCB separating and conveying frame grabbing mechanism

A technology of grabbing mechanism and conveying rack, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of manual classification troubles, affecting the yield of finished products, and low efficiency, so as to improve the continuity of processing and high degree of automation , The effect of facilitating subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

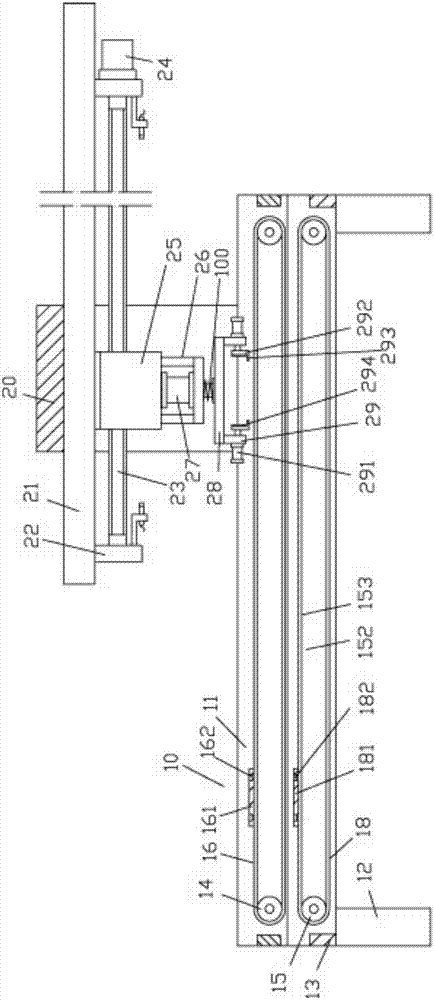

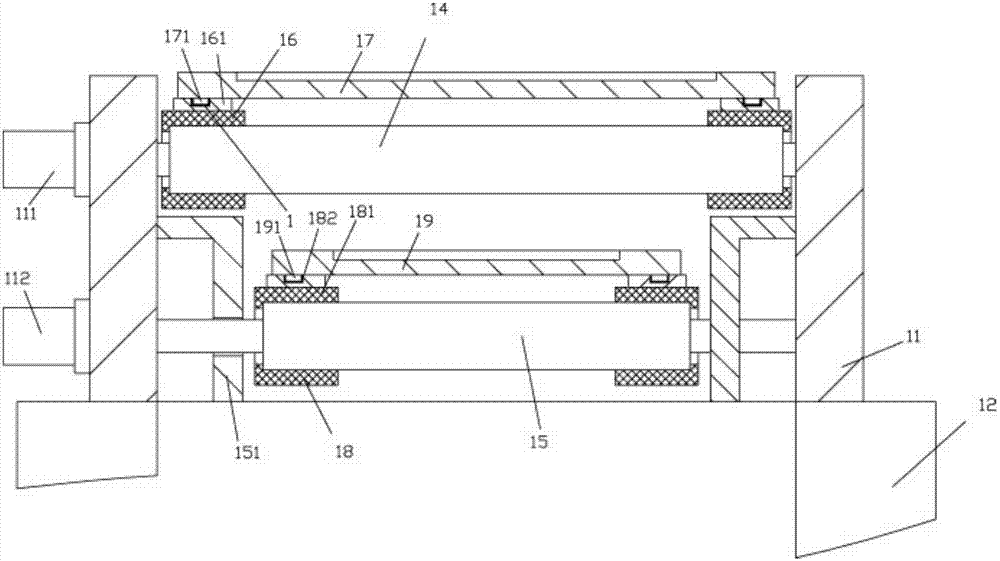

[0026] Examples, see e.g. Figure 1 to Figure 2 As shown, a grabbing mechanism for a PCB sub-board conveying frame includes a frame body 10, and the frame body 10 includes two side plates 11, the bottom of the side plates 11 is fixed with support legs 12, and a plurality of transverse beams 13 are located between two The two ends of the side plate 11 and the two ends of the transverse beam 13 are fixed on the inner side walls of the two side plates 11;

[0027] The top between the two side plates 11 is provided with two upper conveyor belts 16, the bottom is provided with two lower conveyor belts 18, the upper placement plate 17 is on the two upper conveyor belts 16, and the lower placement plate 19 is on the two upper conveyor belts 16. On the lower conveyor belt 18;

[0028] The upper right end upper part of described two side boards 11 is fixed with upper grab connection frame 20, and the bottom surface of the top plate of last grab connection frame 20 is fixed with delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com