Patents

Literature

38results about How to "Improve infrared stealth performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

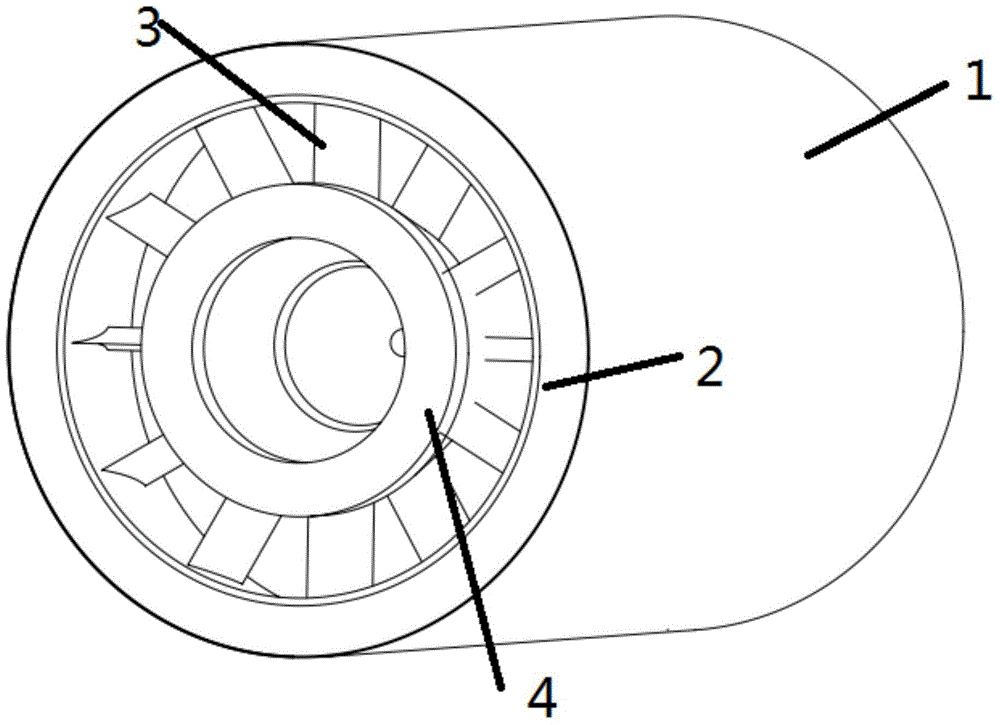

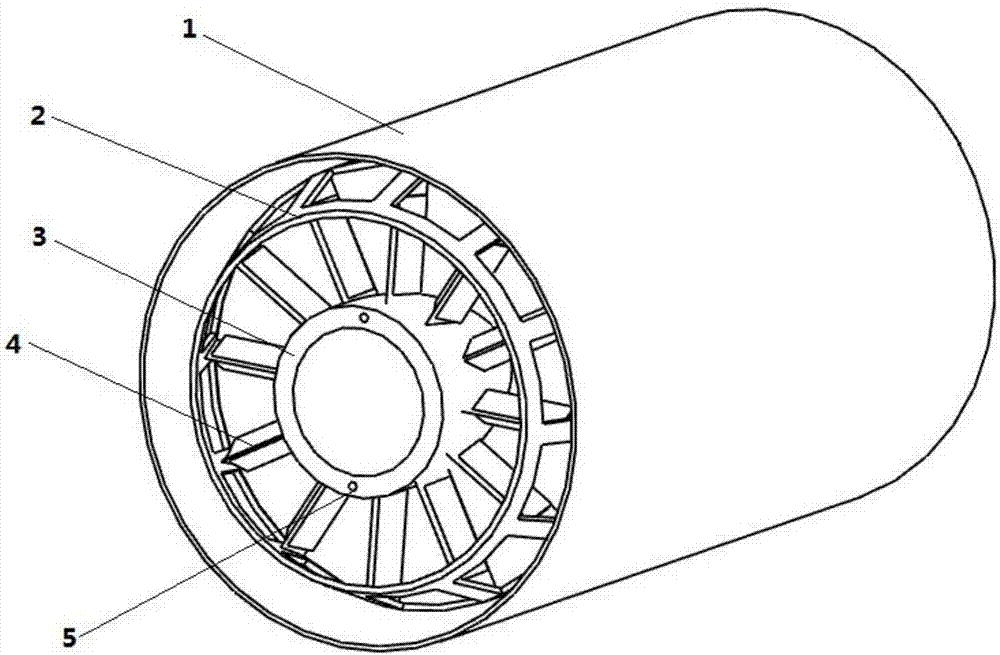

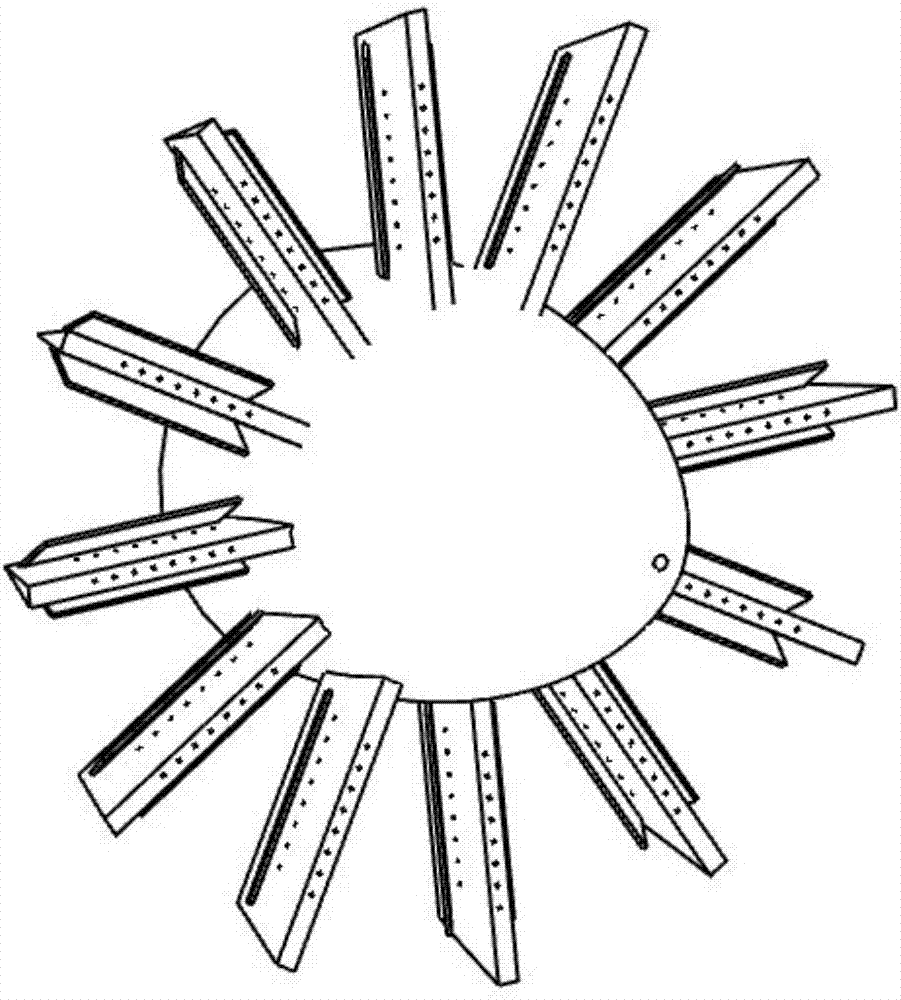

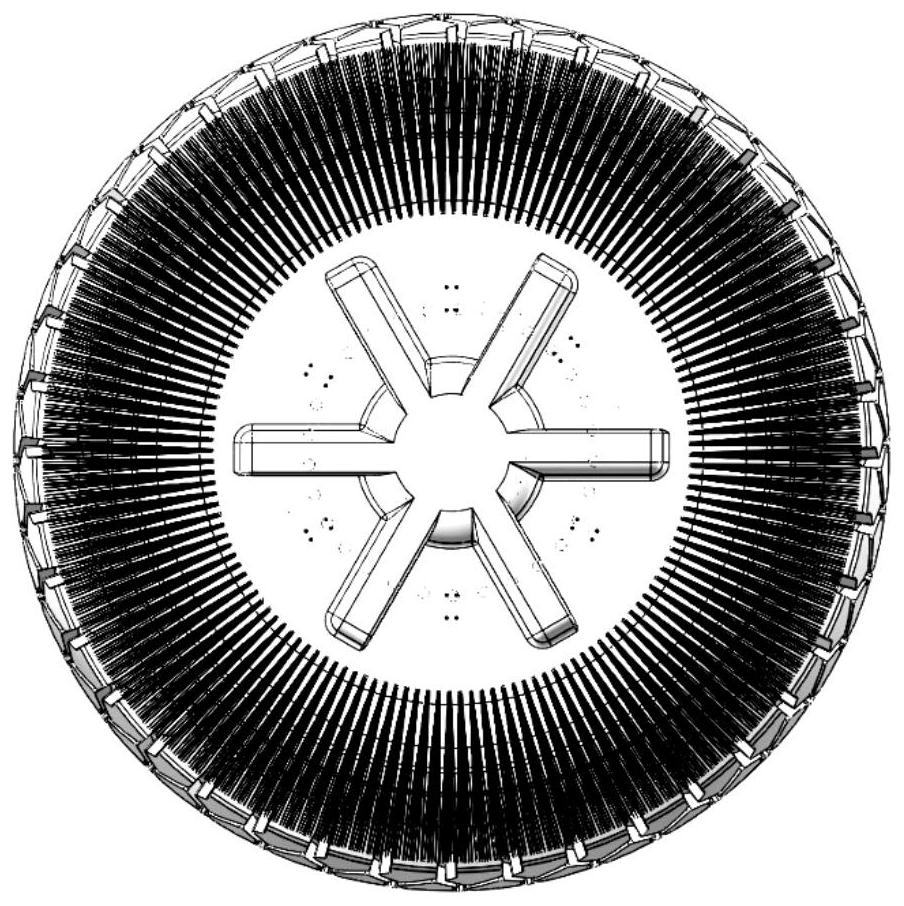

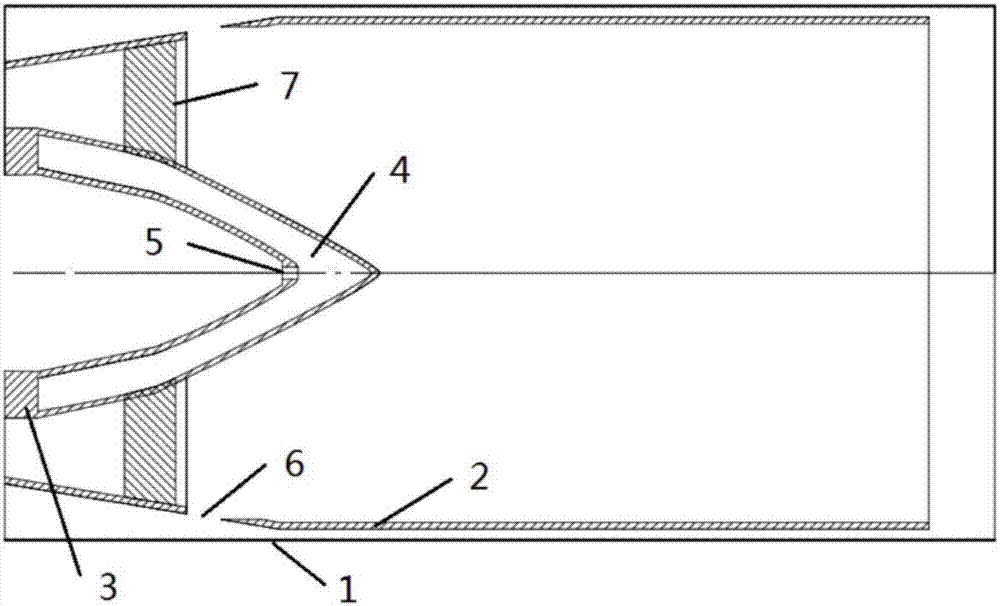

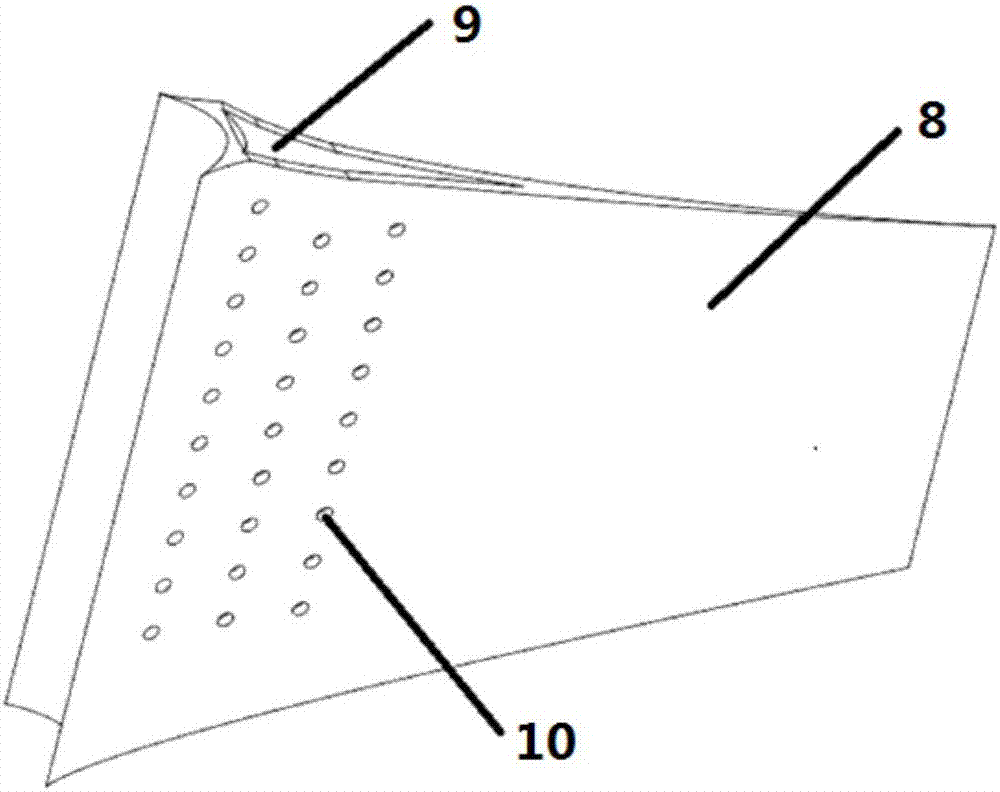

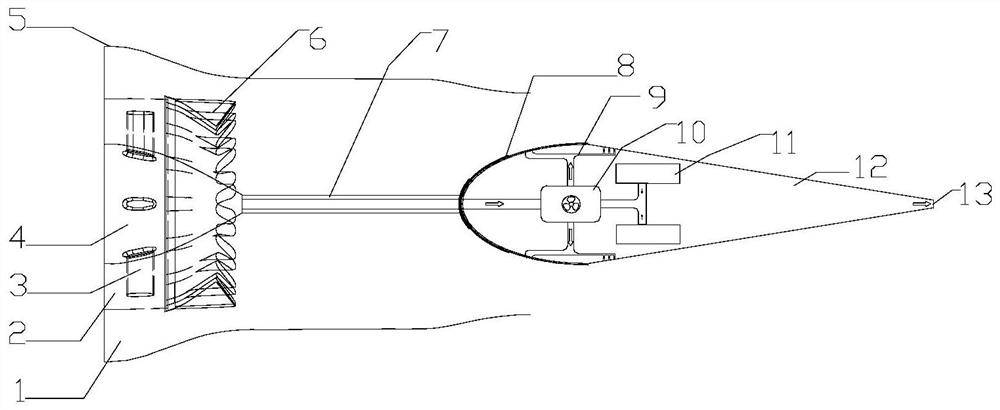

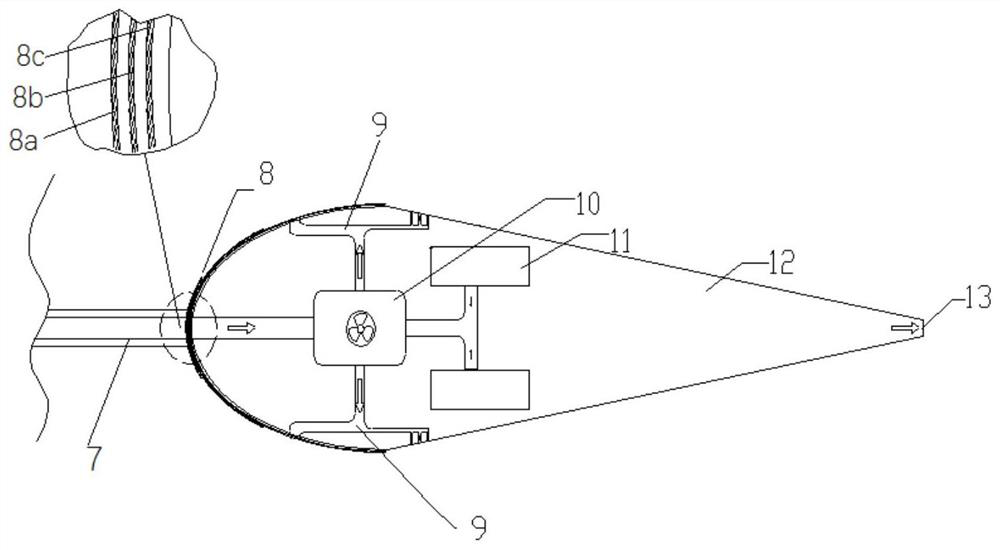

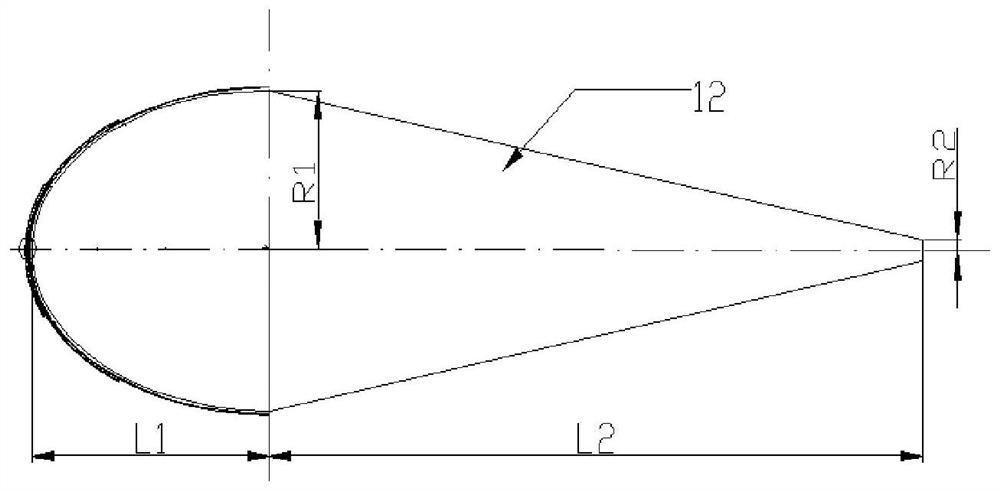

Pre-evaporation type integrated afterburner

InactiveCN105674332AIncrease the degree of mixingReduce the temperatureContinuous combustion chamberCombustion chamberEvaporation

The invention provides a pre-evaporation type integrated afterburner. An oil cavity is formed inside an afterburning inner cone, and is connected with a fuel oil channel inside a rectification support plate flame stabilizer. Fuel oil is heated in the oil cavity to become gas or a supercritical body, and then the gas or the supercritical body enters the fuel oil channel inside the rectification support plate flame stabilizer and is sprayed out from direct-injection type spraying nozzle small holes in the two sides. The spraying nozzle small holes are reasonably formed so that the mixing effect of the fuel oil and the gas can be effectively improved, and the burning efficiency is improved. In addition, a large amount of heat is transmitted to the fuel oil through the afterburning inner cone, so that the self temperature is decreased, and the infrared stealth performance is effectively improved. The pre-evaporation type integrated afterburner has the beneficial effects that on the basis of an integrated afterburner structure, by reasonably leading in the structure of the oil cavity inside the afterburning inner cone and the structure of the fuel oil channel inside the rectification support plate flame stabilizer and reasonably forming the direct-injection type spraying nozzle small holes, the burning efficiency is effectively improved, and the infrared stealth performance is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

