PCB (printed circuit board) divider

A technology of PCB boards and splitters, applied in the field of PCB splitters, can solve problems such as time-consuming, laborious operations, complicated operations, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

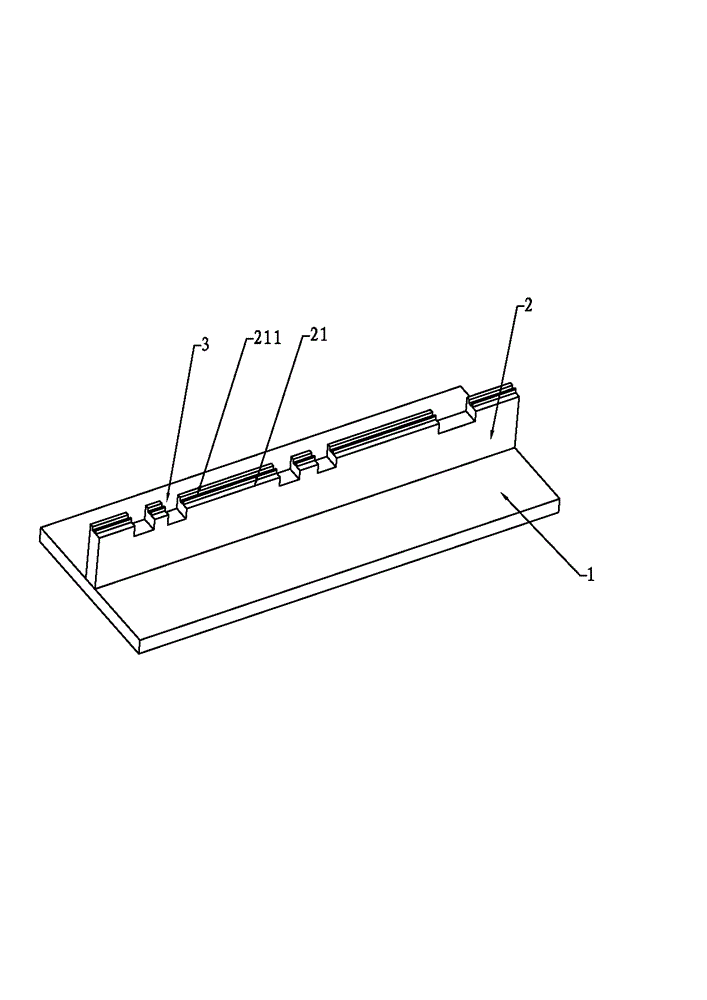

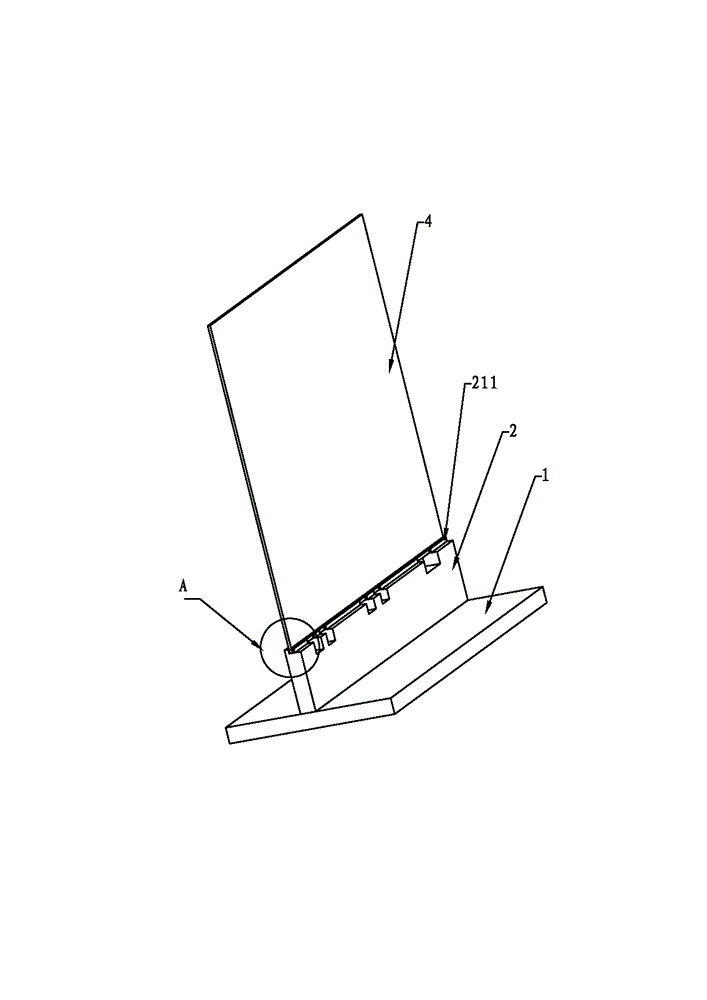

[0024] An embodiment of a PCB splitter of the present invention is figure 1 , figure 2 and image 3 As shown, it includes a base 1 and a cutting board 2 vertically arranged on the base 1. The top of the cutting board 2 is extended with a bump 21 along the vertical direction. There are at least two bumps 21. Groove 3.

