An oxygen sensor heat insulation protection device

A technology of thermal insulation protection and oxygen sensor, which is applied in the direction of exhaust device, muffler device, electric control of exhaust gas treatment device, etc. problems, to achieve the effect of improving the heat dissipation effect, reducing the heat radiation effect, and meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

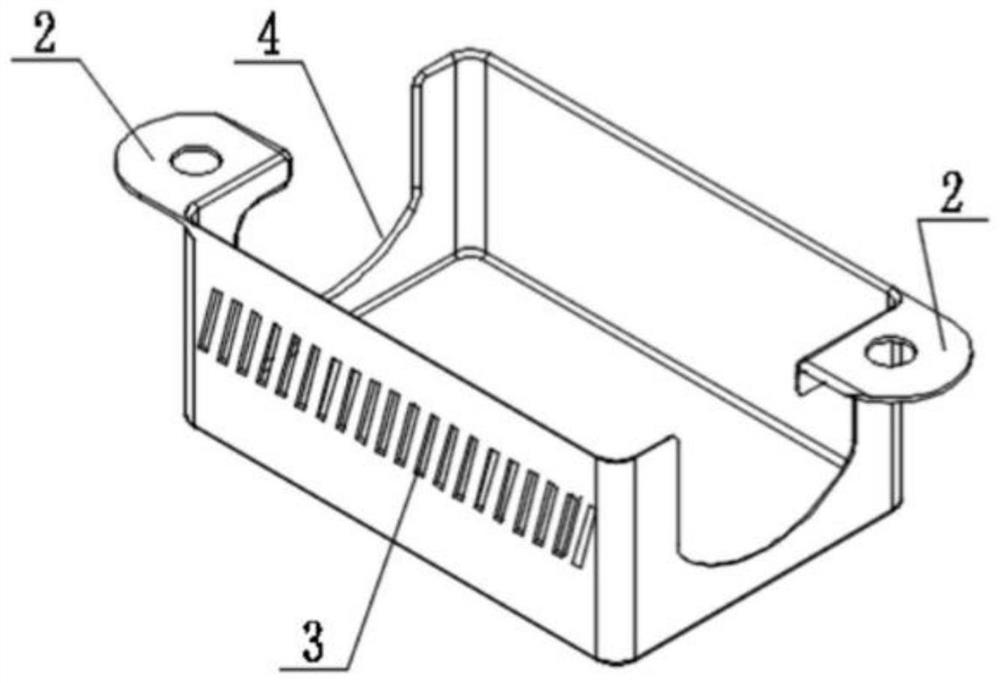

[0036] see image 3 , Figure 4 with Figure 9 As shown, the embodiment of the present invention provides an oxygen sensor heat insulation protection device, including:

[0037] A heat shield 100, the heat shield 100 includes an outer layer 103 and an inner layer 107, a sealed cavity is formed between the outer layer 103 and the inner layer 107, and a first corrugated board 104 and The second wave plate 106; wherein the first wave plate 104 is fixedly connected with the inner wall of the outer layer 103, the second wave plate 106 is fixedly connected with the inner wall of the inner layer 107, and between the first wave plate 104 and the second wave plate 106 A heat insulating layer 105 is provided. The outer layer 103 forms a vacuum layer through the first corrugated board 104 and the heat insulation layer 105 , and the inner layer 107 forms a vacuum layer through the second corrugated board 106 and the heat insulation layer 105 .

[0038] working principle

[0039] An oxy...

Embodiment 2

[0041] see image 3 , Figure 4 with Figure 9 As shown, the embodiment of the present invention provides an oxygen sensor heat insulation protection device. The difference between this embodiment and Embodiment 1 is: the outer layer 103, the inner layer 107, the first wave plate 104 and the second wave plate of the heat shield 100 Plate 106 is a stainless steel plate material. Wherein the outer layer 103 and the inner layer 107 of the heat shield 100 are all 3 mm thick stainless steel plate materials, and the first wave plate 104 and the second wave plate 106 are all 1 mm thick stainless steel plate materials, so as to improve the structural strength of the heat shield 100 and corrosion resistance. The heat insulation layer 105 is glass fiber wool or glass wool, which has excellent characteristics such as high temperature resistance, non-combustibility, low thermal conductivity, and light weight. Filling the gap with a heat insulation layer can further enhance the heat in...