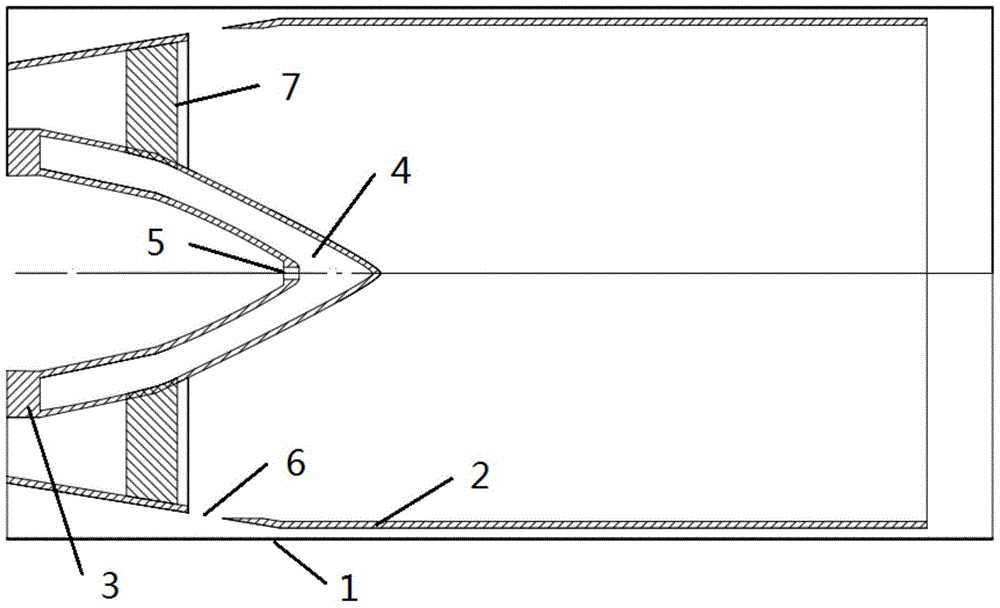

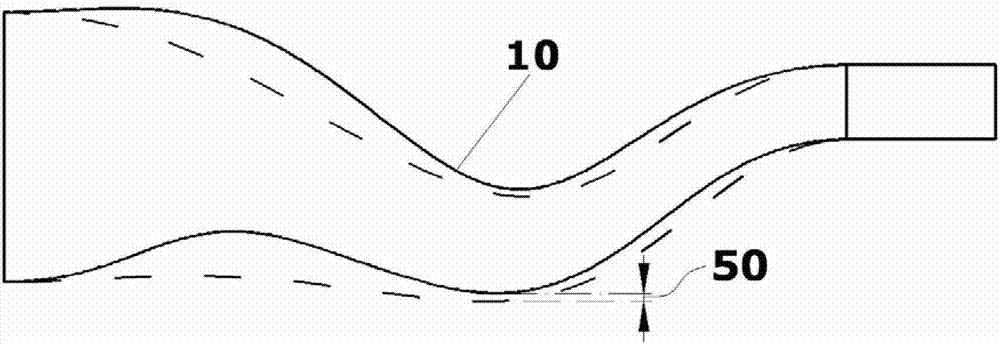

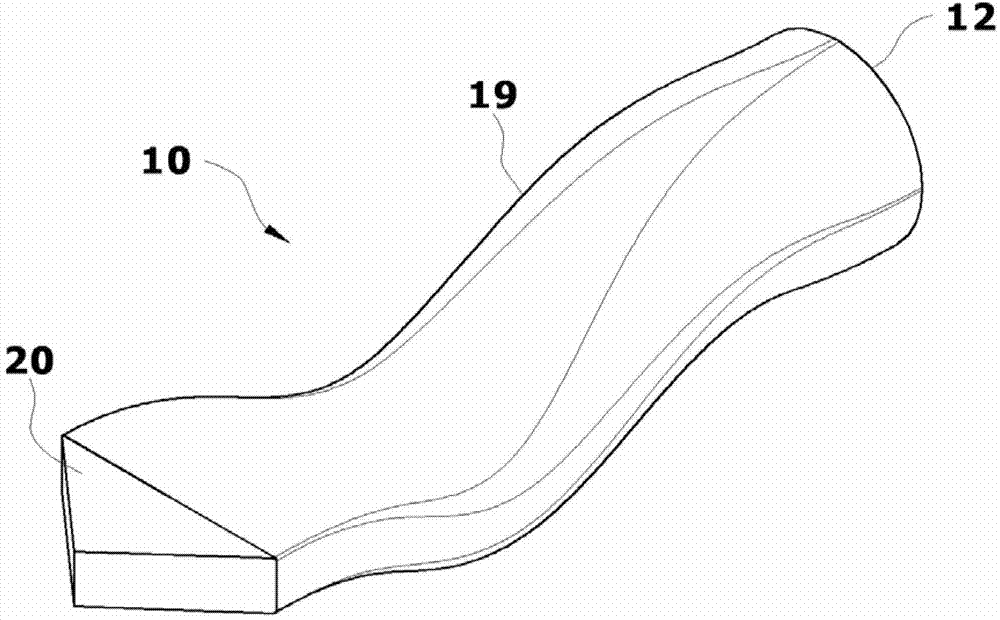

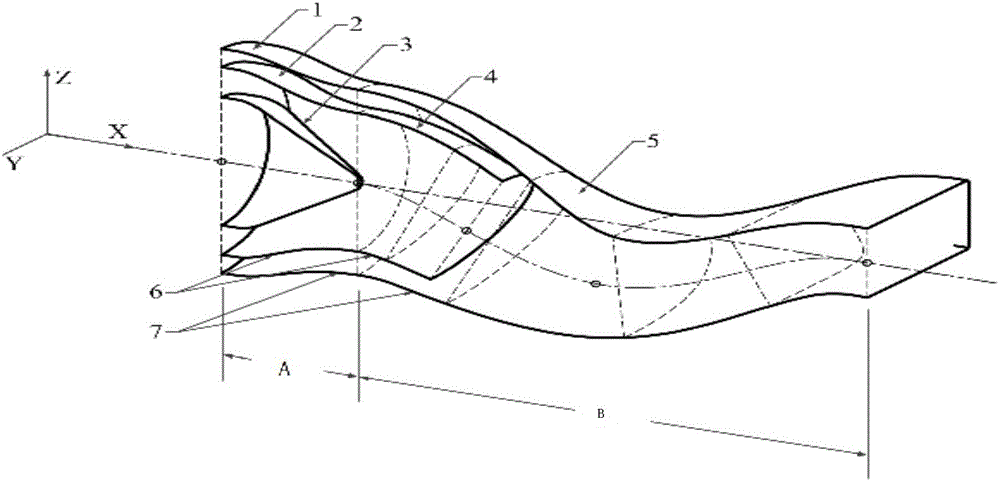

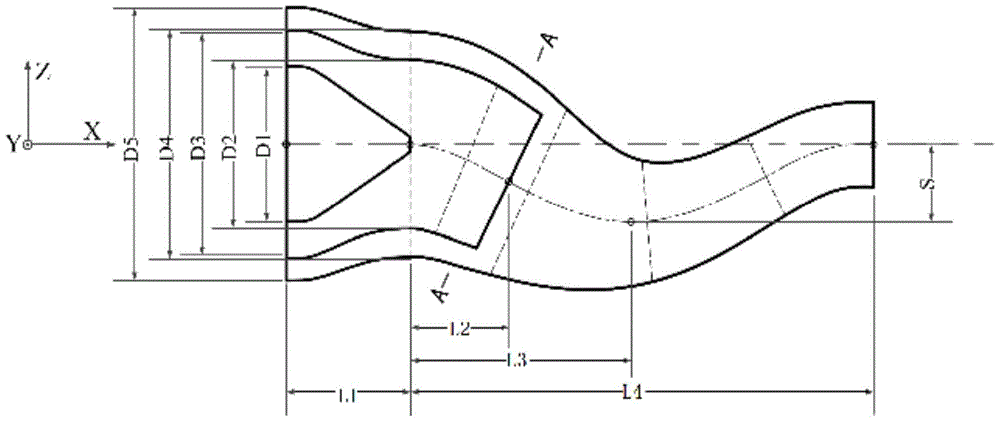

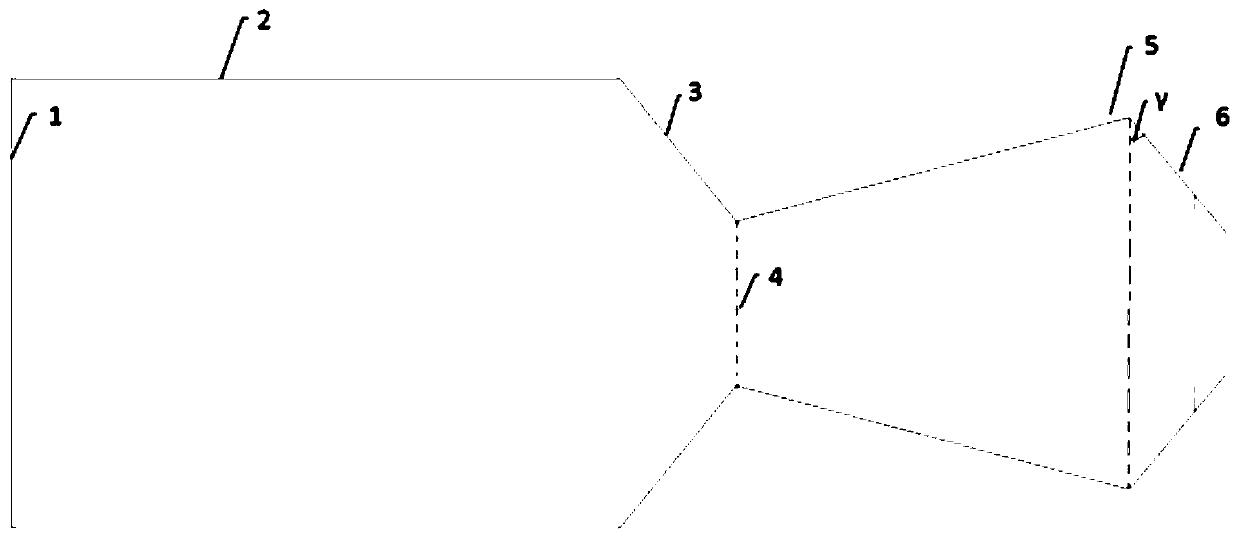

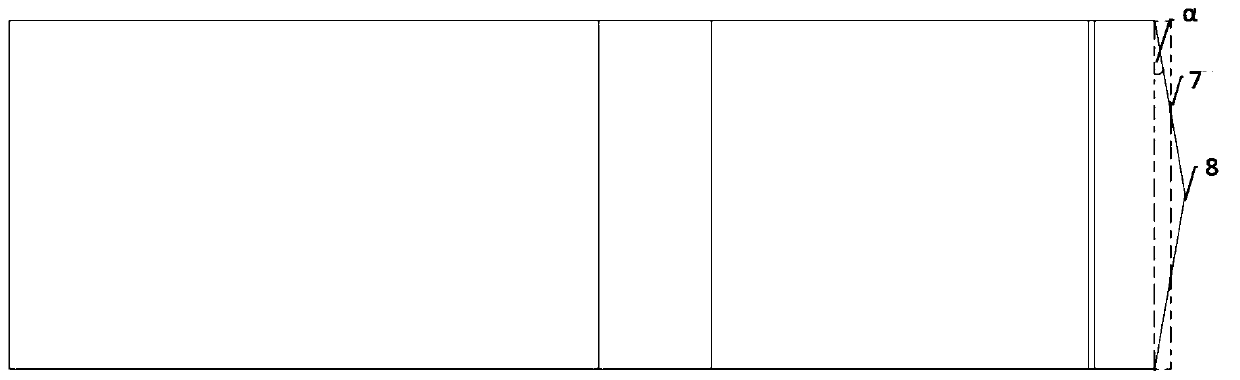

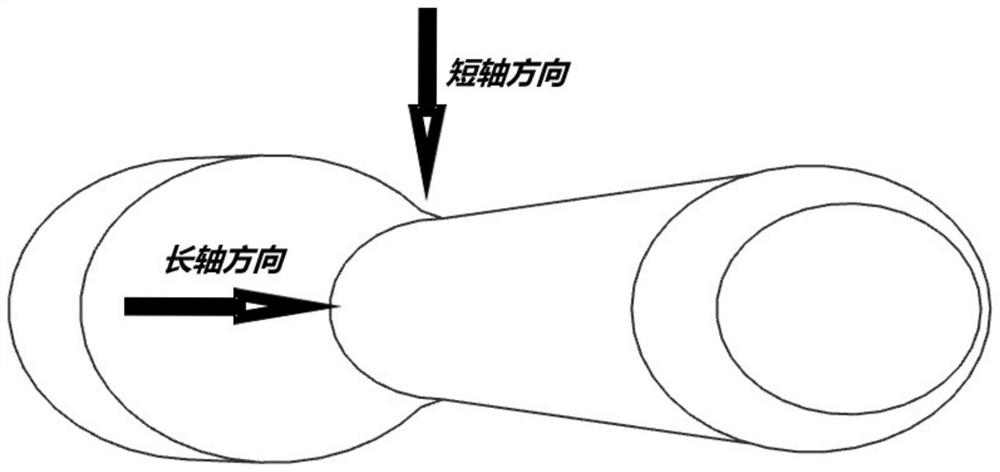

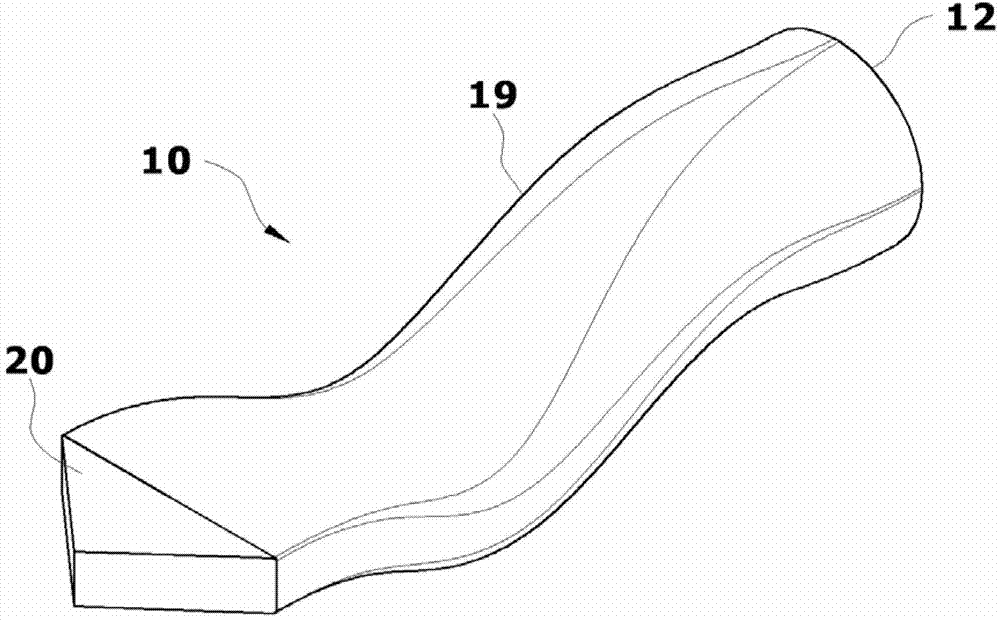

Stealth exhaust system

ActiveCN102926888AImprove adaptabilityImprove infrared stealth performancePower plant exhaust arrangementsJet propulsion plantsThroatRadar

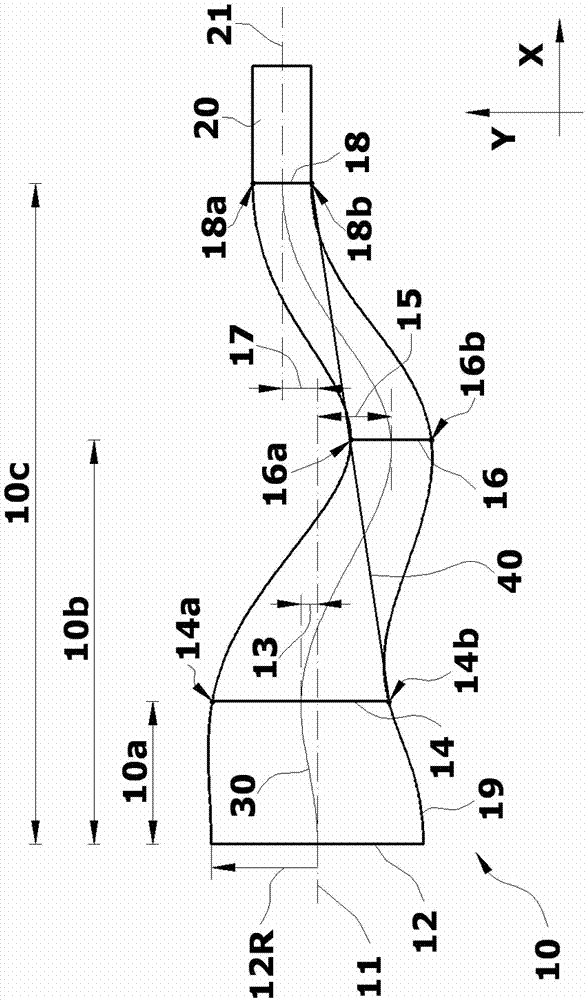

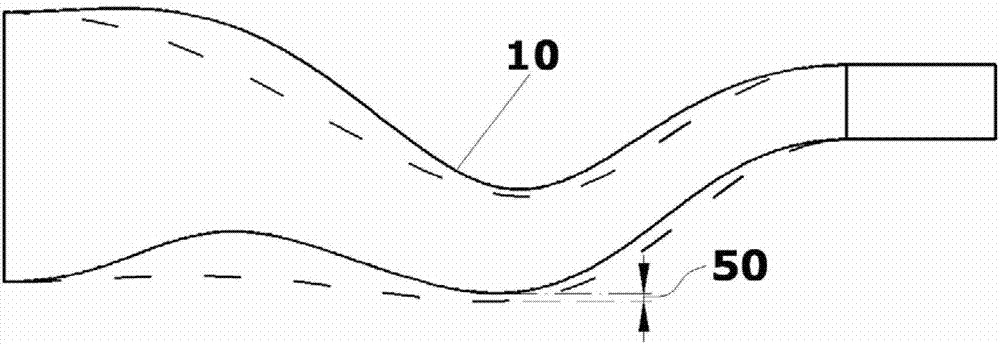

The invention relates to an exhaust system applied to an air vehicle, in particular to a stealth exhaust system. A cross-section shape of a throat of a spray pipe is designed to a non-round shape with an aspect ratio greater than 1, so that mixing of high-temperature exhaust airflow of an engine and ambient air is strengthened, the exhaust temperature is reduced, and an infrared stealth property of the exhaust system is improved. Central lines of the stealth exhaust system are three longitudinal S-bent curves, and the bent central lines can enable sidewalls of the spray pipe to shield high-temperature components of the engine, therefore, the infrared stealth property of the exhaust system can be improved; and simultaneously, the bent central lines can also cause radar waves going into the stealth exhaust system from the rear to difficultly generate backward waves, therefore, a radar stealth property of the exhaust system can be improved. Properties of the exhaust system are considered while the stealth properties are ensured, so that a requirement of the stealth exhaust system on the layout space is reduced, and adaptability of the stealth exhaust system is strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

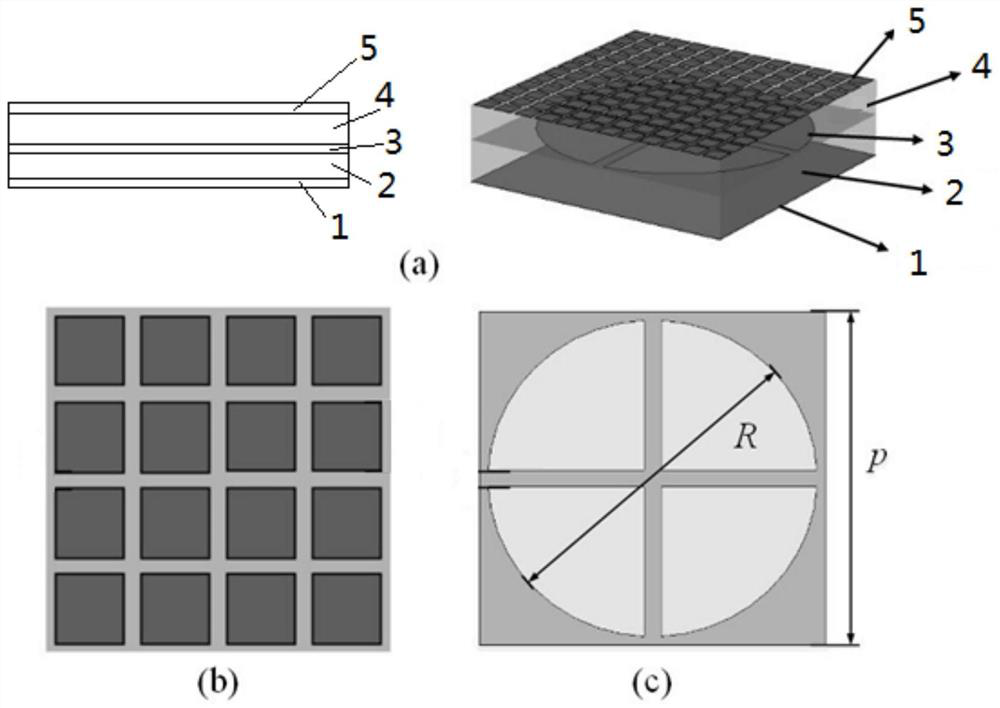

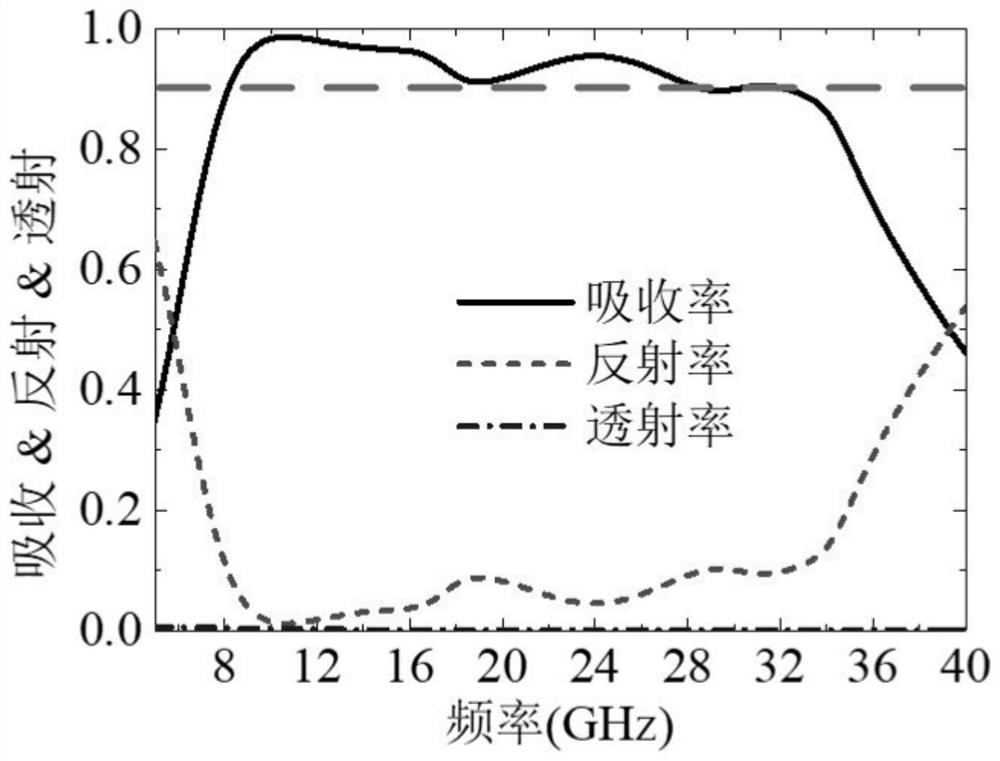

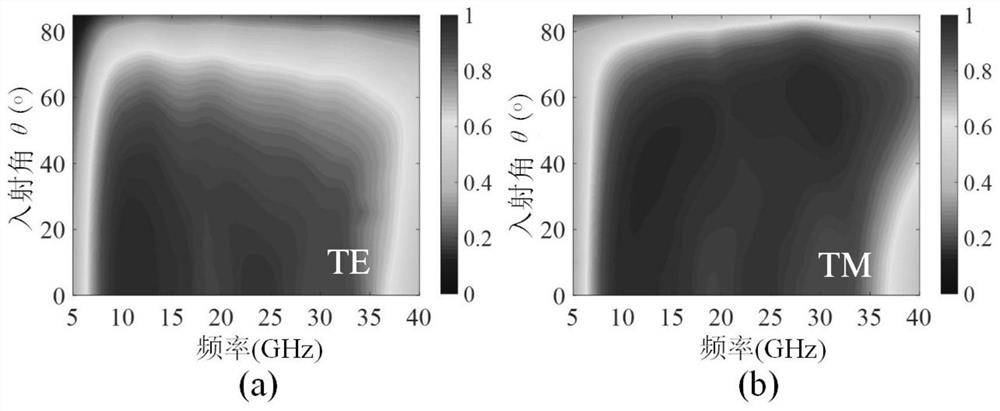

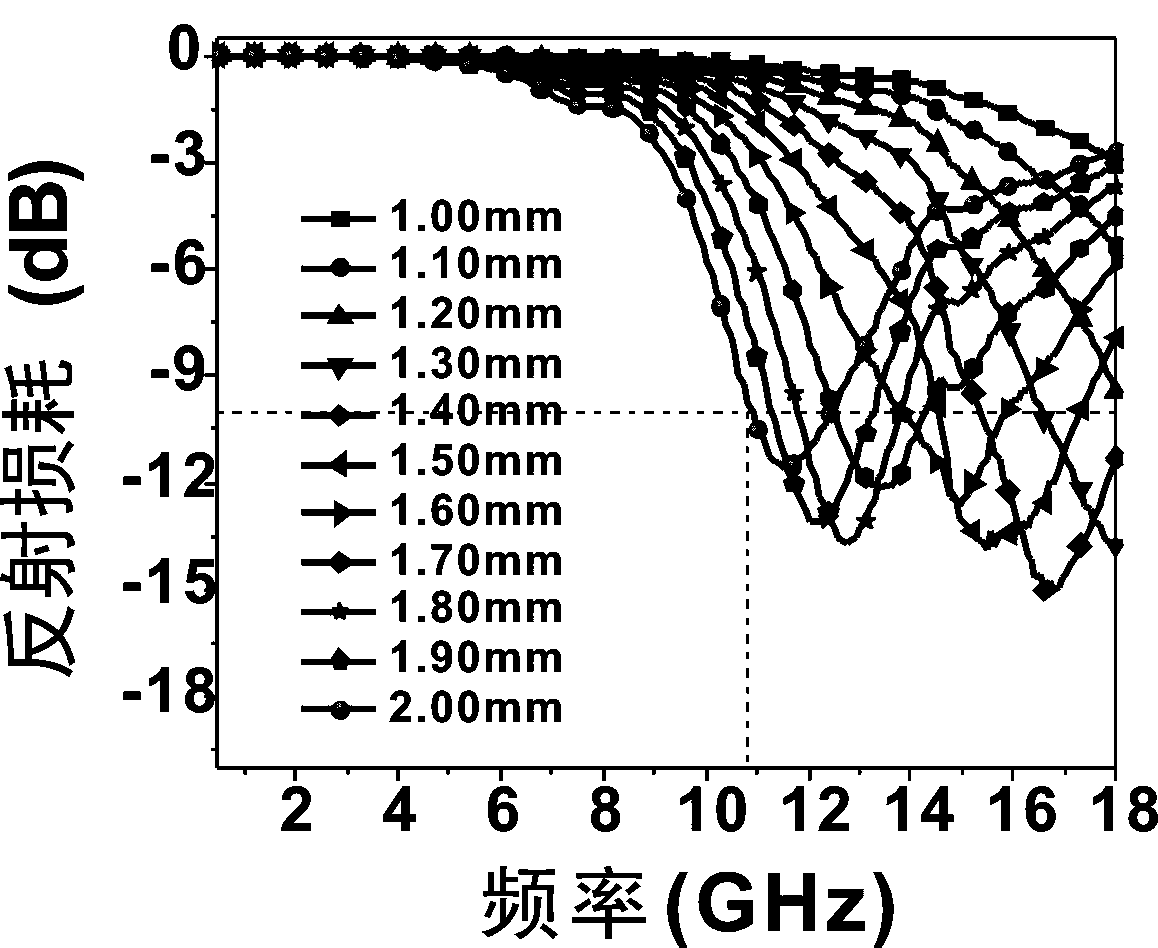

Optical transparent ultra-wideband radar and infrared double-stealth structure

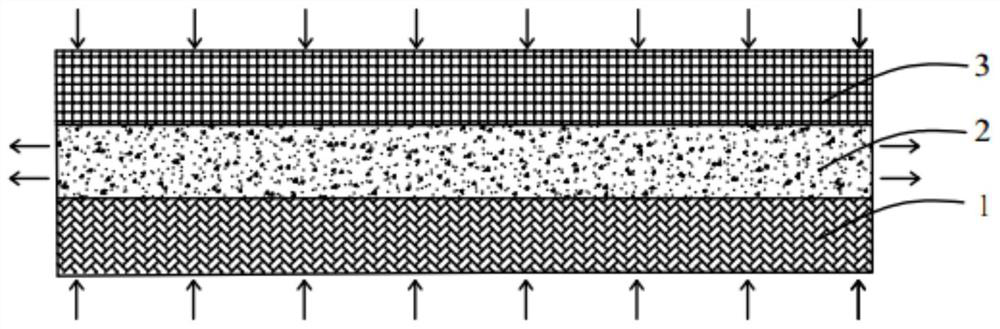

ActiveCN112622391AAddressing Optical TransparencySolving Radar StealthSynthetic resin layered productsCamouflage devicesUltra-widebandDielectric

The invention discloses an optical transparent ultra-wideband radar and infrared double-stealth structure, and relates to the technical field of multi-spectrum stealth, and the stealth structure mainly comprises a low-emissivity infrared stealth layer and an ultra-wideband radar wave-absorbing layer. In order to realize high transmittance of visible light, an optical transparent material transparent conductive film and a transparent dielectric are selected in the overall structural design; the radar wave-absorbing layer adopts a conductive film-medium-conductive film sandwich type wave-absorbing structure; the transparent conductive film is etched into a frequency selective surface by adopting a laser etching process to finish the preparation of the radar and infrared compatible stealth material; the optical transparent ultra-wideband radar and infrared compatible stealth material has high designability, the contradictory problem of optical transparency, radar stealth and infrared stealth can be well solved from the perspective of structural design by adopting a metamaterial technology, and the optical transparent ultra-wideband radar and infrared compatible stealth material has good ultra-wideband radar wave absorption performance, low infrared emissivity and optical transparency.

