Electrodynamic multi-rotor helicopter

A multi-rotor and helicopter technology, applied in the field of general aircraft, to achieve the effect of low cost, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

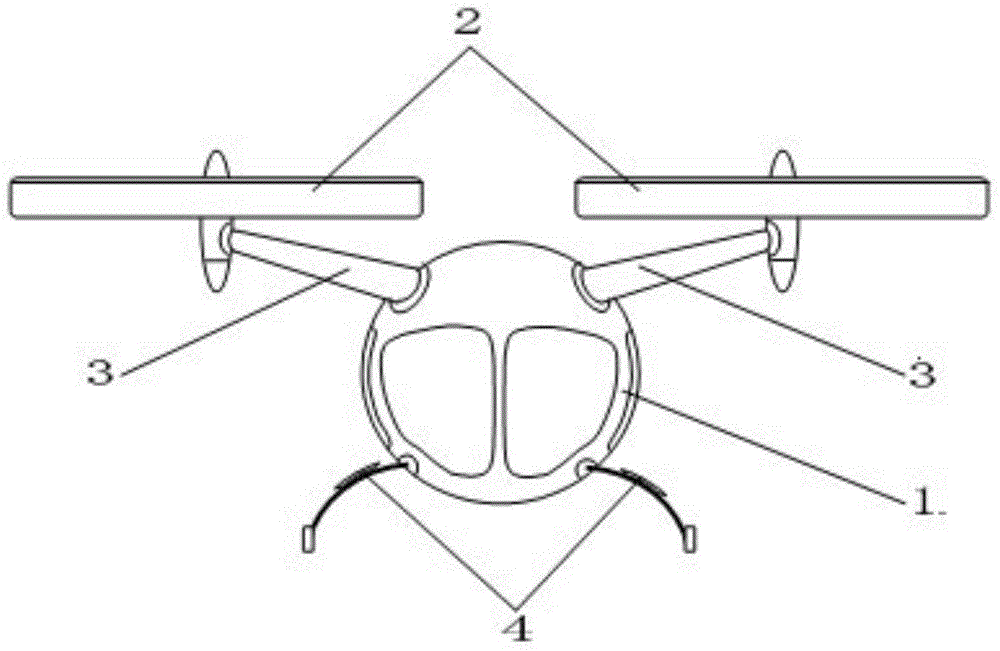

[0032] like Figure 1A , Figure 1B and Figure 1C As shown, the electric multi-rotor helicopter of this embodiment includes a fuselage 1, a powered rotor 2, a rotor support arm 3, a landing gear 4, a power supply system and a flight control system.

[0033] The fuselage 1 of this embodiment is streamlined as a whole, and the side projection and horizontal projection are elliptical. The fuselage 1 is provided with a cockpit, a load compartment and a battery compartment along the horizontal axis (ie, the direction of the long axis of the ellipse) in the forward direction. The battery compartment is arranged at the middle and rear part below the carrying compartment, the power supply system is placed in the battery compartment, and the flight control system is placed in the cockpit.

[0034] Four powered rotors 2 are evenly distributed along the circumferential direction above the fuselage 1, and there are two powered rotors 2 on the left and right sides of the horizontal axis ...

