Optical transparent ultra-wideband radar and infrared double-stealth structure

An ultra-wideband radar, optically transparent technology, applied in the field of multi-spectrum stealth, can solve the problem of less attention to infrared stealth properties, achieve good optical transparency, improve infrared stealth performance, and reduce infrared emissivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

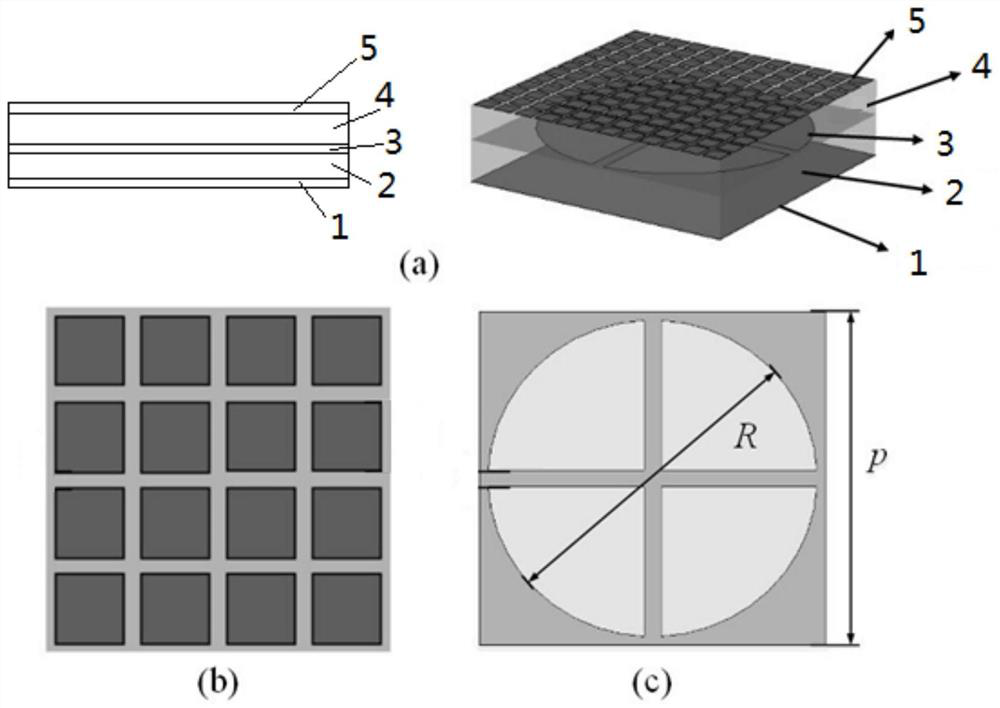

[0035] to combine figure 1 As shown, Embodiment 1 of the present invention provides an optically transparent ultra-wideband radar and infrared double stealth structure, including a low-emissivity infrared stealth layer and an ultra-wideband radar absorbing layer, which is a layered structure, including a backplane 1 from bottom to top , the first intermediate dielectric layer 2 , the first frequency selective surface layer 3 , the second intermediate dielectric layer 4 and the second frequency selective surface layer 5 . Wherein, the first intermediate dielectric layer 2 and the second intermediate dielectric layer 4 are polyethylene terephthalate (PET) with high light transmittance, and its dielectric constant is 3.0 (1-j0.06).

[0036] The first frequency selective surface layer 3 and the second frequency selective surface layer 5 are respectively composed of periodically patterned ITO coatings, and the ITO frequency selective surface substrate layers are both made of PET sh...

Embodiment 2

[0041] An optically transparent ultra-wideband radar and infrared double stealth structure, the structure is the same as that of embodiment 1, the difference is that the square resistance of the first frequency selective surface layer 3 is 15Ω / sq, and the patch in the low emissivity infrared stealth layer The size is 3.5mm, the square resistance of the backplane 1 is 15Ω / sq, the thickness of the first intermediate dielectric layer 2 is 1.2mm, and the thickness of the second intermediate dielectric layer 4 is 1.2mm.

