A high-precision resonant quartz temperature sensor with multiple arrow-shaped vibrating arms

A temperature sensor, high-precision technology, used in thermometers, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve the problems of increased series equivalent resistance, unstable oscillation signal, and decreased accuracy. , to achieve the effect of reducing parasitic vibration mode, improving response speed, and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

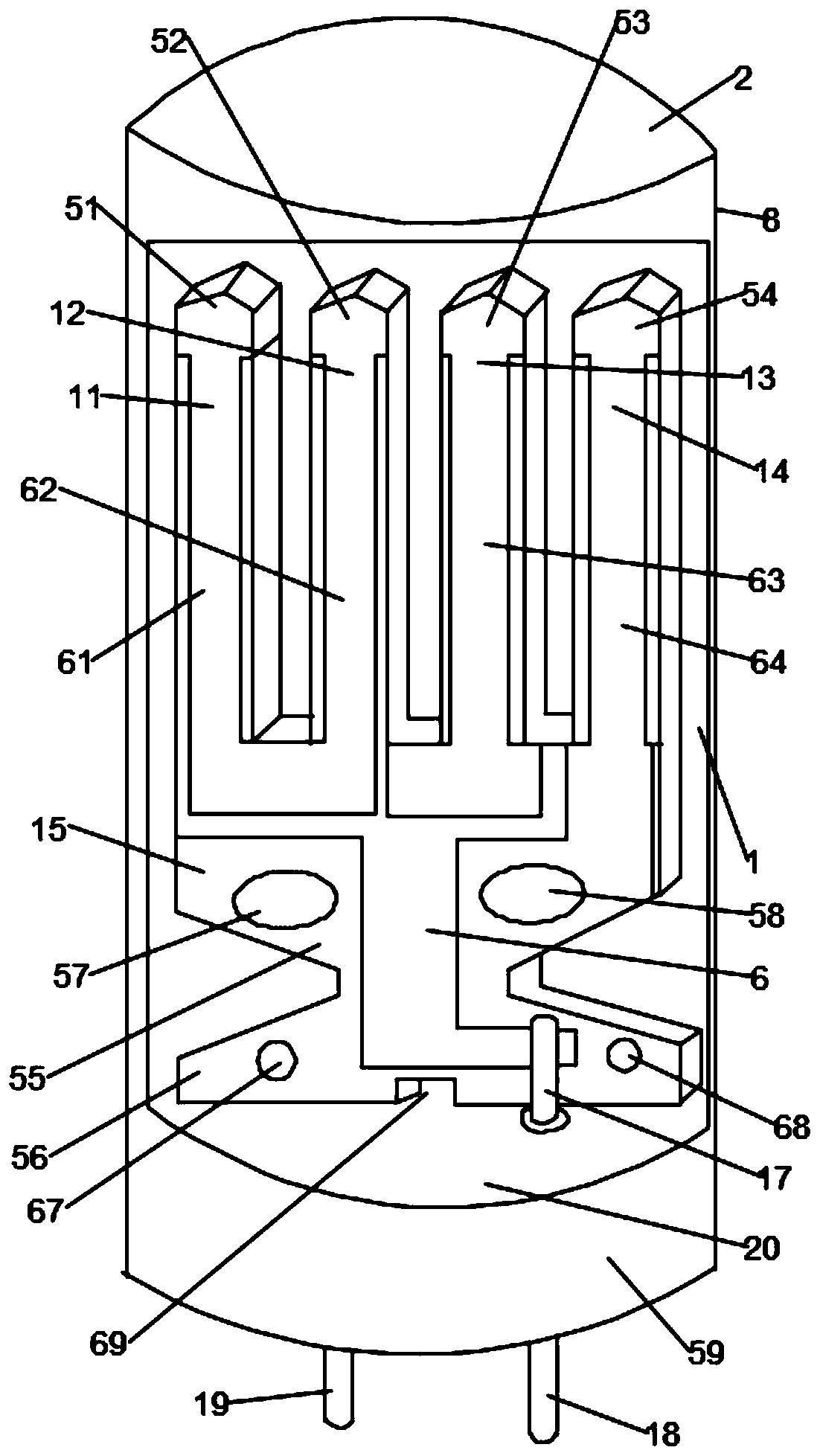

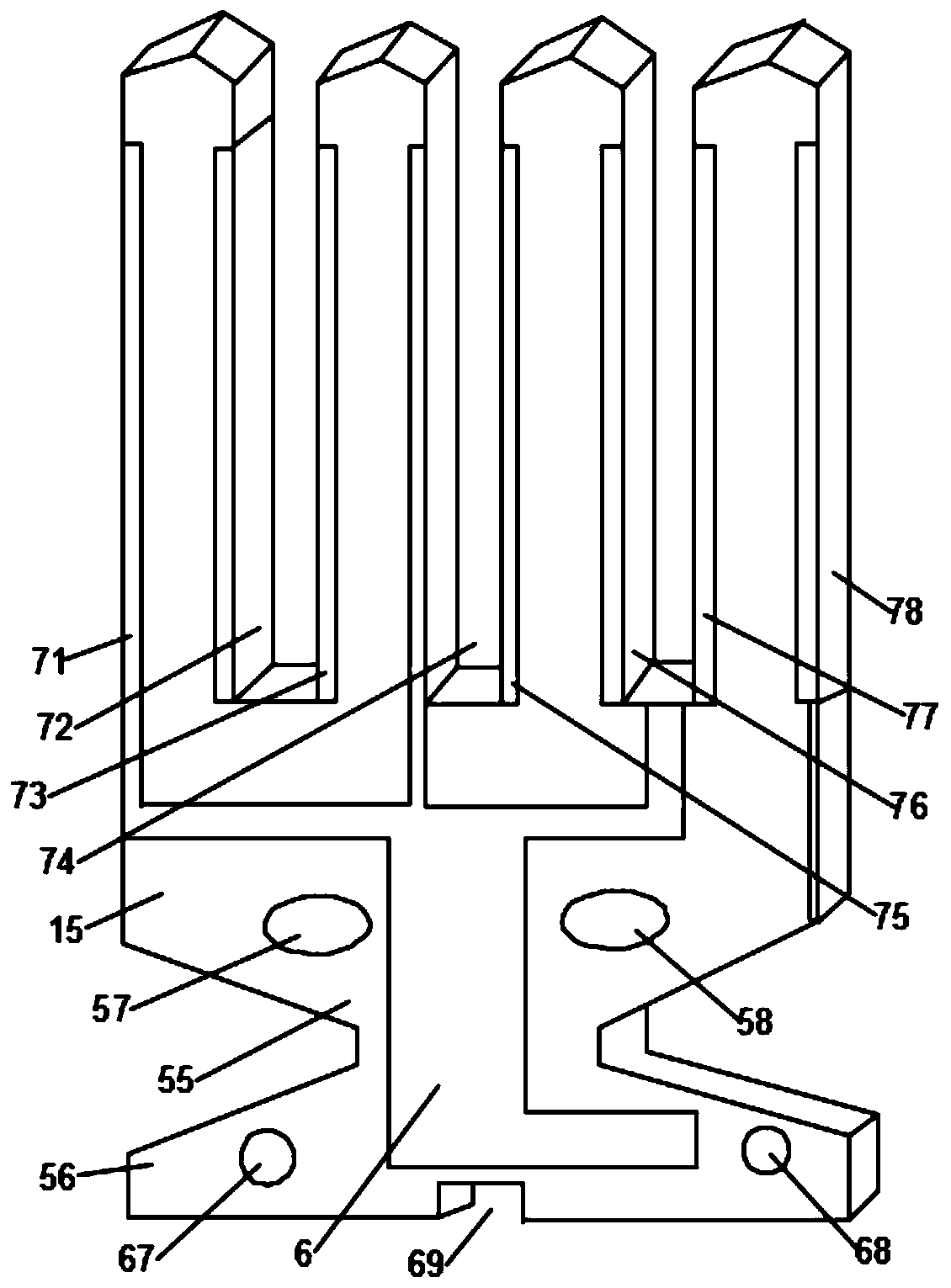

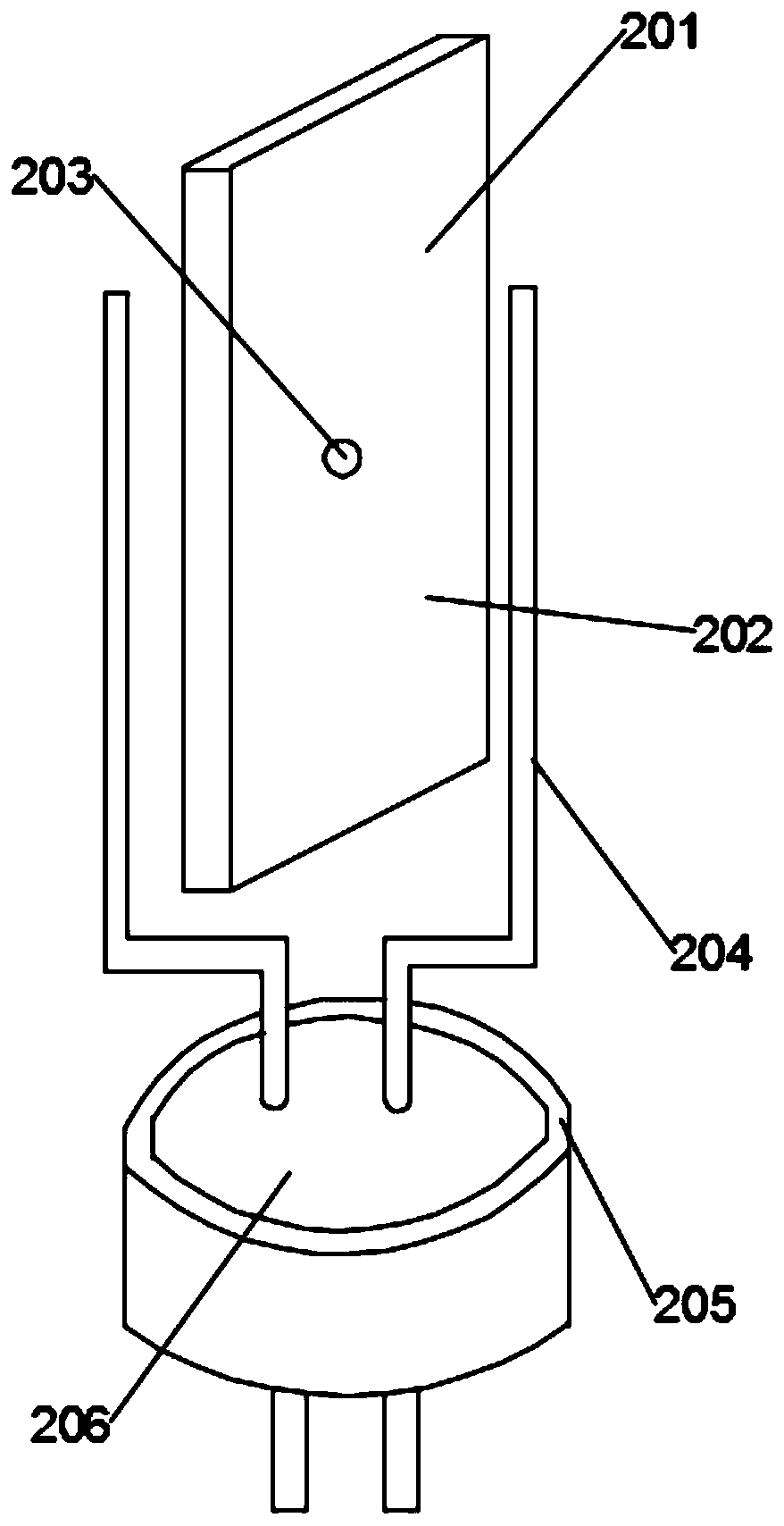

[0053] A high-precision resonant quartz temperature sensor with multiple arrow-shaped vibrating arms, including a tube base 20 composed of a tube cap 2, a first pin 18, a second pin 19 and an insulator 17, the tube cap 2 and the tube base 20 The formed integrated packaging component 