Digital light procession (DLP) light curing 3D printing system

A 3D printing and light-curing technology, applied in the field of 3D printing technology, can solve the problems of small molding size, low printing speed, and low light source utilization rate, and achieve the effect of sufficient strength, improved printing accuracy, and simple and convenient molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

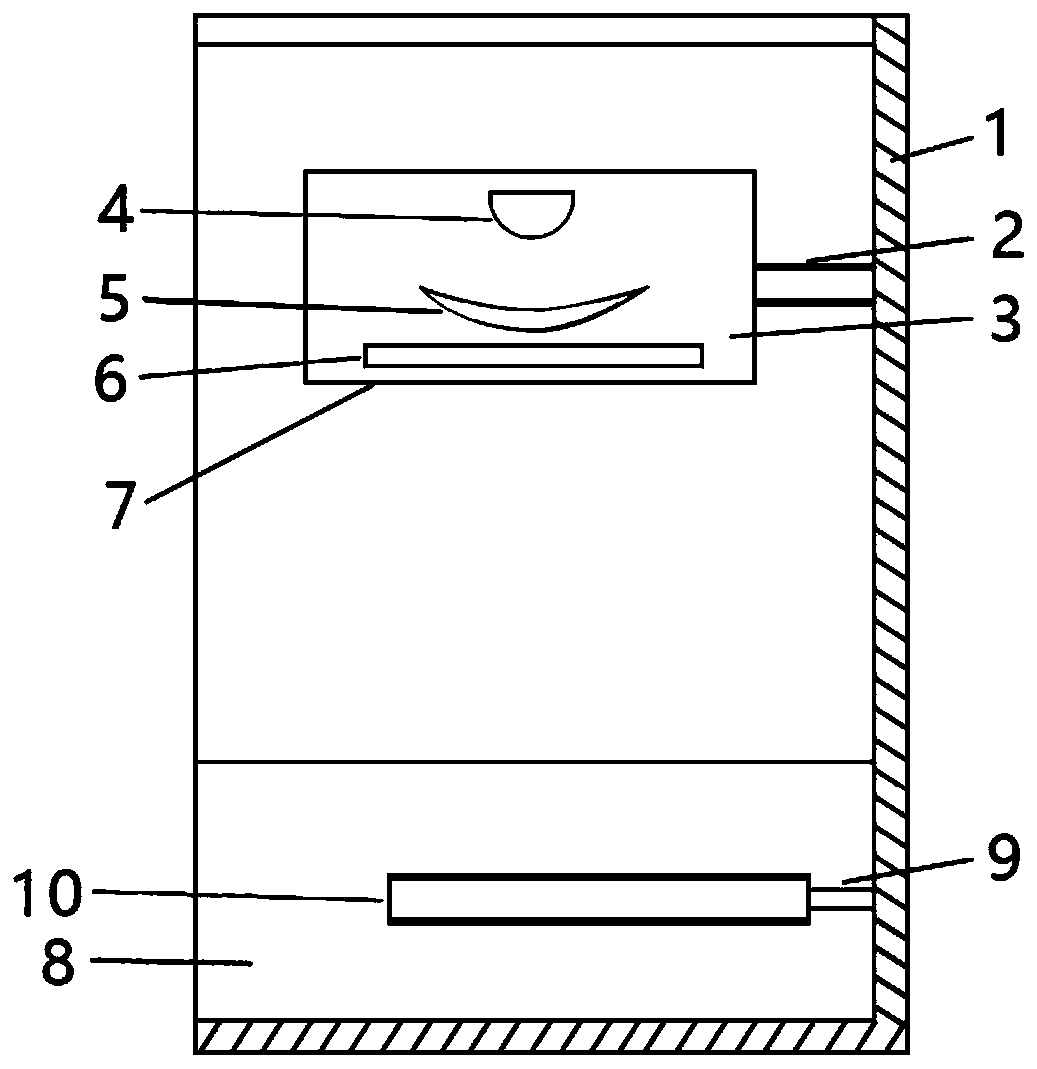

[0026] See figure 1 , A DLP light-curing 3D printing system, the printing system includes frame 1, frame Z a Axis movement module 2, light source system 3, material trough 8, forming table Z b Axis movement module 9 and forming table 10; The light source system 3 includes a light source 4, a curved mirror 5, an optical quartz glass 6 and a container 7. The light source 4, curved mirror 5 and optical quartz glass 6 are installed in the container 7, and the light source 4. The curved mirror 5 and the optical quartz glass 6 are installed sequentially from top to bottom. The light source 4 is a DLP light source containing a DMD chip, and the light source 4 is located at the focal point of the curved mirror 5; the container 7 is made of transparent material, transparent The material is selected from optical quartz glass, acrylic or glass; the bottom surface of the optical quartz glass 6 is attached to the upper surface of the bottom plate of the container 7; the forming table 10 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com