Vertical transporting bucket lifter

A vertical transportation and lift technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of uneven work, accumulation of impurities in the flipper, etc., and achieves maintenance, high lifting efficiency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

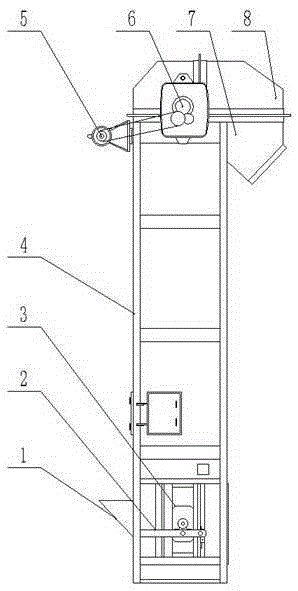

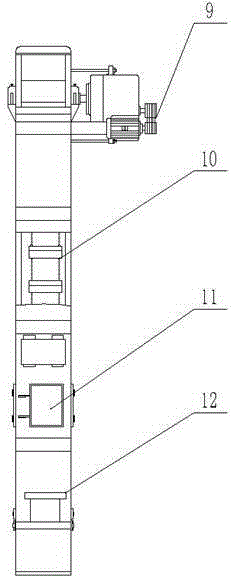

[0017] Such as Figure 1-Figure 2 As shown, a bucket elevator for vertical transportation includes a lifting motor 3, a material turner 6, a pulley 9 and a chain track 10, and a lift housing 4 is installed on one side of the feeding barrel 1, and the feeding barrel 1 A transparent observation hole cover 11 is installed on the upper part to observe the operation inside the machine at any time. The main switch 12 of the machine is installed on the side of the lift shell 4 to control the overall opening and closing of the machine. The lift cover 8 is installed on the upper part of the lift shell 4. , one side of the upper cover 8 of the lift is equipped with a discharge cylinder 7, which is a material output cylinder, and a lifting platform 2 is installed at the bottom of the inside of the lifting machine shell 4, mainly carrying the required materials, and a lifting motor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com