Separator Vacuum Milling Cutter

A technology of splitting machine and milling cutter, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of lower production efficiency, high space occupation rate, and no anti-static mechanism, etc., to reduce production costs , prevent splashing around, better effect of dustproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

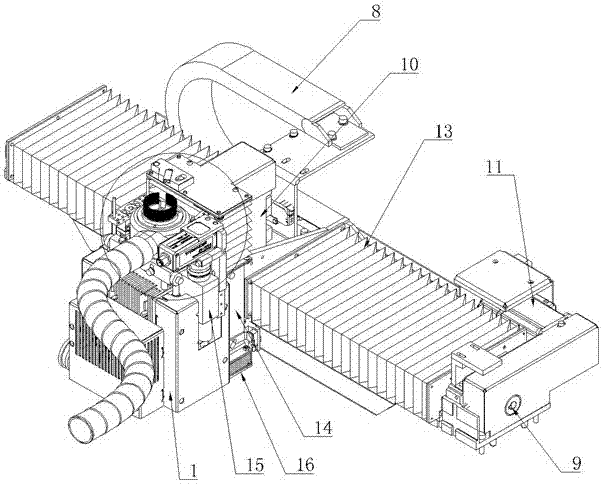

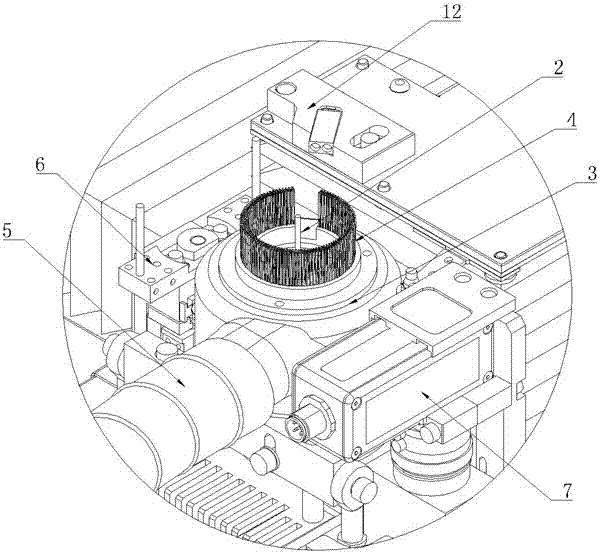

[0015] Such as figure 1 and figure 2 As shown, the present invention includes a lateral moving device, a lifting device arranged on the lateral moving device, and a milling cutter device arranged on the lifting device, and the lifting device is connected with the lateral moving device, the milling cutter device Slidingly matched with the lifting device, the milling cutter device includes a milling cutter seat 1 and a milling cutter 2 arranged on the top of the milling cutter seat 1, and a dust suction chamber 3 is also arranged on the milling cutter seat 1, so The dust-absorbing chamber 3 is covered on the periphery of the milling cutter 1, and several anti-static brushes 4 are arranged on the dust-absorbing chamber 3, and the anti-static fur brushes 4 are at the same height as the milling cutter 2. The dust suction cavity 3 is also in communication with the dust suction pipe 5 . Driven by the lateral moving device, the milling cutter holder 1 can be moved to the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com