Owner:AIR FORCE UNIV PLA

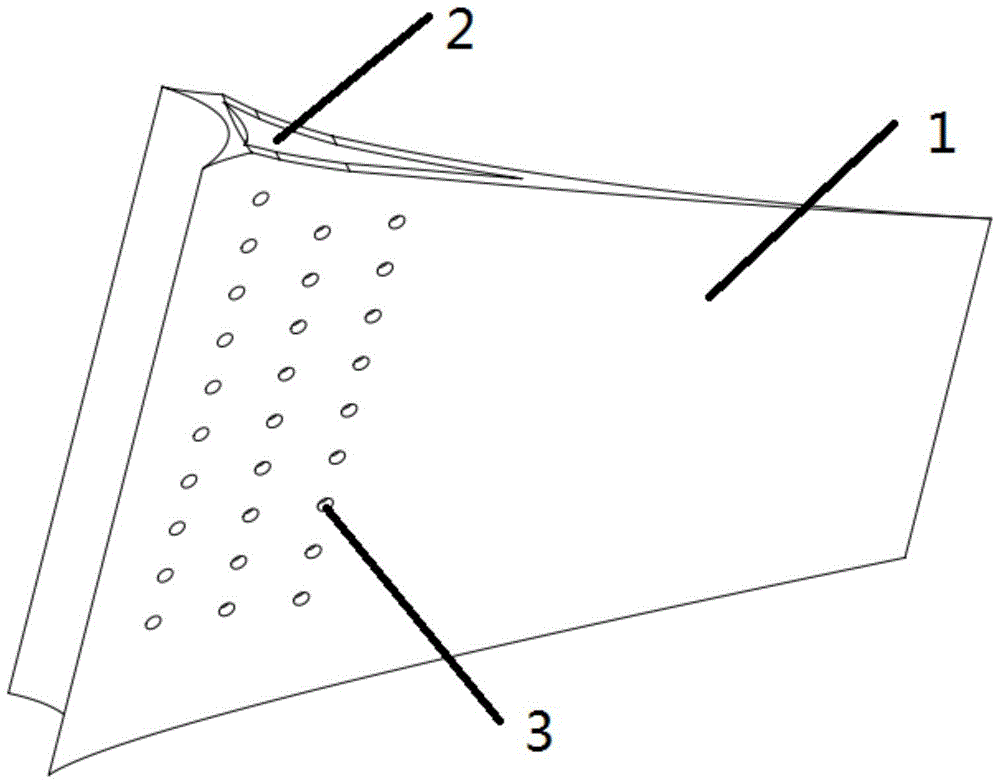

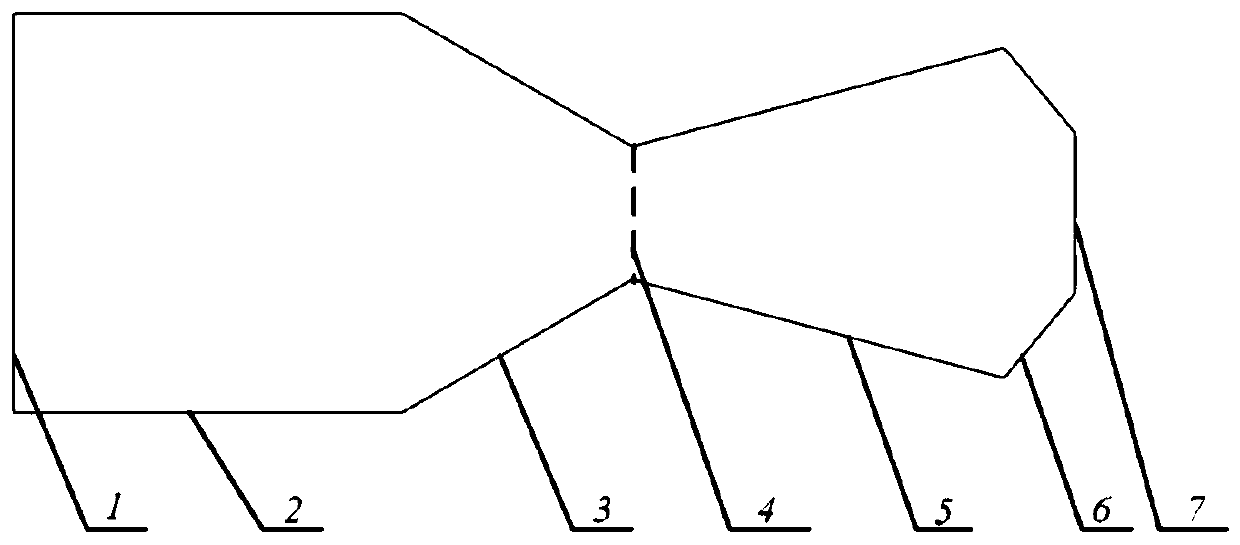

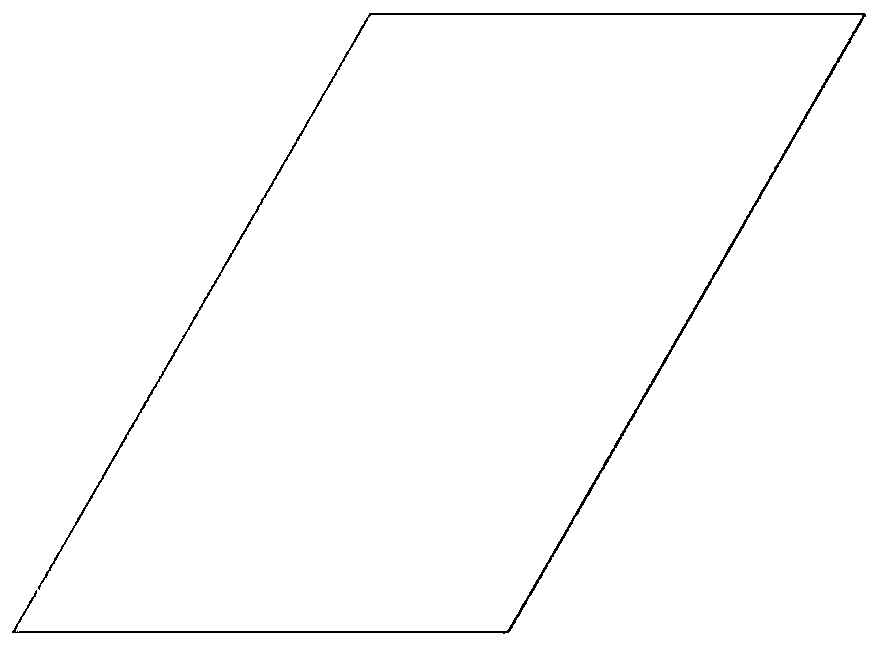

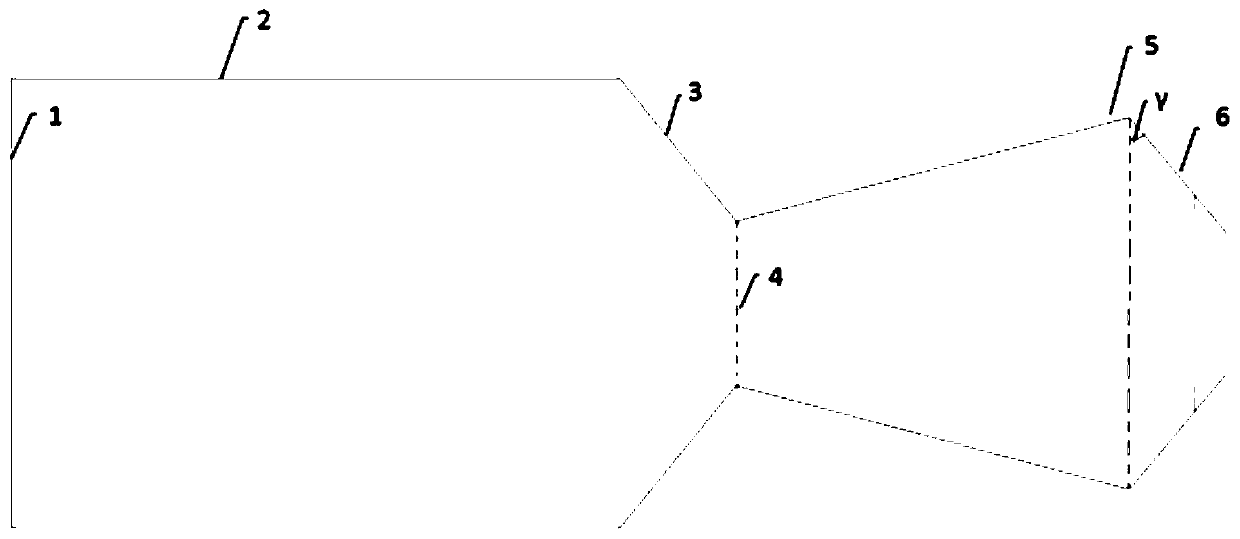

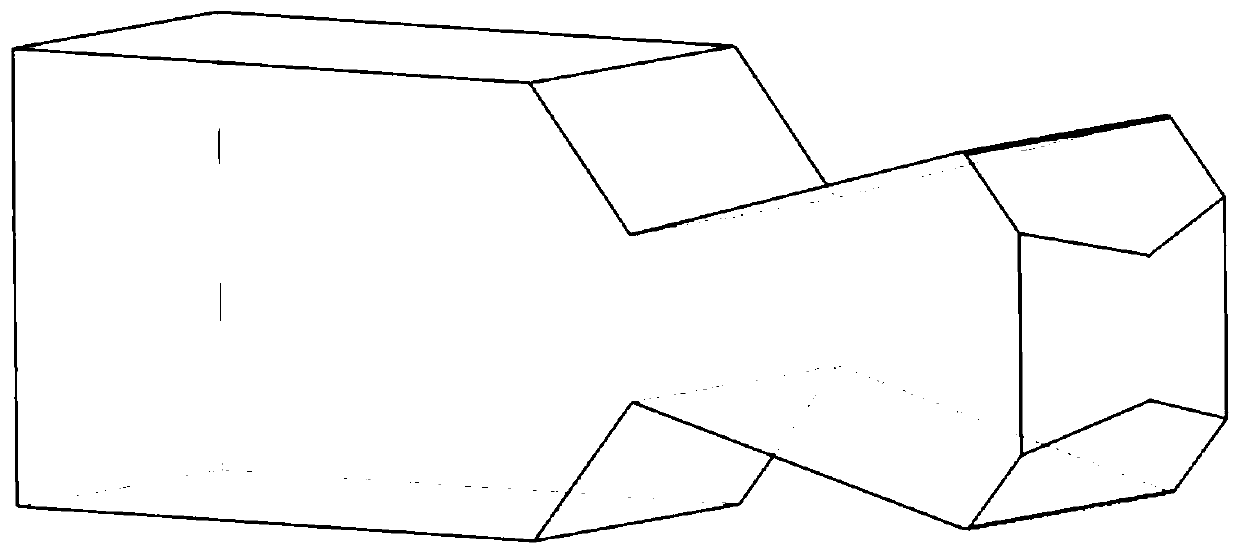

Throat offset type pneumatic vector spraying pipe with parallelogram section

ActiveCN109779780AReduce flight resistance andWide range of usesJet propulsion plantsStraight segmentAerospace engineering

The invention discloses a throat offset type pneumatic vector spraying pipe with a parallelogram section. A spraying pipe inner runner comprises a spraying pipe inlet, an equal straight segment, a first-throat front convergent section, a first throat, a second-throat front expanding segment, a second-throat front convergent section and a second throat which communicate in sequence; an inclined side wall face begins to be arranged on a certain position in the inner runner, the circulation section from the inner runner to the second throat is in a parallelogram shape, through the shape design ofthe parallelogram circulation section, the good airflow mixing effect is obtained, the spraying pipe infrared hidden property is effectively improved, meanwhile, the large thrust vector angle is provided for an aircraft still, the inclined side wall face has the offset effect on the airflow, under the vector and non-vector state, the initial pitching and yaw vector angles exist, the requirement of pneumatic-hidden integrated layout of the future aircraft can be met, and the purpose is wide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

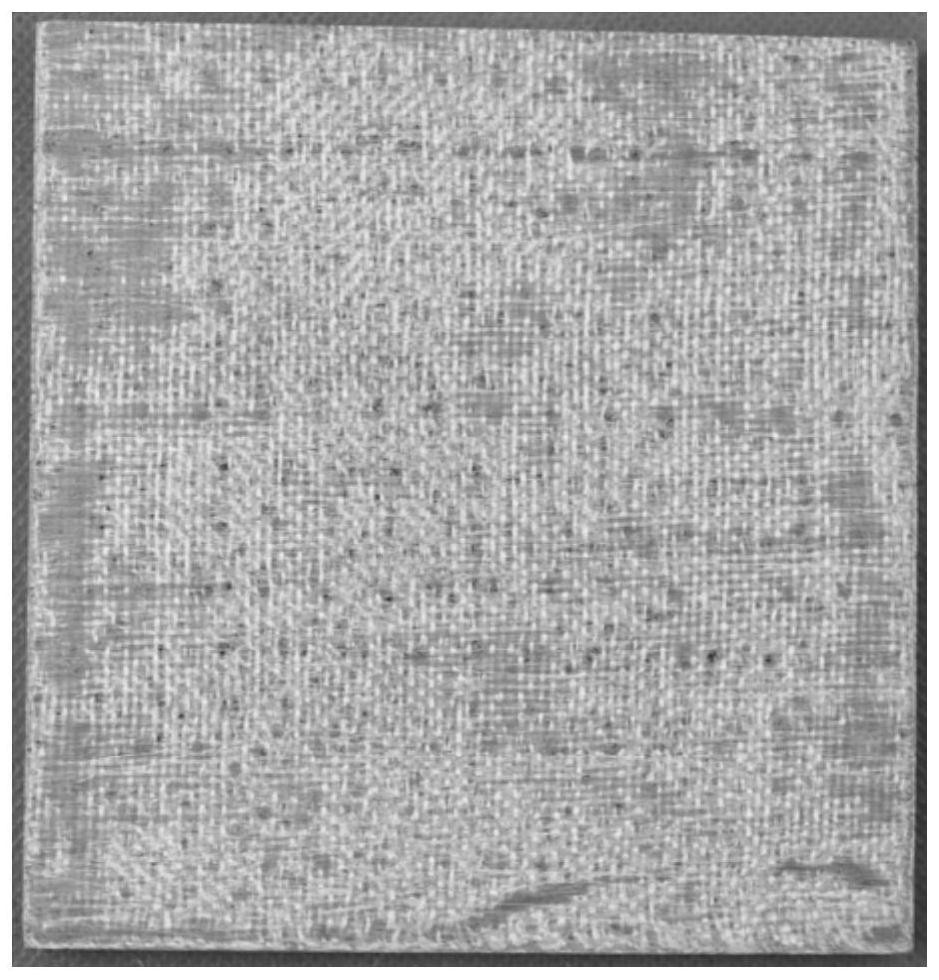

Aerogel composite material with heat insulation and stealth functions and preparation method thereof

ActiveCN112661483AReduce heat radiation effectGood insulation performanceOther chemical processesFiberInsulation layer

The invention provides an aerogel composite material with a heat insulation and stealth function and a preparation method of the aerogel composite material, and belongs to the technical field of aerogel composite materials. The aerogel composite material comprises a nano-fiber aerogel matrix layer, a nano-fiber aerogel conductive layer and a nano-fiber aerogel heat insulation layer. According to the invention, under the condition of not using an adhesive, the effective fixation of aerogel particles and the tight combination between the base material and each functional layer can be realized by utilizing the unique hydrophilicity and pore structure of the nanofibers, and the heat insulation performance of the base material layer and the heat insulation layer is utilized; the electromagnetic shielding and controllable heat transmission performance of the conducting layer can achieve the heat insulation and electromagnetic infrared double-shielding synergistic function, and the invention has application prospects in the fields of national defense military industry and functional textiles.

