A kind of preparation method of organic-inorganic composite infrared stealth material

An inorganic composite, stealth material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult to cover infrared atmospheric windows, and achieve the effects of low price, improved infrared stealth performance, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

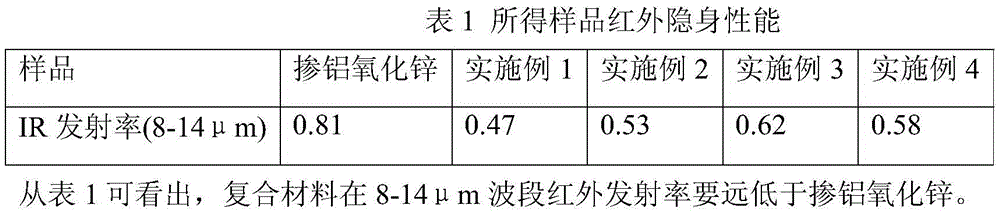

Examples

Embodiment 1

[0025] (1) Dissolve 0.1 mol of zinc acetate dihydrate in 230 g of ethanol, stir magnetically at 30°C for 30 minutes, then cool the solution to room temperature, and slowly add 0.1 mol of triethanolamine solution dropwise under magnetic stirring, and continue stirring after the addition 1h, a transparent and uniform ZnO sol was obtained.

[0026] (2) Dissolve 1g of aluminum isopropoxide in 5g of isopropanol, add 150mL of deionized water into a four-neck flask equipped with a stirrer, reflux condenser and dripping device, heat to 70°C; then slowly add isopropoxide After adding all the aluminum propoxide solution, reflux and stir for 0.5h to form a white precipitate, then raise the temperature to 95°C, and evaporate in the open until all the isopropanol evaporates, then add 7.5ml of concentrated hydrochloric acid, and reflux for 3h to obtain al 2 o 3 Sol.

[0027] (3) ZnO sol and Al 2 o 3 The sols were mixed at a mass ratio of 1:100 to obtain a composite sol, which was aged ...

Embodiment 2

[0031] (1) Dissolve 0.1 mol of zinc acetate dihydrate in 460 g of ethanol, stir magnetically at 60°C for 15 minutes, then cool the solution to room temperature, and slowly add 0.2 mol of ethanolamine solution dropwise under magnetic stirring, and continue stirring for 1.5 h, a transparent and uniform ZnO sol was obtained.

[0032] (2) Dissolve 1g of aluminum isopropoxide in 10g of isopropanol, add 80mL of deionized water into a four-necked flask equipped with a stirrer, reflux condenser and dripping device, heat to 85°C; then slowly add isopropoxide After adding all the aluminum propoxide solution, reflux and stir for 1.5h to form a white precipitate, then raise the temperature to 98°C, evaporate in the open until all the isopropanol is volatilized, add 0.8ml concentrated nitric acid, and reflux for 5h, you can get Al2O3 sol.

[0033] (3) Mix ZnO sol and Al2O3 sol at a mass ratio of 6:100 to obtain a composite sol. After aging for 12 hours to gel the sol, heat treatment at 900°...

Embodiment 3

[0037] (1) Dissolve 0.1 mol of zinc acetate dihydrate in 368 g of ethanol, stir magnetically at 45°C for 25 minutes, then cool the solution to room temperature, and slowly add 0.15 mol of diethanolamine solution dropwise under magnetic stirring, and continue stirring after the addition After 1.5h, a transparent and uniform ZnO sol was obtained.

[0038] (2) Dissolve 1g of aluminum isopropoxide in 8g of isopropanol, add 100mL of deionized water into a four-necked flask equipped with a stirrer, reflux condenser and dripping device, heat to 80°C; then slowly add isopropoxide After all the aluminum propoxide solution is added, reflux and stir for 1 hour to form a white precipitate, then raise the temperature to 95°C, evaporate in the open until all the isopropanol is volatilized, add 2ml of concentrated hydrochloric acid, and reflux for 4 hours to obtain Al2O3 sol .

[0039] (3) Mix ZnO sol and Al2O3 sol at a mass ratio of 3:100 to obtain a composite sol. After aging for 10 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com