Up-down dust suction device of PCB distributor

A technology of vacuuming device and splitter, applied in metal processing machinery parts, milling machine equipment details, maintenance and safety accessories, etc., can solve problems such as affecting the quality of PCB products, difficult to remove dust, and endangering workplace safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

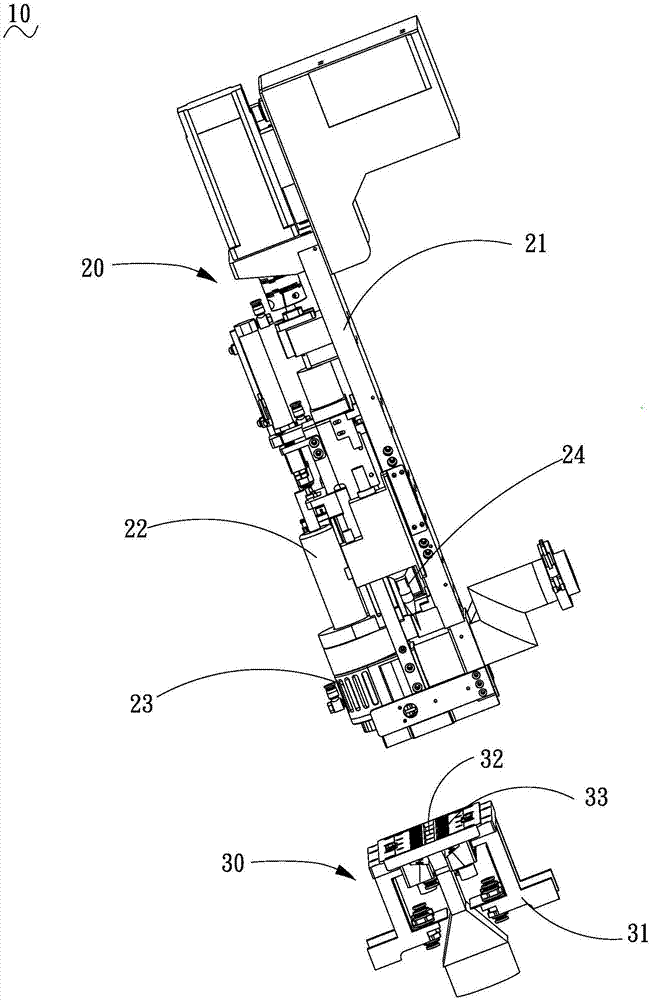

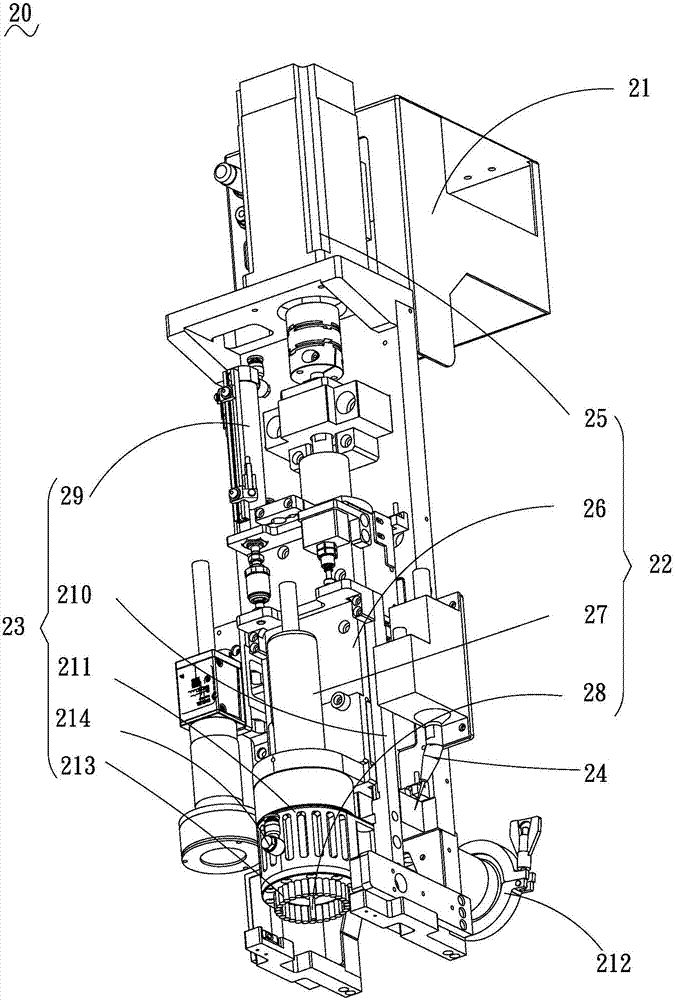

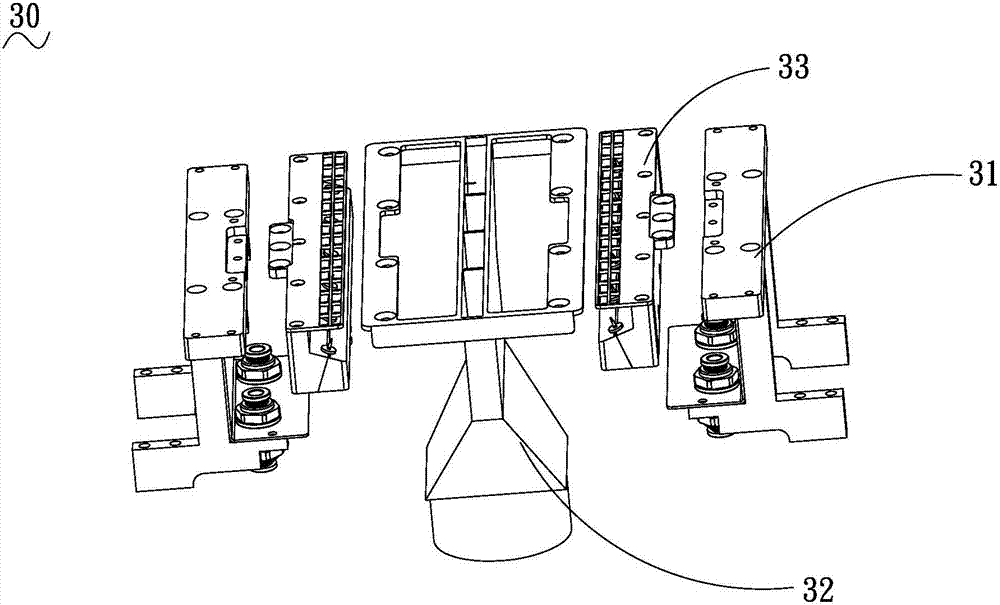

[0024] see Figure 1 to Figure 4 , providing a schematic diagram of the upper and lower dust collection device 10 of a PCB splitter.

[0025] The upper and lower dust suction device 10 of the PCB splitter includes: an upper dust suction assembly 20 and a lower dust suction assembly 30 arranged opposite to the upper dust suction assembly 20 . Wherein, the upper dust suction assembly 20 is used for cutting the PCB and vacuuming one side of the PCB, and the lower dust suction assembly 30 is used for vacuuming the other side of the PCB. The description of each component is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com