Telescopic-type two-way operation lateral evacuation multifunctional operating vehicle and application method

A technology of two-way operation and working vehicles, which is applied in the transportation of passenger cars, railway transportation, railway transportation, etc., can solve the problems of manual lifting, inability to avoid, low work efficiency, high labor intensity of personnel, etc., and achieve simple and feasible combined structure, work High efficiency and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

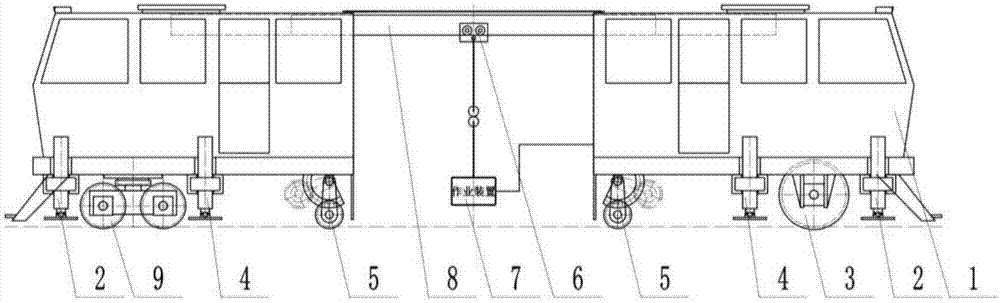

[0070] The work vehicle is a retractable and split type in the middle. When the work vehicle goes from the base to the work surface, the length of the whole vehicle is the shortest length, and the proximal ends of the front body and the rear body shrink and get closer together. The state at this time is called "zero" state After driving the vehicle to the top of the working surface, rotate and lower the supporting wheels of the separation section of the car body, extend the car body from the middle to both sides, lock the telescopic mechanism after reaching the length of the working space, brake the work vehicle, and release the rails The temporary constraint of the work vehicle is to clamp the rail clamping device at the bottom of the work vehicle, and use the lifting mechanism installed on the chassis of the work vehicle to lift the work vehicle together with the steel rail to a specified height and lock it. Move the operating devices suspended on the telescopic beam of the o...

Embodiment 2

[0073] The working vehicle of the present invention is changed from a transition state to a working state operation and use method.

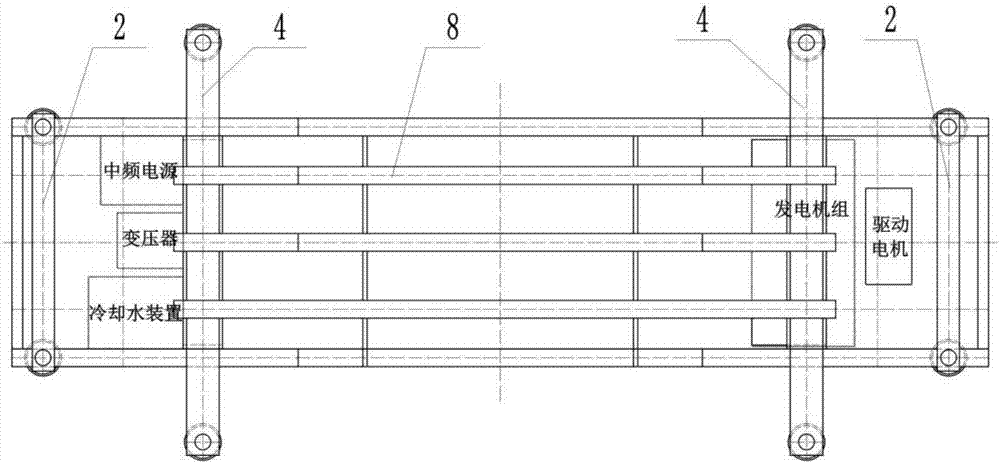

[0074] The operating status of the work vehicle is as follows: figure 1 , figure 2 , image 3 shown. The transfer status of the work vehicle is as follows: Figure 4 , Figure 5 , Figure 6 shown. The main structural design of this embodiment is as follows: five or two longitudinal beams are designed on the top of the car body, and the longitudinal beams are structural beams connecting the front and rear car bodies. The two fixed points of the hydraulic cylinder are installed on the guide post and the guide sleeve, and the hydraulic cylinder is driven to drive the guide post to move in the guide sleeve to realize the expansion and contraction of the vehicle body. Figure 12a -b shown. Among them, the hanging system is installed on the second and fourth longitudinal beams, which undertake the functions of hanging and moving the operation...