Embodiment 3

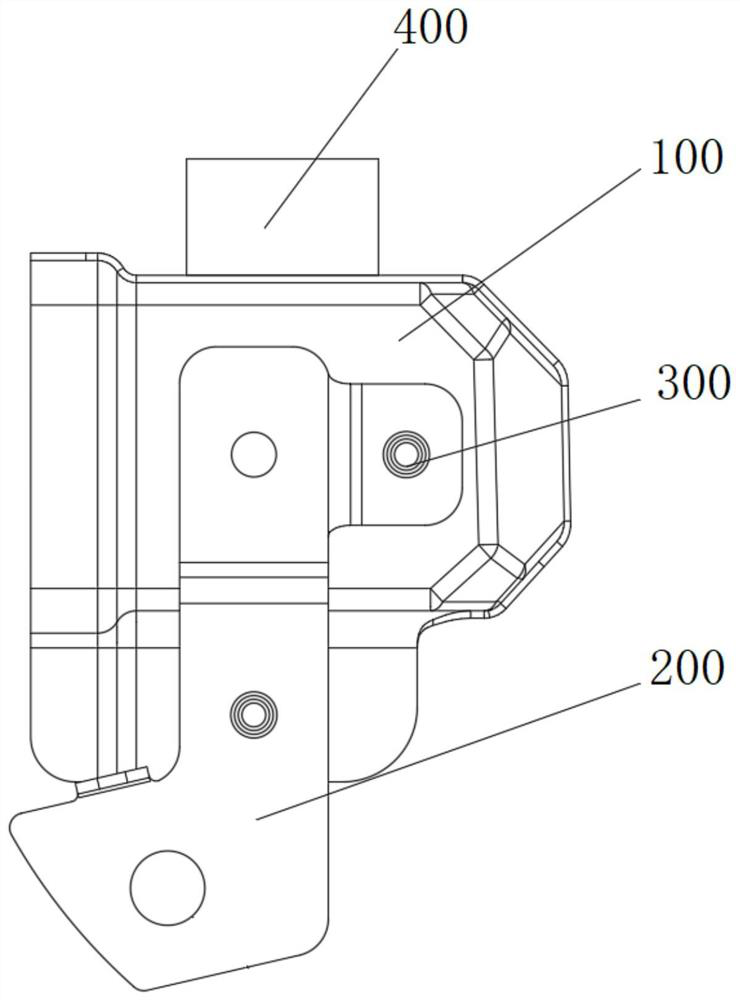

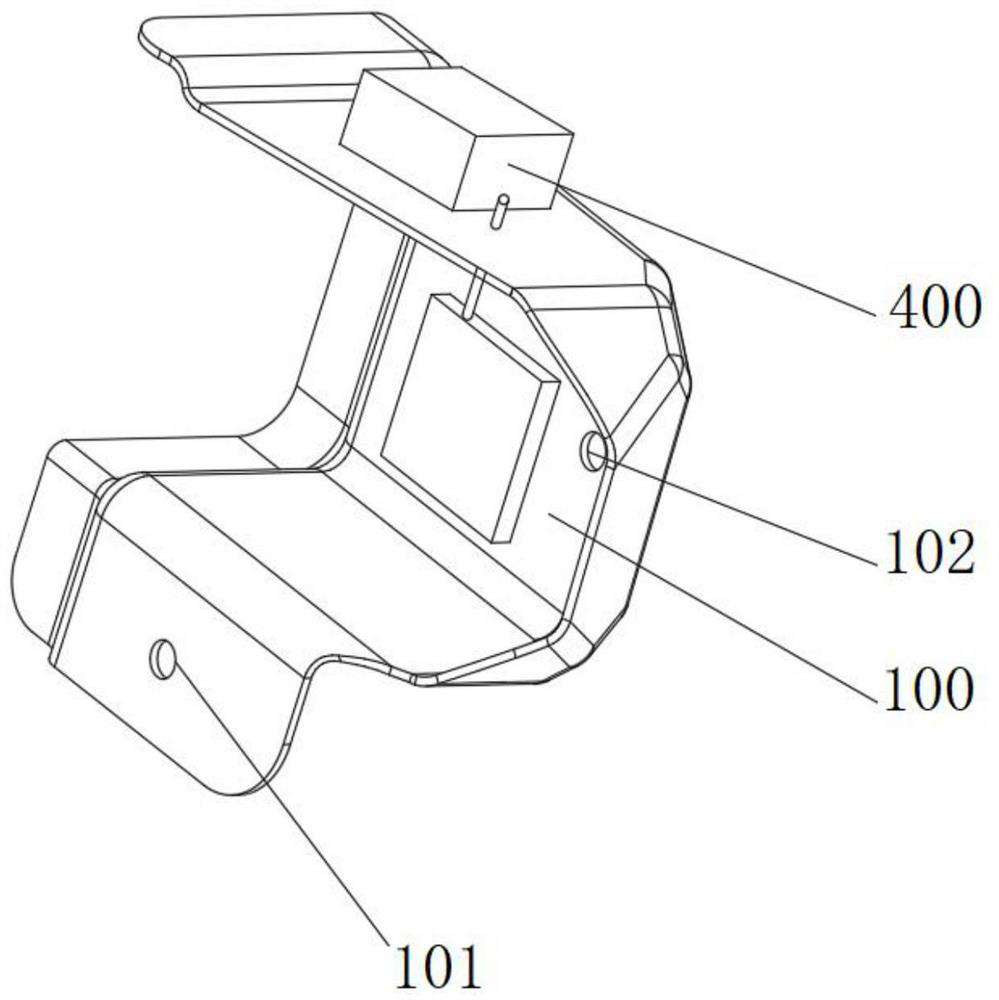

[0043] see figure 2 , Figure 5 , Image 6 with Figure 7 As shown, the embodiment of the present invention provides an oxygen sensor heat insulation protection device. The difference between this embodiment and Embodiment 1 is that this device also includes a mounting bracket 200, and the mounting bracket 200 includes a fixing part 201 connected to the heat shield 100 , a flange is provided on the outer wall of the heat shield 100, a first mounting hole 101 is opened on the flange, a second mounting hole 102 is opened in the groove of the heat shield 100, and the fixing part 201 of the mounting bracket 200 It is fixedly connected with the heat shield 100 through the first installation hole 101 and the second installation hole 102 . A mounting portion 202 extending to the outside of the heat shield 100 is also provided on the mounting bracket 200 , and the mounting bracket 200 is used for fixing the heat shield 100 .

[0044] The fixing portion 201 of the mounting bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com