A kind of preparation method of semiconductor laser cavity mirror

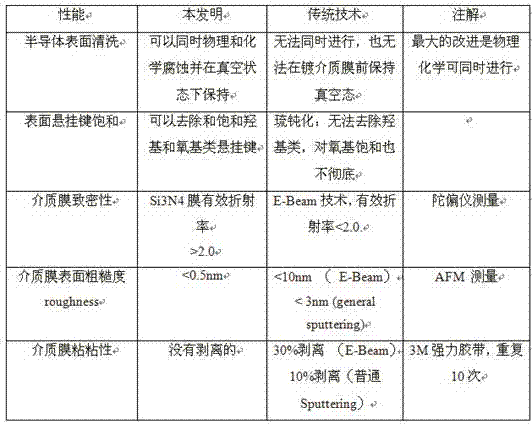

A laser and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of high binding energy of the surface layer, excessive ion beam energy, surface damage, etc., and achieve high production efficiency, reduce contamination, and effectively The effect of surface states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

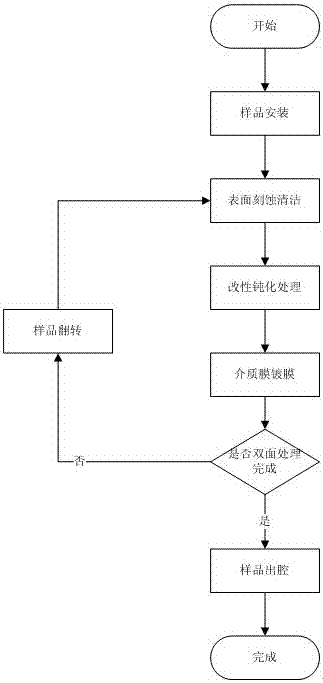

[0045] A method for preparing a semiconductor laser cavity mirror, comprising the following steps:

[0046] Step 1, surface cleaning;

[0047] Step 2, surface modification and passivation;

[0048] Step 3, dielectric coating;

[0049] Step 4, turn over, repeat steps 1 to 3, remove.

Embodiment 1

[0051] Such as figure 1 The specific steps of surface cleaning in the described step one are as follows:

[0052] Surface cleaning:

[0053] (2.1) Put the sample of semiconductor laser cavity mirror into the vacuum cavity and fix it on the sample holder;

[0054] (2.2) Adjust the direction of one of the two end faces of the sample to the same direction as that of the plasma cleaning treatment;

[0055] (2.3) Vacuumize the cavity, and the air pressure in the cavity reaches 10 -5 Pa or 10 -6 Pa;

[0056] (2.4) Adjust the temperature of the sample to 350°C or 400°C or 450°C, and feed inert gas into the vacuum chamber, adjust the air pressure in the vacuum chamber to keep the air pressure within the range of 1-10torr, and activate the vacuum chamber Plasma, to stabilize the plasma state, clean the adsorbate on the surface of the sample by fluoride or argon plasma;

[0057] (2.5) Use electric heating or infrared lamps and thermocouple feedback to control the sample temperatur...

Embodiment 2

[0075] Surface cleaning:

[0076] (2.1) Put the sample of semiconductor laser cavity mirror into the vacuum cavity and fix it on the sample holder;

[0077] (2.2) Adjust the direction of one of the two end faces of the sample to the same direction as that of the plasma cleaning treatment;

[0078] (2.3) Vacuumize the cavity, and the air pressure in the cavity reaches 10 -6 Pa; the air pressure after vacuuming is more suitable for cleaning the surface of the sample;

[0079] (2.4) Adjust the temperature of the sample to 400°C, and feed inert gas into the vacuum chamber, adjust the air pressure in the vacuum chamber to keep the air pressure at 10torr, activate the plasma in the vacuum chamber, wait for the plasma state to stabilize, and Clean up the adsorbate on the surface of the sample; if the temperature is too high or the pressure is too high, the inert gas will lose its function; if the temperature or pressure is too low, the plasma will not be activated;

[0080] (2.5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com