Filamentous sliding discharge closed-loop plasma control system and its control method

A technology of discharge plasma and plasma, which is applied in the field of plasma physics and flow control, can solve the problem of narrow flow conditions and areas within the effective control range, inability to make appropriate adjustments in a targeted manner, and poor environmental adaptability of flow control means and other problems, to achieve the effects of controllable induced vortex intensity, improved control efficiency, and strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

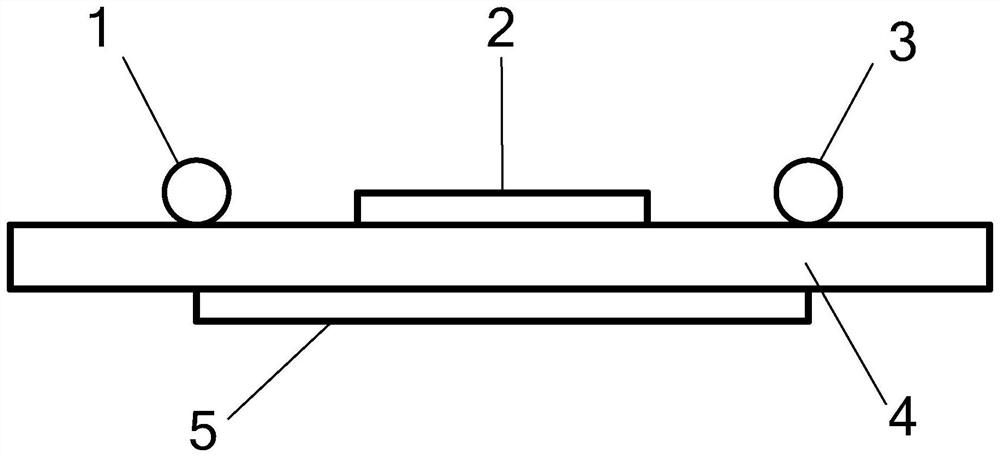

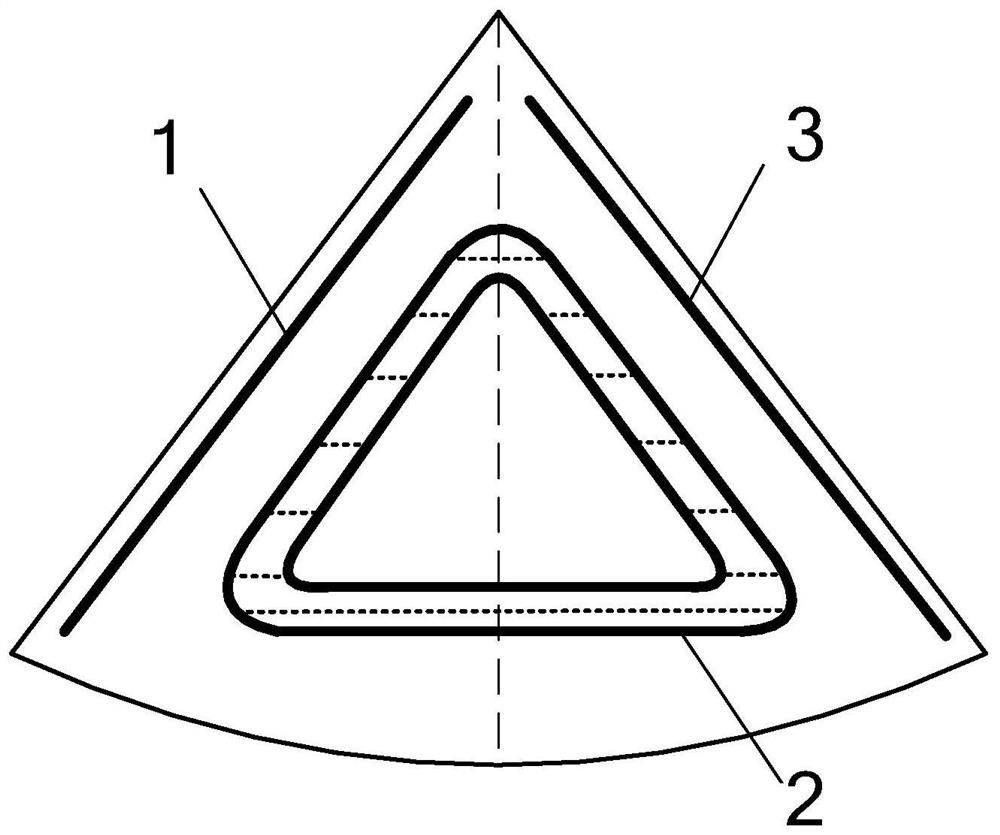

[0067] like image 3 As shown, the overall shape of the filamentary sliding discharge plasma exciter 8 at the head of the elongated body is a 60° fan shape, and the side length of the fan shape is 15 cm. The entire filiform sliding discharge plasma actuator 8 is divided into an upper electrode, an insulating medium layer 4 and a lower electrode layer 5 . The upper electrode consists of three electrodes. The first upper electrode 1 is 130 mm long and 0.1 mm in diameter; the third upper electrode 3 is 130 mm long and 0.1 mm in diameter, which is a mirror image of the first upper electrode 1 centered on the second upper electrode 2 . The second upper electrode 2 is an equilateral triangle hollowed out in the middle. In order to avoid high-voltage arc discharge and power loss, the three corners of the triangle are smooth arcs, and the length of each side of the triangle is 100 mm.

[0068] The insulating medium layer 4 is made of a polytetrafluoroethylene film with a thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com