Preparation method of supported Ni-MoCx catalytic material and application of supported Ni-MoCx catalytic material to prepare synthetic gas by chemical-looping dry gas reforming

A catalytic material, supported technology, applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems of low single-pass conversion rate of methane, deactivation of catalyst carbon deposition, harsh reaction conditions, etc., to achieve high reaction performance, The effect of improving conversion rate and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

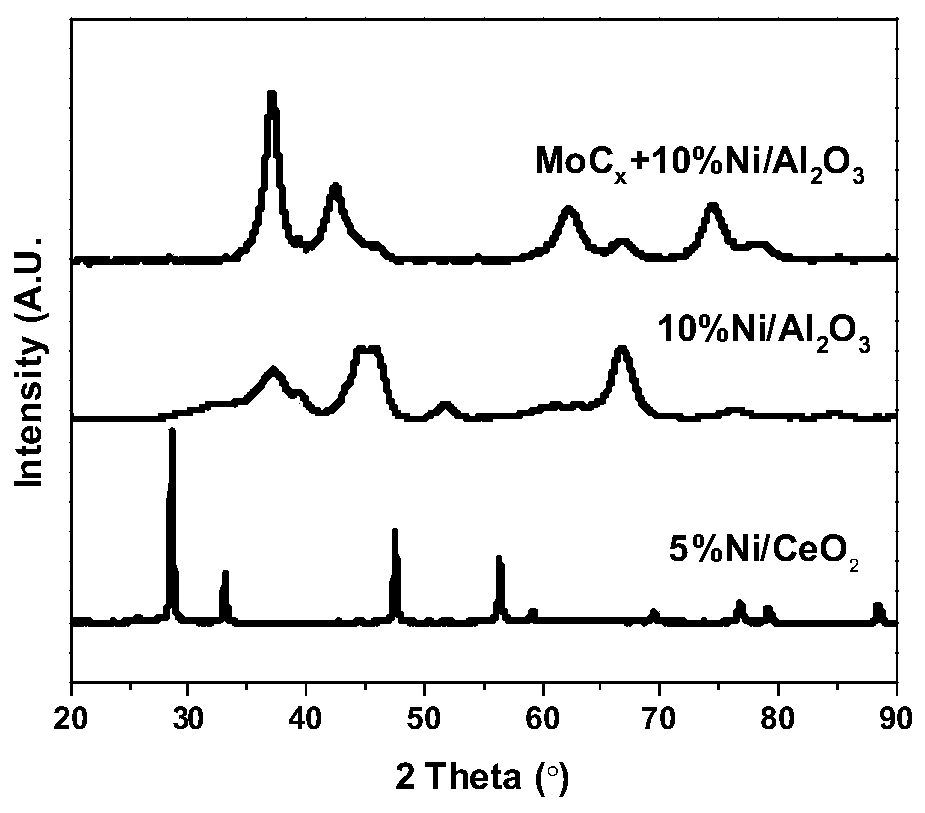

[0029] Catalyst preparation:

[0030] 1) First measure γ-Al 2 o 3 The water absorption rate of the powder is 1.4ml H 2 O / gAl 2 o 3 . According to Ni: (Ni+Al 2 o 3 ) is 10% by mass, weigh 2gγ-Al 2 o 3 Powder sample and 0.35g nickel nitrate, then according to commercial γ-Al 2 o 3 The water absorption of the powder adopts the equal volume impregnation method to dissolve the above-mentioned nickel nitrate in 2.8ml deionized water to make a solution, and mix the above-mentioned Ni salt solution with commercial γ-Al 2 o 3 Mix the powders at room temperature and stir continuously with a glass rod for 1-2 hours, then dry at 100-150°C for 12-24 hours after aging at room temperature for 24 hours, and finally bake in a muffle furnace at 500°C for 4 hours in an air atmosphere, cool and grind After that, get Ni / Al 2 o 3 Matrix material.

[0031] 2) Weigh 1.8g MoO 3 at 20% CH 4 / H 2 Carbonization at 700°C in a mixed atmosphere, the gas flow rate of the mixed gas is 160ml / ...

