Method for manufacturing tiny-pore plate

A kind of orifice plate and fine technology, which is applied in the field of fine orifice plate production, can solve the problems that the actual requirements of fine orifice plates cannot be met, the cost performance cannot be produced, and the production quality is difficult to guarantee, so as to meet the service life, technical economy, and high cost performance , good strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

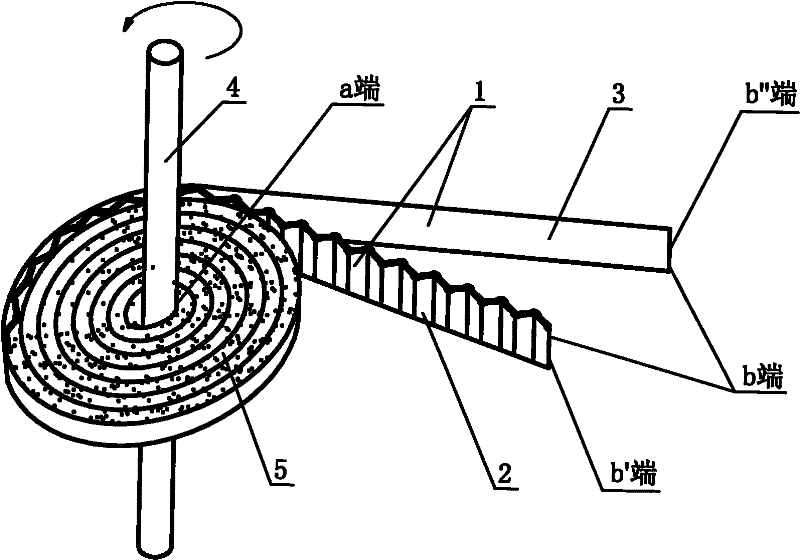

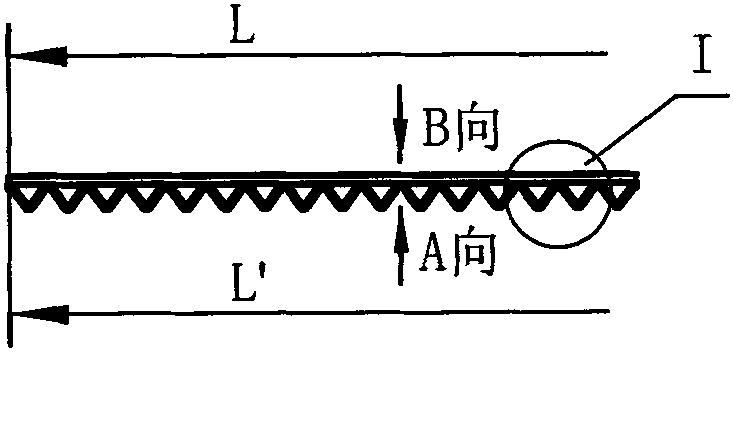

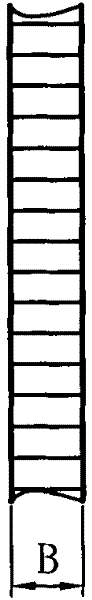

[0033] Such as Figure 1 to Figure 5 as well as Figure 10 to Figure 11As shown, a method for making a fine orifice plate, the method includes the following steps: pressing a straight stainless steel strip with a length of 100m, a thickness of 0.25mm, and a width of 10mm to form a wave pitch P=1mm and a wave height H=0.8mm . A corrugated strip 2 with a sinusoidal curved surface, the corrugated strip 2 has a length L'=82m, a thickness S=0.25mm, and a width B=10mm. Match the corrugated belt 2 with a straight belt 3 made of stainless steel with a length L=87m, a thickness M=0.25mm, and a width B =10mm. Align to form a wave flat belt 1 with one side being a flat surface (i.e. C surface) and the other side being a wave surface (i.e. D surface), and then the wave flat belt 1 starting end (i.e. end a) is fixed on the central axis 4. The central shaft 4 is a hollow tube shaft whose cross section is a ring-shaped plastic material with an inner diameter of 100 mm and an outer diameter...

Embodiment 2

[0035] Such as figure 1 , Figure 10 to Figure 13 Shown, a kind of method for making fine orifice plate, described method comprises the steps: take one side of length L=150m to be flat surface (being C surface) the other side has wave surface (being D surface) The wave flat belt 1 of stainless steel material, the wave surface shape of the wave flat belt 1 is a sinusoidal wave belt 2, the thickness M' of the wave flat belt 1 from the flat surface (ie C surface) to the wave valley point (ie point d) =1.5mm, M' is the vertical distance from the flat surface (C face) in the wave flat band 1 to the valley point (d point) of the wave surface, the width B of the wave flat band 1"=5mm, the wave surface of the wave flat band 1 The wave distance P=1.5mm, wave height H=1.5mm.The initial end (being a end) of this wave flat band is fixed on the central axis.The section of the plastic material that central axis 4 is inner diameter 100mm, outer diameter 120mm is annulus Shaped hollow tube ...

Embodiment 3

[0037] Such as Figure 1 to Figure 6 as well as Figure 10 to Figure 11 As shown, a method for making a micro-orifice plate, its steps are basically the same as in Embodiment 1, the difference is that the wave surface shape of the wave band 2 is arc-shaped, that is, the wave surface shape of the wave flat band 1 is arc-shape. The central axis 4 is a solid axis with a circular cross section. The end end (ie b" end) of the flat strip 3 is bonded. The material of the flat strip 1 is copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com