Owner:广东广纳新材料有限公司

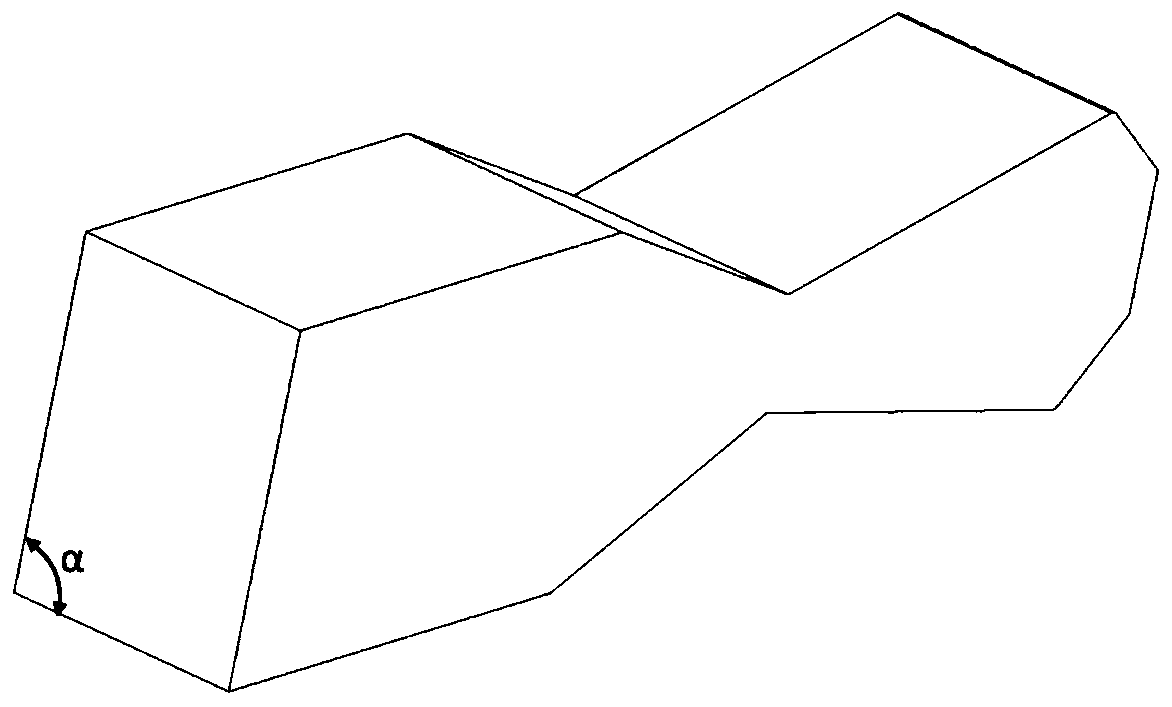

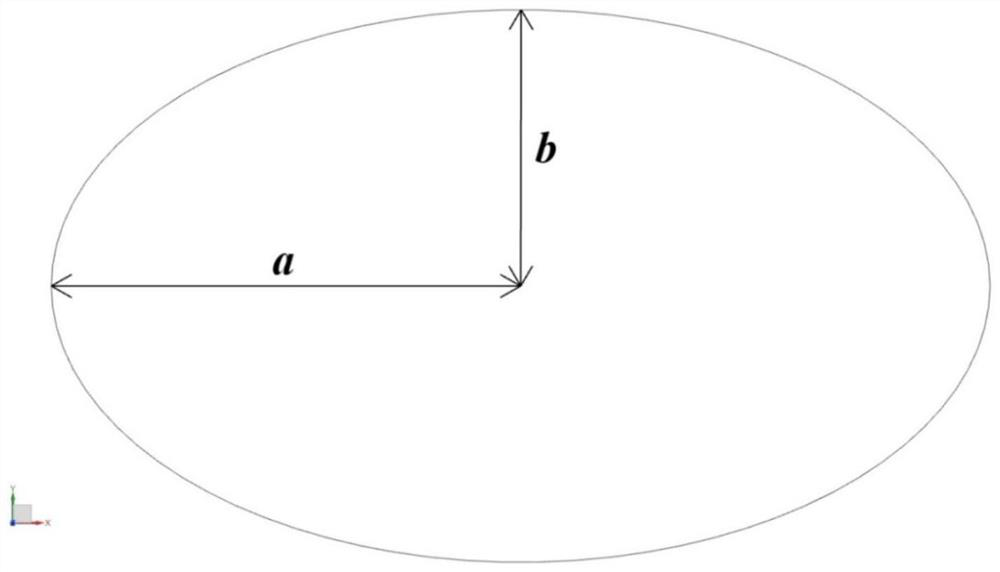

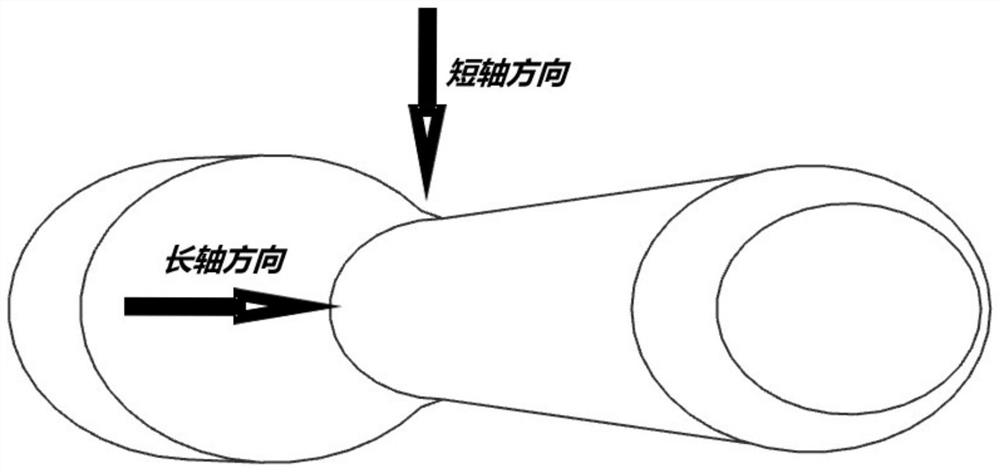

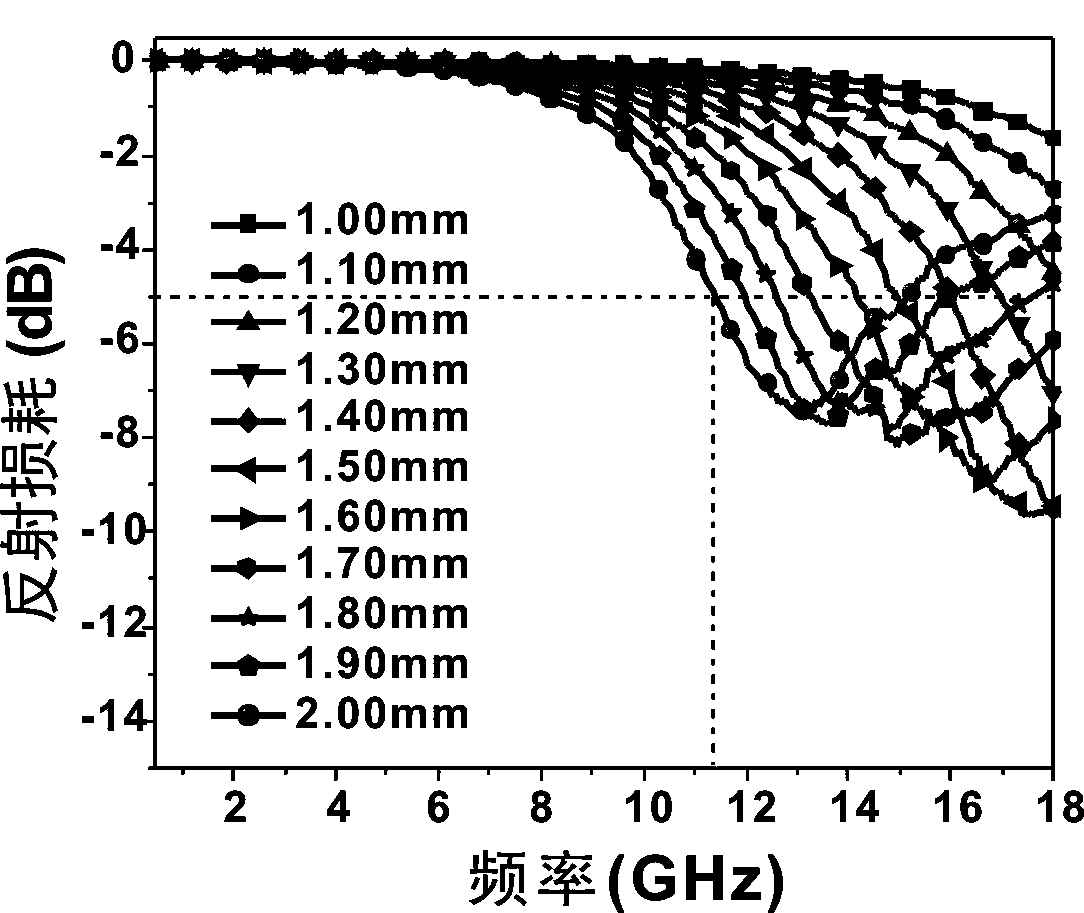

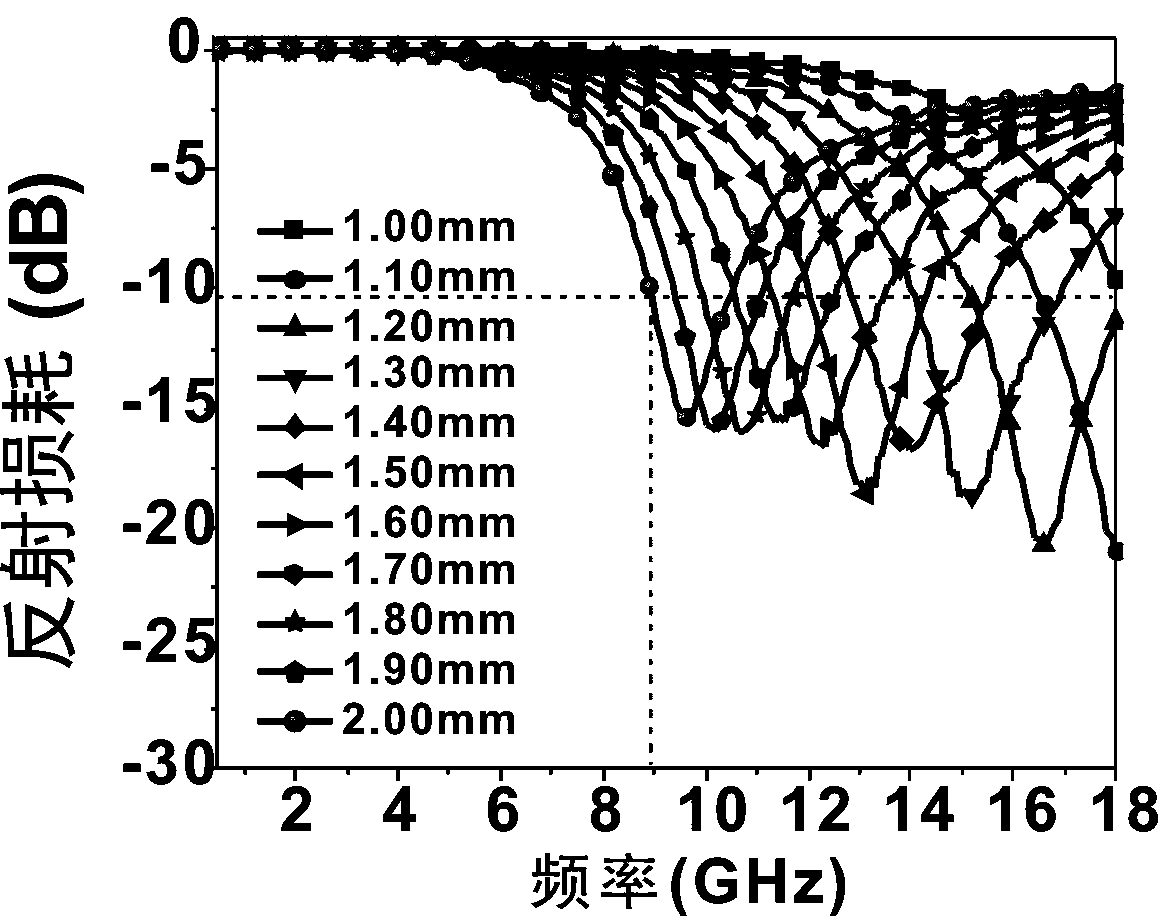

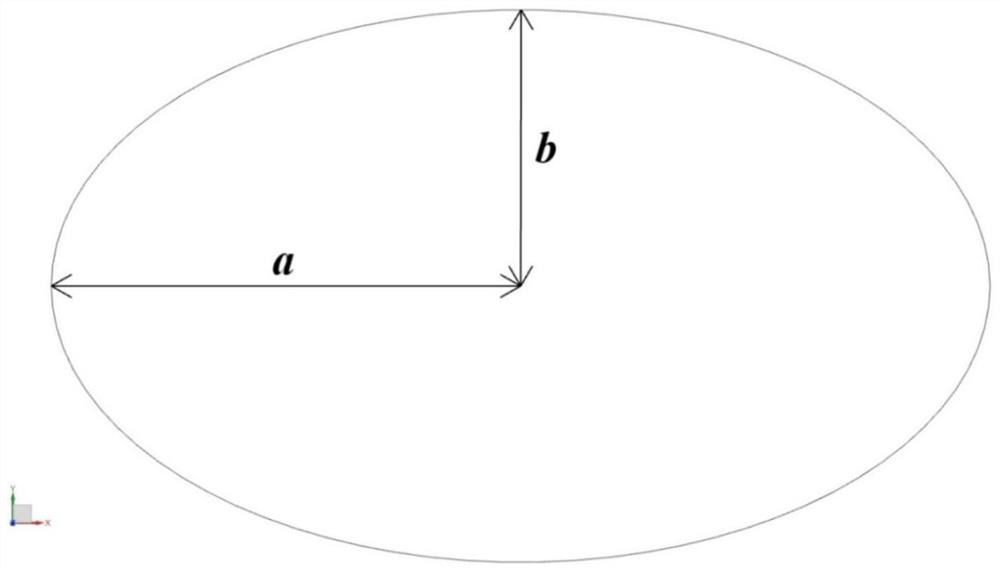

Design method of elliptic throat offset type pneumatic thrust vectoring nozzle

ActiveCN113374595AImprove infrared stealth performanceFlexible controlJet propulsion plantsFlight vehicleControl theory

The invention discloses a design method of an elliptic throat offset type pneumatic thrust vectoring nozzle. An inner flow channel of the elliptic throat offset type pneumatic thrust vectoring nozzle comprises a nozzle inlet, an equal straight section, a first throat front convergence section, a first throat, a second throat front expansion section, a second throat front convergence section and a second throat which communicate in sequence. According to the design method, the flow field structure of the inner flow channel is changed by designing the shape of each section of flow section into an elliptic shape, then a good inner and outer flow mixing effect can be achieved under the conditions of providing an omnidirectional vector angle and ensuring efficient vector thrust performance, and the infrared stealth performance of the spray pipe is effectively improved, so that the urgent requirements of modern aircrafts on strong stealth performance and high maneuvering performance are met; and in addition, the unique flat appearance of the elliptic throat offset type pneumatic thrust vectoring nozzle is more suitable for the aircrafts with special appearances such as flying wing layout, the requirement for the pneumatic-stealth integrated layout of the aircrafts in the future can be met, and the application range is wide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of radar wave absorption composite material with infrared stealth

InactiveCN111286079AAvoid reflectionsIncrease reflection lossSpecial leather manufactureChemical reactionRadar

The invention discloses a preparation method of a radar wave absorption composite material with an infrared stealth function. The preparation method comprises the following steps: preparing a metal particle complex (BM-M) having absorption performance and loaded on a base material by utilizing a chemical reaction between the base material and metal ions, and loading and storing a phase change material PCM by utilizing hydrophobicity and porous structure characteristics of the base material to prepare the product BM-M / PCM. The composite material prepared by the invention has the characteristicsof softness and high mechanical strength, so that the radar wave stealth and infrared stealth compatible leather prepared by taking the leather as the base material has the characteristics of being bendable and wearable.

Owner:SICHUAN UNIV

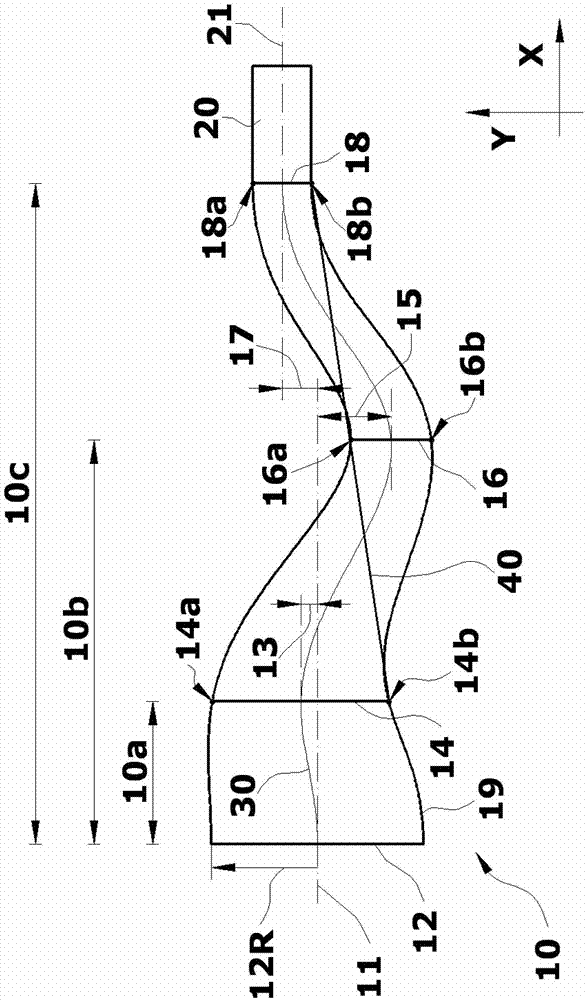

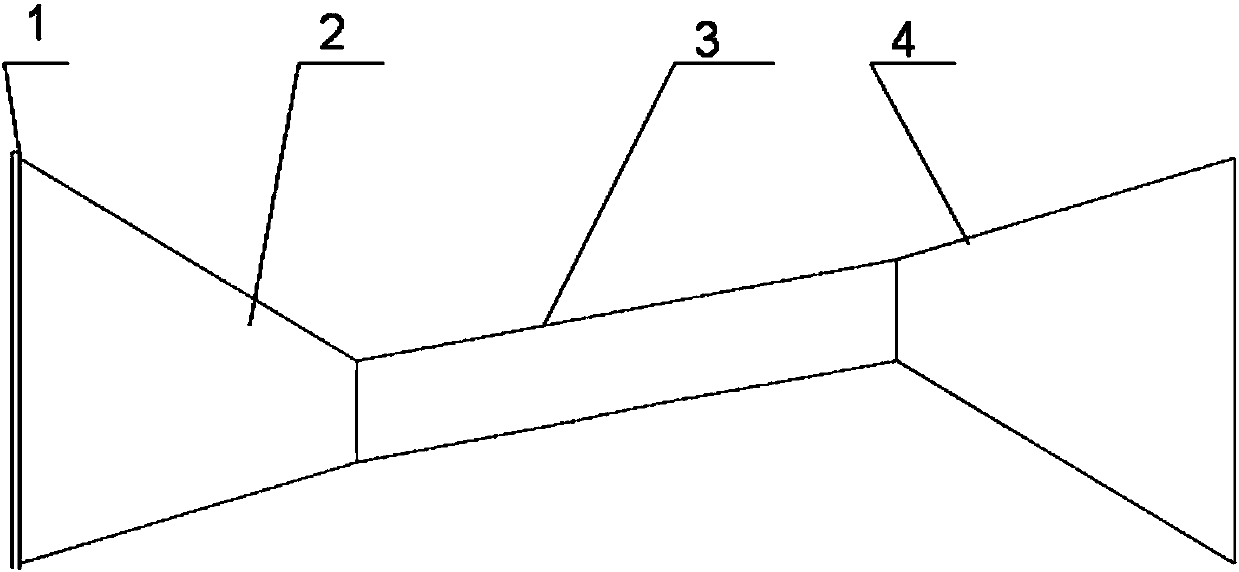

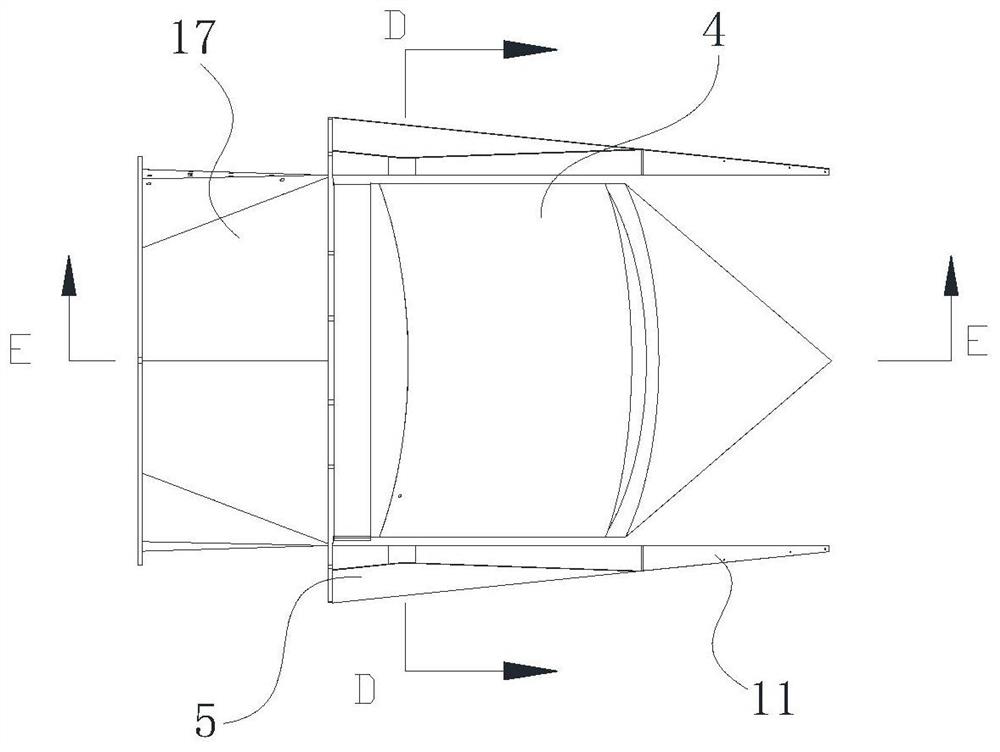

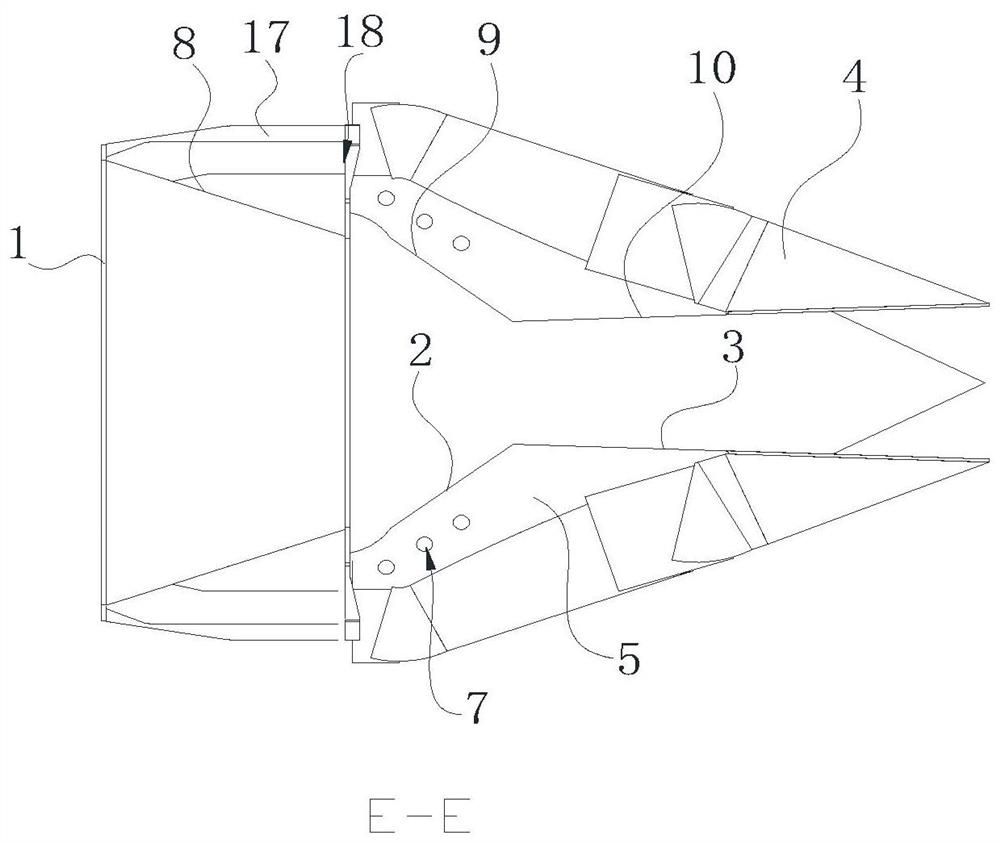

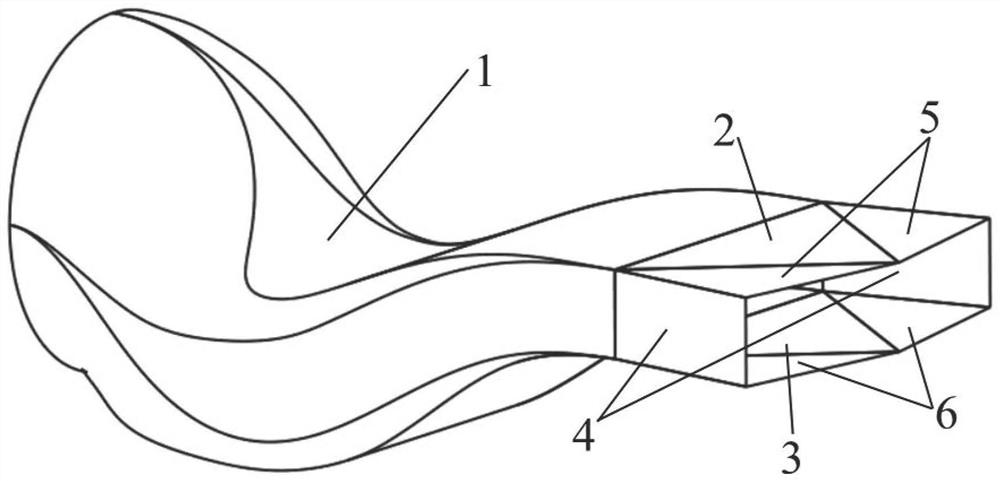

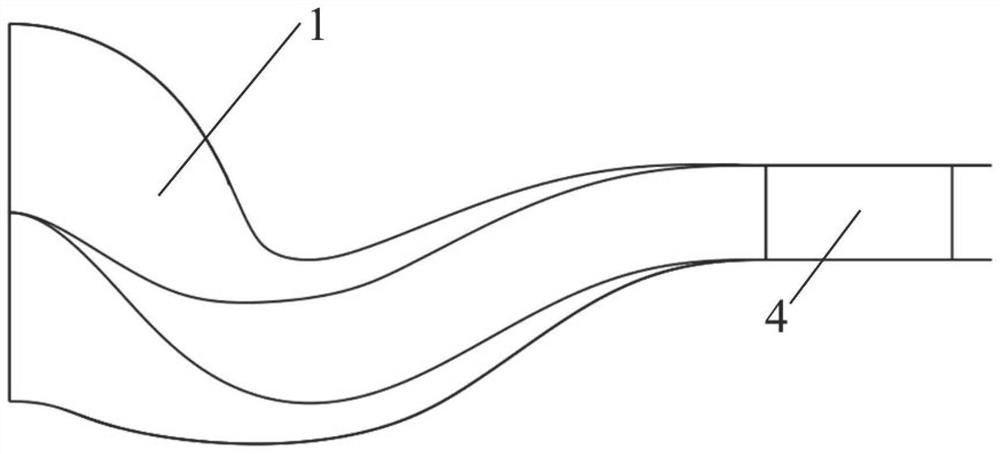

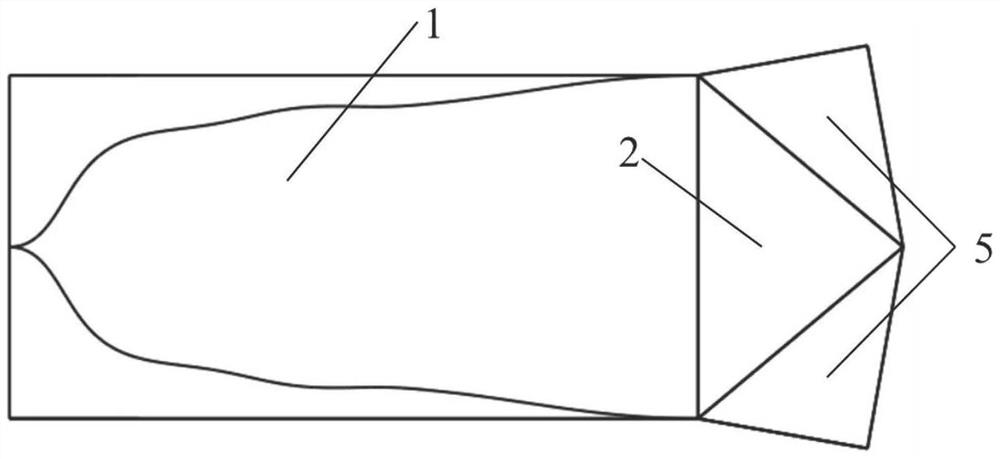

Segmented convergence type double-S-curve binary mixed exhaust system

The invention discloses a segmented convergence type double-S-curve binary mixed exhaust system which is used for infrared stealth of a turbofan engine. The contour of the segmented convergence type double-S-curve binary mixed exhaust system converges in an axial symmetry shape firstly and then converges in a double-S-curve shape. The segmented convergence type double-S-curve binary mixed exhaust system is composed of a pointed conical central cone, an outer culvert axial symmetry convergence section, an outer culvert double-S-curve binary convergence section, an inner culvert axial symmetry convergence section and an inner culvert S-curve convergence section. The pointed conical central cone and the inner culvert axial symmetry convergence section are connected to form an inner culvert wall surface, in this way, local expansion of an inner culvert channel can be prevented, and flow separation on the wall surface of the central cone is restrained. The outer culvert axial symmetry convergence section and the outer culvert double-S-curve binary convergence section are connected to form an outer culvert wall surface, and accordingly blockage on typical high-temperature components such as the central cone and the inner culvert inlet section can be formed more effectively. By the adoption of the segmented convergence type double-S-curve binary mixed exhaust system, compared with an existing double-S-curve binary mixed exhaust system, the infrared emanation characteristic of the exhaust system can be further restrained while the aerodynamic performance of the exhaust system is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

