Optical dielectric film passivation-based vertical cavity surface laser and preparation method therefor

An optical medium, vertical cavity surface technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of increasing chip manufacturing costs, the chip performance is deeply affected by the process, and increasing the complexity of the process. The effect of reducing production costs and reducing error damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

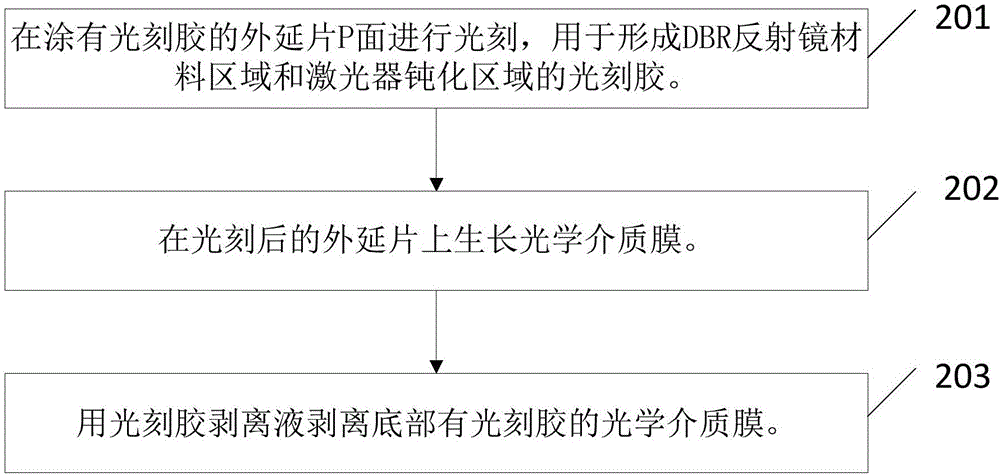

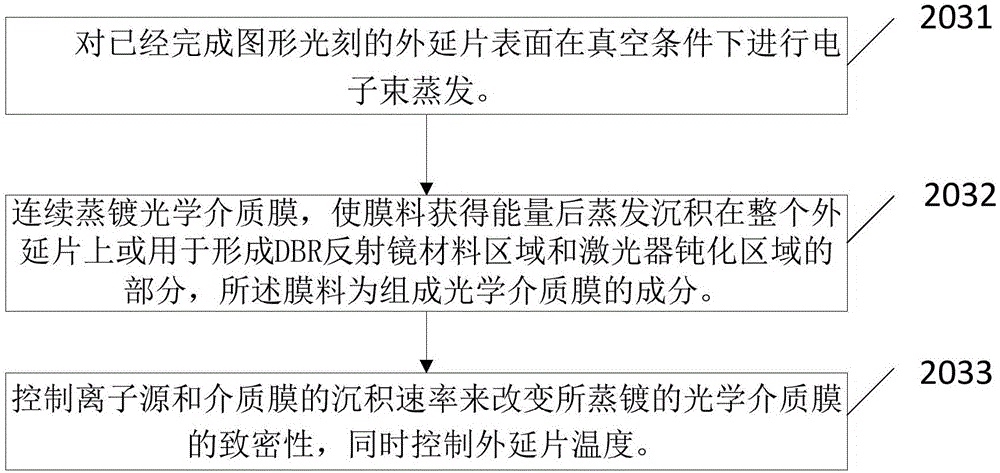

[0084] An embodiment of the present invention provides a method for fabricating a vertical cavity surface laser based on optical dielectric film passivation, such as figure 1 As shown, the preparation method specifically includes the following steps:

[0085] In step 201, photolithography is performed on the surface P of the epitaxial wafer coated with photoresist to etch the photoresist used to form the DBR mirror material region and the laser passivation region.

[0086] In step 202, an optical dielectric film is grown on the epitaxial wafer after photolithography.

[0087] In step 203, the optical medium film with the photoresist at the bottom is stripped with a photoresist stripper.

[0088] In the embodiment of the present invention, the preparation of the passivation film and the material of the DBR reflector is completed in the same vacuum chamber at one time, which not only improves the performance of the laser, but also reduces the possible damage caused by the numbe...

Embodiment 2

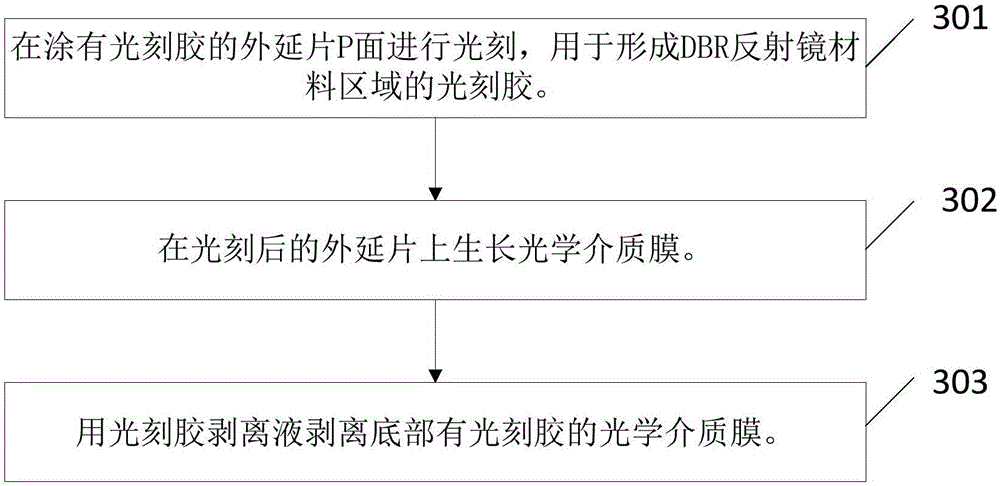

[0100] Corresponding to the preparation method of a vertical cavity surface laser based on optical dielectric film passivation described in Example 1, there is another embodiment in the present invention, a preparation of a vertical cavity surface laser based on an optical dielectric film as a DBR material method, using optical dielectric film as DBR reflector material, such as image 3 shown, including:

[0101] In step 301, photolithography is performed on the surface P of the epitaxial wafer coated with photoresist to form the photoresist in the material region of the DBR reflector.

[0102] In step 302, an optical dielectric film is grown on the epitaxial wafer after photolithography.

[0103] In step 303, the optical medium film with the photoresist at the bottom is stripped with a photoresist stripper.

[0104] The laser of the present invention adopts the optical dielectric film as the DBR mirror material, which reduces the series resistance, absorption loss and inter...

Embodiment 3

[0115] Corresponding to the preparation method of a vertical cavity surface laser based on the passivation of the optical dielectric film described in Example 1, there is also an embodiment in the present invention, wherein the laser uses the optical dielectric film as the passivation medium of the laser cavity surface film, such as Figure 5 Shown, described passivation dielectric film preparation process comprises:

[0116] In step 401, photolithography is performed on the surface P of the epitaxial wafer coated with photoresist, which is used for the photoresist in the passivation region of the laser cavity surface.

[0117] In step 402, an optical dielectric film is grown on the epitaxial wafer after photolithography.

[0118] In step 403, the optical medium film with the photoresist at the bottom is stripped with a photoresist stripper.

[0119] In a specific implementation, the step 402 can usually be implemented by the following steps, such as Image 6 Shown:

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com