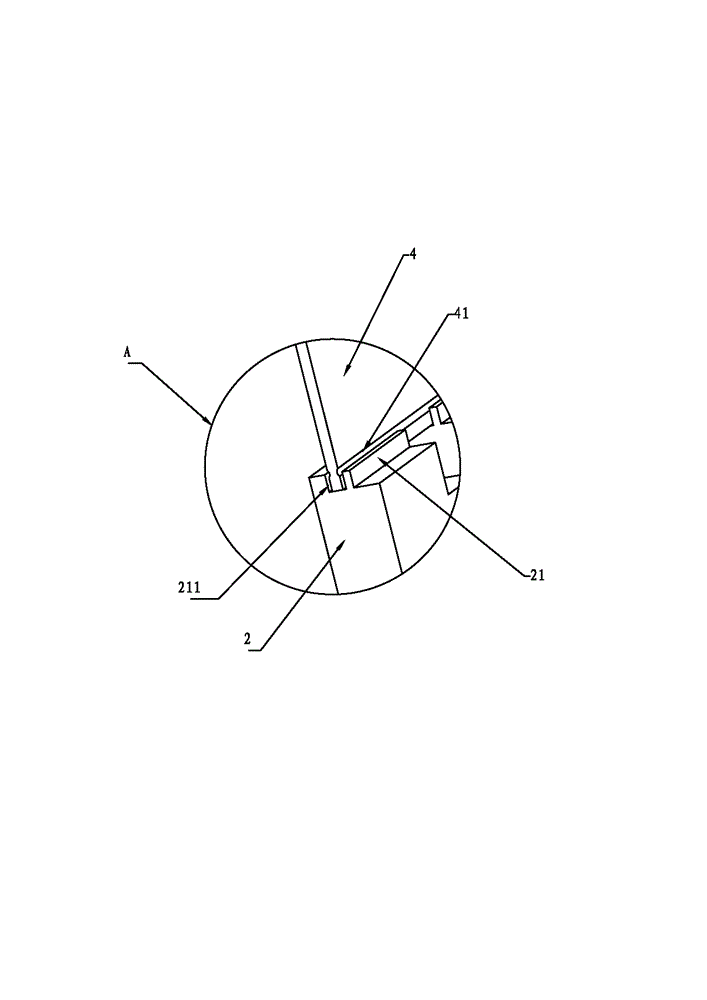

[0025] The protrusion 21 is provided with a cutting groove 211 for accommodating the PCB 4 , and the width of the opening of the cutting groove 211 matches the thickness of the PCB 4 . When the PCB board 4 is put into the cutting groove 211, the cutting line 41 marked on the edge of the PCB board 4 to be divided is just exposed on the outer edge of the cutting groove 211, and the groove 3 between the adjacent protrusions 21 It is convenient to separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com