Drive circuit of picture element array for display panel

A display panel and drive circuit technology, applied to static indicators, TVs, instruments, etc., can solve problems such as shift signal overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

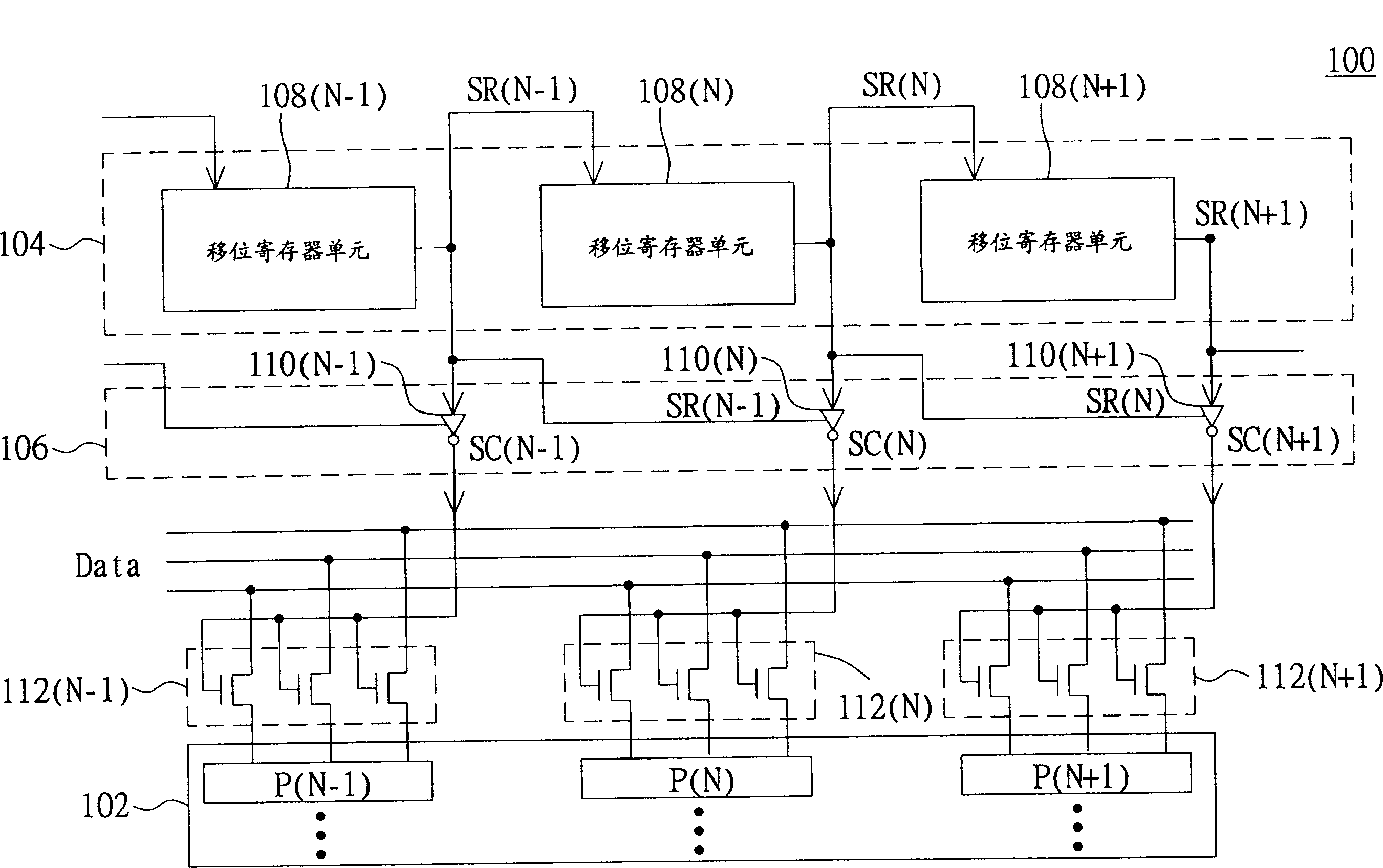

[0021] Please refer to figure 1 , which represents a circuit diagram of a driving circuit according to a first embodiment of the present invention. The driving circuit 100 is used for driving a pixel array 102 of a display panel. The driving circuit 100 at least includes a shift register circuit 104 , an output buffer circuit 106 and a plurality of switch groups 112 . The shift register circuit 104 includes a plurality of shift register units, such as shift register units 108(N−1), 108(N) and 108(N+1). The output buffer circuit 106 includes a plurality of output buffer units, such as main inverters, including main inverters 110(N−1), 110(N) and 110(N+1).

