A Mechanically Adjustable S-Bent Nozzle Nozzle Structure

A mechanical, nozzle technology, used in machines/engines, jet propulsion devices, etc., can solve problems such as air leakage loss, eliminate air leakage loss, solve the degradation of nozzle thrust performance, and enhance infrared stealth performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

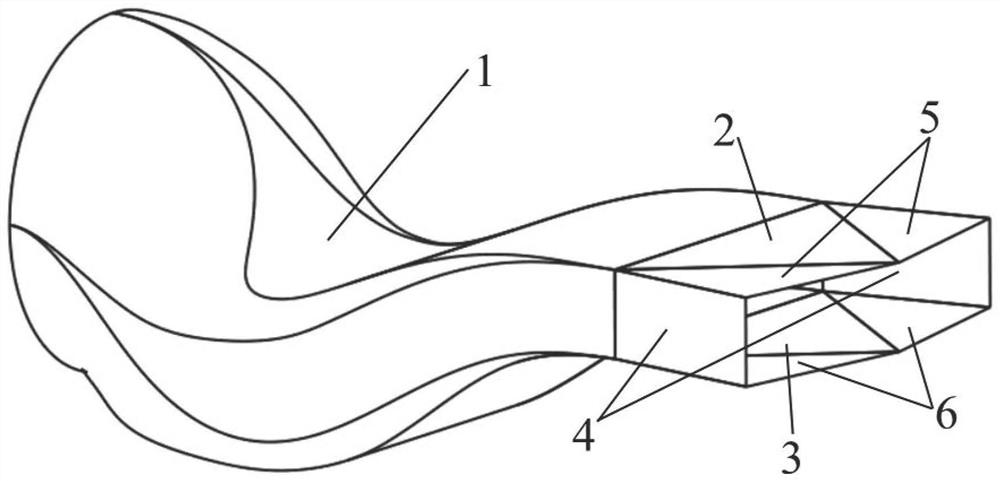

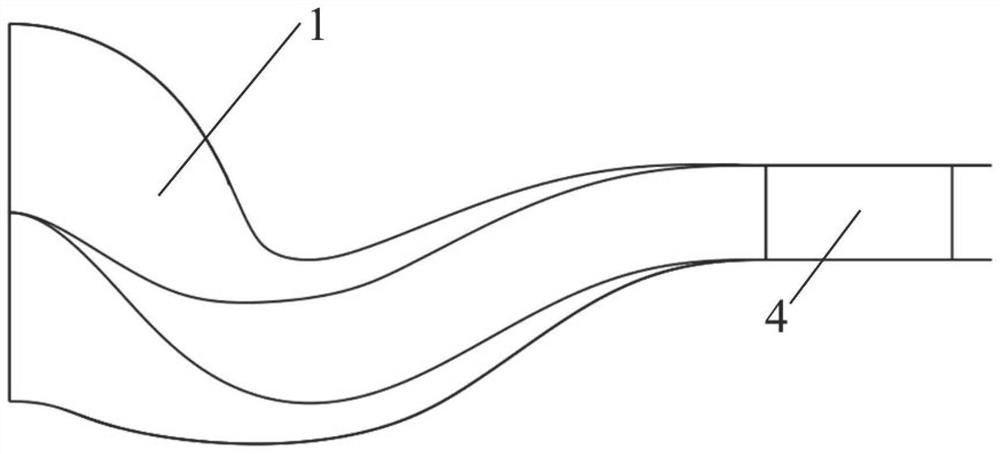

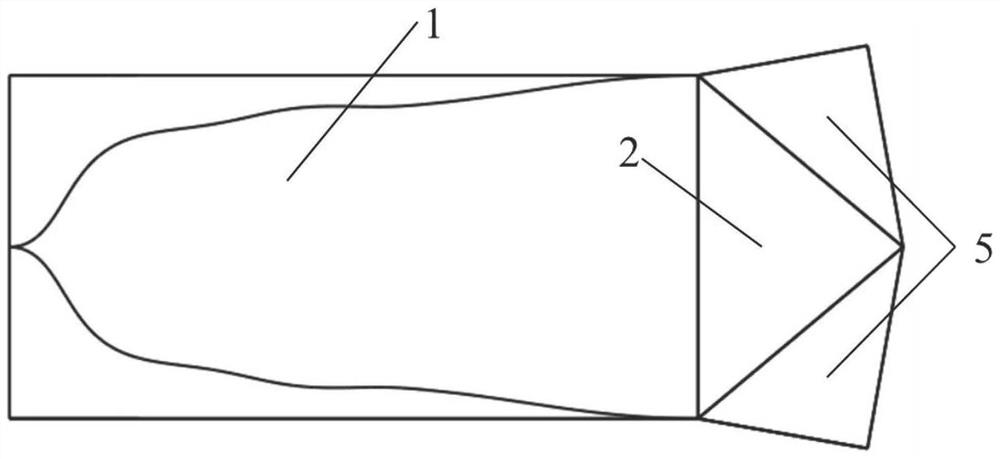

[0030] The embodiment of the present invention is a mechanically adjustable S-bend nozzle structure, such as figure 1 As shown, it includes: S-bend section 1, upper adjustment piece 2, lower adjustment piece 3, two side adjustment pieces 4, two upper side adjustment pieces 5, and two lower side adjustment pieces 6, S bend section 1 is circular The inlet is connected to the engine outlet, and the upper, lower and side edges of the rectangular outlet of the S-bend section 1 are respectively connected to the upper regulating piece 2, the lower regulating piece 3 and the side regulating piece 4, and the side edge of the upper regulating piece 2 and the upper edge of the side regulating piece 4 are connected The upper side regulating piece 5, the side edge of the lower reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com