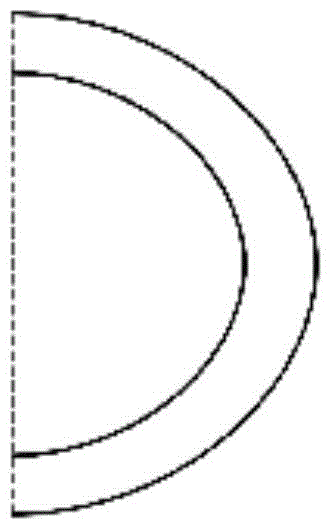

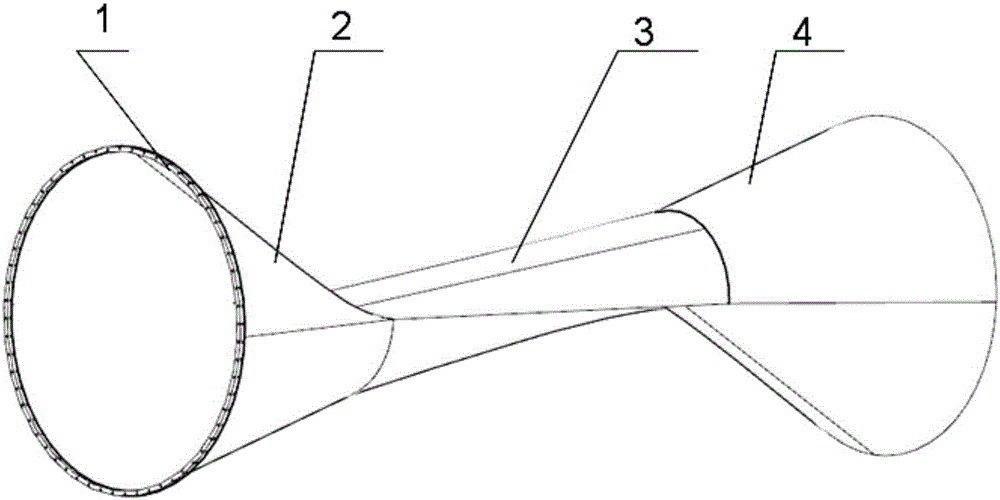

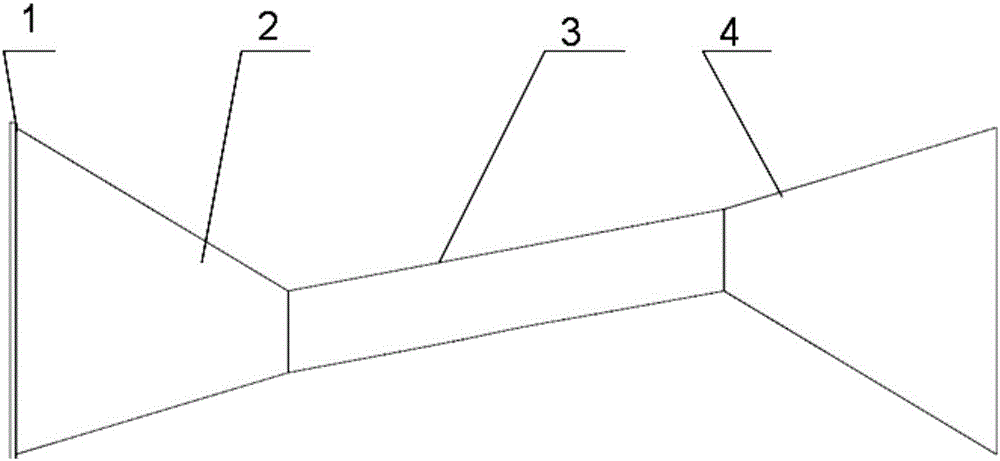

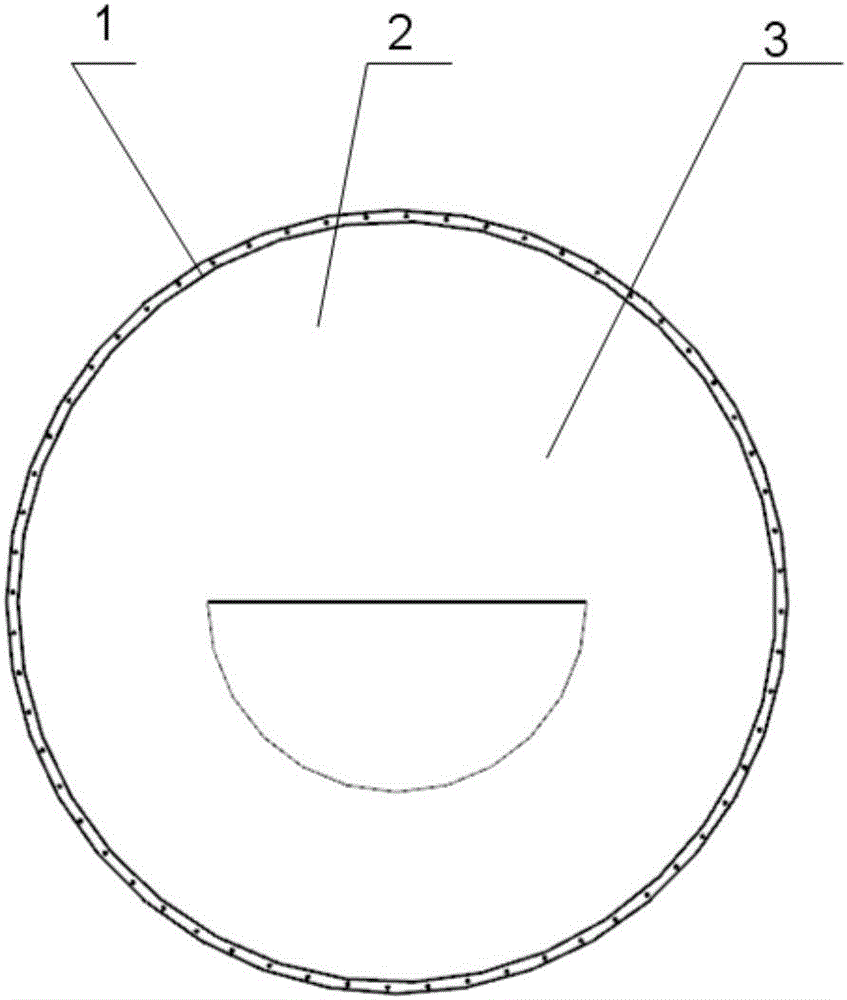

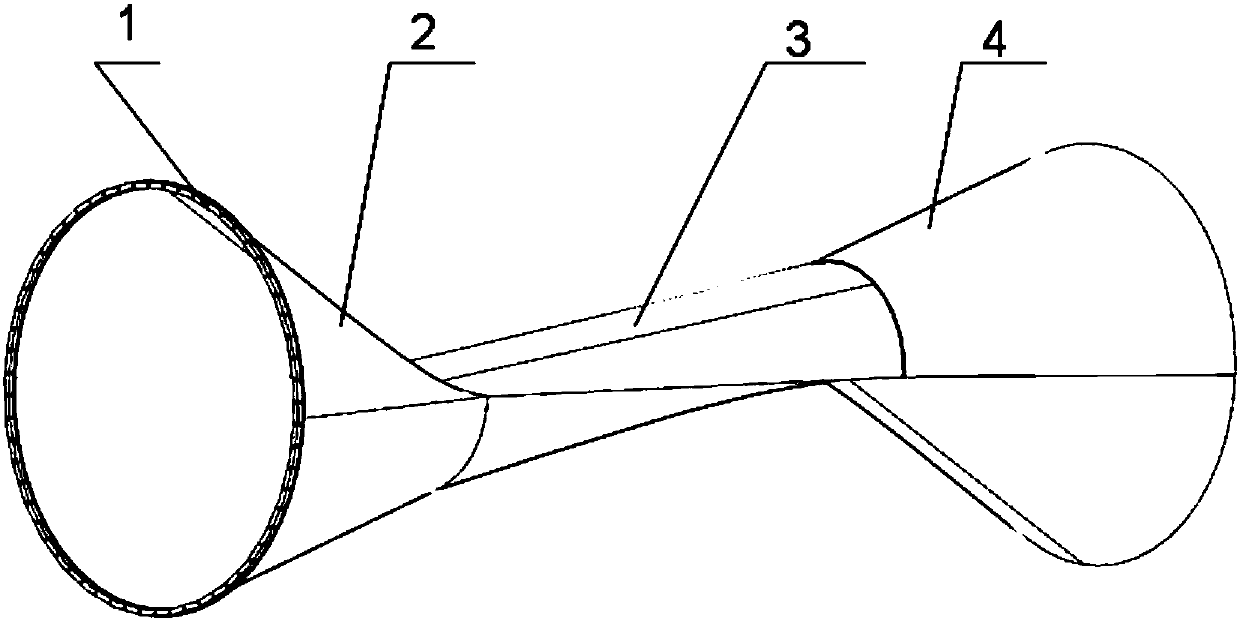

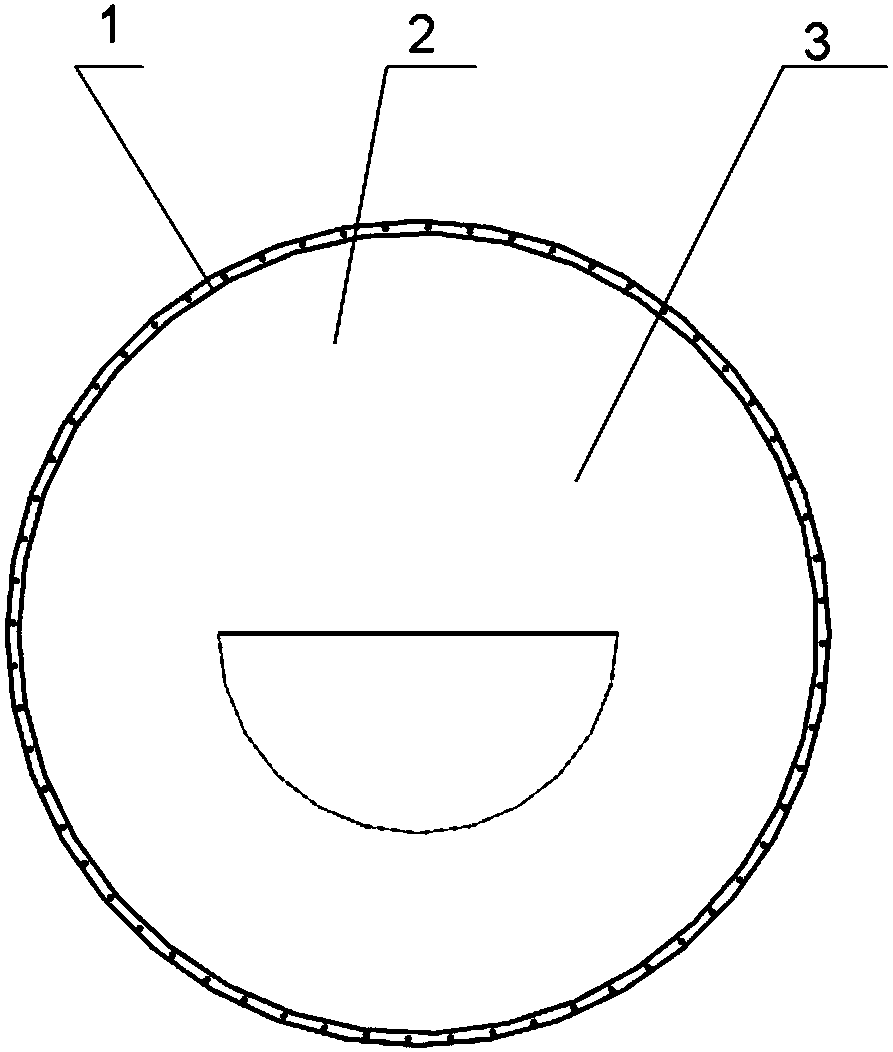

Convergent-divergent nozzle with stealth function

The invention relates to the design technique of aero-engine nozzles, in particular to a convergent-divergent nozzle with a stealth function, and aims to at least solve the problem of large occupation of a conventional convergent-divergent nozzle. The convergent-divergent nozzle with the stealth function comprises a convergent segment, a divergent segment and a straight tubular transition throat segment, wherein the end surface of a first inlet end of the convergent segment is circular, the end surface of a first outlet end, parallel to the end surface of the first inlet end, is semi-circular, and the centers of the two end surfaces are on the same plane; the end surface of a second inlet end of the divergent segment is semi-circular, the end surface of a second outlet end, parallel to the end surface of the second inlet end, is circular, and the centers of the two end surfaces are on the same plane; and the straight tubular transition throat segment is connected with the first outlet end in a sealing manner through a third inlet end and connected with the second inlet end in a sealing manner through a third outlet end. The convergent-divergent nozzle with the stealth function is simple in structure, light in weight, high in reliability and convenient to mount, manufacture and lose weight, and can enhance the infrared stealth effect and the radar stealth effect without changing the structure of a plane.

Owner:AECC SHENYANG ENGINE RES INST

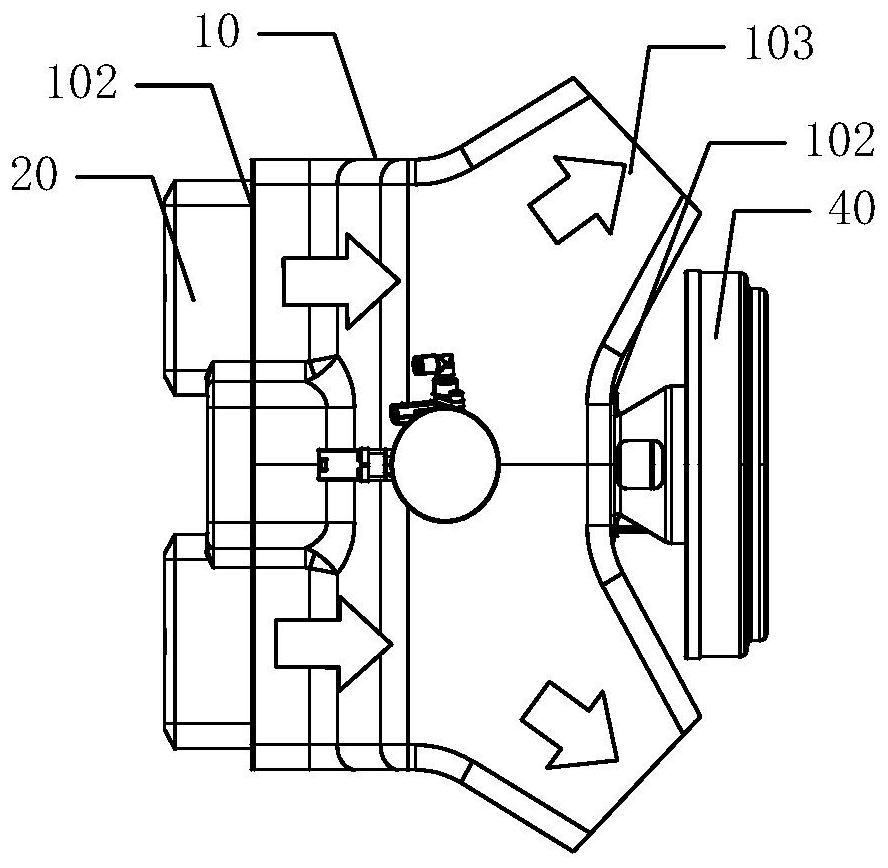

Double-oil-way jet integrated afterburner

InactiveCN106949496AReduce the temperatureImprove combustion efficiencyContinuous combustion chamberCombustion chamberLow speed

The invention provides a double-oil-way jet integrated afterburner. A double-oil-way jet mode is adopted in the integrated afterburner. Jet positions for fuel oil jetting are the central position of the tail of a fairing spoke flameholder and the central position of a thrust augmentation inner cone. Compared with the prior art, the fuel oil jetting mode is changed, and as for an outer oil way, the jetted fuel oil is mixed with high-temperature mixed gas, and the atomizing effect is improved under the effect of the shear force of the high-temperature mixed gas; and as for a central oil way, since the thrust augmentation inner cone enables a wide low-speed backflow area to be formed behind the afterburner, the jetted fuel oil of the part is fully mixed with high-temperature mixed gas in the low-speed area, and the premixing effect is enhanced. Combustion is jointly conducted through the two oil ways in the afterburner, so that the combustion efficiency of the afterburner is improved, and the combustion stability is good. Meanwhile, the fuel oil can effectively decrease the temperature of the thrust augmentation inner cone to improve the infrared stealth performance of an engine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