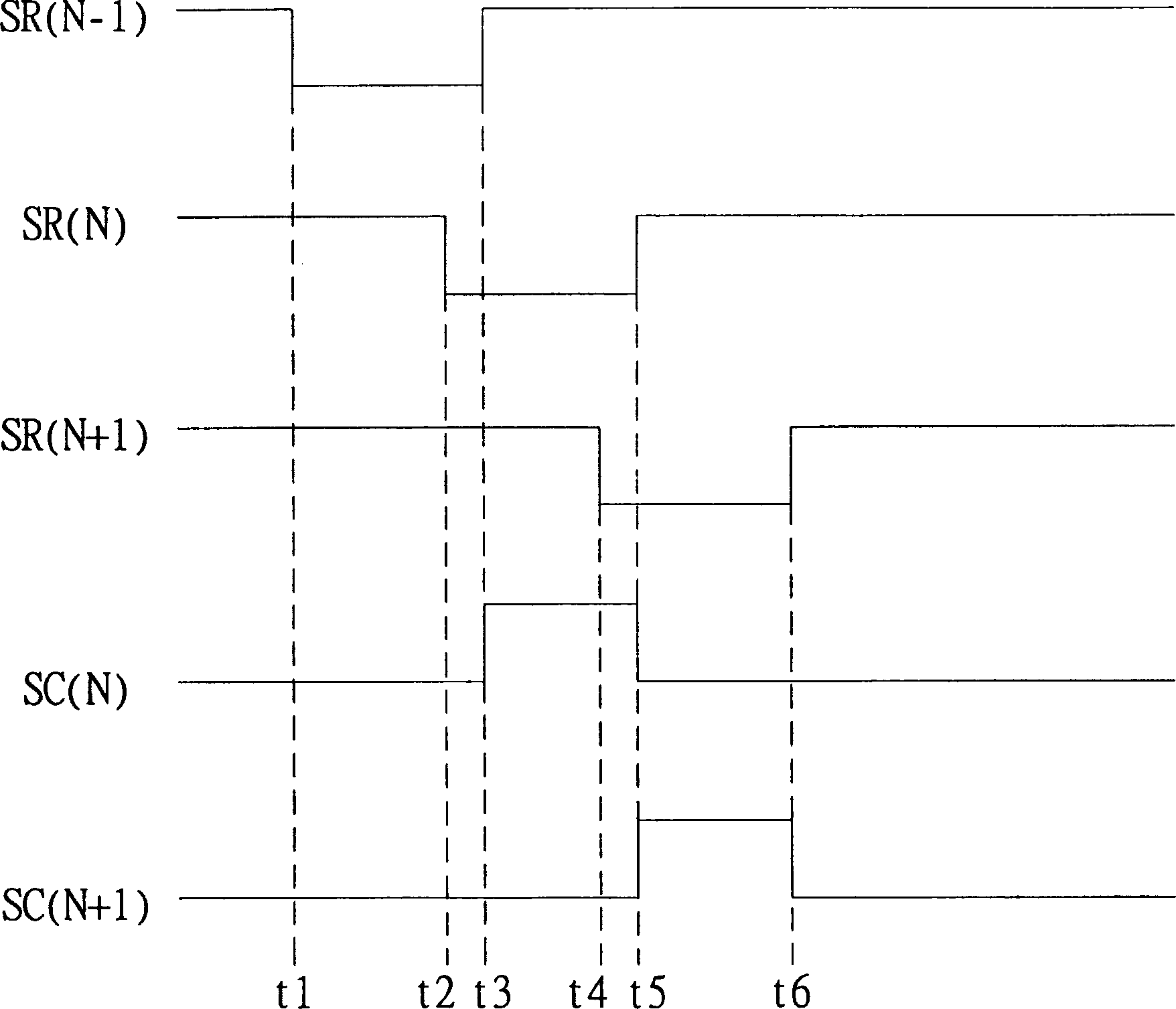

[0022] The shift register units 108(N-1), 108(N) and 108(N) respectively output shift signals SR(N-1), SR(N) and SR(N+1), and the shift signal SR(N -1), SR(N) and SR(N+1) are enabled sequentially. When the shift signals SR(N-1), SR(N) and SR(N+1) are enabled respectively, the levels of the shift signals SR(N-1), SR(N) an...