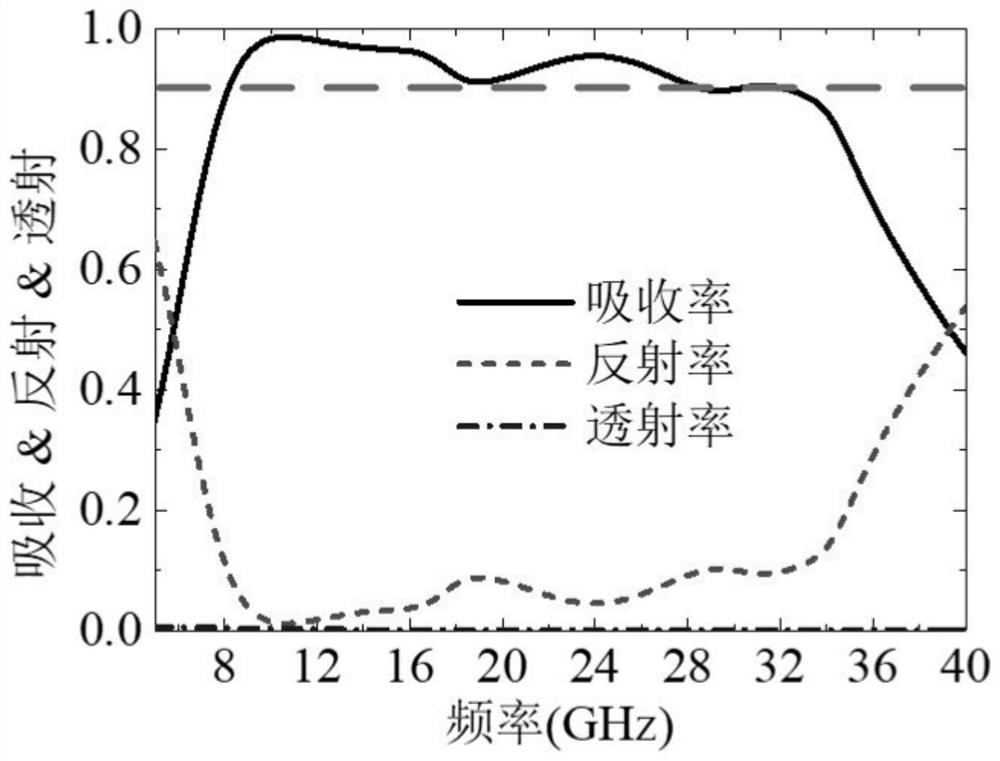

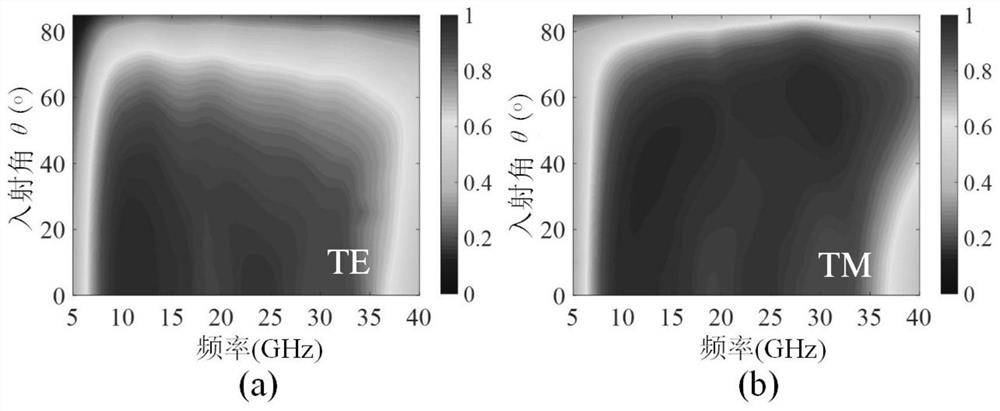

[0042] The properties of the materials prepared in Examples 1-2 are similar, and only the calculation of the absorption characteristics and reflection characteristics is performed on the optically transparent ultra-wideband radar and the infrared double stealth structure in Example 1, as shown in Figure 2-3 As shown, the optically transparent ultra-wideband radar and the infrared double stealth structure in Embodiment 1 can realize broadband wave absorption with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com