Antibacterial aluminum alloy material and preparation method thereof

An aluminum alloy material, antibacterial technology, applied in the field of aluminum alloy products, can solve problems such as easy breeding of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the above-mentioned antibacterial aluminum alloy material, comprising the following steps:

[0038] Put pure copper, manganese, cobalt, magnesium, nickel, titanium, zirconium, molybdenum, scandium, and silicon into a melting furnace for smelting at a melting temperature of 800-900°C. After complete melting, heat up to 900-950°C and add samarium , ytterbium, gadolinium, silver, heat preservation for 20 to 30 minutes, to obtain aluminum alloy solution;

[0039] Insulating the aluminum alloy melt and die-casting to obtain an aluminum alloy product.

[0040] The above technical scheme has simple and reasonable process, high production efficiency, low production cost, less product waste, and the aluminum alloy products produced have high yield and high strength.

Embodiment 1

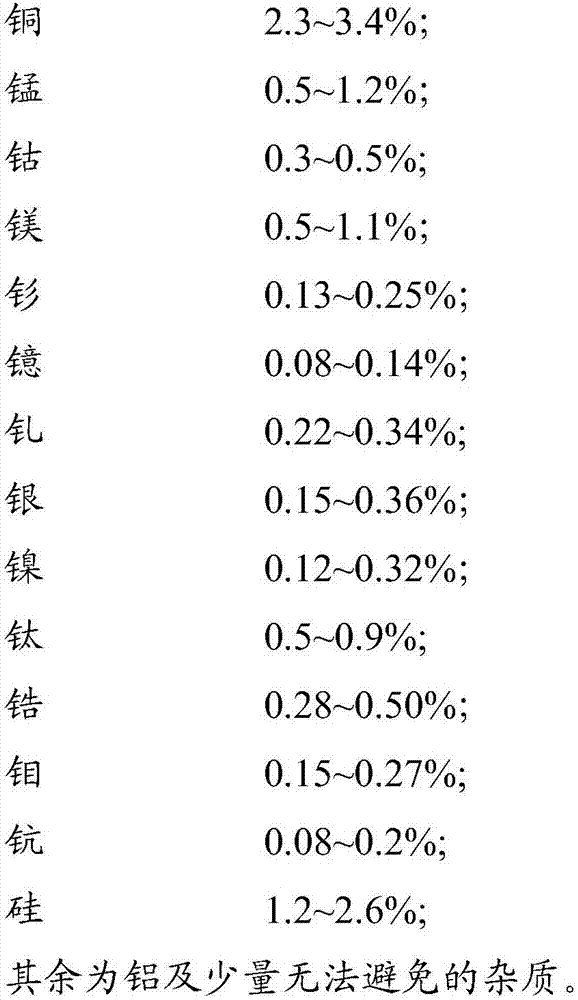

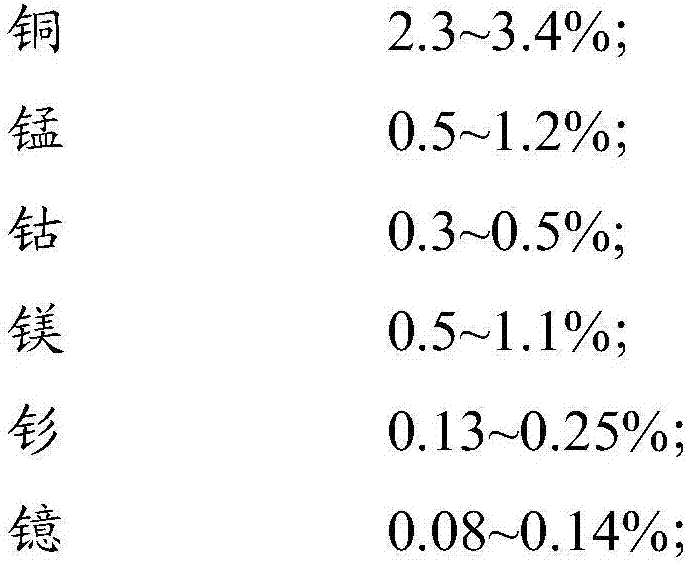

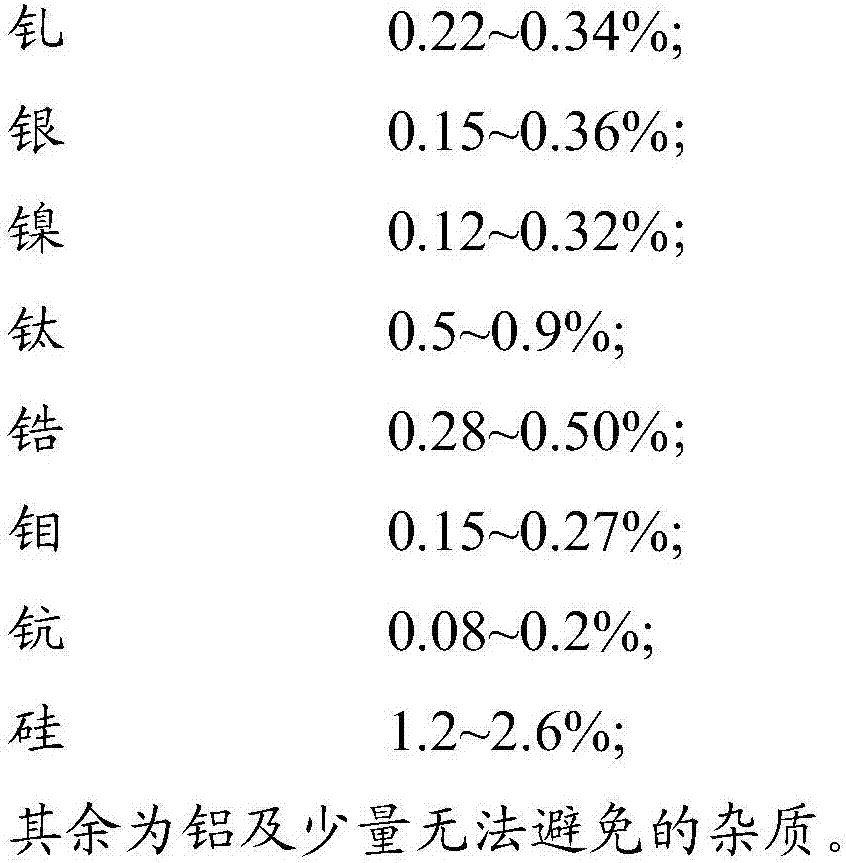

[0044] The antibacterial aluminum alloy material consists of the following components by weight percentage:

[0045] 3.0% copper, 0.8% manganese, 0.38% cobalt, 0.85% magnesium, 0.2% samarium, 0.12% ytterbium, 0.25% gadolinium, 0.30% silver, 0.19% nickel, 0.65% titanium, 0.36% zirconium, 0.2% molybdenum, 0.14% Scandium, 1.7% silicon, the rest is aluminum and a small amount of unavoidable impurities;

