Aerogel composite material with heat insulation and stealth functions and preparation method thereof

A composite material and aerogel technology, which is applied in the field of aerogel composite materials with thermal insulation and stealth function and its preparation field, can solve the problems of uneven distribution of aerogel powder, affecting the thermal insulation and thermal insulation effects, etc. Thermal insulation and infrared stealth performance, the effect of realizing electromagnetic shielding function, reducing heat radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

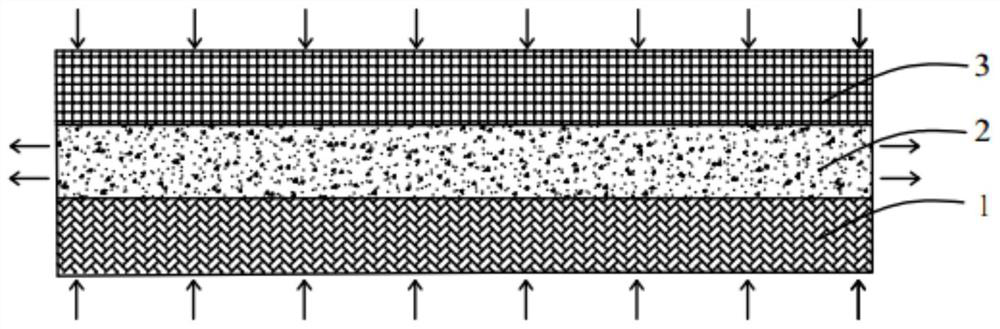

[0042] In another aspect of the present invention, there is also provided a method for preparing the above-mentioned airgel composite material with thermal insulation and stealth function, comprising the following steps:

[0043] 1) adding the silica airgel into the nanofiber suspension, and fully mixing to obtain the first composite slurry; loading the first composite slurry on the surface of the substrate to form a nanofiber airgel matrix layer;

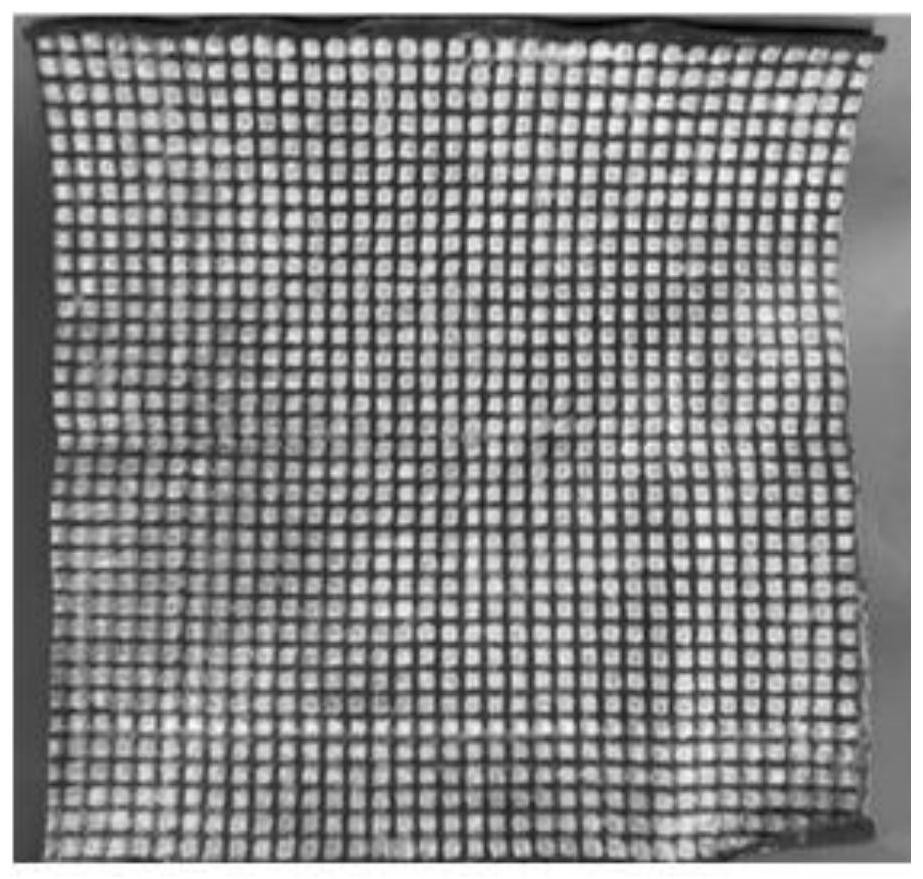

[0044] 2) adding the silica airgel conductive material with a multi-layered structure into the nanofiber suspension, and mixing thoroughly to obtain a second composite slurry; loading the second composite slurry on the nanofibers in step 1) The surface of the airgel matrix layer forms a nanofiber airgel conductive layer;

[0045] 3) Add the composite powder material containing silica airgel and phase change material into the nanofiber suspension, and mix thoroughly to obtain the third composite slurry; load the third composite slur...

Embodiment 1

[0056] This embodiment provides a method for preparing an airgel composite material with thermal insulation and stealth function, including the following steps:

[0057] S1. Preparation of nanofiber airgel matrix layer 1

[0058] Disperse EVOH nanofibers with a diameter range of 200-800nm in a solvent mixed with isopropanol and water 1:1 to make a suspension of EVOH nanofibers; Added to the EVOH nanofiber suspension, sheared at a high speed of 500rpm for 10min to make it evenly mixed to obtain the first composite slurry; in the first composite slurry, the mass fraction of silica airgel was 15 %. Then, using the non-woven fabric as the base material, the first composite slurry was sprayed on the surface of the base material 1 to form a nanofiber airgel layer 1 with a thickness of 3 mm.

[0059] S2. Preparation of nanofiber airgel conductive layer 2

[0060] Disperse silica airgel, two-dimensional material MXene, sodium anthraquinone-2-sulfonate and pyrrole monomer in deion...

Embodiment 2-3

[0074] Embodiments 2-3 respectively provide a kind of airgel composite material with thermal insulation and stealth function. Compared with Embodiment 1, the difference is that the type of substrate is changed. The substrates of Embodiment 2-3 are machine Woven cotton and knitted fabrics.

[0075] The Cro value of the substrate used in embodiment 2-3 and the airgel composite material prepared thereof is measured, and the results are as follows: Figure 5 shown. Figure 5 Among them, the woven cotton cloth and the knitted fabric represent the substrates used in Example 2-3 respectively; the airgel modified woven cotton cloth and the airgel modified knitted cloth represent the airgel composite materials prepared in Example 2-3 respectively.

[0076] Depend on Figure 5 It can be seen that the Cro values of the airgel composites prepared in Examples 2-3 are significantly higher than the base material used, indicating that the method provided by the present invention can great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com