Working method for conveying sorting device

A sorting device and working method technology, applied in chemical instruments and methods, grading, solid separation, etc., can solve the problems of waste materials, leakage and scattering of materials, large volume and weight of unloading bins, etc., to improve operation speed and efficiency. , the effect of increasing the sorting space and reducing the sorting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

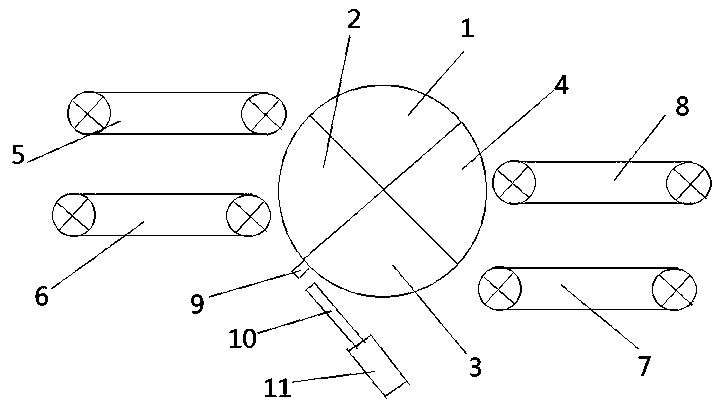

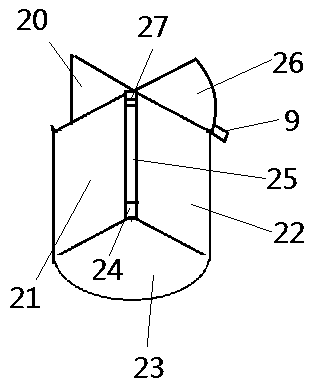

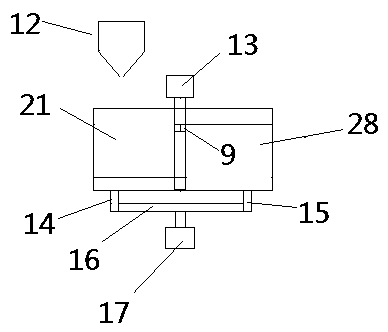

[0040] As shown in the figure: a working method of a conveying and sorting device, the conveying and sorting device includes a first sorting area, a second sorting area, a third sorting area, a fourth sorting area, a first conveyor belt, a second conveyor belt, The third conveyor belt, the fourth conveyor belt, the support rod, the piston rod, the cylinder, the feeding valve, the main motor, the first pillar, the second pillar, the support connecting frame, the auxiliary motor, the ball head, the protective pad, and the connecting baffle , connection baffle plate two, connection baffle plate three, connection baffle plate four, lower sorting plate one, lower sorting plate two, upper sorting plate, lower connecting ring, main shaft, upper connecting ring; described working method includes the first Sorting area selection method, second sorting area selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com