Heat exchanger for raw coke oven gas ascending pipe

A raw gas heat exchanger technology, applied in indirect heat exchangers, coke oven heating, coke ovens, etc., can solve the problem that the wall temperature of the raw gas heat exchanger cannot be too low, it is difficult to remove tar residue, and the heat transfer effect is poor and other problems, to achieve the effect of weakening the heat radiation effect, improving the heat transfer coefficient, and eliminating carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

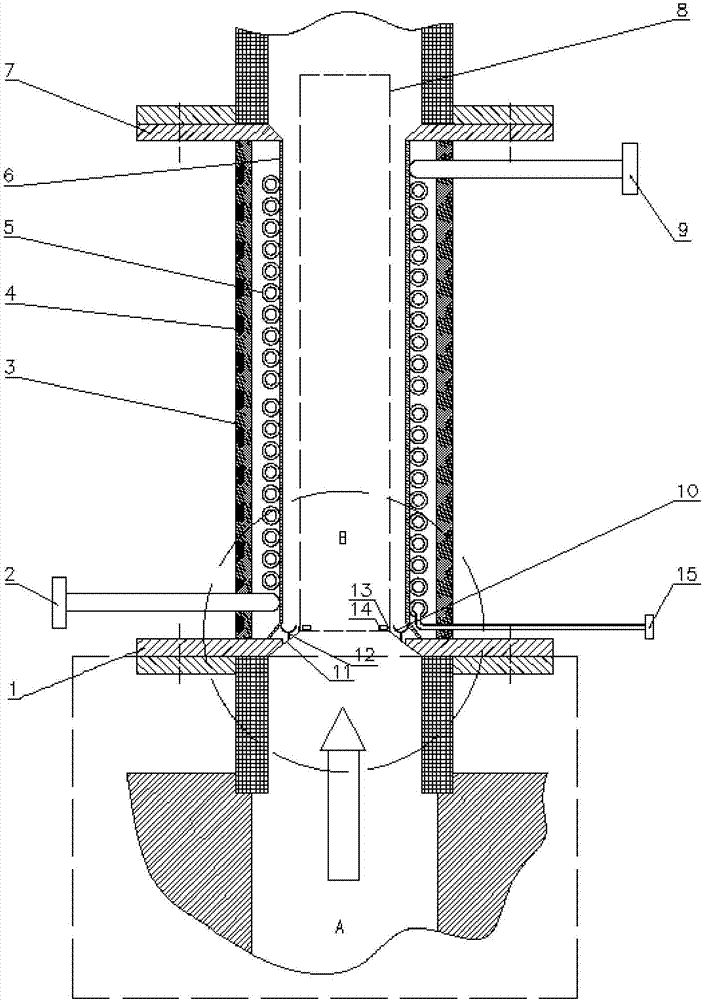

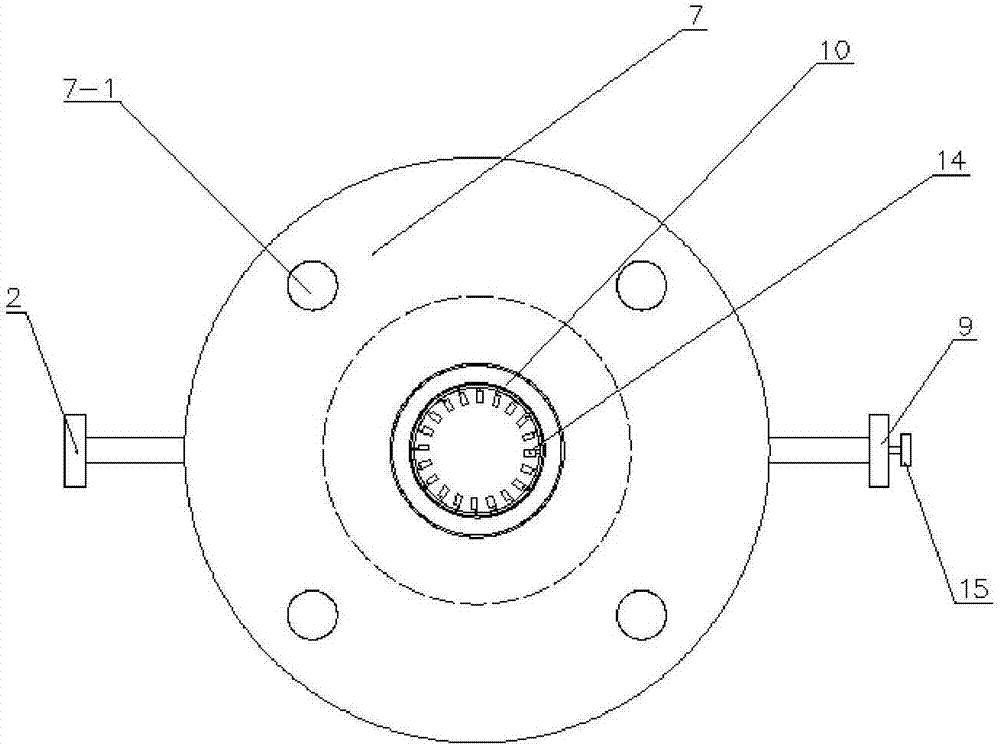

[0022] like figure 1 , figure 2 and image 3 As shown, the coke oven raw gas riser heat exchanger of the present invention includes an upper flange 7, a lower flange 1 and a cylindrical heat exchange assembly arranged between the upper flange and the lower flange;