8 and the heat-sensitive quartz resonator 1 with multiple arrow-shaped vibrating arms installed in it and working in the length-stretching mode are filled with helium gas 59 with high-speed thermal conductivity inside the integrated packaging component 8 .

[0054] The first pin 18 of the Kovar wire and the second pin 19 of the gold-plated Kovar wire are respectively connected to the first bus bar electrode 6 of the heat-sensitive quartz resonator 1 working in the length-stretch mode with multiple arrow-shaped vibrating arms 1. The second bus bar electrode (the second bus bar electrode is on the back of the thermosensitive quartz resonator 1, so it is not shown) is electrically connected together, t...

Embodiment 2

[0088] A high-precision resonant quartz temperature sensor with multiple arrow-shaped vibrating arms, including an integrated packaging component 8 and a heat-sensitive quartz resonator 1, and the integrated packaging component 8 is filled with helium 59, and the integrated packaging component 8 Including a tube cap 2 and a tube base 20, the tube base 20 includes an insulator 17, a first pin 18 and a second pin 19, the first pin 18 is connected to the first bus bar electrode 6 of the thermosensitive quartz resonator 1, the second The second pin 19 is connected to the second bus bar electrode of the thermosensitive quartz resonator 1. The thermosensitive quartz resonator 1 includes a base region 15 and n vibration arms, where n is an even number not less than four, and the tops of the vibration arms are all isosceles triangles , the bottoms of the vibrating arms are all rectangular, and the vibrating arms all extend from the base area 15 along the positive direction of the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com