Embodiment 2

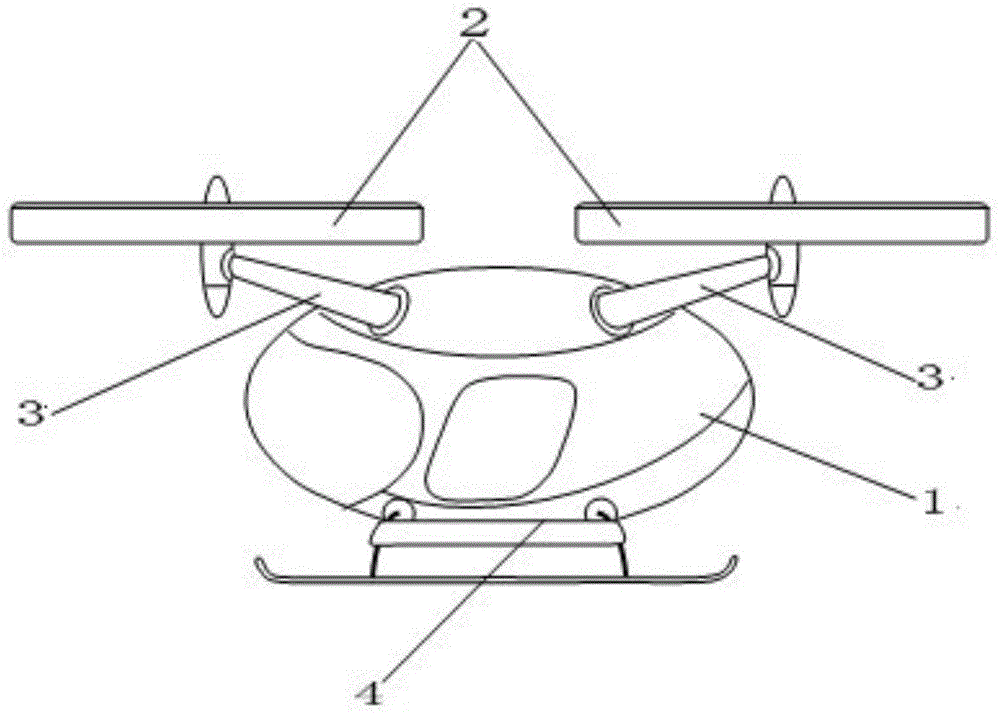

[0038] like Figure 2A , Figure 2B and Figure 2C As shown, the difference between the present embodiment and the first embodiment is that the fuselage 1 of the present embodiment is spherical, and the fuselage 1 is provided with a two-person cockpit, the bottom is provided with a battery compartment, and the power supply system is placed in the battery compartment. The flight control system is placed in the cockpit. Others are all the same as in Embodiment 1.

Embodiment 3

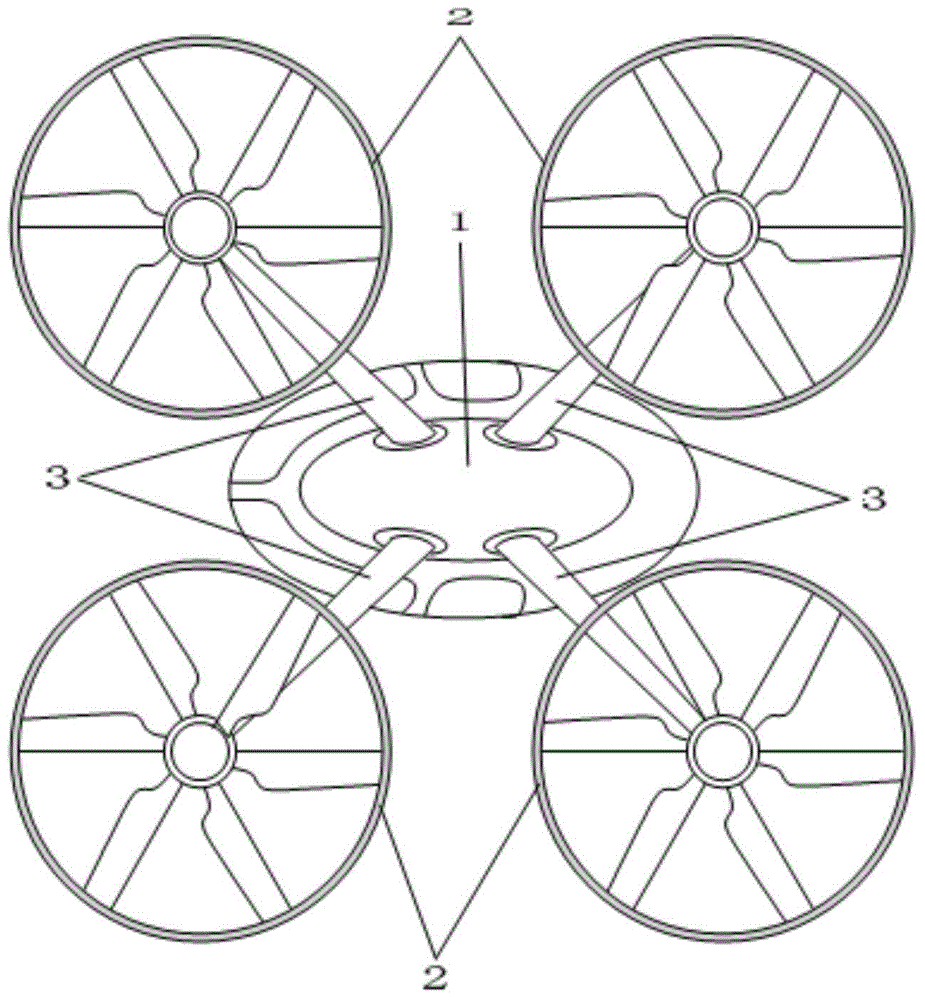

[0040] like Figure 3A , Figure 3B and Figure 3C As shown, the electric multi-rotor helicopter of this embodiment includes a fuselage 1, a powered rotor 2, a rotor support arm 3, a landing gear 4, a power supply system and a flight control system.

[0041] The fuselage 1 of this embodiment is streamlined as a whole, and the side projection and the horizontal projection are generally rectangular in length, and the fuselage 1 is provided with a cockpit, a load compartment and a battery along the horizontal axis (ie, the centerline of the length direction of the rectangle) in the forward direction. The battery compartment is located under the carrying compartment, the power supply system is placed in the battery compartment, and the flight control system is placed in the cockpit.

[0042] Six power rotors 2 are arranged on the top of the fuselage 1, and the power rotors 2 are symmetrically arranged on the left and right sides of the horizontal axis in the forward direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com