Cooling structure of hybrid power system

A technology of hybrid power system and cooling structure, applied in the direction of engine cooling, coolant flow control, engine components, etc., can solve problems affecting engine power and fuel consumption, increase of intake air temperature, decrease of intake air volume, etc., to achieve Effects of reducing exhaust back pressure, increasing power, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

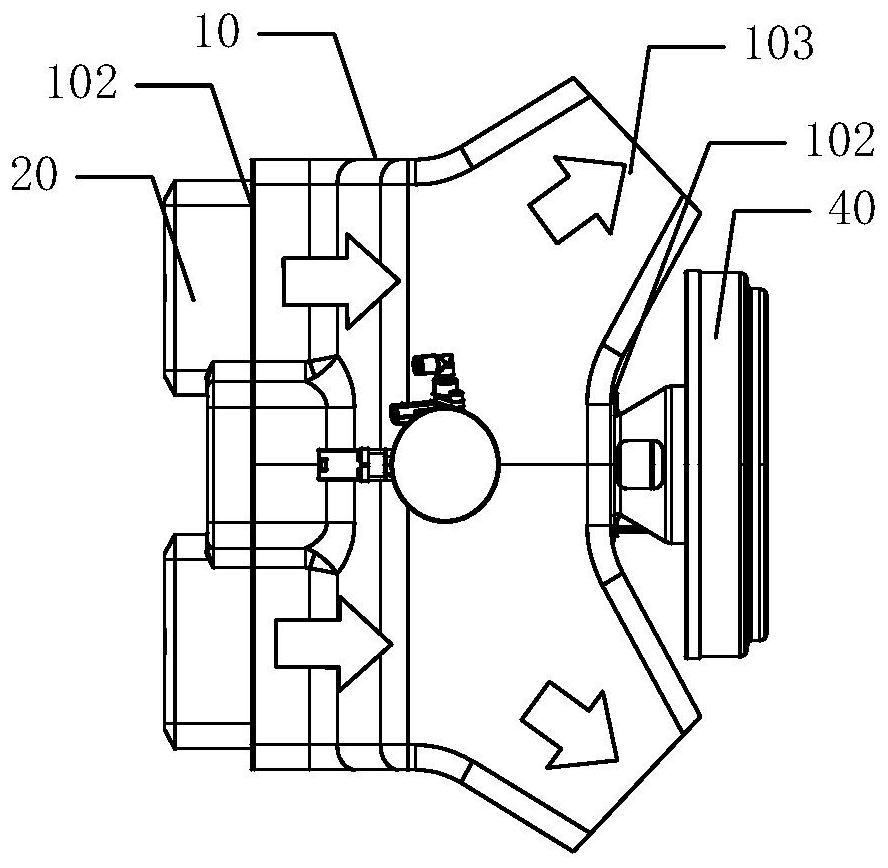

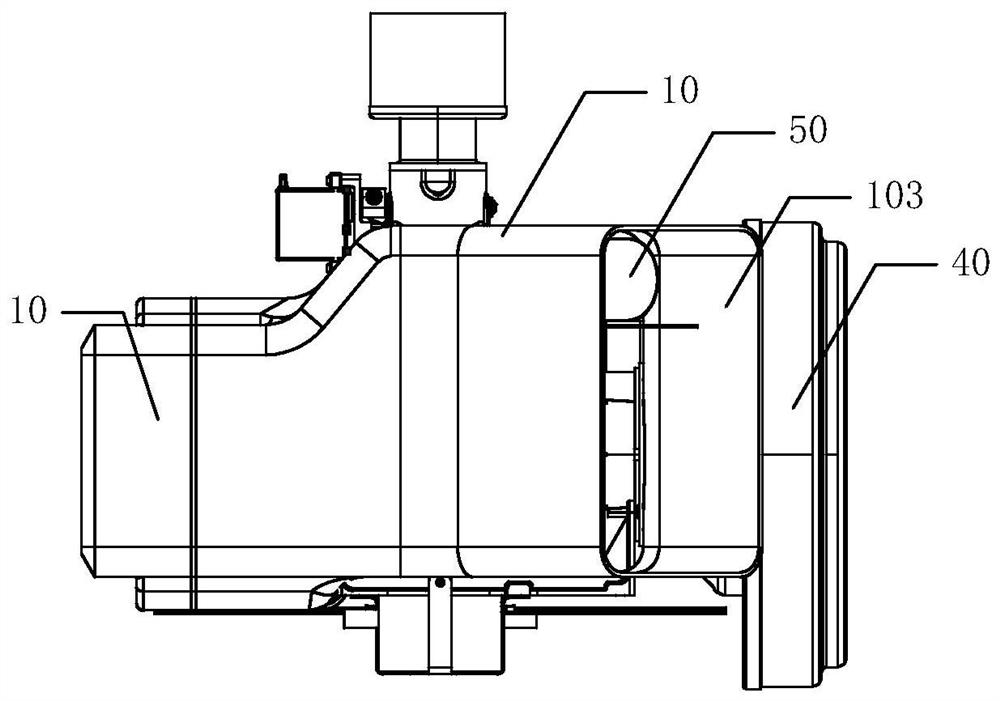

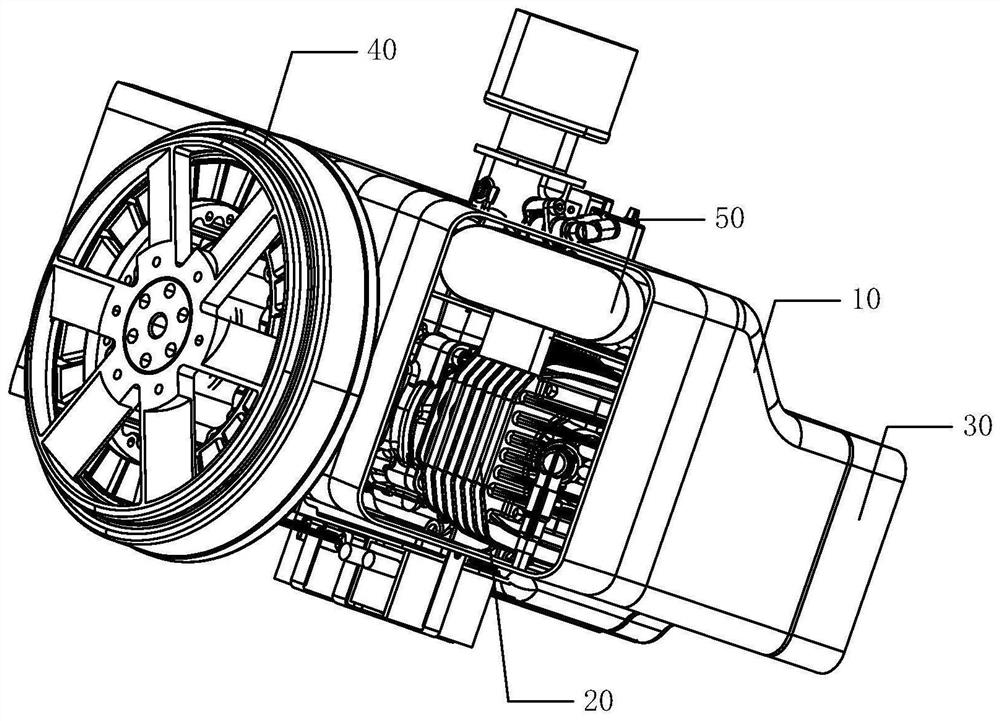

[0023] Such as Figure 1 to Figure 3 As shown, one aspect of the present invention provides a cooling structure for a hybrid power system. The cooling structure includes a shroud 10 that wraps the muffler. The inside of the shroud 10 is hollow, and the inside of the air outlet channel 103 protrudes upwards. A muffler installation space is formed for installing the muffler 50 .

[0024] Such as Image 6 with Figure 7 As shown, the air guide cover 10 of the present invention is hollow inside and is used to wrap the engine 20. One end opening of the air guide cover 10 is an air inlet 101, and a cooling suction fan 30 is installed at the air inlet 101; the air guide cover 10 and the air inlet 101 The opposite end is provided with a magneto installation opening 102, and the two sides of the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com