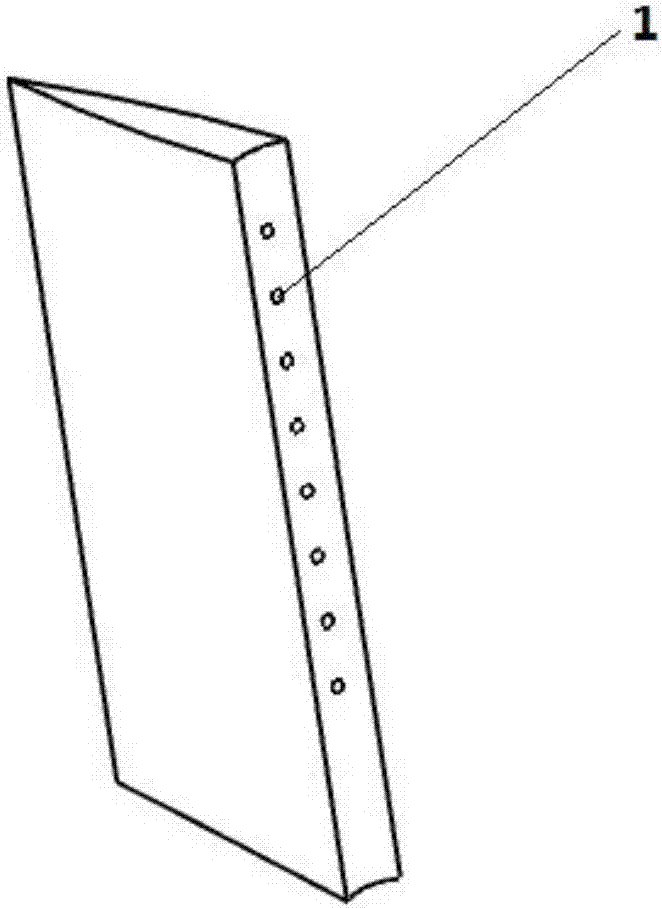

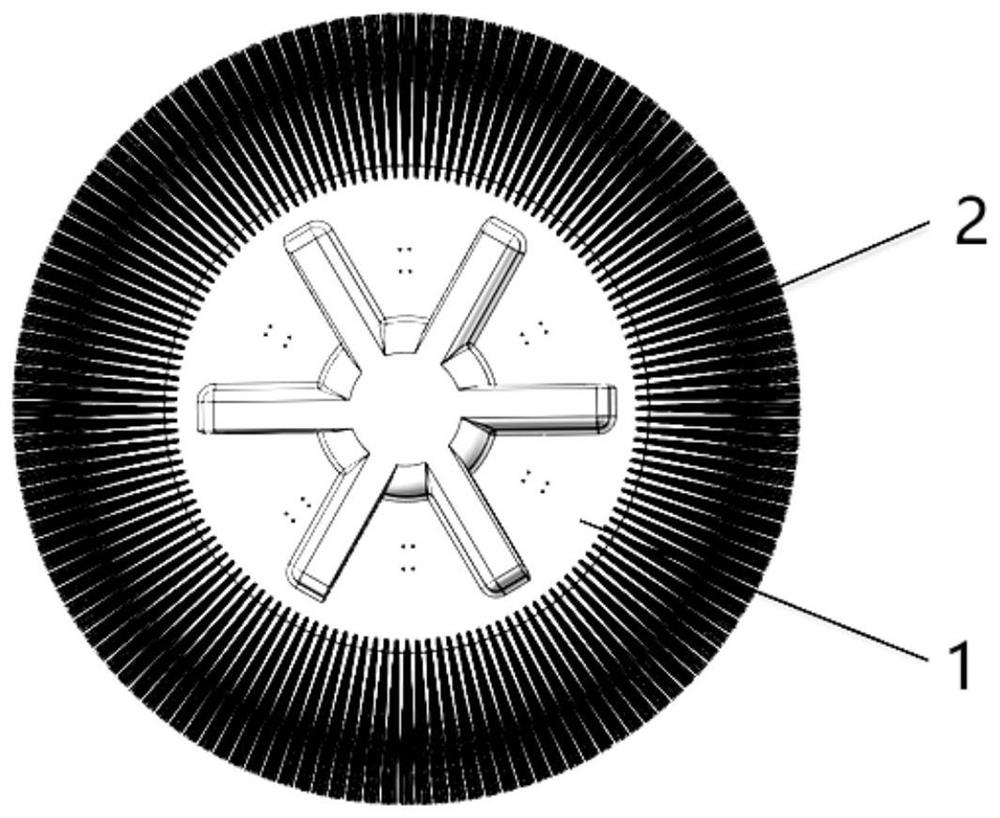

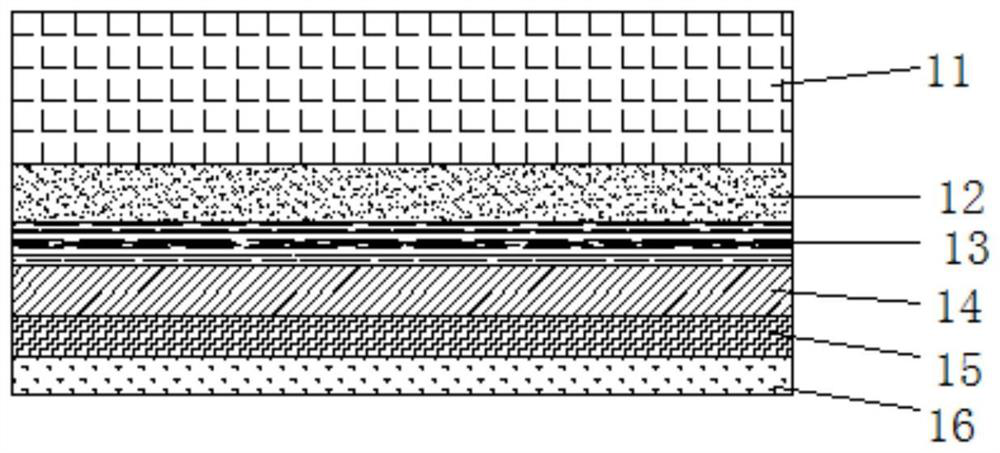

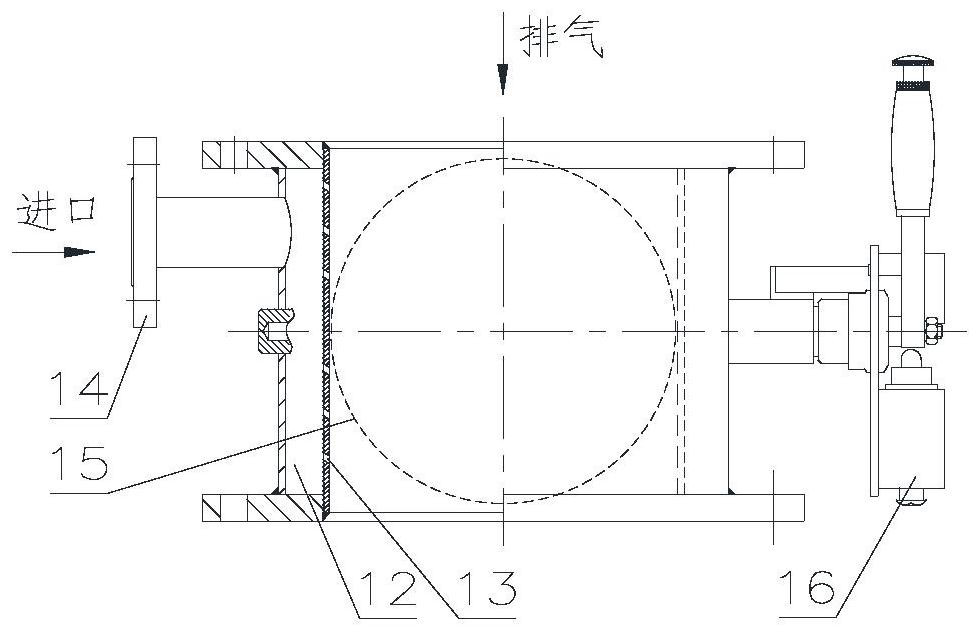

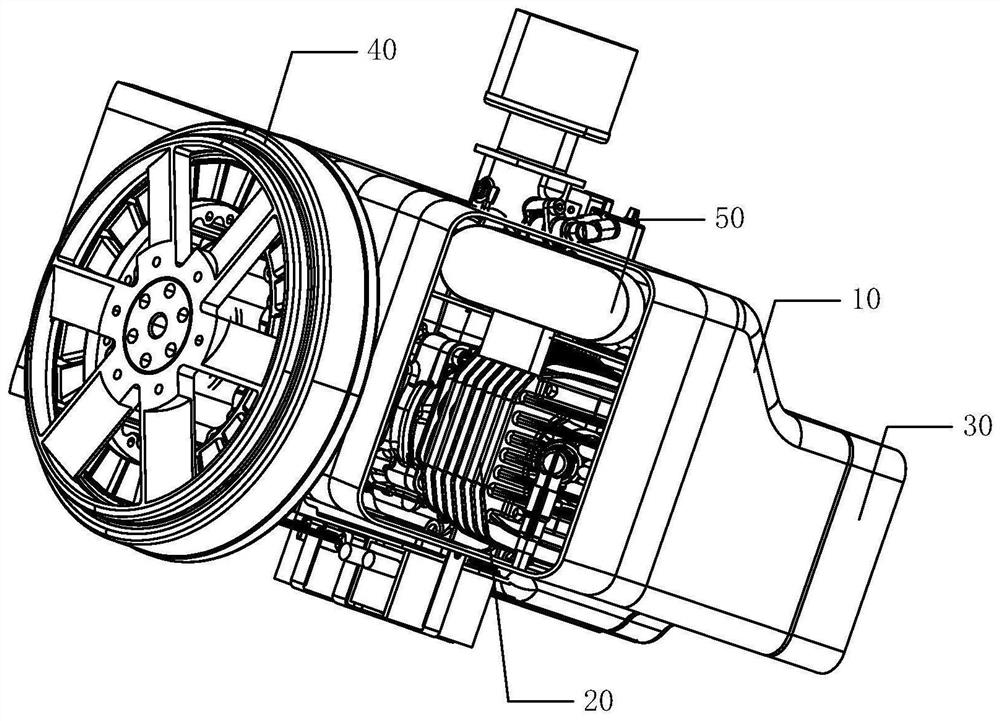

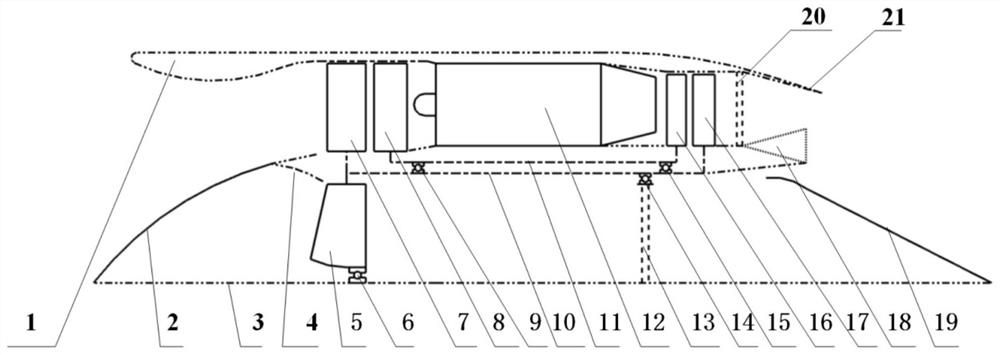

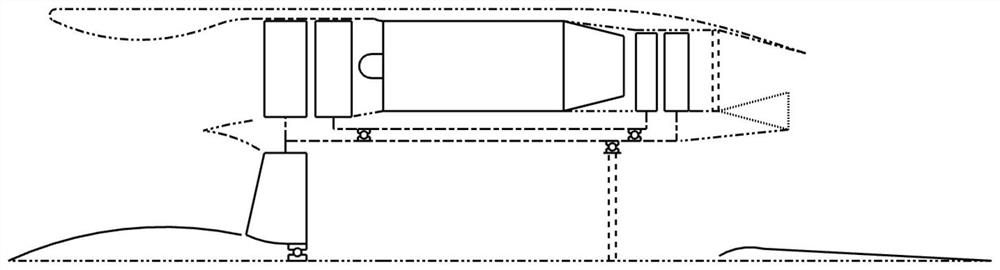

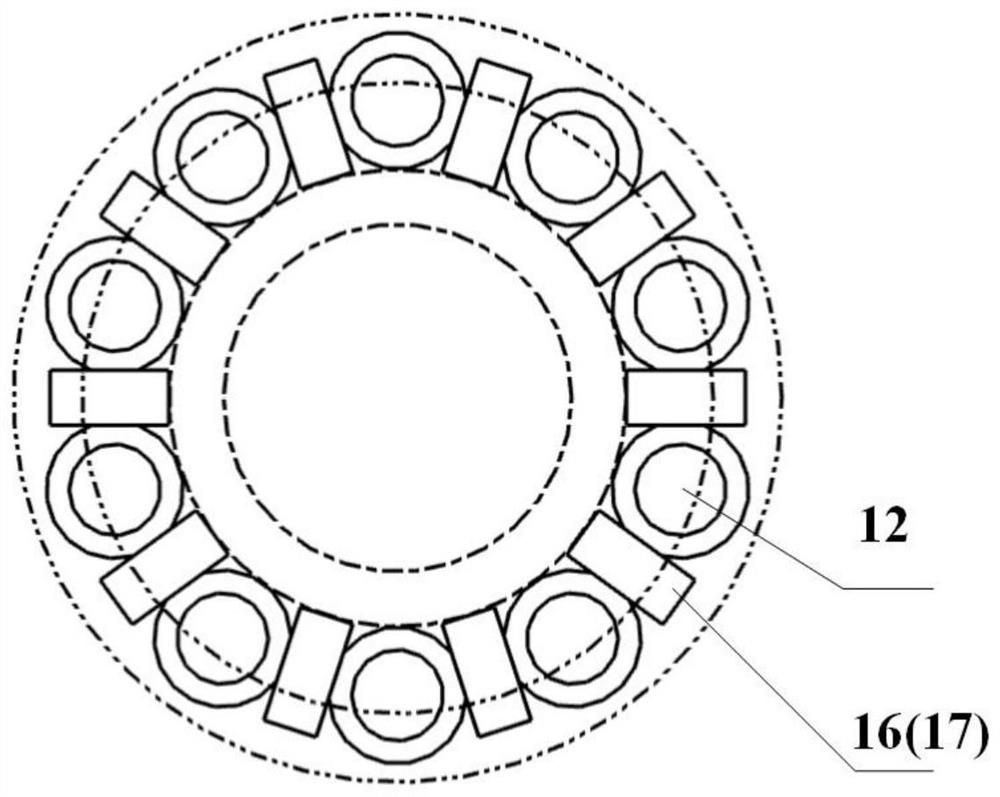

Invisible tire decorative cover and preparation method thereof

ActiveCN112123997AImprove infrared stealth performanceComplementPolyurea/polyurethane coatingsWheel protectionStructural engineeringProtection layer

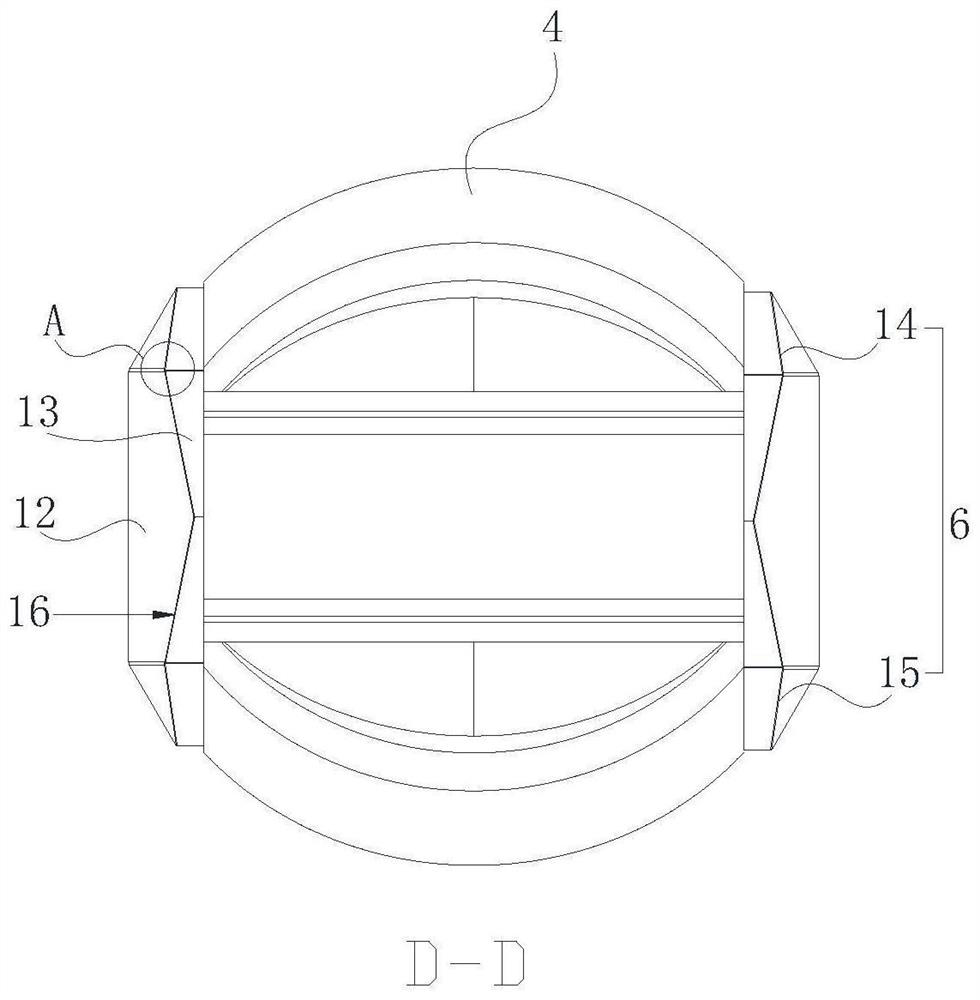

The invention belongs to the technical field of functional materials, and provides an invisible tire decorative cover. The invisible tire decorative cover comprises a hub cover (1) and camouflage grass (2); a fixed support is arranged on the inner side of the hub cover (1); the hub cover is fixedly connected on a vehicle hub through the fixed support; the hub cover (1) is of a multi-layer structure and sequentially comprises a base material (16), an infrared camouflage coating, a radar absorbing coating (13), a metal reflection layer (12) and a protective layer (11); when the hub cover (1) isfixedly connected with the vehicle hub, the protective layer (11) is positioned on the side close to the vehicle hub; the camouflage grass is pasted on the surface of the side, away from the infraredcamouflage coating, of the base material (16) of the hub cover (1); and the infrared camouflage coating comprises a cooling coating and a heat insulation coating, wherein phase change capsules are dispersed in the cooling coating, and the heat insulation coating is low in heat conductivity coefficient. The invisible tire decorative cover can solve the problem of invisibility of a tire part of a vehicle, and the infrared camouflage effect is remarkably improved.

Owner:中国人民解放军96901部队25分队 +1

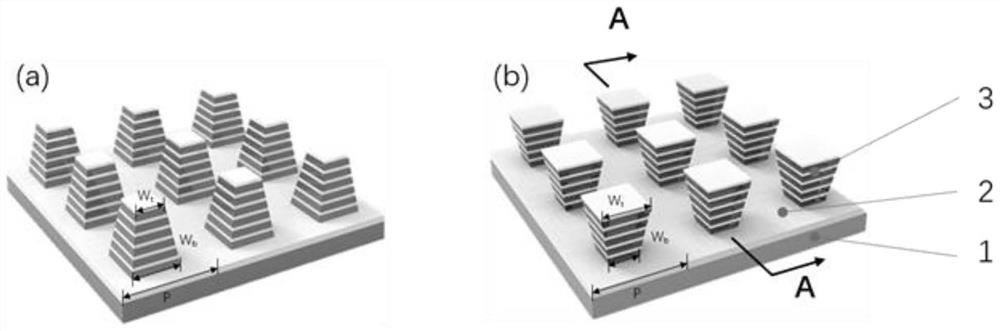

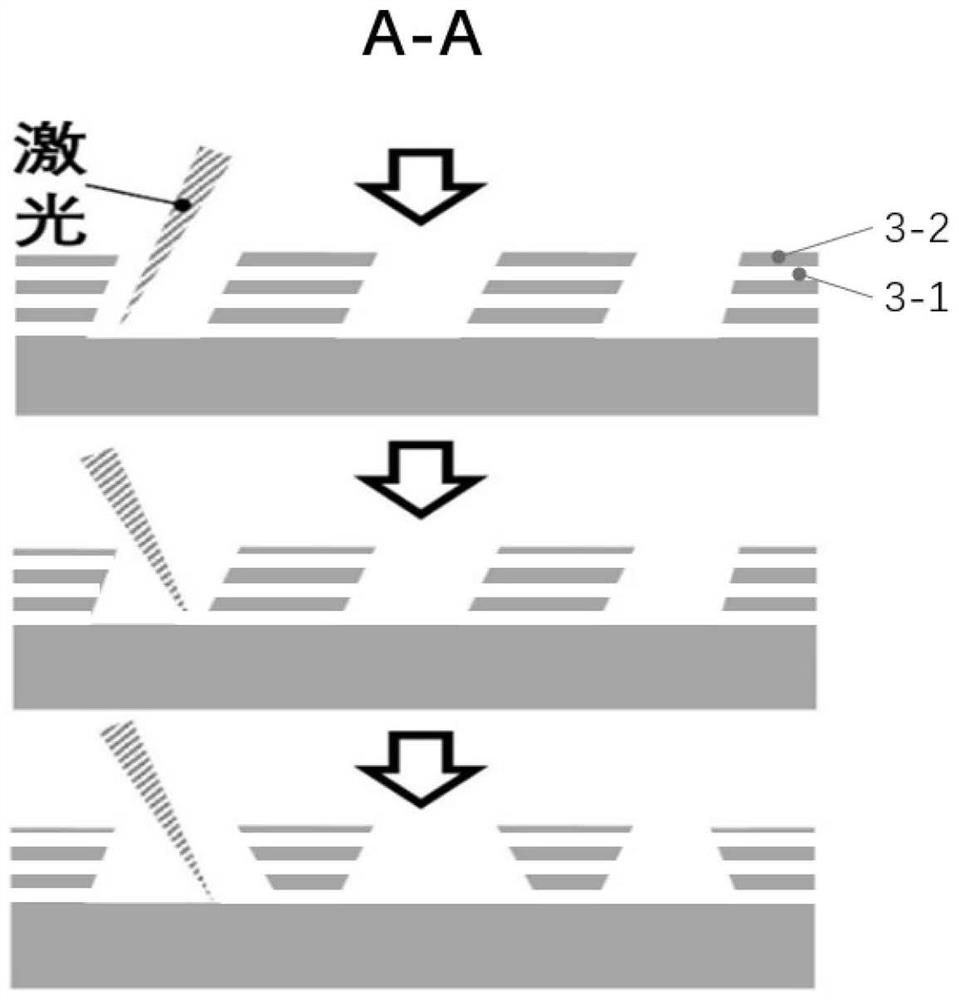

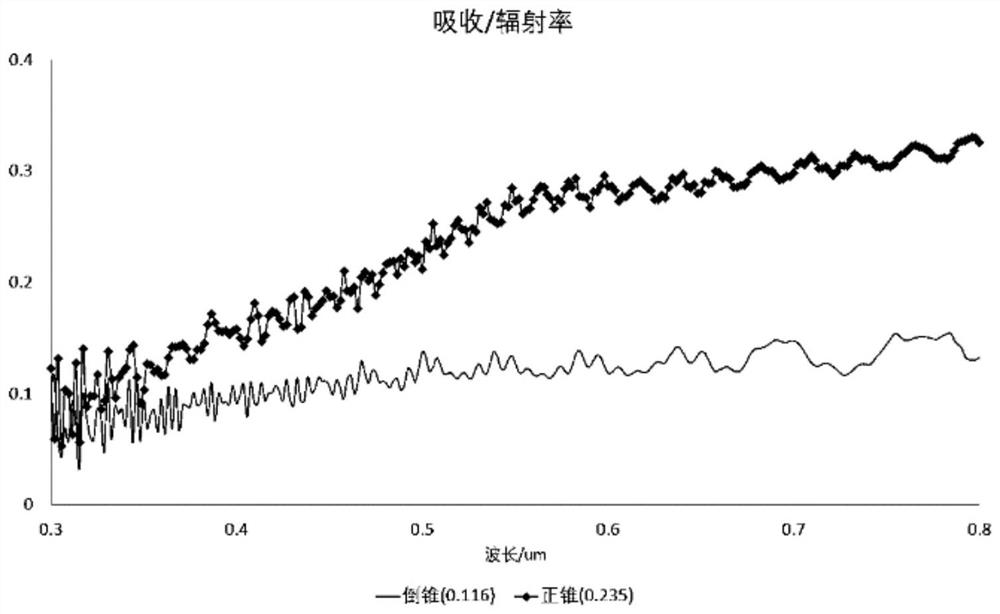

Electromagnetic wave broadband selective absorption micro-nano structure and preparation method thereof

PendingCN114265134AReduce visible light absorptionImprove consistencyOptical elementsNano structuringPhysical chemistry

The invention discloses an electromagnetic wave broadband selective absorption micro-nano structure and a preparation method thereof. The micro-nano structure comprises a substrate, a reflector and an absorber which are continuously connected, the base material is a dielectric medium or metal; the reflector is a metal layer and covers the substrate; the absorber is located above the reflector and is of an inverted cone periodic structure or an arrangement type multi-scale coplanar unit periodic structure formed by overlapping a metal layer and a dielectric layer; wherein the inverted cone periodic structure is a structure formed by periodically arranging a plurality of inverted cone monomers in a matrix, each inverted cone monomer is formed by overlapping at least two groups of metal layers and dielectric layers, and the top layer is a metal layer; the arrangement type multi-scale coplanar unit periodic structure is an arrangement type multi-scale coplanar unit periodic structure of a continuous dielectric layer or an arrangement type multi-scale coplanar unit periodic structure of a discontinuous dielectric layer. The plasma broadband selective absorption micro-nano structure disclosed by the invention can be used for compatible design of infrared stealth and radiation cooling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

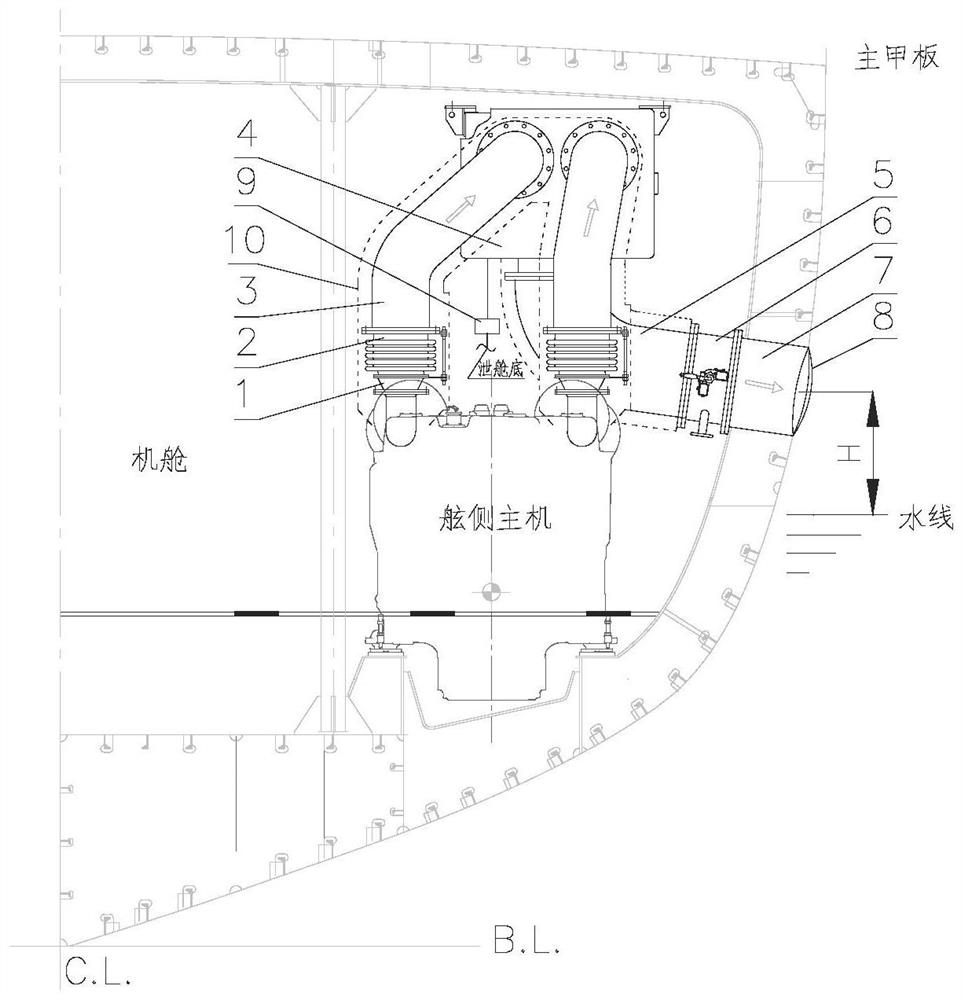

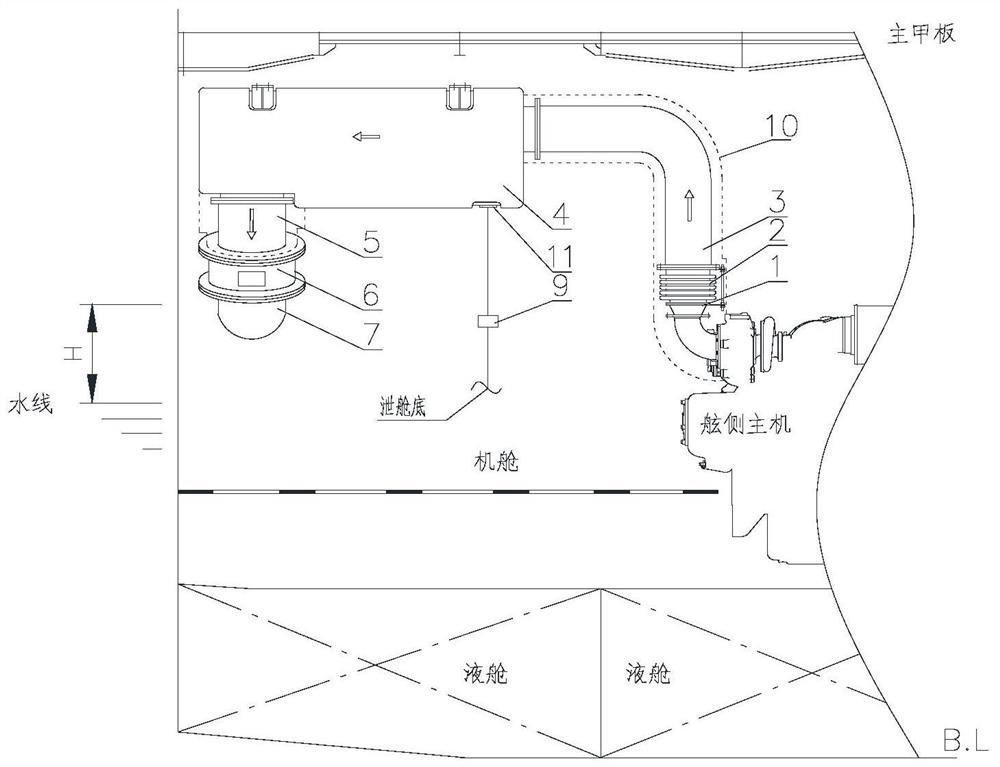

Compact ship broadside exhaust system

InactiveCN111734518ASmall heightReduce heatExhaust apparatusPropulsion power plantsHull structureInsulation layer

The invention discloses a compact ship broadside exhaust system. The compact ship broadside exhaust system sequentially comprises a main engine outlet reducer pipe, an omega-shaped exhaust expansion joint, an exhaust bent pipe, a broadside exhaust square silencer, an exhaust bent pipe, an exhaust baffle valve, a broadside connecting pipe, a broadside flow guide cap, a drainer and the like, a heatinsulation layer is arranged in the broadside exhaust square silencer, heat insulation layers are laid outside an exhaust pipe and pipeline accessories, and the exhaust system is fixed to a ship bodystructure through an elastic hanging bracket. The system adopts various measures to ensure that seawater does not enter the main engine when the ship sails, and vibration and heat of the main engine can be effectively prevented from being transferred to the ship body structure.