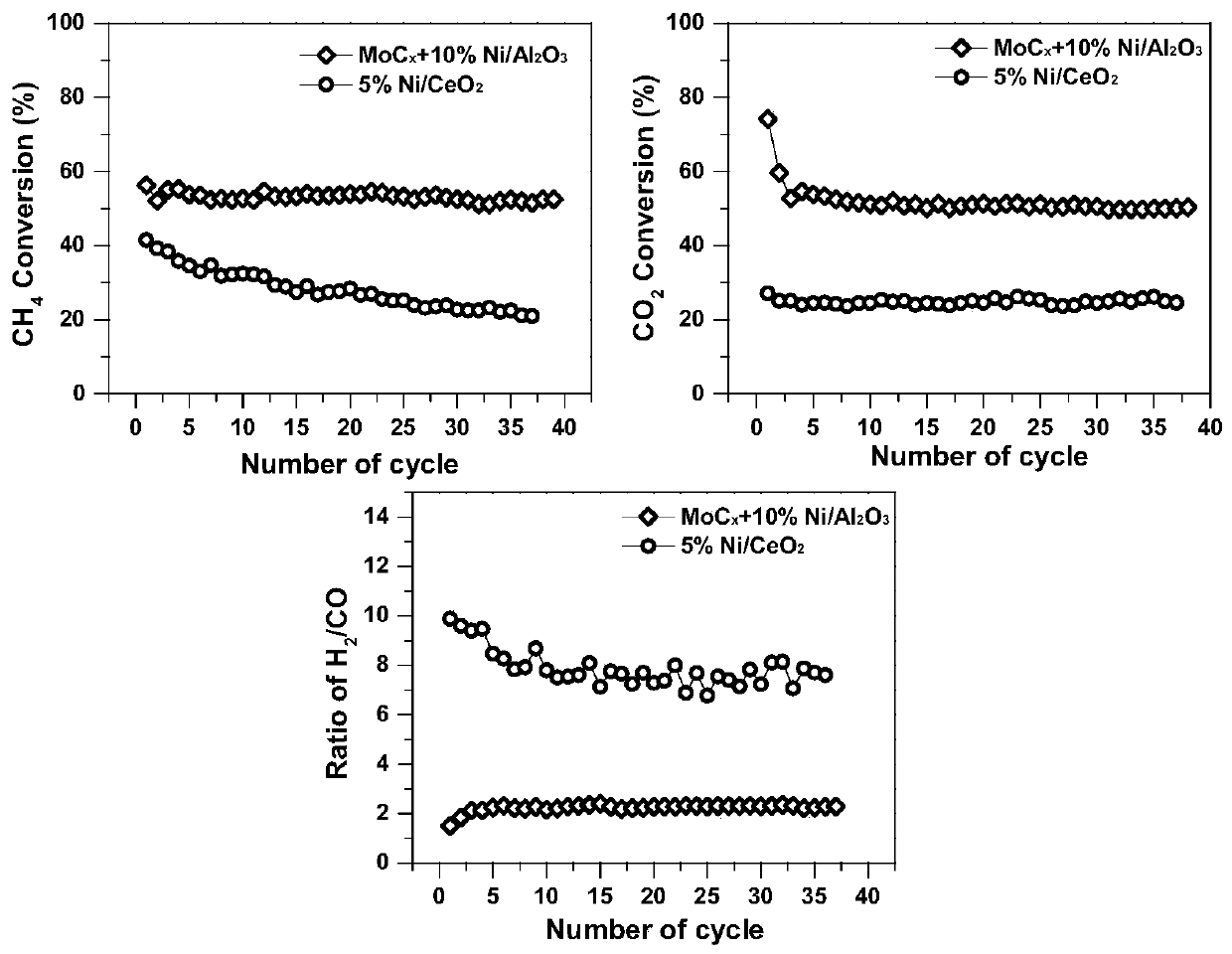

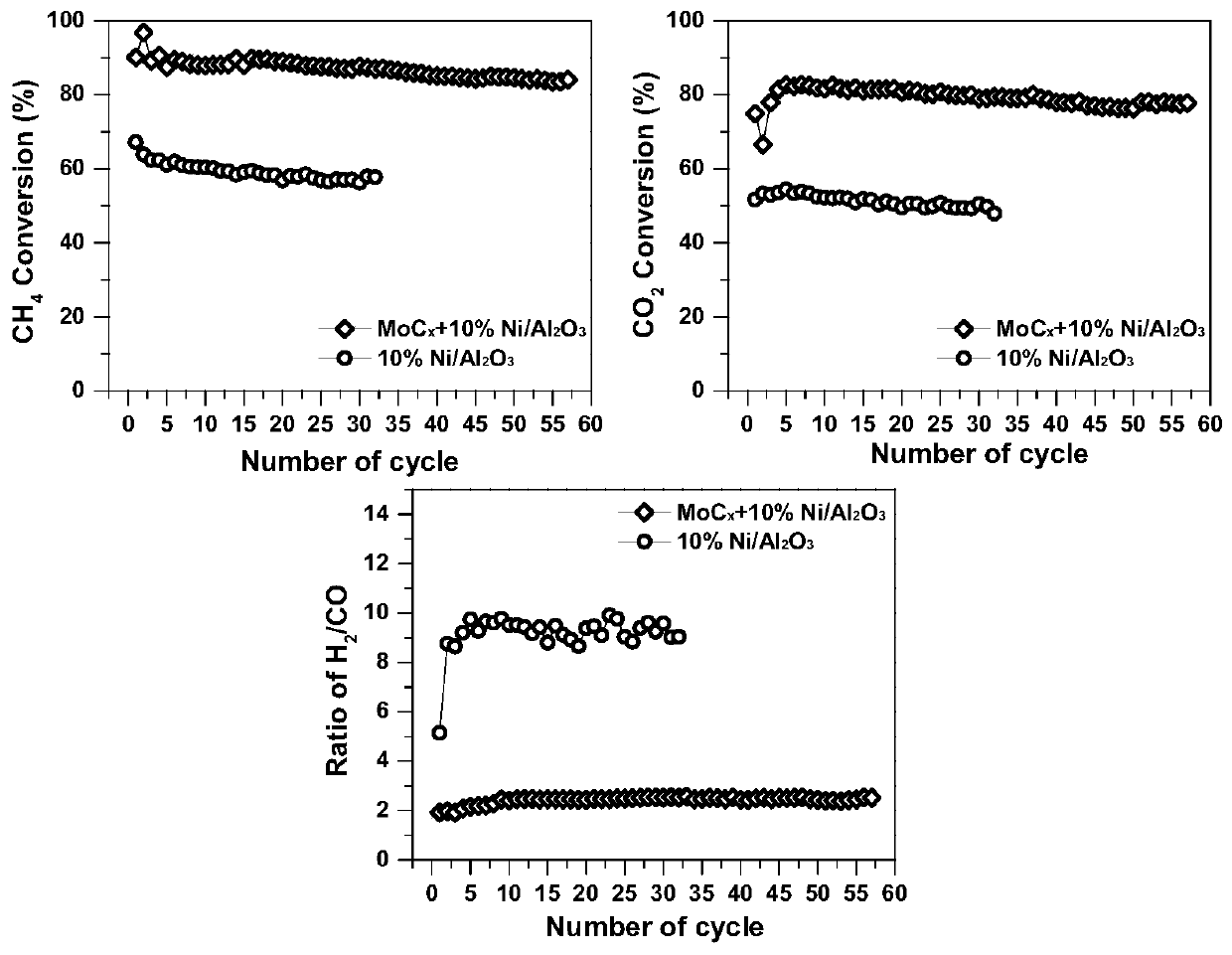

Embodiment 3

[0053] The steps and process conditions of this embodiment are all the same as in Example 1, the difference is only in the following two points: 1. Weigh 1g10%Ni / Al 2 o 3 The matrix material and 3g molybdenum carbide material are mixed mechanically at room temperature according to the mass percentage of 1:3, fully ground in a mortar for 1-2 hours, and finally mixed in 15% CH 4 / H 2 Calcined at 500°C for 2 hours in a mixed atmosphere to prepare MoC x +10%Ni / Al 2 o 3 (SSI1 / 3) catalyst; ②Evaluate its activity. When the reaction temperature is 600°C, the initial conversion rate of methane is about 82%, and the initial conversion rate of carbon dioxide is about 75%. 2 The / CO ratio is about 3.0.

Embodiment 4

[0055] The steps and process conditions of this embodiment are all the same as in Example 1, the difference is only in the following two points, 1. Weigh 3g10%Ni / Al 2 o 3 The matrix material and 1g molybdenum carbide material are mixed mechanically at room temperature according to the mass percentage of 1:1, fully ground in a mortar for 1-2 hours, and finally mixed in 15% CH 4 / H 2 Calcined at 500°C for 2 hours in a mixed atmosphere to prepare MoC x +10%Ni / Al 2 o 3 (SSI3 / 1) catalyst; ②Evaluate its activity. When the reaction temperature is 600°C, the initial conversion rate of methane is about 75%, and the initial conversion rate of carbon dioxide is about 68%. 2 The / CO ratio is about 2.35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com