Embodiment 3

[0078] The invention relates to a method for using a working vehicle avoidance track circuit.

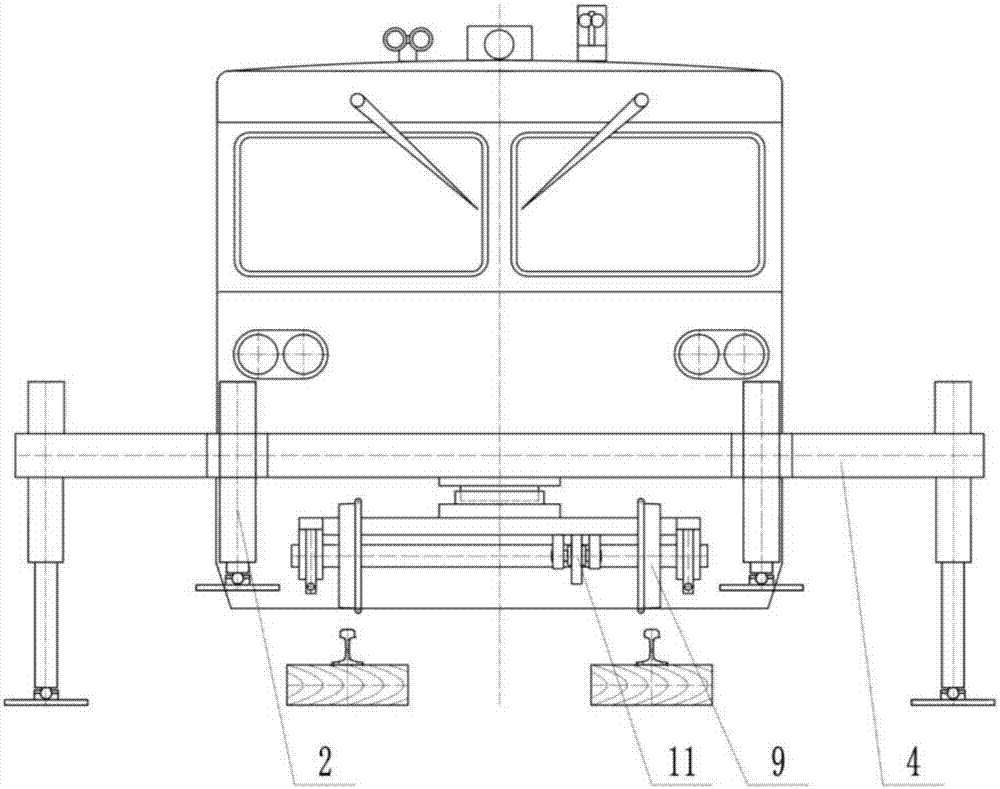

[0079] Work vehicle avoidance track lines such as Figure 7 , Figure 8 , Figure 9 shown. The car body is designed with five or two longitudinal beams on the top of the structure. The longitudinal beams are the structural beams connecting the front and rear car bodies. The two fixed points of the oil cylinder drive the hydraulic oil cylinder to drive the guide column to move in the guide sleeve to realize the expansion and contraction of the car body. The whole vehicle traverse lifting mechanism and fixed lifting mechanism are designed near the active traveling wheel and the driven traveling wheel. The traversing lifting mechanism is a hydraulic cylinder traversing support combination structure. The traversing mechanism of the traversing lifting mechanism is designed as a guide sleeve and guide post structure. One end of the guide post is installed with a traversing jacking cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com