Owner:708TH RES INST OF CSSC

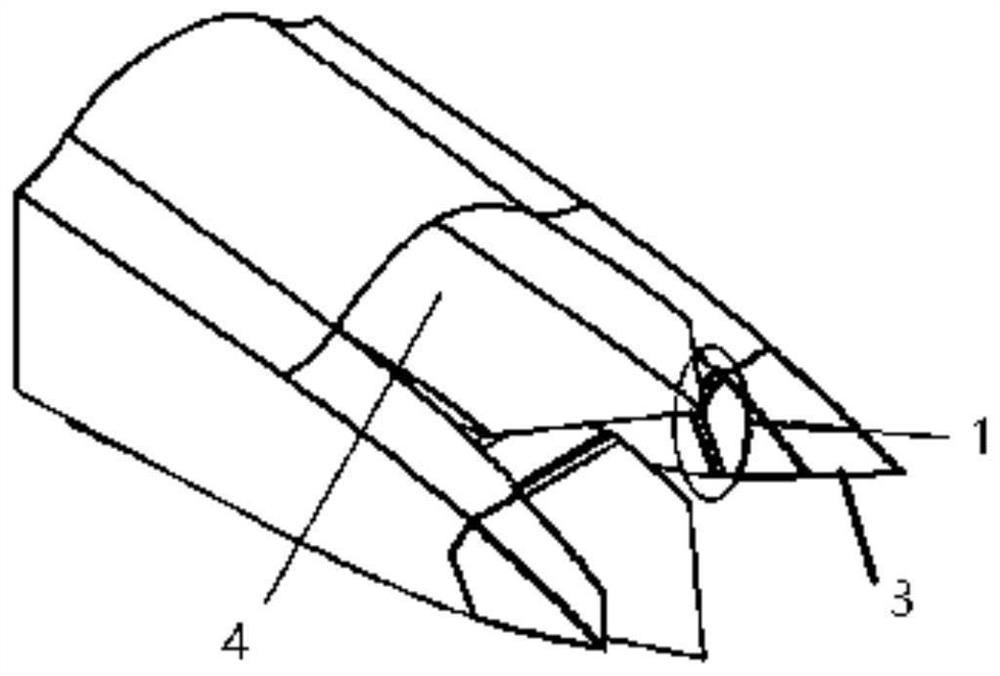

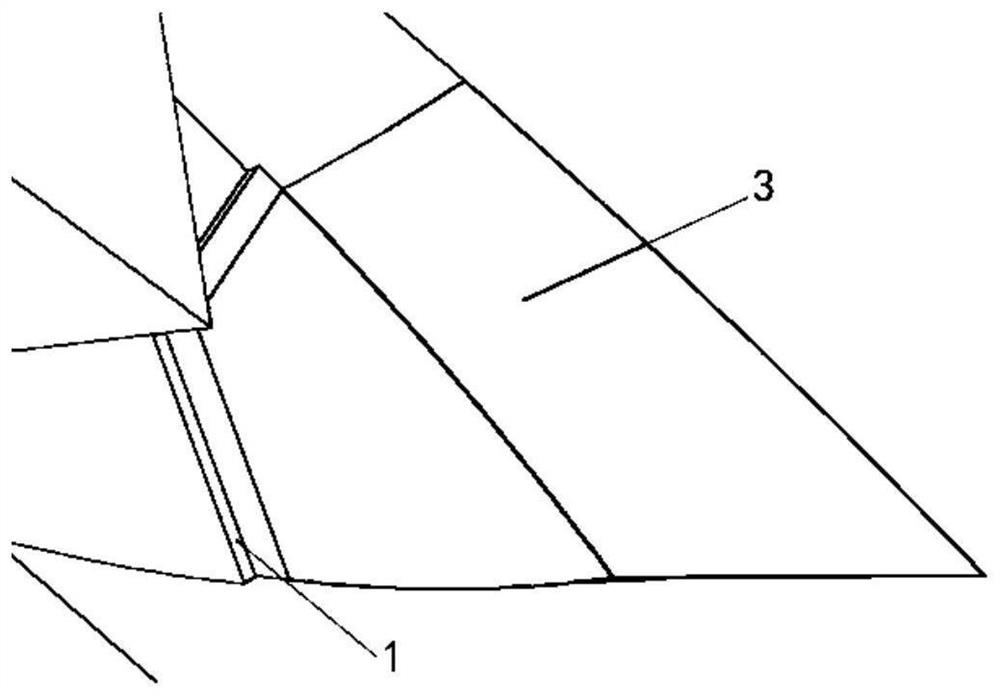

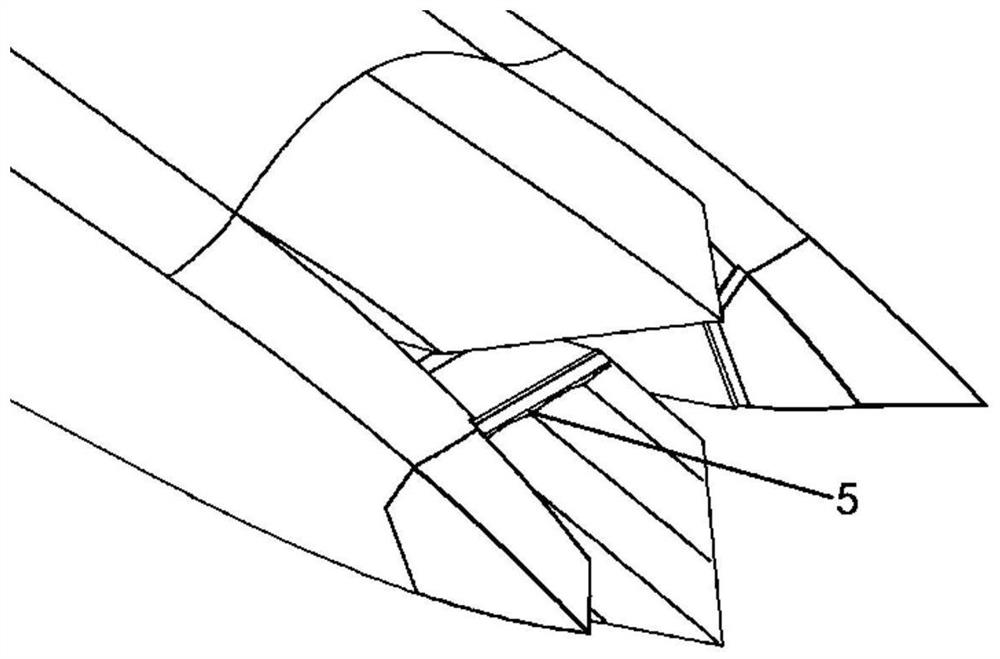

Spray pipe and aircraft afterbody slit exhaust cooling device

PendingCN114017203AHigh strengthLarge cooling rangePower plant exhaust arrangementsJet propulsion plantsJet flowCooling effect

The invention belongs to the technical field of engine design, and particularly relates to a spray pipe and an aircraft afterbody slit exhaust cooling device. The device comprises a gas collecting cavity communicated with an engine outer culvert, the gas collecting cavity is located between the side wall of a spray pipe and the inner wall face and the outer wall face of a throat adjusting piece, the gas collecting cavity is provided with a side wall exhaust slit (1) at the rear end of the side wall of the spray pipe, the side wall exhaust slit (1) is formed in the front side of an aircraft afterbody or a tail cone (3), and exhaust of the side wall exhaust slit (1) is roughly parallel to the jet flow direction of the spray pipe; the air collecting cavity is provided with an expansion section exhaust slit (5) on the inner wall surface of the expansion section of the throat adjusting sheet of the spray pipe, and the exhaust direction of the expansion section exhaust slit (5) is approximately parallel to the airflow flowing direction of the near wall surface of the expansion section adjusting sheet of the spray pipe. The overall strength of the cooling mechanism is improved, the machining difficulty and the machining cost are reduced, the cooling range of the spray pipe and the aircraft afterbody is larger, the cooling effect is better, and meanwhile the backward radar stealth and infrared stealth effects of an aircraft can be better improved.

Owner:AECC SHENYANG ENGINE RES INST

Resin-based heat-proof composite material with surface coated with high-temperature infrared stealth coating and preparation method thereof

ActiveCN112920442ASimple equipment and processImprove infrared stealth performanceFireproof paintsCamouflage paintsSilicone resinQuartz fiber

The invention relates to the field of high-temperature stealth materials, and particularly discloses a resin-based heat-proof composite material with the surface coated with a high-temperature infrared stealth coating and a preparation method thereof. The resin-based heat-proof composite material takes high silica fiber, Shi Ying fiber, aluminosilicate fiber or basalt oxide fiber as reinforcements, the resin matrix is one or a mixture of phenolic aldehyde and silicon resin, and the hollow microspheres are additives in the resin matrix; according to the high-temperature infrared stealth coating, precious metal serves as low-emissivity filler, lead-free glass serves as a binder, and the glass softening point temperature is 400-1100 DEG C. The composite material has good thermal insulation and infrared stealth properties, and a glass phase in the high-temperature infrared stealth coating on the surface of the composite material can be quickly melted in a medium-low heat flow high-temperature environment, so that the surface of the decomposed composite material is effectively sealed and filled; and the glass melt and oxide fibers in the composite material are sintered to be firmly attached to the surface of the material so that falling and stripping of the coating caused by decomposition of the composite material are avoided.

Owner:NAT UNIV OF DEFENSE TECH

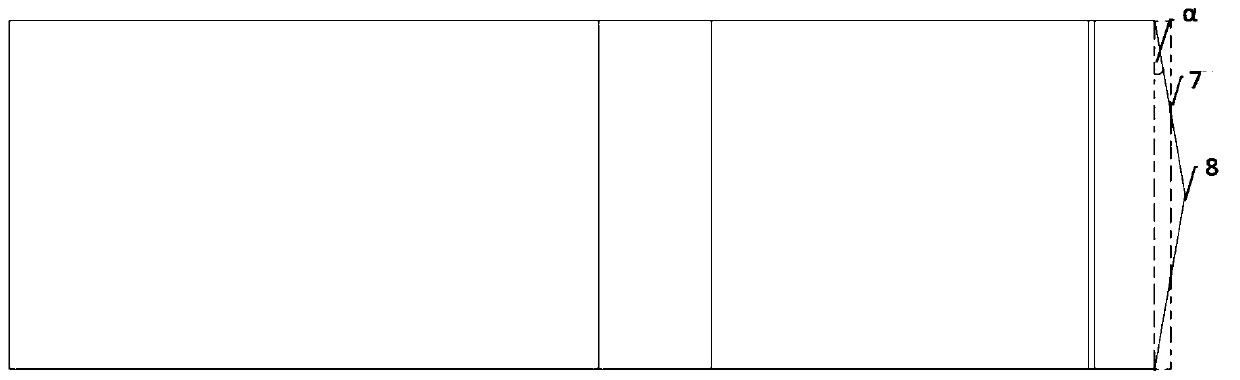

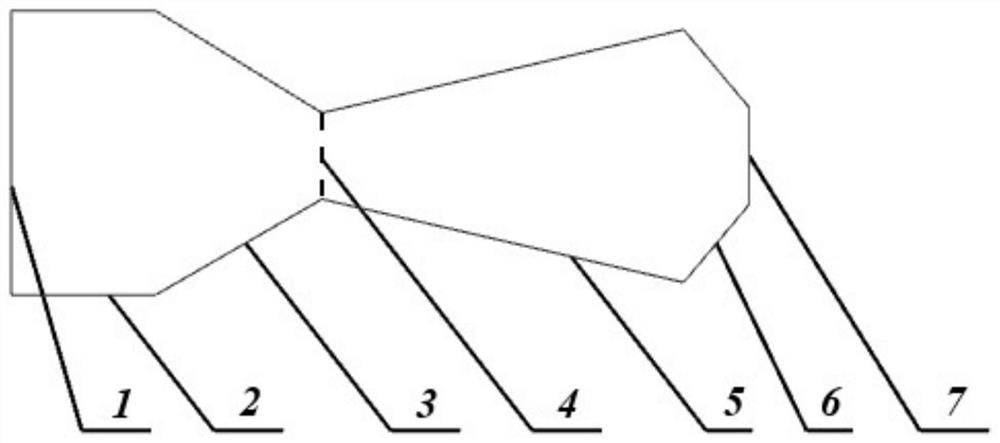

Throat offset type pneumatic vectoring exhaust nozzle with saw-tooth-shaped solid tabs at outlet

The invention discloses a throat offset type pneumatic vectoring exhaust nozzle with saw-tooth-shaped solid tabs at an outlet. The throat offset type pneumatic vectoring exhaust nozzle comprises an exhaust nozzle body, wherein a flow channel in the exhaust nozzle sequentially comprises an exhaust nozzle inlet, an isometric section, a first throat front part convergent section, a first throat, a second throat front part expanding section, a second throat front part convergent section and a second throat; and the saw-tooth-shaped solid tabs are arranged on upper and lower wall surfaces at the downstream of the second throat front part convergent section and a projection area of the outlet of the exhaust nozzle is not changed. According to the throat offset type pneumatic vectoring exhaust nozzle disclosed by the invention, the saw-tooth-shaped solid tabs which are inclined toward are arranged at upper and lower sides of the outlet; and an infrared stealth function of the exhaust nozzle is improved under the condition that the projection area of the outlet is equal to an original projection area. Compared with a standard throat offset type pneumatic vectoring exhaust nozzle with a rectangular outlet section, the exhaust nozzle provided by the invention can be used for effectively reducing the speed of a flow spraying central line and reducing the length of a core region and noisesthrough reinforcing flow spraying and blending of the outlet; and meanwhile, the exhausting temperature is reduced and the infrared stealth function is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

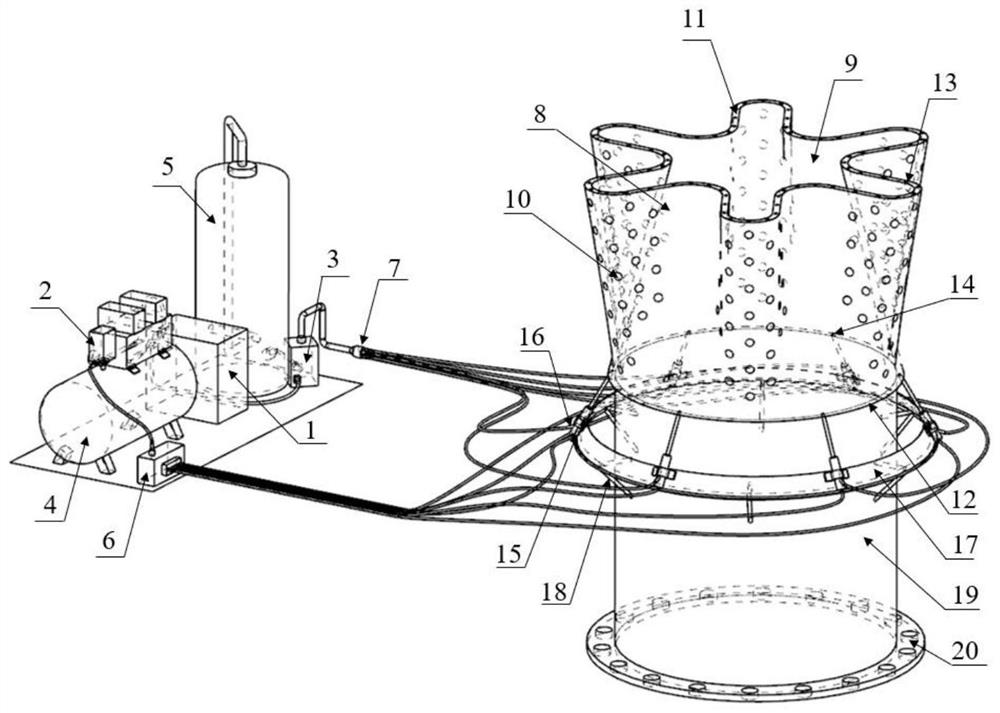

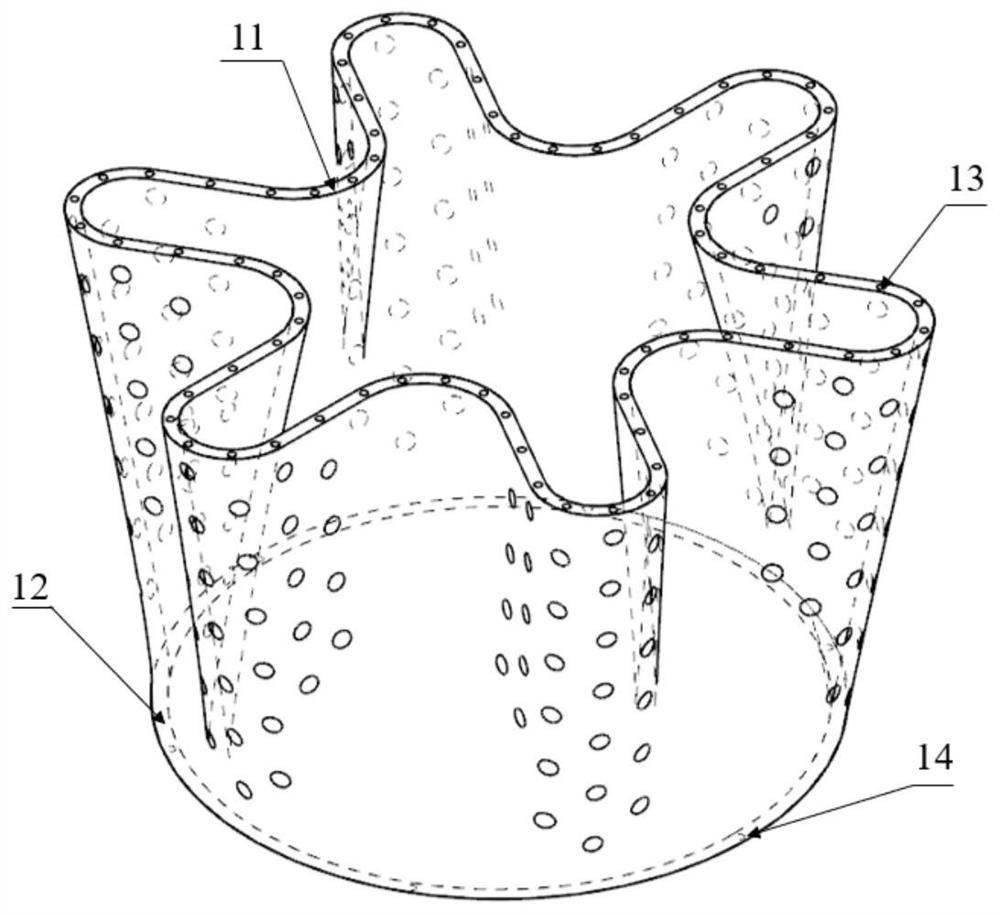

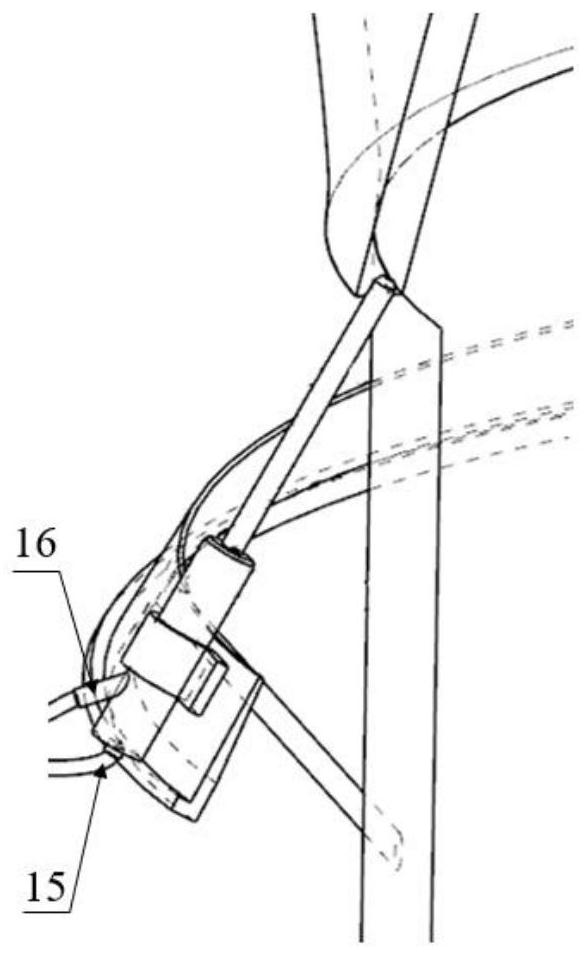

Lobe ejection system with high infrared stealth characteristic

PendingCN114084326AReduce vibrationReduce flue gas temperatureDefensive equipmentOffensive equipmentFlue gasPower apparatus

The invention discloses a lobe ejection system with a high infrared stealth characteristic. The lobe ejection system comprises a double-layer lobe ejector, an air film cooling device and a spray cooling device. The lobe ejector is connected with an exhaust outlet of a power device and composed of an inner wall face and an outer wall face, the inner wall face is completely closed, through holes are formed in wave crests of the outer wall face, the inner wall face and the outer wall face are connected through a head gasket and a tail gasket, the head gasket is provided with through holes used for exhausting airflow and spraying mist, and a nozzle is installed on the tail gasket. The nozzle comprises an inflation connector and a water spraying connector. The air film cooling device is used for inflating the cavity, and the spray cooling device is used for spraying mist into the cavity. The inner lobe can be cooled, flue gas can be secondarily cooled at the same time, vibration of the lobe ejector in the operation process can be weakened through the double-layer structure, and the stability of the device is improved. The temperature of the wall face of the exhaust pipe and the temperature of the smoke are reduced, meanwhile, the high temperature brought by the smoke to the ejector body is reduced, and the infrared stealth performance and the survivability of a ship can be improved.

Owner:JIANGSU UNIV OF SCI & TECH

A shrinking and expanding nozzle with stealth function

The invention relates to the design technique of aero-engine nozzles, in particular to a convergent-divergent nozzle with a stealth function, and aims to at least solve the problem of large occupation of a conventional convergent-divergent nozzle. The convergent-divergent nozzle with the stealth function comprises a convergent segment, a divergent segment and a straight tubular transition throat segment, wherein the end surface of a first inlet end of the convergent segment is circular, the end surface of a first outlet end, parallel to the end surface of the first inlet end, is semi-circular, and the centers of the two end surfaces are on the same plane; the end surface of a second inlet end of the divergent segment is semi-circular, the end surface of a second outlet end, parallel to the end surface of the second inlet end, is circular, and the centers of the two end surfaces are on the same plane; and the straight tubular transition throat segment is connected with the first outlet end in a sealing manner through a third inlet end and connected with the second inlet end in a sealing manner through a third outlet end. The convergent-divergent nozzle with the stealth function is simple in structure, light in weight, high in reliability and convenient to mount, manufacture and lose weight, and can enhance the infrared stealth effect and the radar stealth effect without changing the structure of a plane.

