burner

A burner and exciter technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as dissipative plasma-induced flow, and achieve the effects of stable combustion, enhanced stability, and enhanced excitation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

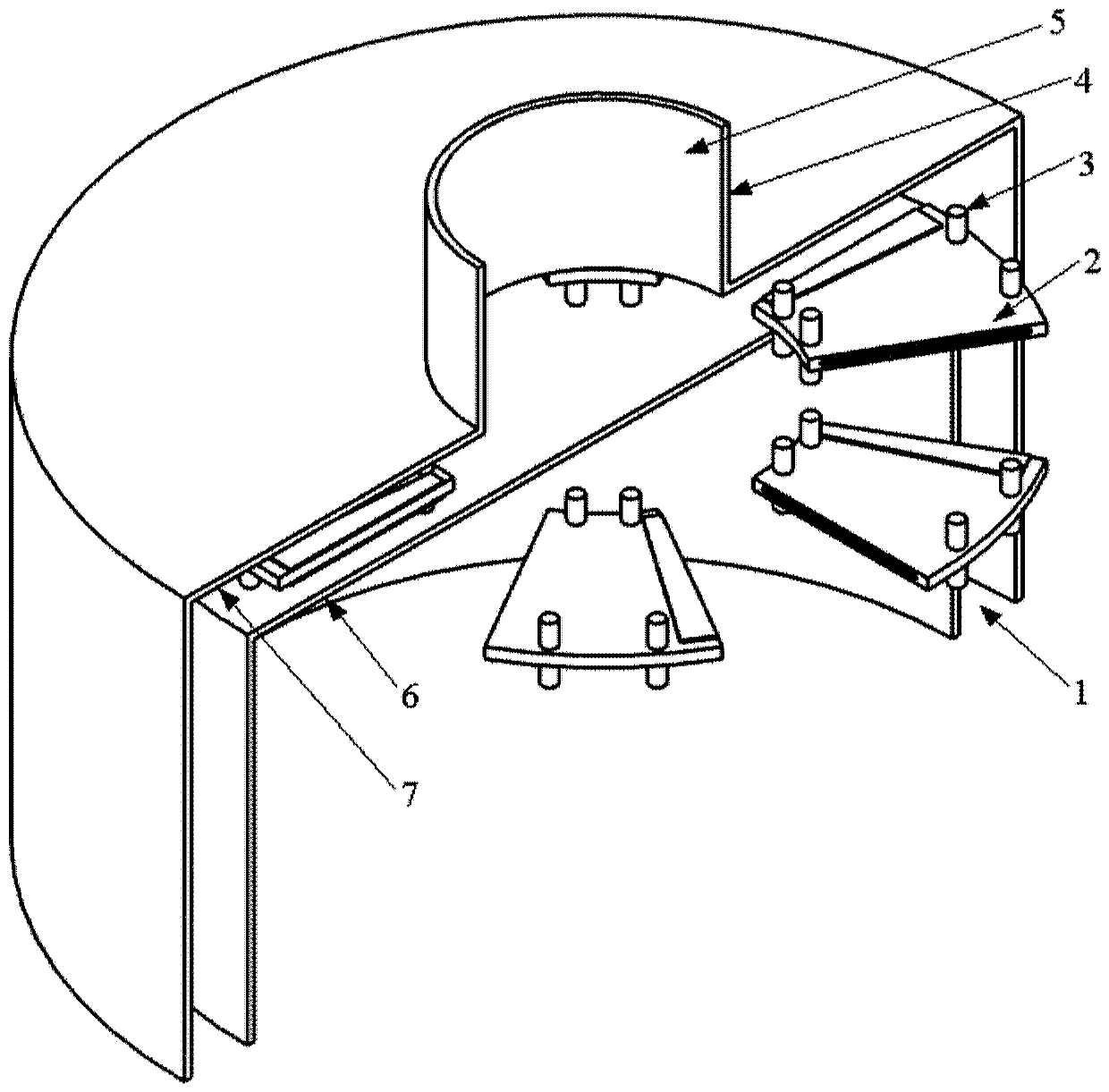

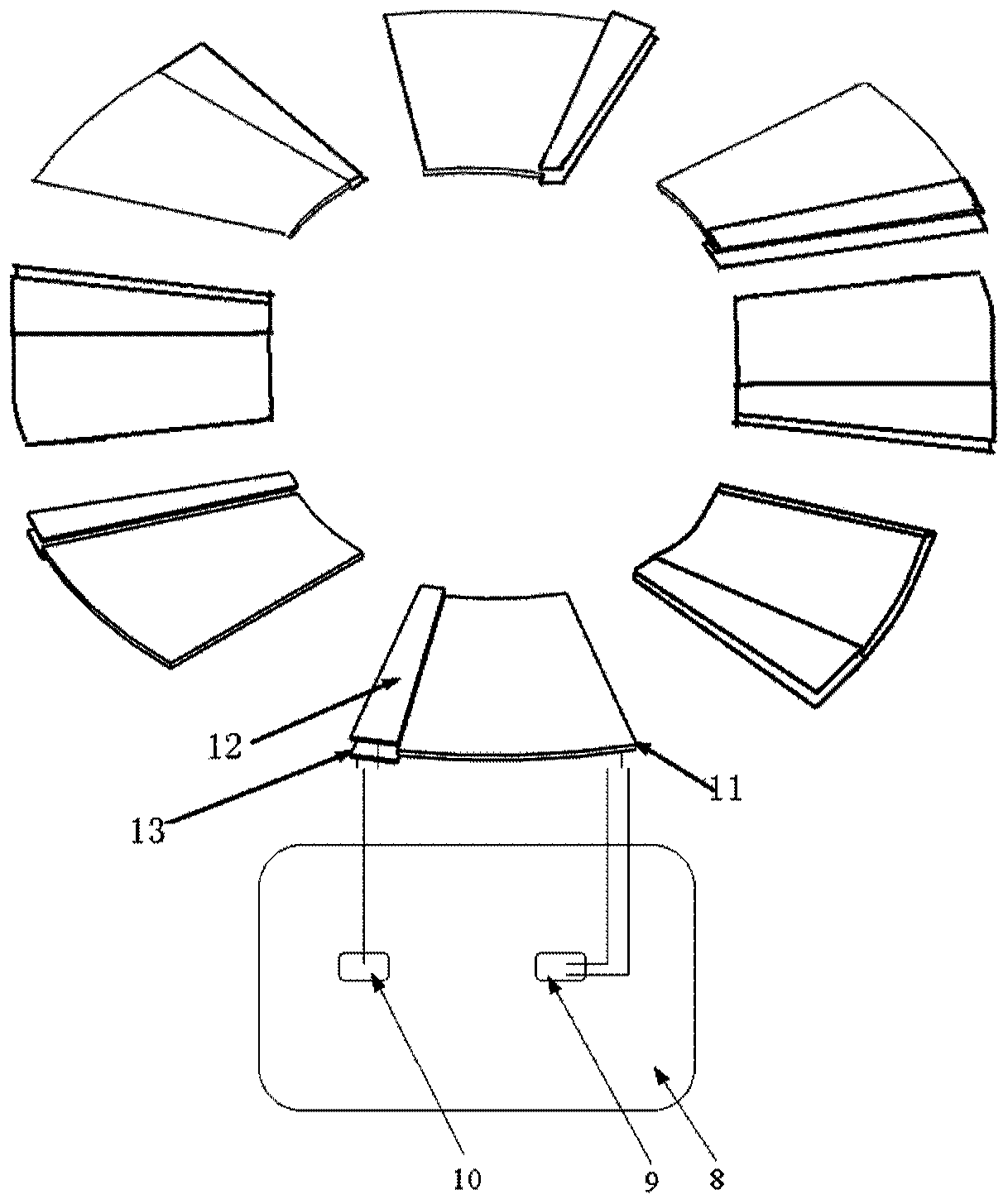

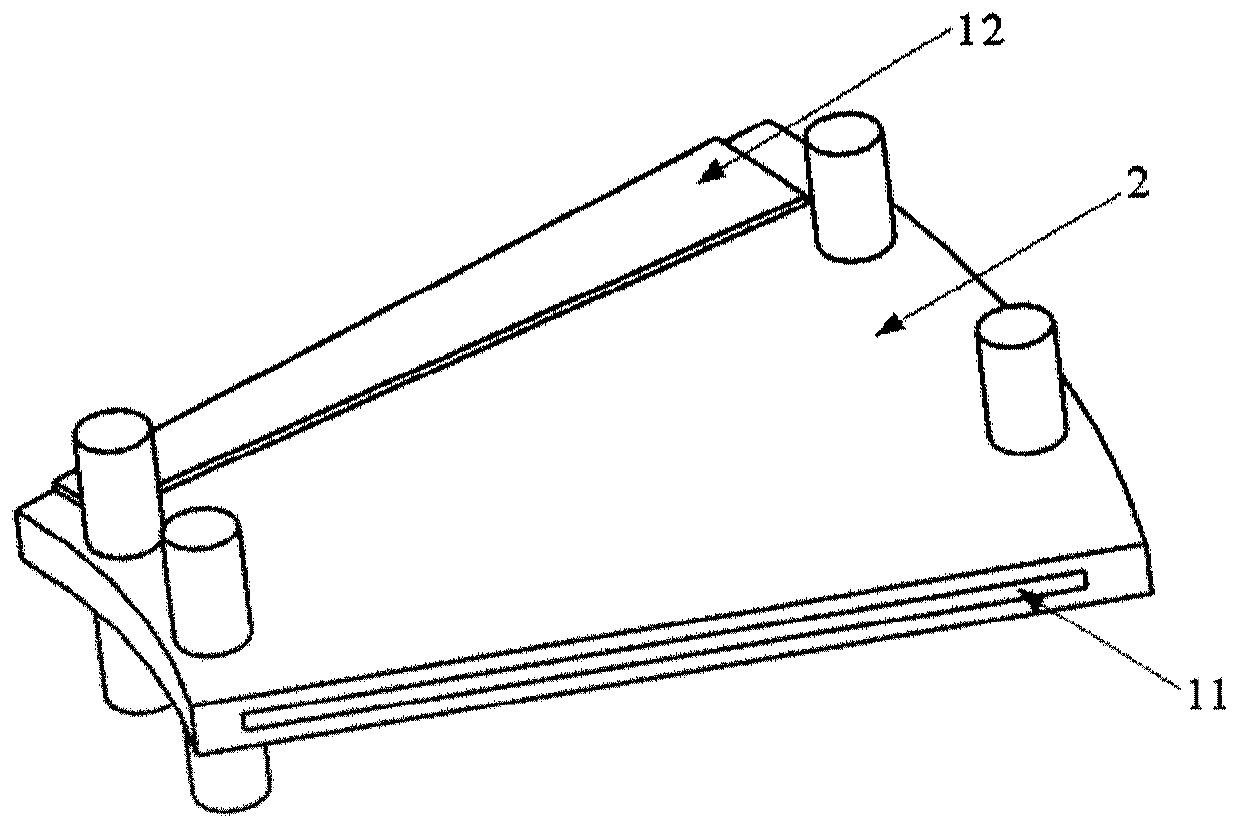

[0065] This embodiment proposes a plasma burner with radial suspension plates, see Figure 1 to Figure 3 , A channel for the radial flow of combustion reactants is formed between the upper end plate 7 and the lower end plate 6 of the burner, and the axial distance between the suspension plate and the upper and lower end plates of the burner is 3 mm. Such as figure 1 As shown, the suspension plate 2 is arranged in the flow channel between the upper and lower end plates along the radial direction, and the suspension plate support column 3 fixes the suspension plate 2 between the upper and lower end plates of the burner. The number of suspension boards 2 is 8, uniformly distributed along the circumferential direction, and there is one high-voltage power supply 8 . Such as figure 2 As shown, the ground electrode 11 of the plasma actuator is embedded in the suspension plate and connected to the ground terminal 10 of the high voltage power supply 8; as image 3 As shown, the hig...

Embodiment 2

[0069] This embodiment proposes a plasma burner with a radial suspension plate. For the purpose of brief description, the same technical features as those used in the above-mentioned embodiment 1 will not be repeated. See Image 6 , is a schematic diagram of the electrode distribution structure of a single set of plasma actuators in the burner proposed in this embodiment, that is, in a single cycle, three suspension plates fixed with ion source actuators are arranged along the radial direction of the burner, and the adjacent suspension plates staggered by 30° in the circumferential direction. The advantages of this are as follows: the plasma exciter is staggered at a certain angle, which can make the effect of plasma excitation uniformly distributed along the circumferential direction, which helps to enhance the effect of plasma excitation, make the flow more uniform and stable, and thus make the flame more stable. Figure 7 for Image 6 Schematic diagram of the full cycle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com