[0046] The preparation method of antibacterial aluminum alloy material comprises the following steps:

[0047] Put pure copper, manganese, cobalt, magnesium, nickel, titanium, zirconium, molybdenum, scandium, and silicon into a melting furnace for smelting. The melting temperature is 800°C. After complete melting, heat up to 950°C and add samarium, ytterbium, and gadolinium. , silver, and heat preservation for 20 minutes to obtain an aluminum alloy solution;

[0048]Insulating the aluminum alloy melt and die-casting to obtain an aluminum alloy product.

Embodiment 2

[0050] The antibacterial aluminum alloy material consists of the following components by weight percentage:

[0051] 2.3% copper, 0.9% manganese, 0.3% cobalt, 1.1% magnesium, 0.22% samarium, 0.14% ytterbium, 0.27% gadolinium, 0.28% silver, 0.16% nickel, 0.9% titanium, 0.42% zirconium, 0.24% molybdenum, 0.12% Scandium, 2.1% silicon, the rest is aluminum and a small amount of unavoidable impurities;

[0052] The preparation method of antibacterial aluminum alloy material comprises the following steps:

[0053] Put pure copper, manganese, cobalt, magnesium, nickel, titanium, zirconium, molybdenum, scandium, and silicon into a melting furnace for smelting. The melting temperature is 850°C. After complete melting, heat up to 950°C and add samarium, ytterbium, and gadolinium. , silver, and heat preservation for 20 minutes to obtain an aluminum alloy solution;

[0054] Insulating the aluminum alloy melt and die-casting to obtain an aluminum alloy product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com