Liquid injection explosion-proof pole structure of cylindrical power battery

A power battery, cylindrical technology, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of small diameter of liquid injection hole, long liquid injection time, riveting dislocation, etc., to reduce the liquid injection time, solve extreme problems The column space is small, and the effect of overcoming the tight sealing of the steel column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

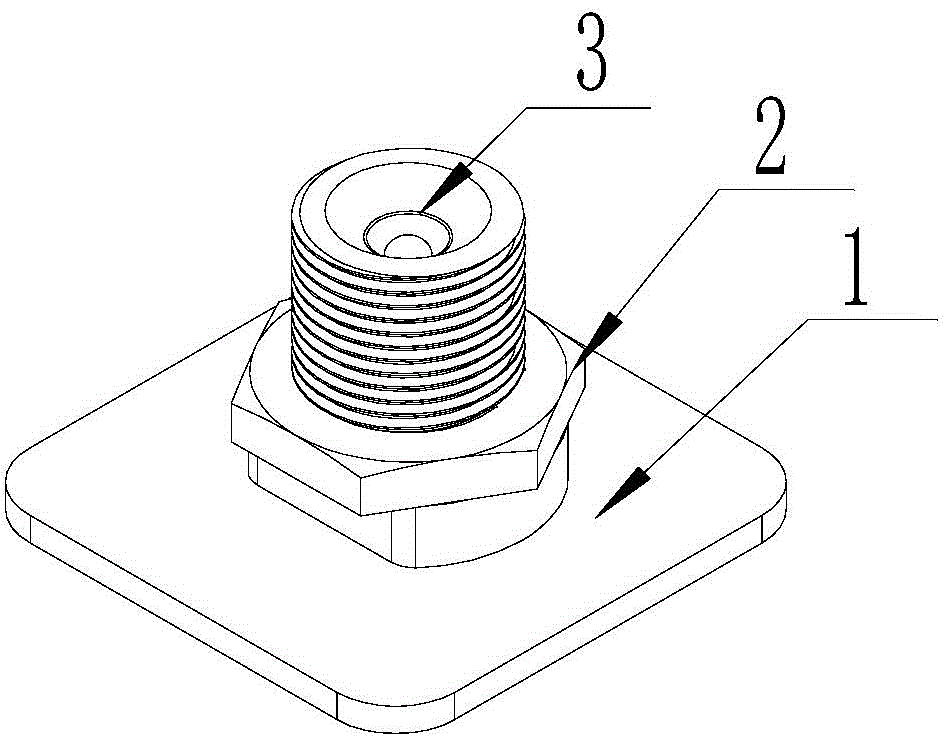

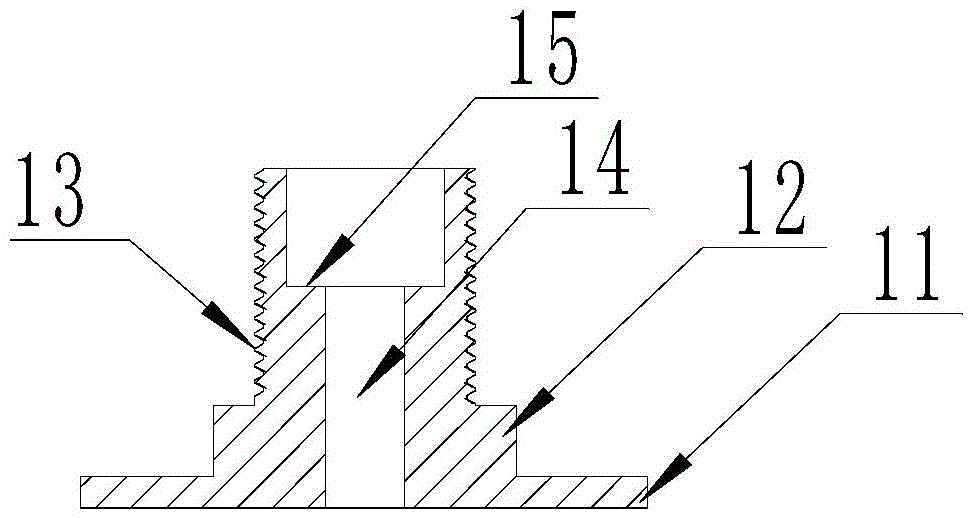

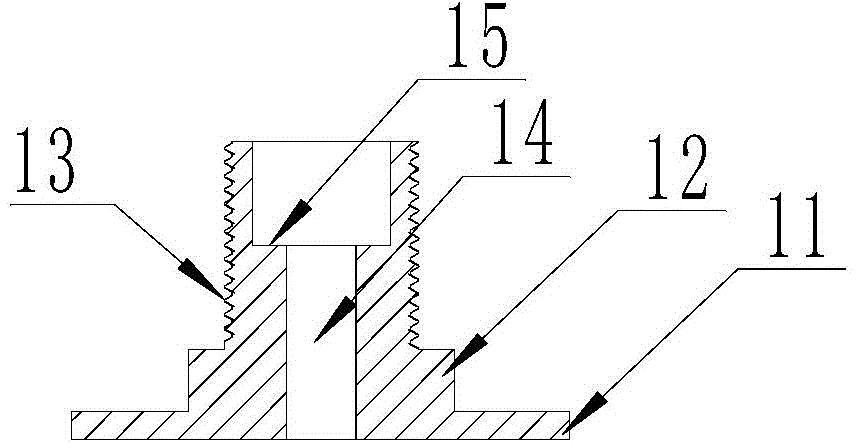

[0023] Such as figure 1 , 2 As shown in and 3, a cylindrical power battery injection explosion-proof pole structure includes a pole 1, a pole nut 2 and a safety valve plate 3, the pole 1 includes a connecting plate 11 and a pole 12, and the connection The plate 11 is provided with a column body 12, and the column body 12 is provided with a pole thread 13, and the pole thread 13 on the column body 12 is matched with the pole nut 2, between the connecting plate 11 and the pole nut 2. A battery cover is provided between the pole nuts 2, and the pole nut 2 cooperates with the pole thread 13 to fix the pole 1 and the battery cover under the action of a certain pre-tightening force. There is a sealing or insulating device between the connecting plates 11; or there is a sealing or insulating device between the battery cover plate and the pole nut 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com