Compact ship broadside exhaust system

An exhaust system, compact technology, applied in the direction of exhaust devices, ships, ship construction, etc., can solve the difficulty of designing the side exhaust system, the muffler, the stuffy car of the main engine of the side exhaust system, and the influence of the ship's navigation Safety and other issues, to achieve the effect of improving infrared stealth, small height and reducing exhaust noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

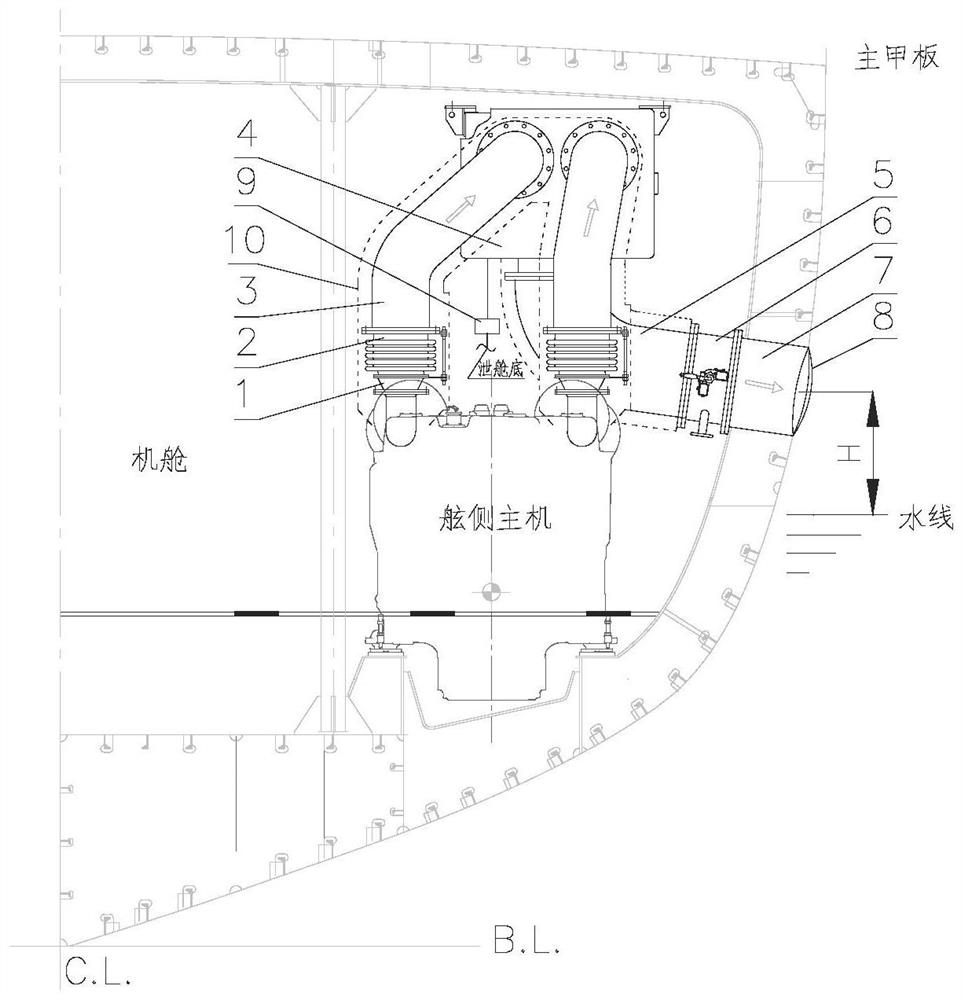

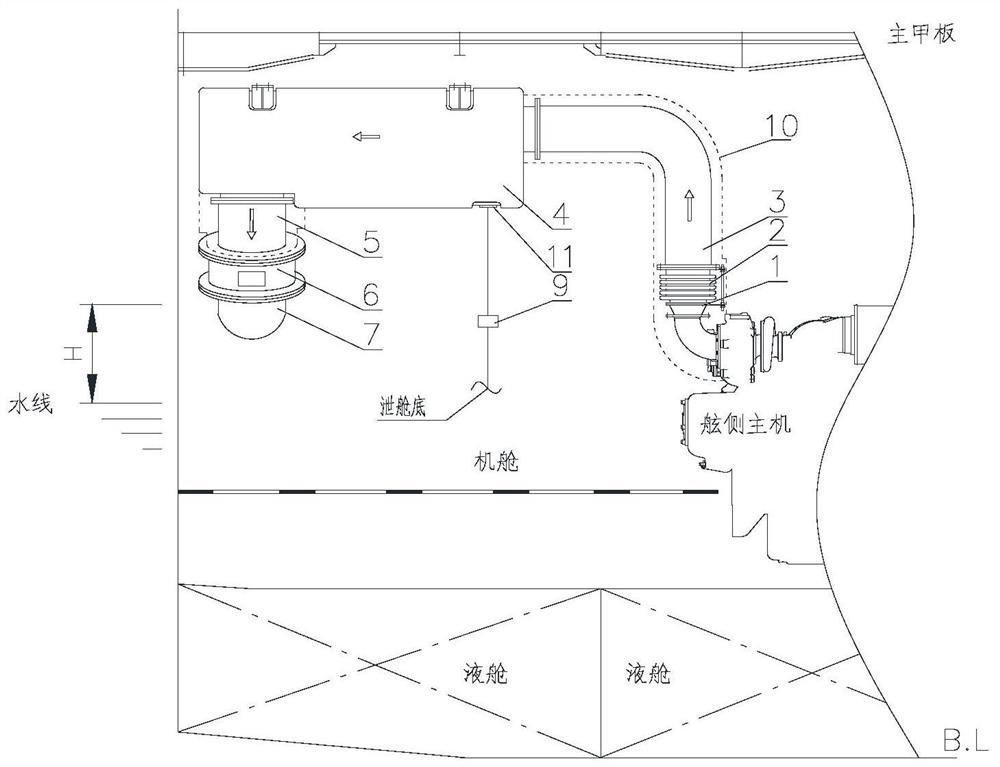

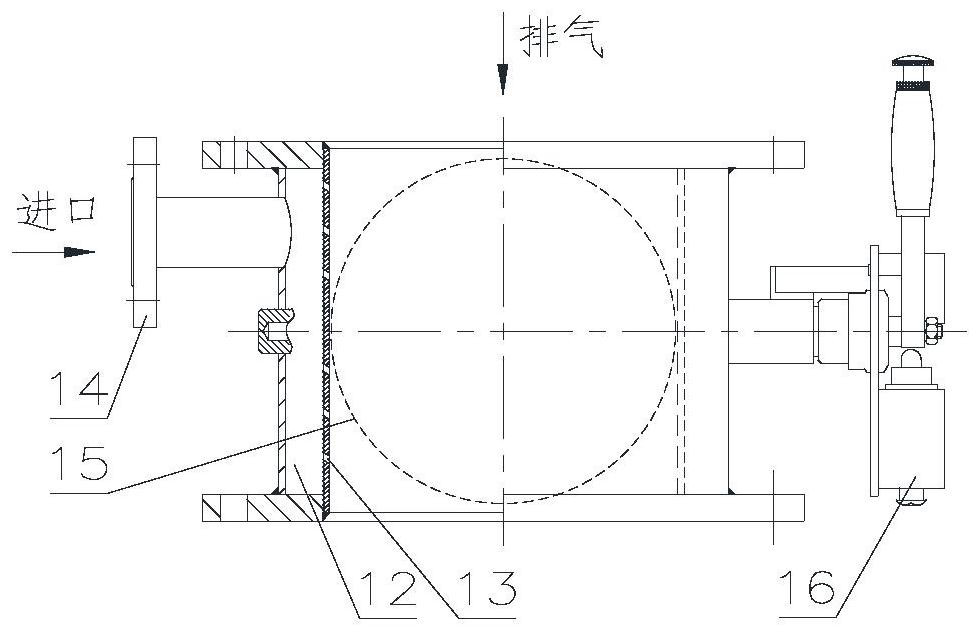

[0026] In order to make the technical means, creative features, goals and advantages achieved in order to make the present invention easy to understand, the following examples are combined with the attached figure 1 to attach Figure 4 The technical solution provided by the present invention is further described as follows.

[0027] Please refer to figure 1 and figure 2 , a compact boat side exhaust system disclosed in this example, from the main engine exhaust outlet to the outside sequentially includes: main engine outlet reducing pipe 1, Ω-shaped exhaust expansion joint 2, exhaust elbow 3, side row Square muffler 4, exhaust elbow 5, exhaust baffle valve 6, side connection pipe 7, side deflector cap 8, in addition, it also includes the drain connecting the side row square muffler 4 and exhaust baffle valve 6 9, the inside of the stern muffler 4 is provided with a heat insulation layer, and the exhaust pipeline and pipeline accessories are equipped with a heat insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com