Owner:AECC SHENYANG ENGINE RES INST

A pre-evaporation integrated afterburner

InactiveCN105674332BIncrease the degree of mixingReduce the temperatureContinuous combustion chamberCombustion chamberSpray nozzle

The invention provides a pre-evaporation type integrated afterburner. An oil cavity is formed inside an afterburning inner cone, and is connected with a fuel oil channel inside a rectification support plate flame stabilizer. Fuel oil is heated in the oil cavity to become gas or a supercritical body, and then the gas or the supercritical body enters the fuel oil channel inside the rectification support plate flame stabilizer and is sprayed out from direct-injection type spraying nozzle small holes in the two sides. The spraying nozzle small holes are reasonably formed so that the mixing effect of the fuel oil and the gas can be effectively improved, and the burning efficiency is improved. In addition, a large amount of heat is transmitted to the fuel oil through the afterburning inner cone, so that the self temperature is decreased, and the infrared stealth performance is effectively improved. The pre-evaporation type integrated afterburner has the beneficial effects that on the basis of an integrated afterburner structure, by reasonably leading in the structure of the oil cavity inside the afterburning inner cone and the structure of the fuel oil channel inside the rectification support plate flame stabilizer and reasonably forming the direct-injection type spraying nozzle small holes, the burning efficiency is effectively improved, and the infrared stealth performance is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

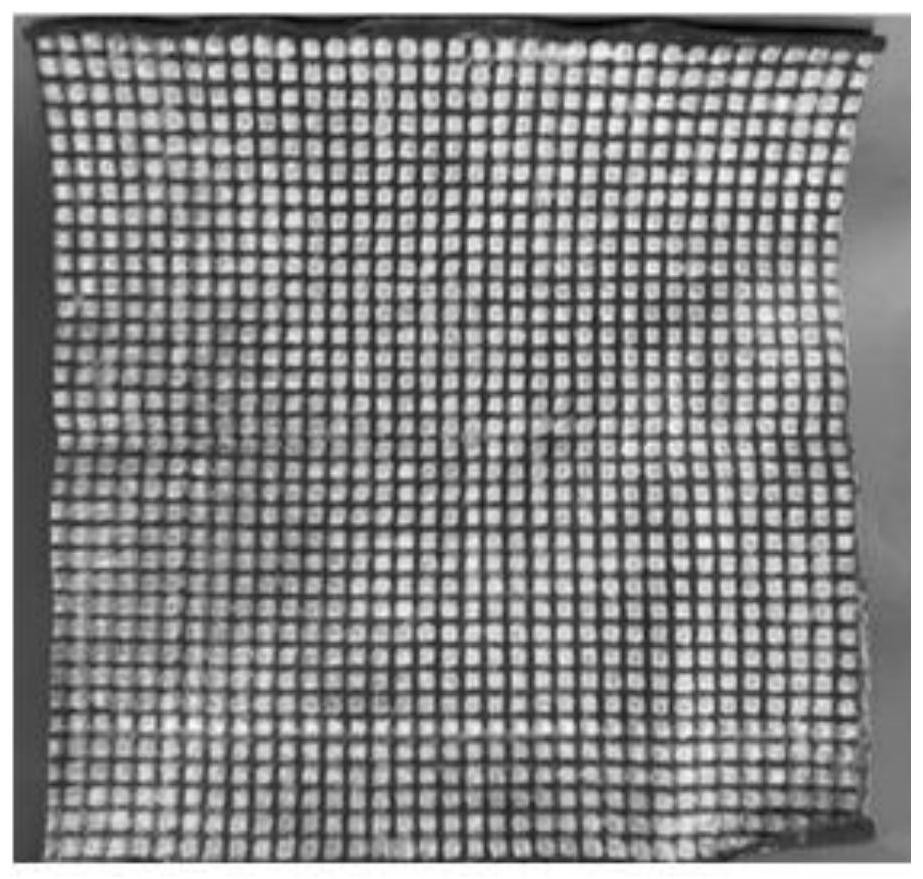

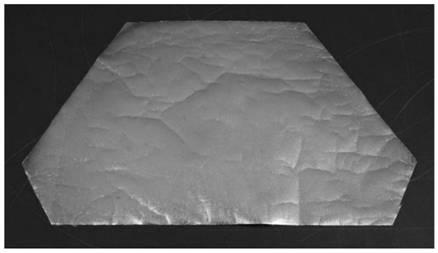

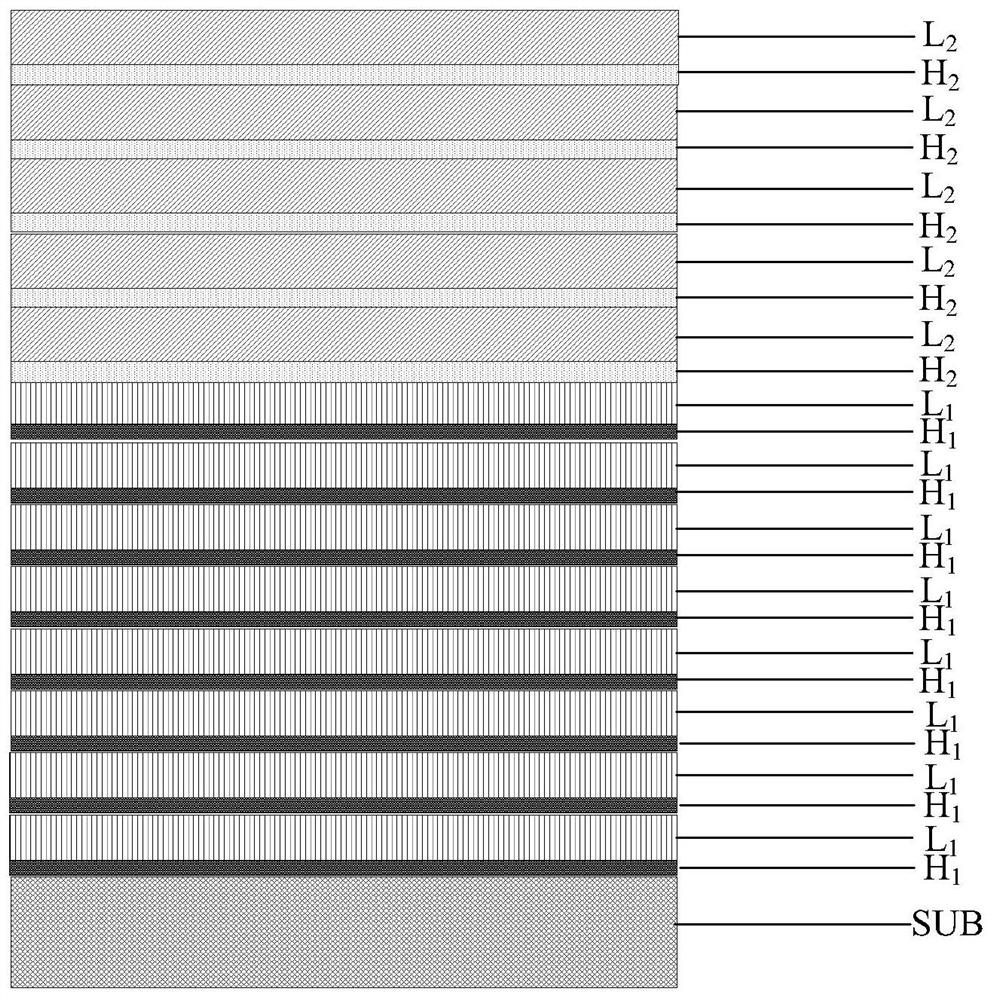

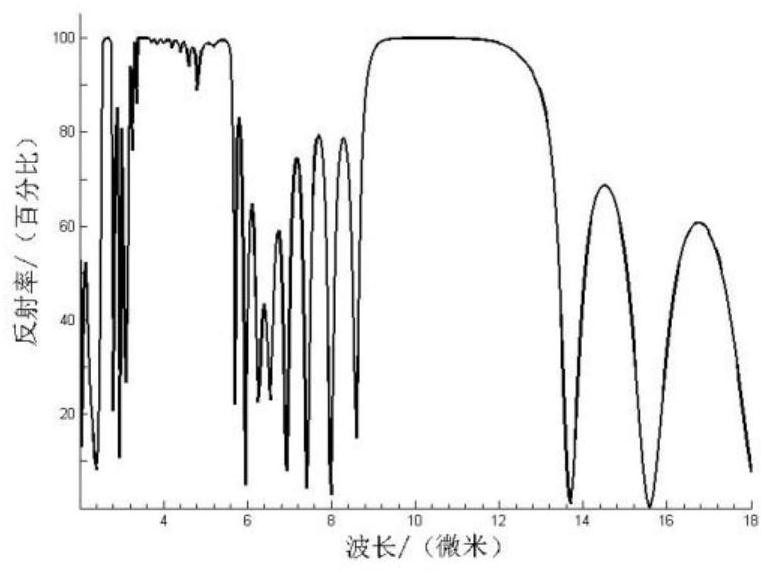

Infrared stealth film for radar antenna and preparation method thereof

ActiveCN112363262ARealize effective stealth and timely heat dissipationImprove infrared stealth performanceMirrorsVacuum evaporation coatingThin membraneWave band

The invention relates to an infrared stealth film for a radar antenna and a preparation method of the infrared stealth film; the film is of a multi-layer film structure, the multi-layer film structurecomprises a substrate, and high-refractive-index material layers and low-refractive-index material layers which are sequentially and alternately stacked on the substrate from inside to outside, and the specific arrangement is SUB|(H1L1)m(H2L2)n|AIR, wherein SUB is a substrate, AIR represents air, H1 and H2 represent high-refractive-index materials with two thicknesses, L1 and L2 represent low-refractive-index materials with two thicknesses, and each layer has a specific physical thickness, and m and n represent the number of layers. According to the invention, low emission is realized on a common infrared detection waveband, high emission is realized on other wavebands, and the material and the substrate have high-transmittance characteristics on radar waves, so that the radar antenna canwork normally, and effective invisibility and timely dissipation of a heat source target can be realized.

Owner:NAT UNIV OF DEFENSE TECH

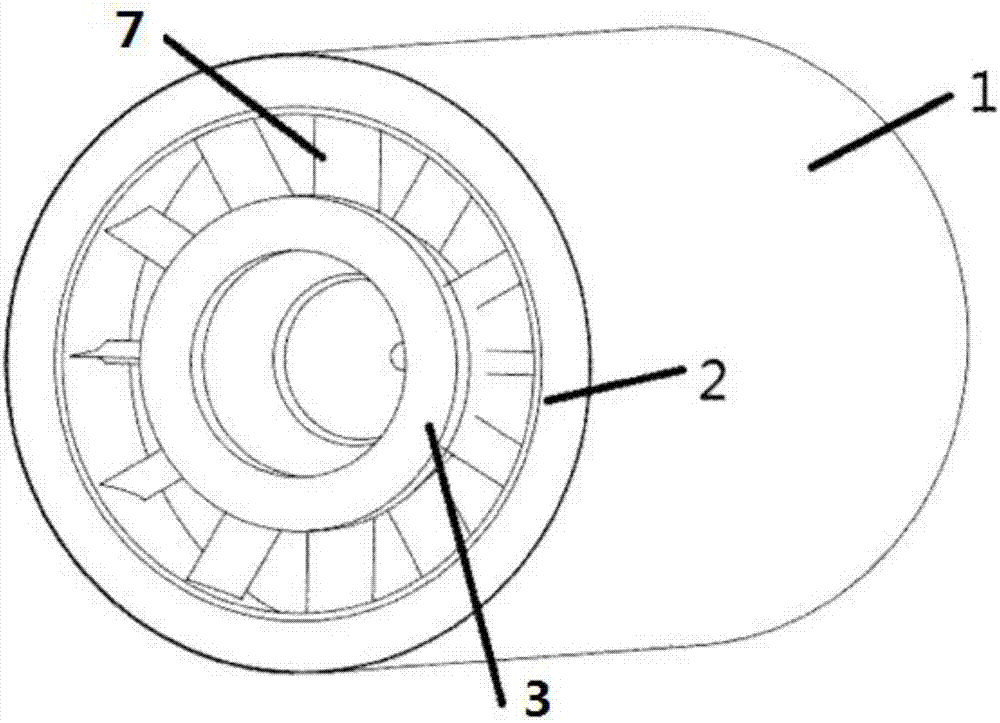

A stealth exhaust pipe with adjustable tapered cavity

ActiveCN109339975BSolving problems that are not working optimallyReduce the intensity of infrared radiationEngine componentsJet propulsion plantsAir pumpEngineering

The invention discloses a stealth exhaust pipe provided with an adjustable conical cavity. The exhaust pipe comprises an exhaust system; the exhaust system comprises an outer duct, an inner duct, a supporting plate, a central cone, a spraying pipe wall surface, a telescopic sleeve, the conical cavity and an aerosol injection device; the telescopic sleeve is arranged at the cone vertex of the central cone of the exhaust system and comprises an inner sleeve and an outer sleeve; the inner sleeve penetrates through the conical cavity to communicate with the aerosol injection device arranged insidethe conical cavity; a plurality of aerosol storage devices are arranged inside the conical cavity and communicate with the aerosol injection device; a plurality of aerosol discharging pipelines are connected onto the aerosol injection device; outlets of the aerosol discharging pipelines are arranged on the outer surface of the conical cavity; and an air pump is arranged inside the aerosol injection device. According to the exhaust pipe, the stealth requirement of an aircraft for the exhaust pipe is considered, and meanwhile, the problems that wave absorbing media are prone to loss and fallingdue to coating of high-temperature wall surfaces and the thrust loss is relatively high due to exhaust pipes adopting S-bend structures are avoided.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

A Throat Offset Pneumatic Vectoring Nozzle with a Serrated Solid Tab at the Outlet

The invention discloses a throat offset type pneumatic vectoring exhaust nozzle with saw-tooth-shaped solid tabs at an outlet. The throat offset type pneumatic vectoring exhaust nozzle comprises an exhaust nozzle body, wherein a flow channel in the exhaust nozzle sequentially comprises an exhaust nozzle inlet, an isometric section, a first throat front part convergent section, a first throat, a second throat front part expanding section, a second throat front part convergent section and a second throat; and the saw-tooth-shaped solid tabs are arranged on upper and lower wall surfaces at the downstream of the second throat front part convergent section and a projection area of the outlet of the exhaust nozzle is not changed. According to the throat offset type pneumatic vectoring exhaust nozzle disclosed by the invention, the saw-tooth-shaped solid tabs which are inclined toward are arranged at upper and lower sides of the outlet; and an infrared stealth function of the exhaust nozzle is improved under the condition that the projection area of the outlet is equal to an original projection area. Compared with a standard throat offset type pneumatic vectoring exhaust nozzle with a rectangular outlet section, the exhaust nozzle provided by the invention can be used for effectively reducing the speed of a flow spraying central line and reducing the length of a core region and noisesthrough reinforcing flow spraying and blending of the outlet; and meanwhile, the exhausting temperature is reduced and the infrared stealth function is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A binary nozzle structure for ejecting cold air from the engine compartment

ActiveCN113217225BReduced infrared radiation propertiesImprove infrared stealth performanceJet propulsion plantsCold airAviation

Owner:AECC SHENYANG ENGINE RES INST

A Design Method of Elliptical Throat Offset Pneumatic Vectoring Nozzle

ActiveCN113374595BImprove infrared stealth performanceFlexible controlJet propulsion plantsFlight vehicleEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

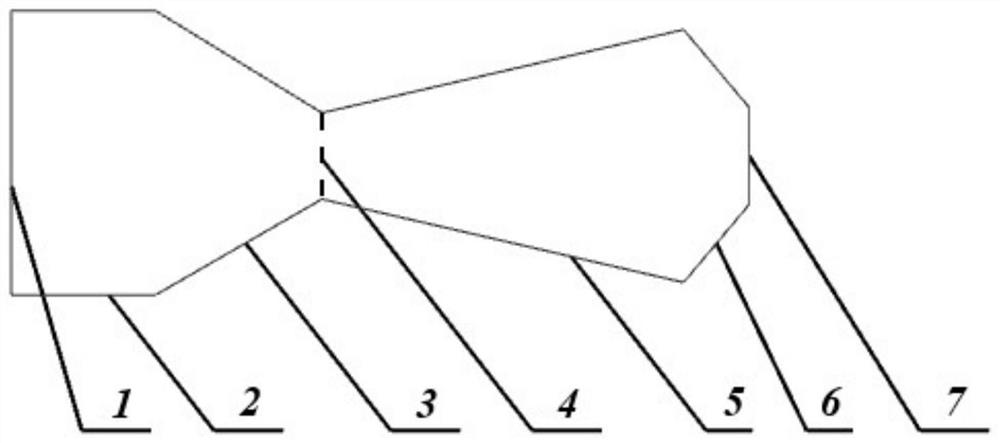

Visible light and thermal infrared double camouflage material and preparation method thereof

InactiveCN109772664ARealize deep integrationImprove infrared stealth performanceSpecial surfacesCoatingsEmissivityThermography

The invention provides a visible light and thermal infrared double camouflage material and a preparation method thereof. The preparation method comprises the following steps that a first coating to annth coating are provided, wherein the first coating has a first color and a first emissivity, the nth coating has an nth color and an nth emissivity, and the n is a positive integer larger than or equal to 2; a camouflage pattern with a first patch pattern to an nth patch pattern is generated; a first coating is coated, and a first drawing is uncovered after the coating is finished; the steps from attaching the drawing to a substrate to removing the drawing are repeated until the nth coating is coated on the nth drawing, the nth drawing is uncovered after the coating is finished, and after the coating of the nth patch pattern is dried, the visible light and thermal infrared double camouflage material is namely obtained. The double camouflage material is capable of remarkably reducing thethermal imaging brightness of a target and effectively segmenting the appearance characteristic of the target.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

A stealth exhaust system

ActiveCN102926888BImprove adaptabilityImprove infrared stealth performancePower plant exhaust arrangementsJet propulsion plantsRadarAmbient air

The invention relates to an exhaust system applied to an air vehicle, in particular to a stealth exhaust system. A cross-section shape of a throat of a spray pipe is designed to a non-round shape with an aspect ratio greater than 1, so that mixing of high-temperature exhaust airflow of an engine and ambient air is strengthened, the exhaust temperature is reduced, and an infrared stealth property of the exhaust system is improved. Central lines of the stealth exhaust system are three longitudinal S-bent curves, and the bent central lines can enable sidewalls of the spray pipe to shield high-temperature components of the engine, therefore, the infrared stealth property of the exhaust system can be improved; and simultaneously, the bent central lines can also cause radar waves going into the stealth exhaust system from the rear to difficultly generate backward waves, therefore, a radar stealth property of the exhaust system can be improved. Properties of the exhaust system are considered while the stealth properties are ensured, so that a requirement of the stealth exhaust system on the layout space is reduced, and adaptability of the stealth exhaust system is strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

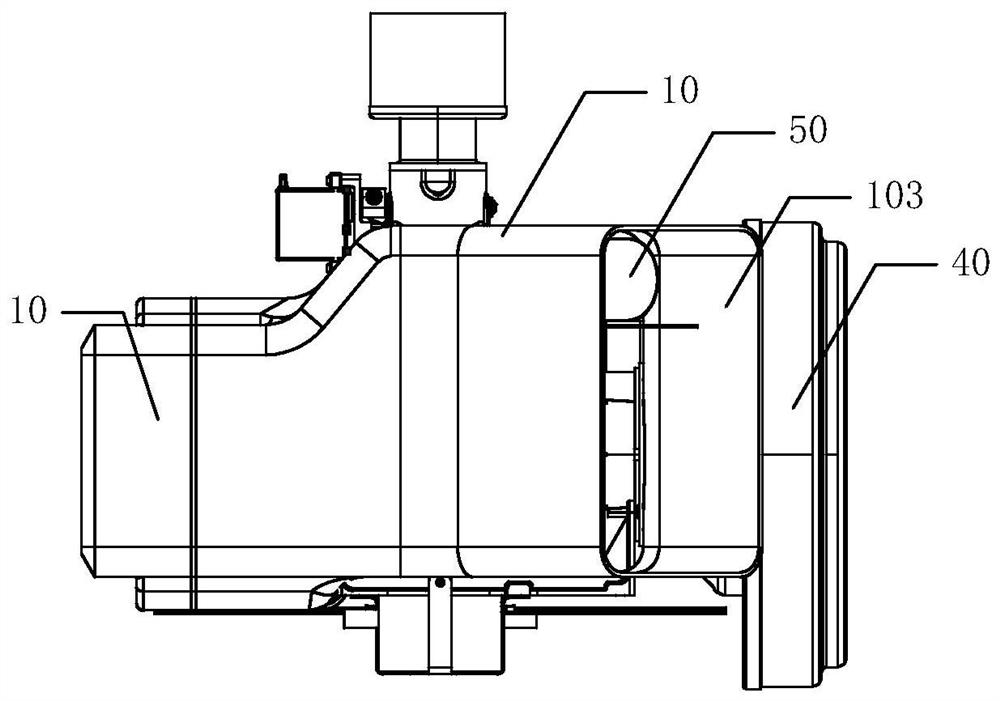

Cooling structure of hybrid power system

PendingCN111878215ASolve the cooling problemReduce exhaust back pressureCoolant flow controlExhaust apparatusCrankcaseCylinder (engine)

The invention provides a cooling structure of a hybrid power system. The cooling structure comprises a flow guide cover wrapping a silencer, the interior of the flow guide cover is hollow, and the interior of an air outlet channel of the flow guide cover protrudes upwards to form a silencer mounting space for mounting the silencer. According to the cooling structure, the silencer is arranged in the flow guide cover, cooling air of a cooling suction fan forms negative pressure after flowing through an air cylinder body, a crankcase and the silencer, waste gas in the silencer can be sucked out,the exhaust back pressure of a two-stroke air-cooled engine is reduced, and the power of the two-stroke air-cooled engine is improved; the waste gas of the silencer is mixed with the cooling air flowing through the air cylinder body, the crankcase and the silencer at the rear end of the flow guide cover, and the temperature of the waste gas flowing out of the silencer from the silencer is greatlyreduced, so that the infrared stealth effect of the hybrid power system is greatly improved; and the flow guide cover completely covers the silencer and can absorb part of noise generated by exhaust,and therefore the noise reduction effect is achieved.

Owner:天津轩云科技有限公司

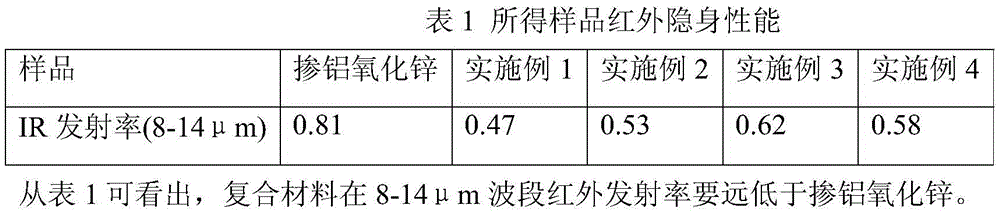

A kind of preparation method of organic-inorganic composite infrared stealth material

InactiveCN103865263BImprove stabilityImprove infrared stealth performanceOther chemical processesConductive polymerZinc

Owner:临泉县嘉鸿装饰工程有限公司

Encircling-type double-duct variable-cycle engine and control method

PendingCN113982780ALow manufacturing costReduce tip speedJet propulsion plantsInternal combustion piston enginesAutomotive engineeringHigh-speed flight

Owner:太仓点石航空动力有限公司

A Mechanically Adjustable S-Bent Nozzle Nozzle Structure

ActiveCN112943481BImprove infrared stealth performanceAddressing Thrust Performance DegradationJet propulsion plantsEngineeringAero engine

The invention discloses a mechanically adjustable S-bend nozzle nozzle structure, belonging to the field of aero-engines; it includes an S-bend section and 8 adjustment pieces, and the 8 adjustment pieces are hinged in the circumferential direction to form an annular structure; the annular structure is hinged to the S-bend. The inner wall of the rectangular outlet of the curved section constitutes a sealed air flow channel; the 8 regulating pieces are an upper regulating piece, a lower regulating piece, two side regulating pieces, two upper regulating pieces, and two lower regulating pieces; Each side regulating piece is hinged on the short sides of the rectangular outlet of the S-bend segment; the upper regulating piece and the lower regulating piece are respectively hinged on the long sides of the two sides of the rectangular outlet of the S-curve segment; the two upper regulating pieces are hinged on the between the two side adjustment pieces and the upper adjustment piece; the two lower side adjustment pieces are hinged between the two side adjustment pieces and the lower adjustment piece respectively. The invention can enhance the infrared stealth performance of the nozzle through the shielding of the high-temperature engine components by the S-bend section, and compared with the conventional axisymmetric nozzle, the infrared radiation intensity can be reduced by more than 70%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com