Visible light and thermal infrared double camouflage material and preparation method thereof

A technology of thermal infrared and visible light, which is applied to coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of incompatibility between visible light and thermal infrared camouflage, achieve good integration, enhance infrared stealth effect, and camouflage performance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

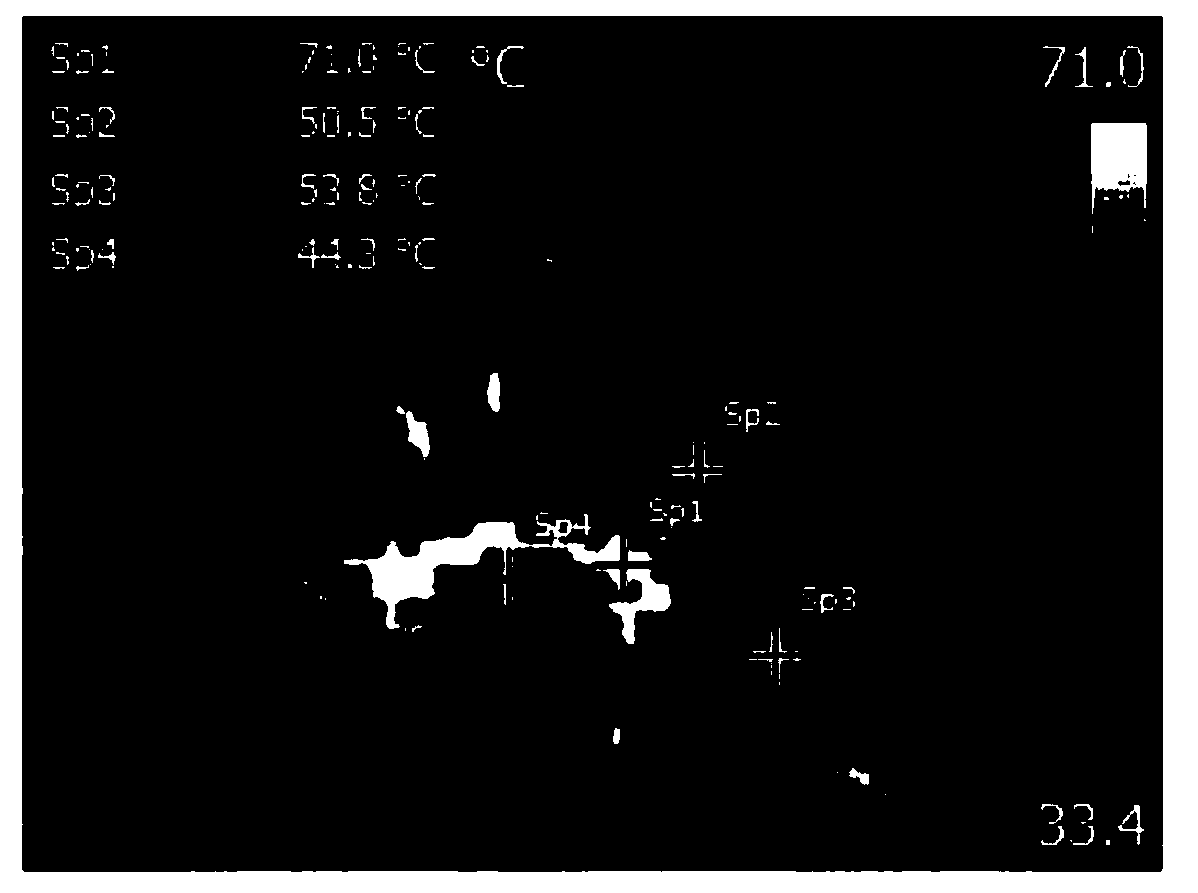

Embodiment 1

[0032]Infrared coatings with modulated infrared emissivity of 0.42, 0.63, 0.75, and 0.89 are ready for use, wherein each color corresponds to an emissivity, and the colors are silver, yellow, green, and black; a pattern of A4 size is generated by a computer, Among them, according to the area ratio of 30%, 20%, 20%, and 30%, four plaque patterns are generated, which are the first plaque pattern, the second plaque pattern, the third plaque pattern and the fourth plaque pattern , to print 4 copies of it as a template. Attach the A4 flexible film to the pre-treated A4 size polyethylene board, hollow out the first patch pattern, and paste the hollowed out edge, and spray the paint with an emissivity of 0.42 and a silver color on the flexible film. After spraying, peel off the flexible film, blow the air to dry the coating, and the dry film thickness of the sprayed coating is about 40 μm; after the coating is dry, repeat the steps of attaching the flexible film until the coating is ...

Embodiment 2

[0035] Infrared coatings with modulated infrared emissivity of 0.4, 0.55, 0.7, and 0.85 are ready for use, wherein each color corresponds to an emissivity, and the colors are red, yellow, green, and black; a pattern of A4 size is generated by a computer, Among them, according to the area ratio of 20%, 40%, 20%, and 20%, four plaque patterns are generated, which are the first plaque pattern, the second plaque pattern, the third plaque pattern and the fourth plaque pattern , to print 4 copies of it as a template. Attach the A4 cardboard to the pre-treated A4 size fiber film, hollow out the first patch pattern, and paste the hollowed out edge, spray the red paint with an emissivity of 0.4 on the cardboard, and spray After the coating is finished, remove the cardboard and wait for the coating to dry. The dry film thickness of the sprayed coating is about 40 μm; after the coating is dry, repeat the steps of attaching the cardboard until the coating is dry. Paste the hollowed-out e...

Embodiment 3

[0038] Modulate infrared paints with infrared emissivity of 0.4, 0.6, and 0.8 for use, wherein each color corresponds to an emissivity, and the colors are red, yellow, and green; use a computer to generate an A4-sized pattern, in which according to the area occupied The ratios are 30%, 40%, and 30% respectively to generate three patch patterns, which are the first patch pattern, the second patch pattern and the third patch pattern, and print three copies of it as a template. Attach the A4 flexible film to the pre-treated A4 size fiber film, hollow out the first patch pattern, and paste the hollowed out edge, spray the paint with an emissivity of 0.4 and the color is red on the flexible film, spray After the coating is finished, peel off the flexible film and wait for the coating to dry. The dry film thickness of the sprayed coating is about 40 μm; after the coating is dry, repeat the steps of attaching the flexible film until the coating is dry, hollow out the second patch patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com