Sheet metal lifting device, provided with automatic locating device, for PCB splitting machine

An automatic positioning and board splitting machine technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as low efficiency, affecting yield, increasing difficulty, etc., to achieve high efficiency, good effect, and convenient handling The effect of grabbing or grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

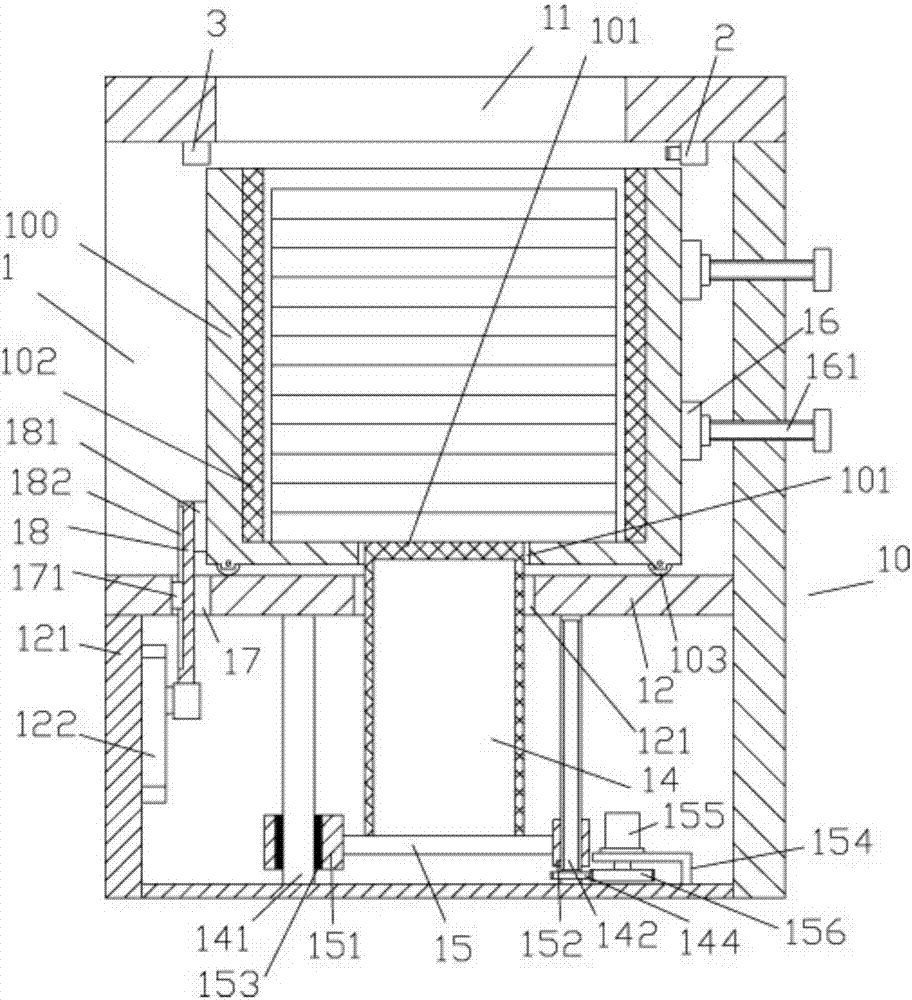

[0021] Examples, see e.g. figure 1 As shown, a PCB splitting machine is equipped with a plate lifting device with an automatic positioning device, including a feeding frame 10, the middle part of the top plate of the feeding frame 10 has a discharge through hole 11, and the middle part of the feeding frame 10 is fixed with Support plate 12, the left side between the support plate 12 and the top plate of the feeding frame 10 has a material pushing port 1, the middle part of the support plate 12 has a lifting through hole 121, and the pushing column 14 is inserted and sleeved in the lifting through hole 121, and the pushing column The bottom end of 14 is below the support plate 12 and is fixed with a lifting connecting plate 15, and the left end of the lifting connecting plate 15 is fixed with a guide block 151, and the right end of the lifting connecting plate 15 is fixed with a screw joint block 152, and the bottom plate of the feeding frame 10 The left end is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com