Embodiment 2

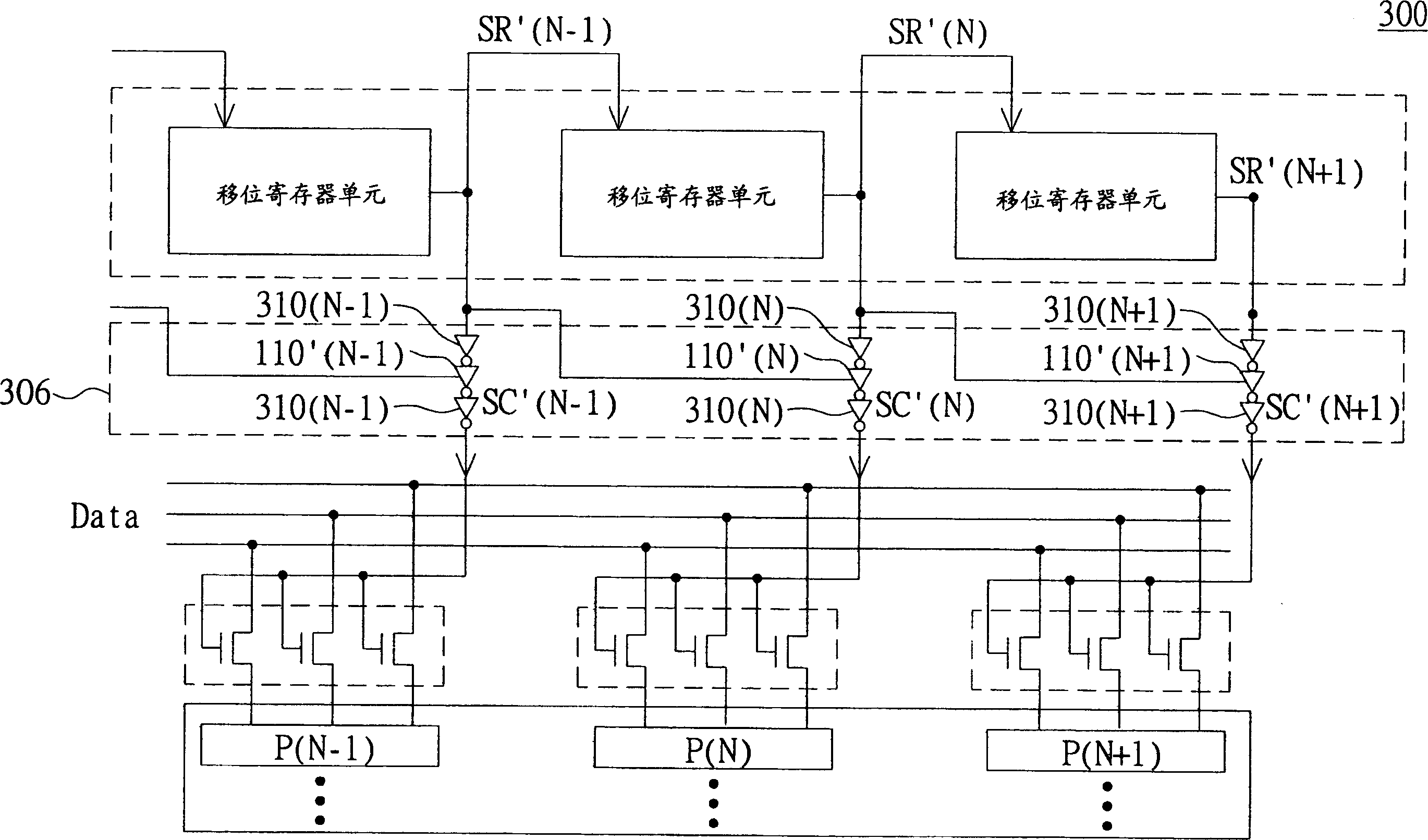

[0029] Please refer to image 3, which represents a circuit diagram of a driving circuit according to a second embodiment of the present invention. Different from the first embodiment, in the driving circuit 300 of the second embodiment of the present invention, the output buffer circuit 306 further includes a plurality of auxiliary inverters 310 (N-1), a plurality of auxiliary inverters 310 ( N) and a plurality of auxiliary inverters 310 (N+1), such as two auxiliary inverters 310 (N-1), two auxiliary inverters 310 (N) and two auxiliary inverters 310 ( N+1). The two auxiliary inverters 310(N-1) are connected in series with the main inverter 110'(N-1), and the two auxiliary inverters 310(N) are connected in series with the main inverter 110'(N). connected, and the two auxiliary inverters 310(N+1) are connected in series with the main inverter 110'(N-1). The positive voltage supply terminals of all auxiliary inverters can receive the shift signal of the upper stage, or be dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com