Array-type multi-makeup PCB splitting method

A PCB board, array technology, applied in the field of array multi-imposition PCB sub-board, can solve the problems of multi-process cost, easy to scratch other products and electronic components, no competitive advantage, etc., to achieve neat board edges and no residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with specific embodiments. A kind of array type multi-imposition PCB splitting method that is convenient for splitting, comprises the following steps:

[0017] (1) Remove the design of the stamp hole and the connecting block, and reduce the single spacing to 0.4mm;

[0018] (2) Pre-process: including material cutting, drilling, copper sinking, board electrical, dry film and graphic electrical, then etching, AOI, solder mask, and finally engraving text;

[0019] (3) CNC: carry out data design and export data, drill positioning holes after arranging the milling cutters, punch pins, put on the board, start the CNC equipment to remove the PCB sub-board frame, and finally collect the PCB sub-board;

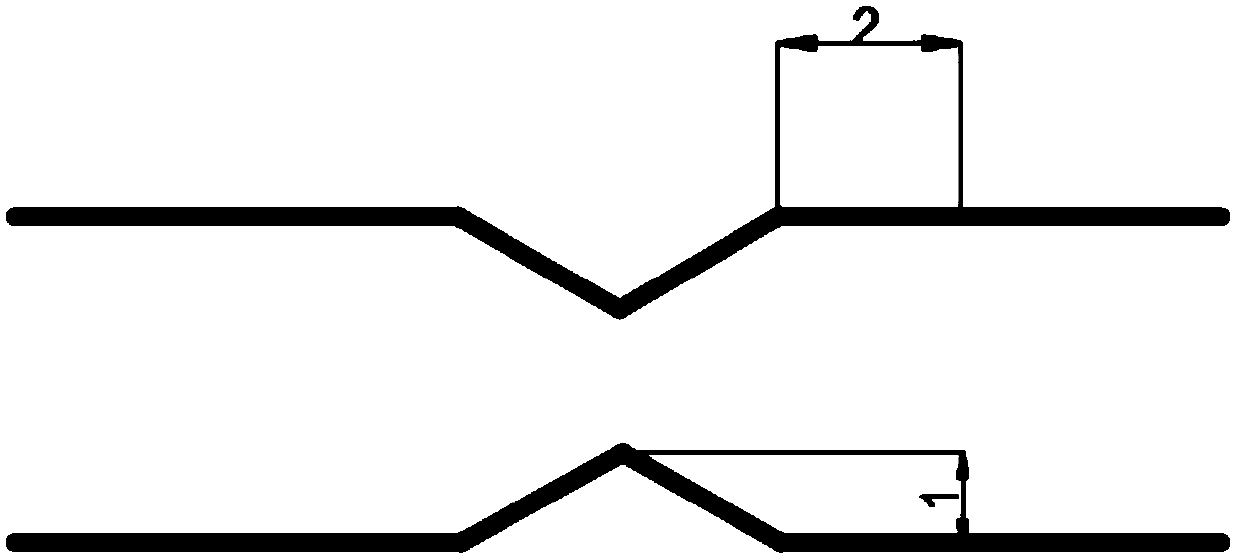

[0020] (4) Use a V-CUT knife to open corresponding V-shaped grooves on both sides of the designed PCB sub-board, the depth of the V-shaped groove is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com