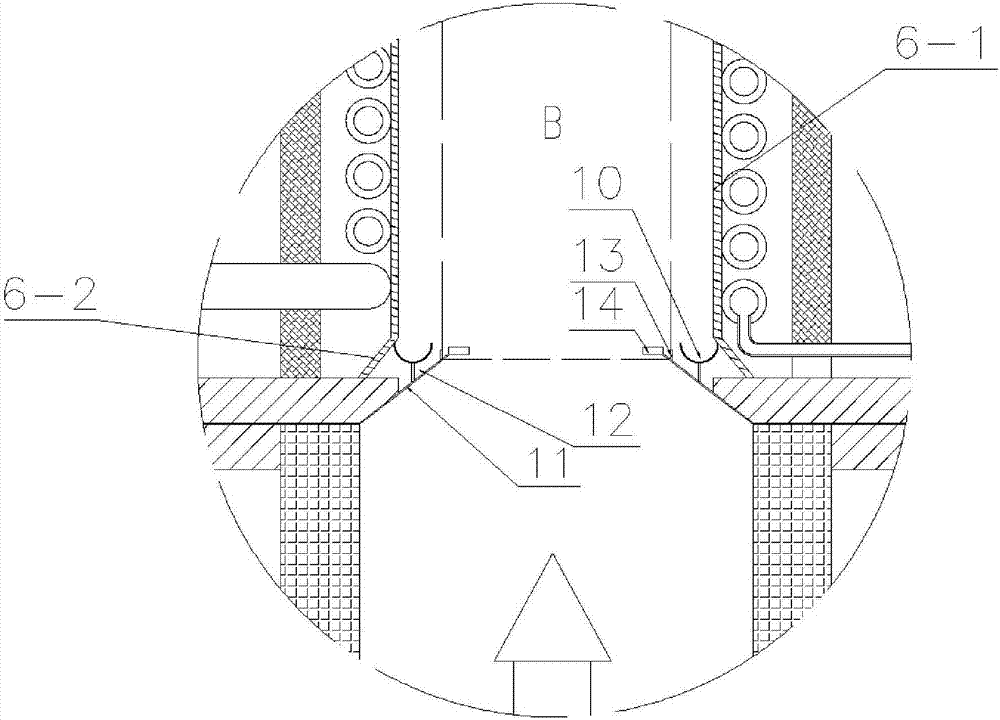

[0023] The lower flange 1 is provided with an annular flame shield 11 extending toward the heat exchange chamber of the cylindrical heat exchange assembly, the diameter of the smoke inlet of the flame shield 11 is larger than the diameter of the smoke outlet, and the The edge of the smoke outlet of the flame shield is provided with a number of interfering flow vanes 14 toward the center. The diameter of the circumference of the lower part of the flame shielding plate 11 is equal to the internal diameter of the riser.

[0024] In this embodiment, the raw coal gas enters the heat exchanger of the rising pipe from the ascending pipe of the carbonization chamber. Due to the contraction of the flame shield 11, the r...

Embodiment 2

[0026] As a specific solution of Example 1, the cylindrical heat exchange assembly includes an inner shell 6, a coil pipe 5, an insulation layer 4, and an outer shell 3 arranged sequentially from the inside to the outside, and the inner shell is provided with an oil collecting tank 10 along the circumference. , the outer circular side wall of the oil collection tank 10 is in contact with the inner shell 6, the bottom of the oil collection tank is provided with a number of oil outlets, the flame shield is provided with a number of oil inlets, each of the oil outlets An oil guide pipe 12 is arranged between the oil inlet and the oil inlet.

[0027] The inner diameter of the inner shell 6 of the heat exchanger is 1.1 to 1.25 times the diameter of the upper circumference of the flame shield 11 .

[0028] Specifically, the oil guide pipe includes a round pipe 12-1 connected to the oil outlet hole of the oil collection tank, and a horn tube 12-2 connected to the oil inlet of the fla...

Embodiment 3

[0032] As a specific solution of Embodiment 1, the angle between the spoiler blade and the horizontal direction is in the range of 20°-80°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com