Resin-based heat-proof composite material with surface coated with high-temperature infrared stealth coating and preparation method thereof

A high-temperature infrared and composite material technology, applied in coatings, fire-retardant coatings, camouflage coatings, etc., to achieve the effects of good environmental protection, simple process and equipment, and improved infrared stealth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

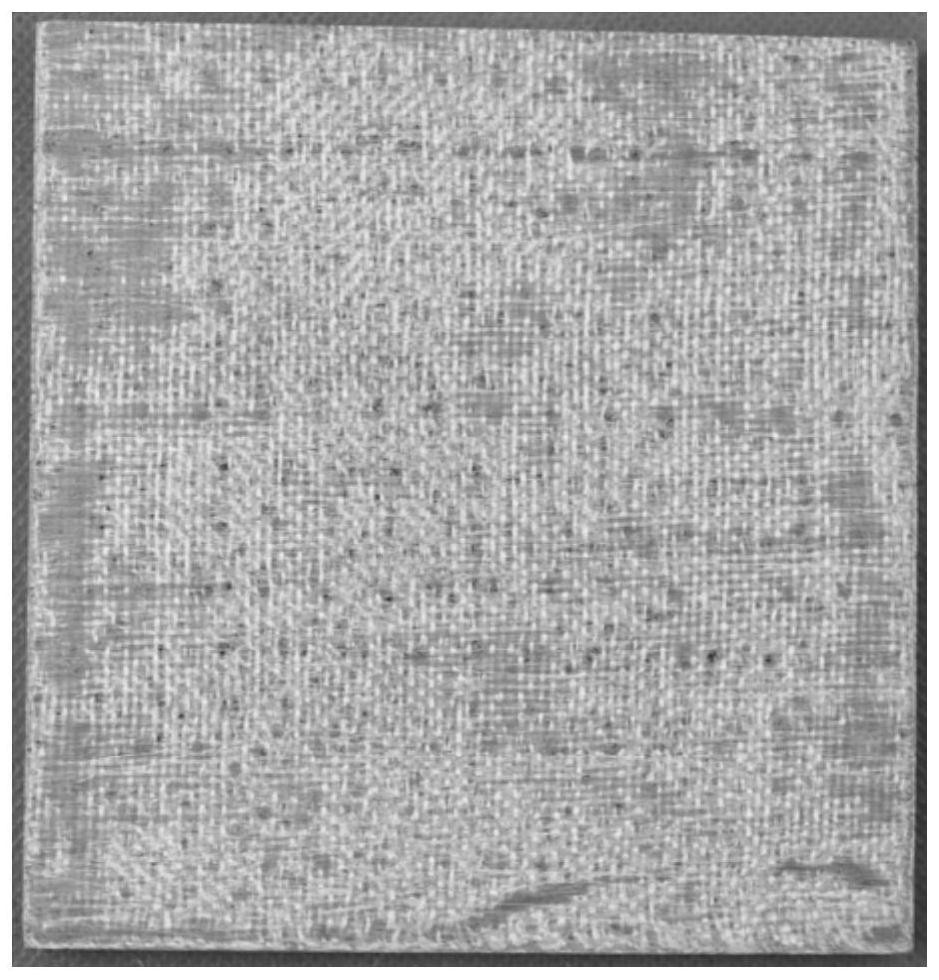

[0027] A resin-based heat-resistant composite material coated with a high-temperature infrared stealth coating on the surface. The resin-based heat-resistant composite material uses quartz fiber stitched fabric as a reinforcement, the resin matrix is phenolic resin, and hollow microbeads are used as additives. The resin-based heat-resistant composite Material density is 1.41g / cm 3 , the density of hollow microspheres is 0.35g / cm 3 , the particle size is 30 μm, and the volume content of hollow microspheres in the resin-based heat-resistant composite material is 5%; the high-temperature infrared stealth coating uses silver as a low-emissivity filler, and the mass content of silver in the coating is 90%. Binder is BaO-B 2 o 3 -ZnO system lead-free low melting point glass, the glass softening point temperature is 530°C. The thickness of the high-temperature infrared stealth coating is 6 μm.

