Cut-off PCB (printed circuit board) separator

A technology of PCB board and board splitting machine, which is applied in the direction of shearing machine equipment, shearing device, metal processing equipment, etc., can solve the problems of expensive consumables, inflexibility, and low efficiency of milling cutters, and achieve air pollution and applicability wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

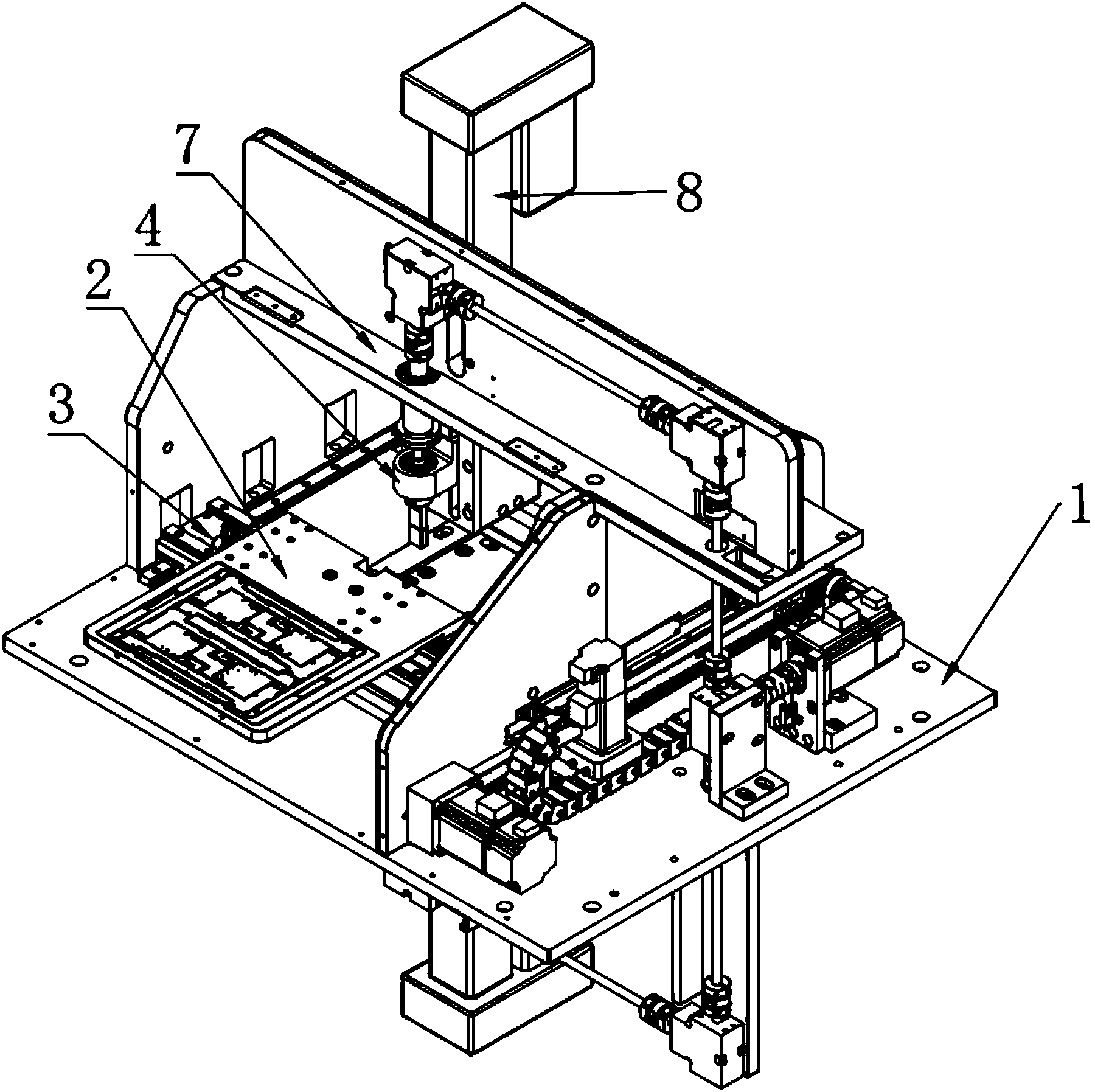

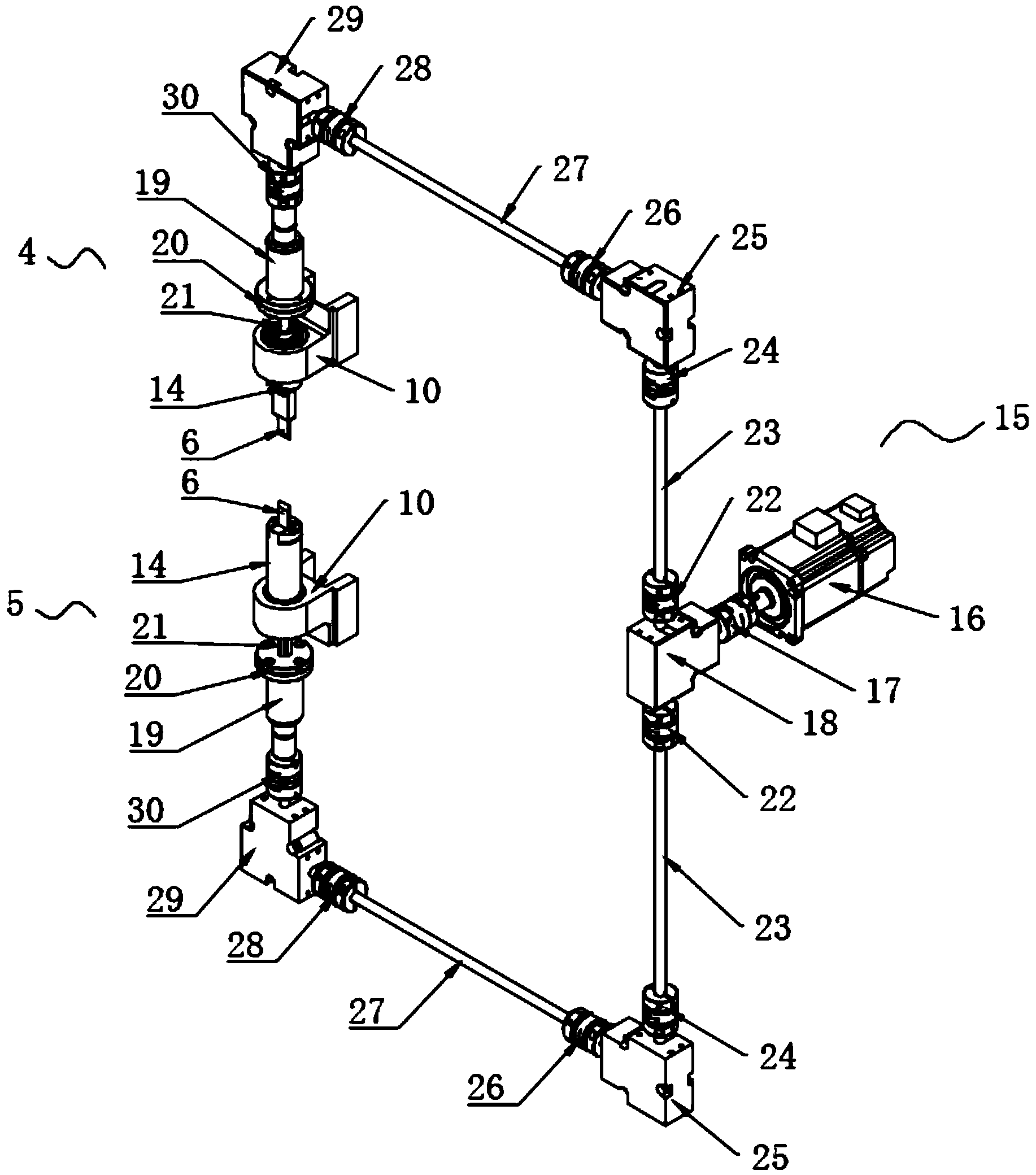

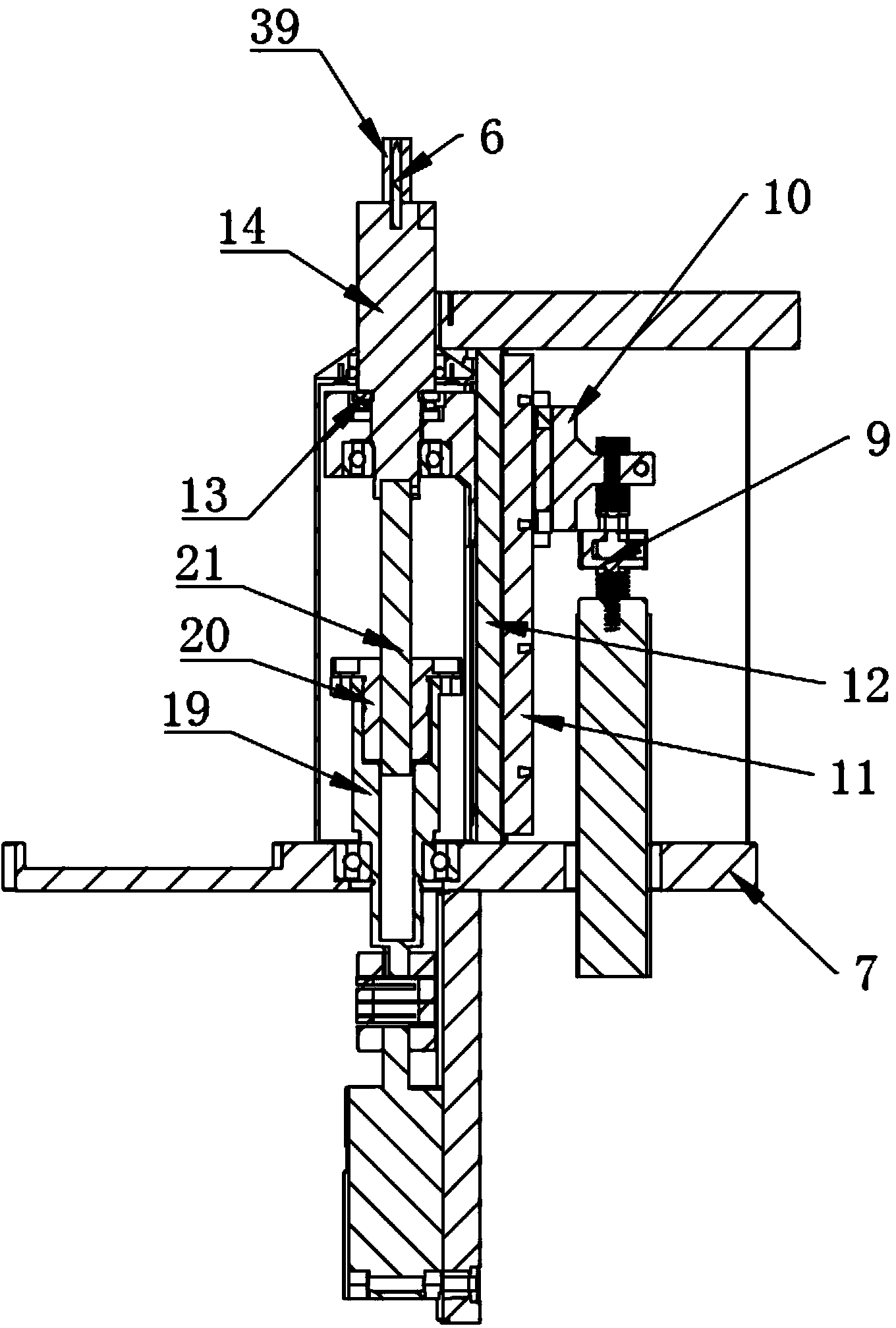

[0024] combine figure 1 and figure 2 As shown, the present embodiment provides a shearing type PCB splitter, including a work platform 1, the work platform 1 is provided with a loading jig 2 for fixing the PCB board and is used to drive the loading jig 2 horizontally on the horizontal working surface. With the X-Y motion platform mechanism 3 that moves longitudinally, the loading jig 2 is installed on the X-Y motion platform mechanism 3, and the upper and lower sides of the loading jig 2 are provided with an upper cutter that cuts the upper and lower sides of the PCB board simultaneously. Knife mechanism 4 and lower cutting knife feeding mechanism 5.

[0025] like figure 2 As shown, the front portion of the upper cutter feed mechanism 4 and the lower cutter feed mechanism 5 is provided with a shear knife 6, and the loading fixture 2 is provided with a processing channel for the shear knife 6 to extend into. The feed mechanism 4 and the lower cutter feed mechanism 5 are sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com