Plasma actuator having slotted ventilation structure

A ventilation structure and plasma technology, applied in the field of plasma, can solve the problem of low plasma-induced jet velocity, etc., and achieve the effects of increasing the induced jet velocity and strengthening the excitation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

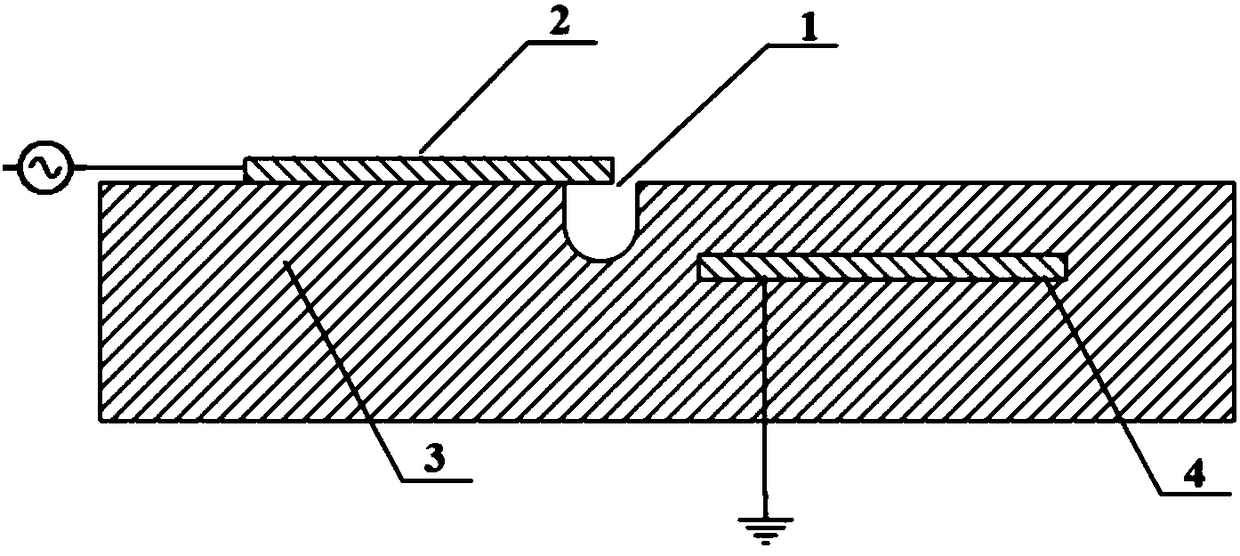

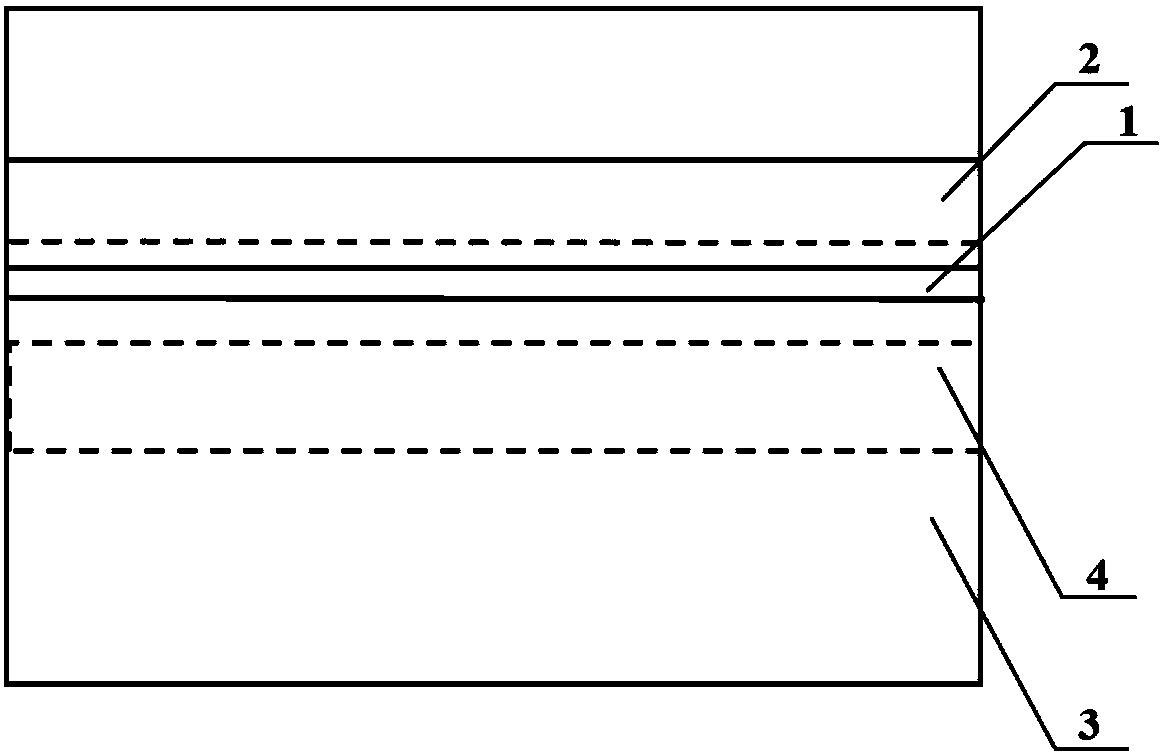

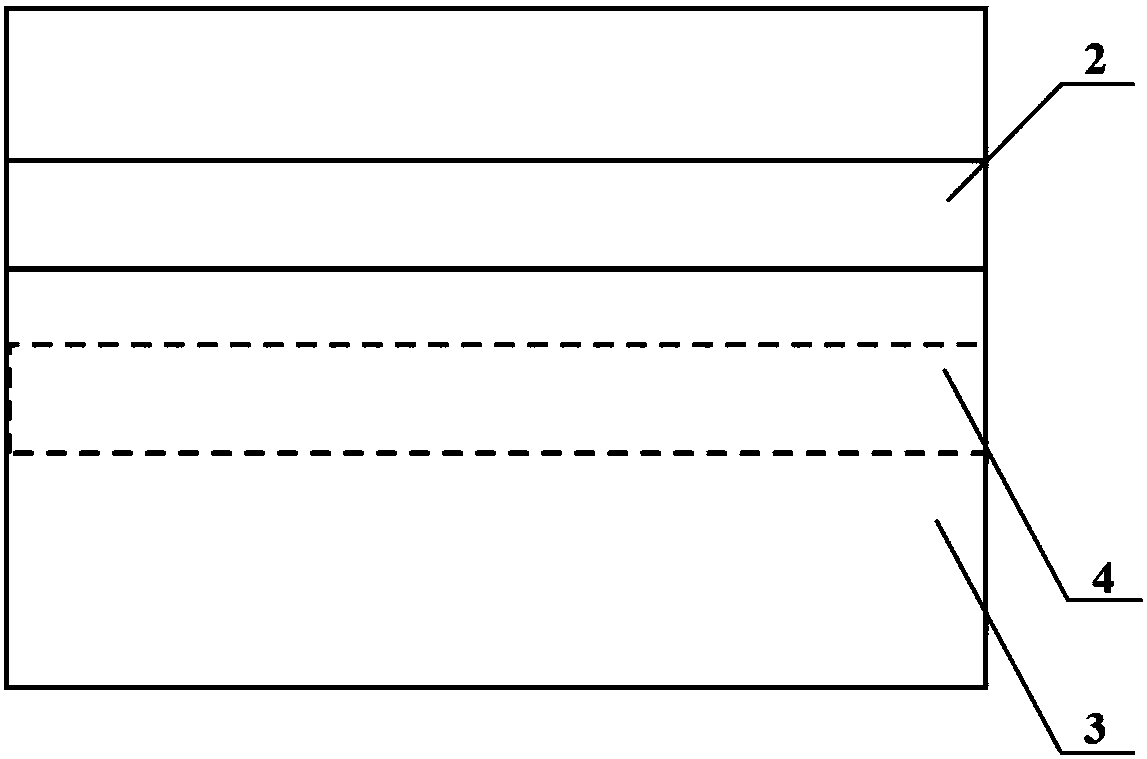

[0027] combine figure 1 As shown, the width of the dielectric surface electrode 2 is selected to be 4 mm, the width of the channel 1 is 3 mm, the dielectric surface electrode 2 partially covers the channel 1, and the width of the gap formed by the dielectric surface electrode 2 and the side wall of the channel 1 is 0.6 mm. Channel 1 has a depth of 3mm.

[0028] In order to verify the effect of the present invention, the plasma actuator with the same structure as the present invention but without slots is simultaneously measured for the induced velocity:

[0029] Make the power input of the two plasma exciters the same: the voltage is 100V, and the input current is 0.35A. The measured plasma velocity at 10 mm downstream of the electrode 2 on the surface of the medium is: 1.3 m / s for the plasma actuator without slots, and 2.1 m / s for the present invention. It can be seen from calculation that the induction speed of the present invention is relatively increased by 61.5%. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com