[0028] This embodiment also provides a method for preparing a resin-based heat-resi...

Embodiment 2

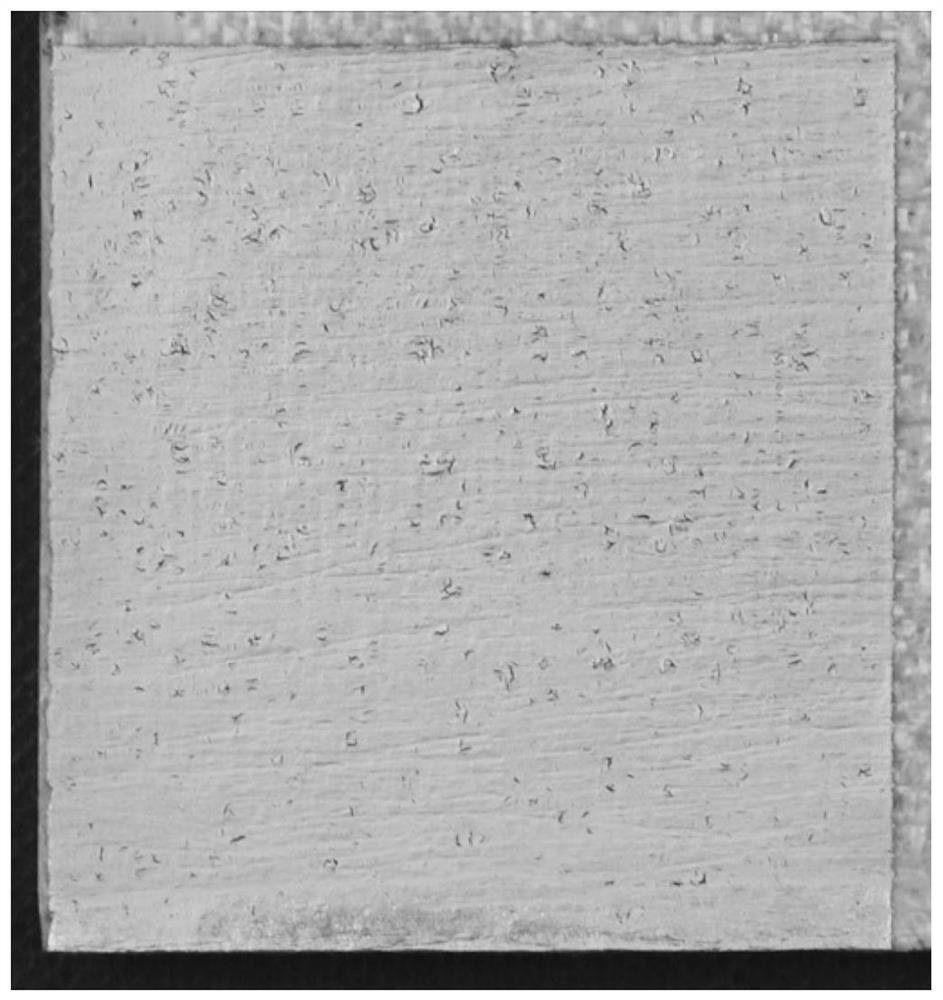

[0034] A resin-based heat-resistant composite material coated with a high-temperature infrared stealth coating on the surface. The resin-based heat-resistant composite material uses quartz fiber needle-punched parts as reinforcements, the resin matrix is phenolic resin, and hollow microbeads are used as additives. The resin-based heat-resistant The density of the composite material is 0.42g / cm 3 , the density of hollow microspheres is 0.4g / cm 3 , the particle size is 30 μm, and the volume content of hollow microspheres in the resin-based heat-resistant composite material is 8%; the high-temperature infrared stealth coating uses silver as a low-emissivity filler, and the mass content of silver in the coating is 92%. Binder is BaO-B 2 o 3 -ZnO system lead-free low melting point glass, glass softening point temperature is 580°C. The thickness of the high-temperature infrared stealth coating is 12 μm.

[0035]This embodiment also provides a method for preparing a resin-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com